Steel plate cold rolling coating integrated production unit and its production process

A coating and steel plate technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of many processes, high investment in fixed assets, and high production costs, reducing processes and reducing investment in fixed assets. and production costs, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

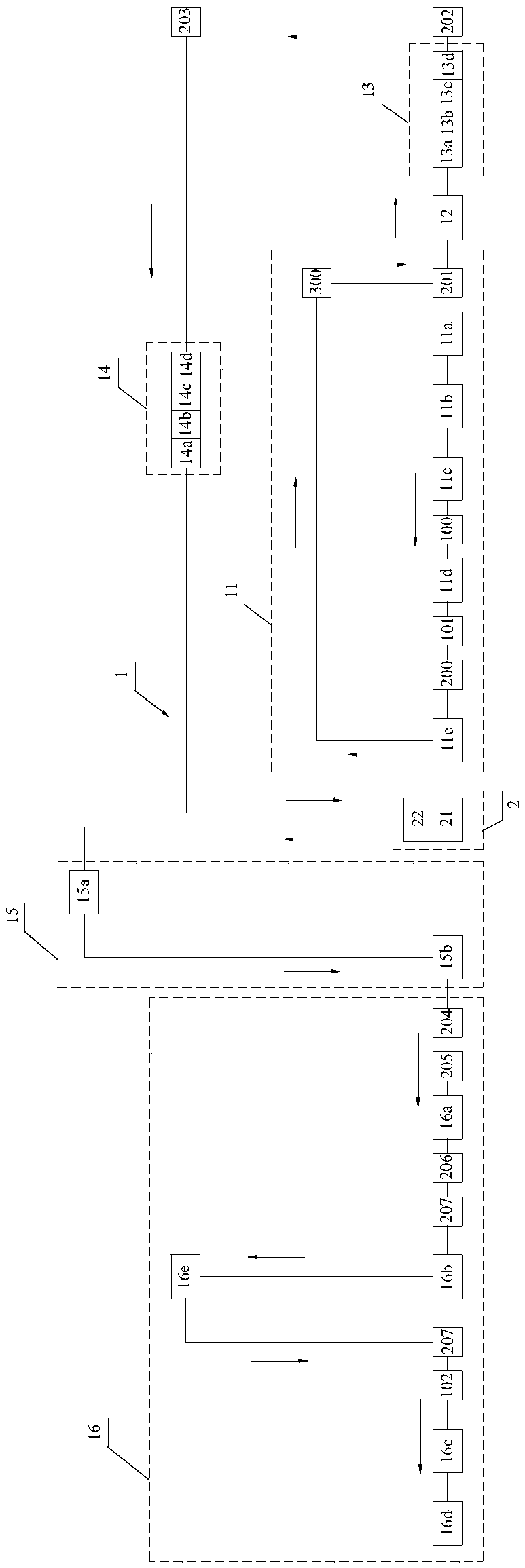

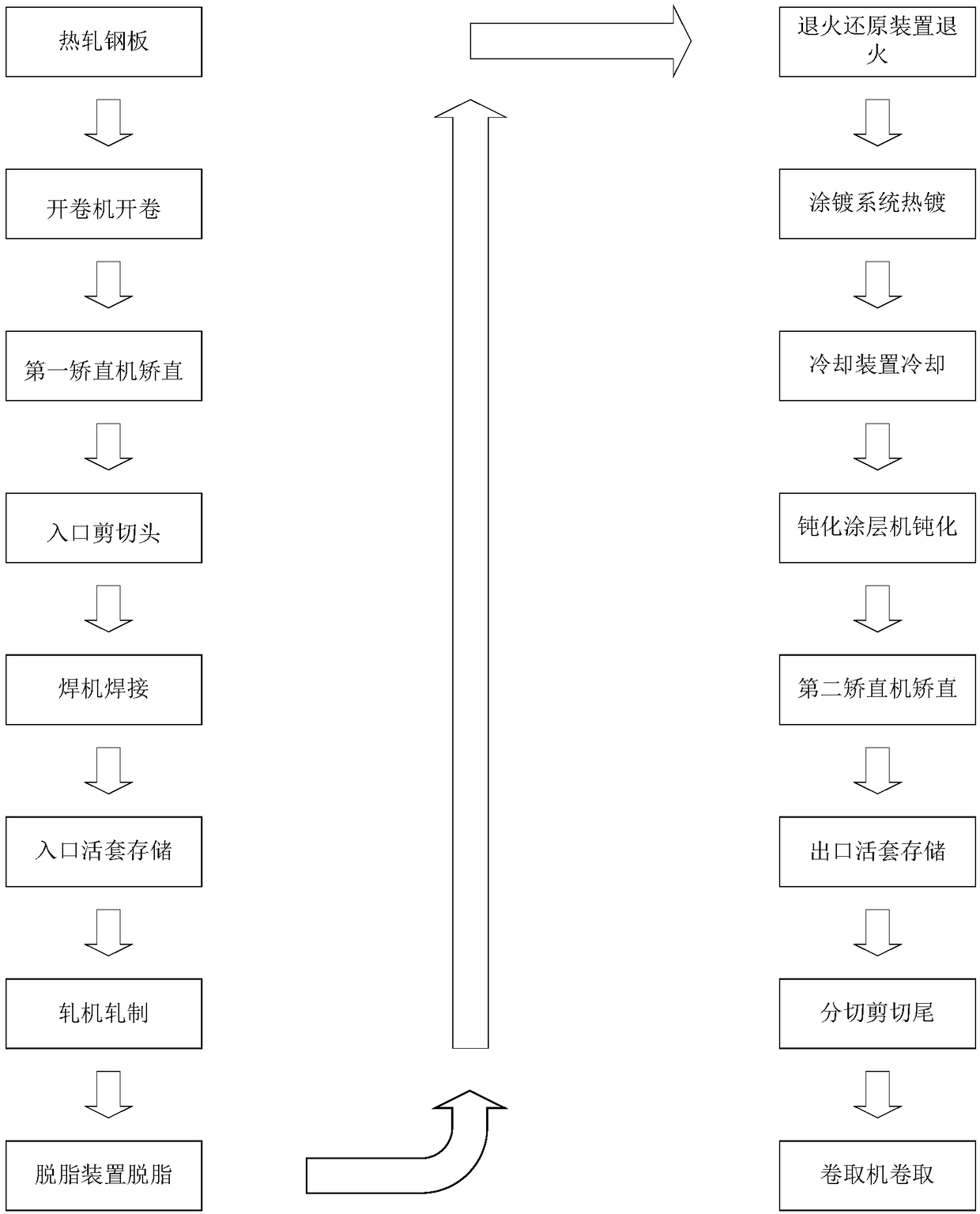

[0026] see figure 1 As shown, the present invention provides an integrated production unit for cold rolling and coating of steel plates, including a cold rolling system 1 and a coating system 2 .

[0027] The cold rolling system 1 includes a raw material preparation device 11 , a rolling mill 12 , a degreasing device 13 , an annealing reduction device 14 , a cooling device 15 and a finishing device 16 . The steel plate cold-rolling and coating integrated production unit in the present invention is divided into a ground unit, a middle unit and an upper unit according to the spatial distribution plan. The ground unit is a series of devices installed on the ground of the factory building, the upper unit is a series of devices with the highest level in the entire production unit, and the middle unit is a series of devices located between the ground unit and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com