Hydraulic motor cushion block and preparation method thereof

A technology of hydraulic motors and pads, which is applied to mechanical equipment, machines/engines, solid-state diffusion coatings, etc., can solve problems such as low material utilization, high production costs, and low processing efficiency, and achieve simple procedures and reduced processing costs , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

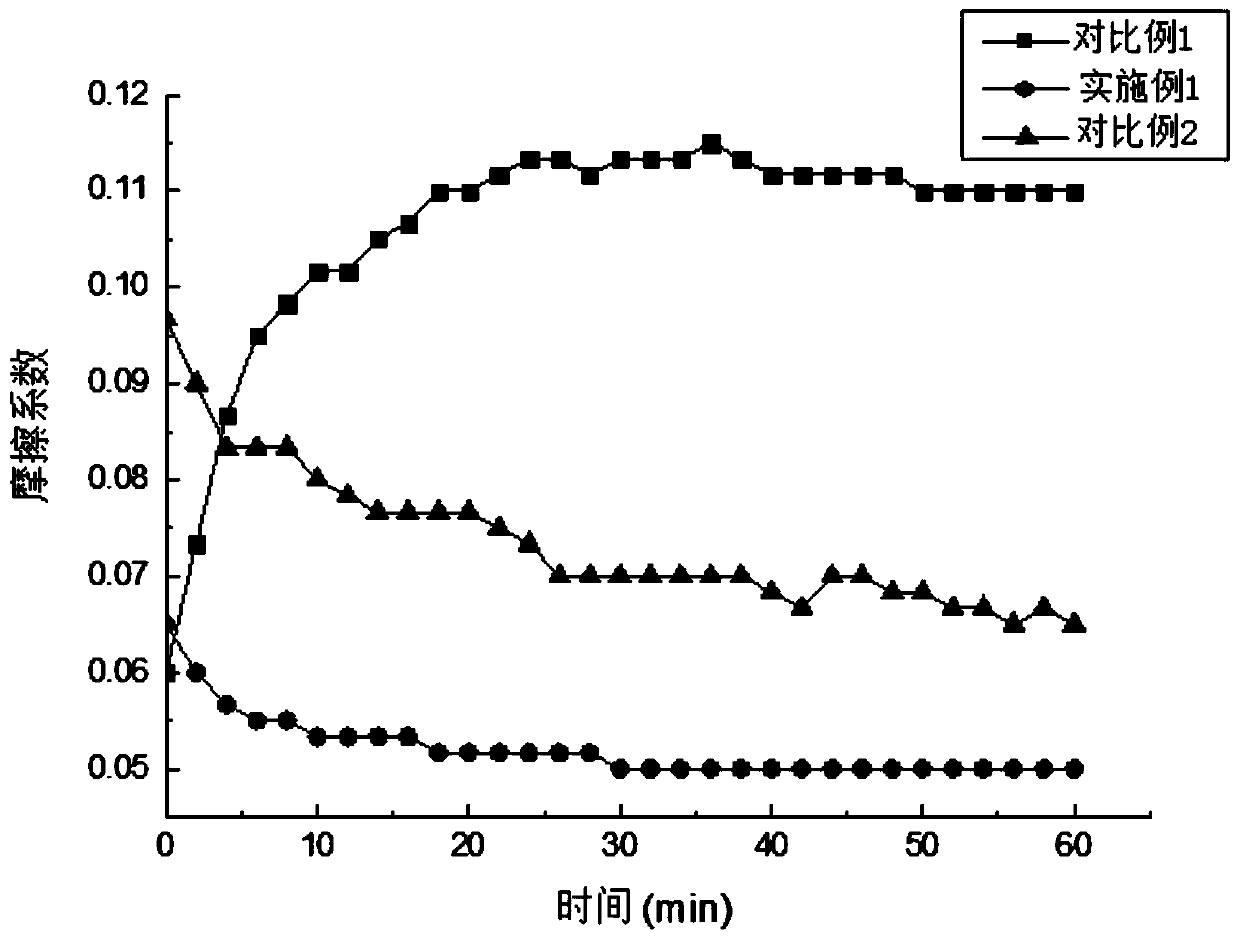

Examples

Embodiment 1

[0026] (1) Mixing materials: take by weight 1.7% nickel, 0.5% vanadium, 0.5% manganese sulfide, 0.8% graphite, 0.7% zinc stearate, 0.06% spindle oil, and the balance is iron powder, and mix well to obtain Matrix mixed powder: Weigh 2.7% iron, 0.5% lithium stearate, and the remaining copper powder in proportion, and mix them evenly to obtain copper-infiltrated sheet mixed powder;

[0027] (2) Compressing the green compact: adding the matrix mixed powder and the copper infiltrated sheet mixed powder into the block mold and the copper infiltrated sheet mold respectively, and pressing and forming respectively to obtain the matrix compact and the copper infiltrated sheet; wherein, the density of the matrix compact is 6.8g / cm 3 , the density of copper infiltrated sheet is 7.5g / cm 3 ;

[0028] (3) Copper-infiltrated sintering: place the copper-infiltrated sheet on the top surface of the substrate compact, and sinter in a sintering furnace with decomposed ammonia gas as a protective...

Embodiment 2

[0033] (1) Mixing materials: take by weight 1.5% nickel, 0.3% vanadium, 0.3% manganese sulfide, 0.6% graphite, 0.6% zinc stearate, 0.03% spindle oil, and the balance is iron powder, and mix well to obtain Matrix mixed powder; weigh 2.5% iron, 0.4% micro-wax powder, and the remaining copper powder in proportion, and mix them evenly to obtain copper-infiltrated sheet mixed powder;

[0034] (2) Compressing the green compact: adding the matrix mixed powder and the copper infiltrated sheet mixed powder into the block mold and the copper infiltrated sheet mold respectively, and pressing and forming respectively to obtain the matrix compact and the copper infiltrated sheet; wherein, the density of the matrix compact is 6.81g / cm 3 , the density of copper infiltrated sheet is 7.47g / cm 3 ;

[0035] (3) Copper-infiltrated sintering: place the copper-infiltrated sheet on the top surface of the substrate compact, and sinter in a sintering furnace with decomposed ammonia gas as a protecti...

Embodiment 3

[0038] (1) Mixing: Take by weight 2% nickel, 0.7% vanadium, 0.6% manganese sulfide, 1.2% graphite, 1.2% zinc stearate, 0.12% spindle oil, and the balance is iron powder, and mix well to get Matrix mixed powder: Weigh 3.5% iron, 0.65% lithium stearate, and the remaining copper powder in proportion, and mix evenly to obtain copper infiltrated sheet mixed powder;

[0039] (2) Compressing the green compact: adding the matrix mixed powder and the copper infiltrated sheet mixed powder into the block mold and the copper infiltrated sheet mold respectively, and pressing and forming respectively to obtain the matrix compact and the copper infiltrated sheet; wherein, the density of the matrix compact is 6.77g / cm 3 , the density of copper infiltrated sheet is 7.53g / cm 3 ;

[0040] (3) Copper-infiltrated sintering: place the copper-infiltrated sheet on the top surface of the substrate compact, and use decomposed ammonia gas as a protective atmosphere to sinter in a sintering furnace wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com