Hot rolling hot straightening roll suitable for thick steel plates with thickness of less than or equal to 60mm and preparation method thereof

A technology for hot straightening rolls and thick steel plates, which is applied in the field of metallurgical hot-rolled steel plate equipment and hot-rolled hot straightening rolls for wide and thick steel plates, which can solve problems such as thermal stability and insufficient wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A hot-rolled hot straightening roll suitable for steel plates with a thickness of ≤60mm, the material of which is modified H13 hot work die steel, and the weight percentage of each component element is:

[0039] Cr 4.5~6.0%,

[0040] Mo 1.0~2.0%,

[0041] Si 0.6~1.5%,

[0042] Ni 0.8~1.2%,

[0043] V 0.8~2.0%,

[0044] C 0.35~0.6%,

[0045] P≤0.02%,

[0046] S≤0.01%,

[0047] Fe and unavoidable impurity balance.

[0048]The surface hardness of the product roll is in the range of HRC56-63, the surface hardness difference is ≤2HRC, and the effective hardened layer is in the range of 10-15mm. The metallographic structure of the quenched layer on the surface of the finished hot-rolled hot straightening roll is a fine-grained structure of grade 8 or above of tempered martensite and dispersed granular carbides. The yield strength of the finished hot-rolled hot straightening roll is in the range of 920-970Mpa, the tensile strength is in the range of 1100-1200Mpa, the y...

Embodiment 2

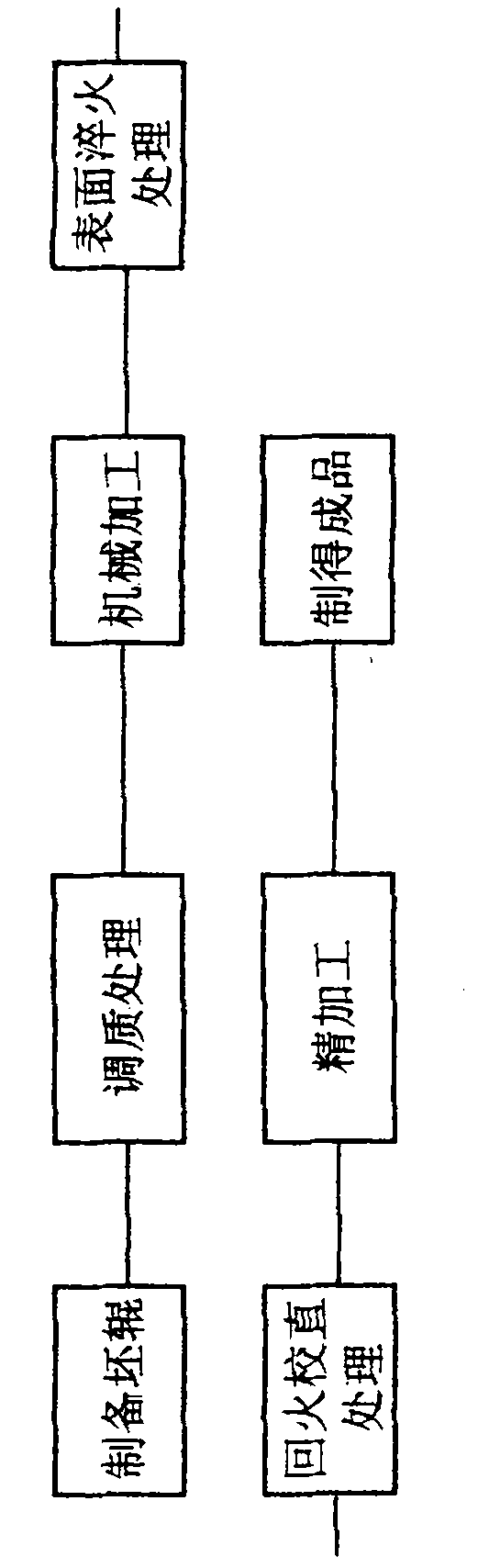

[0049] Embodiment 2, as attached figure 2 shown.

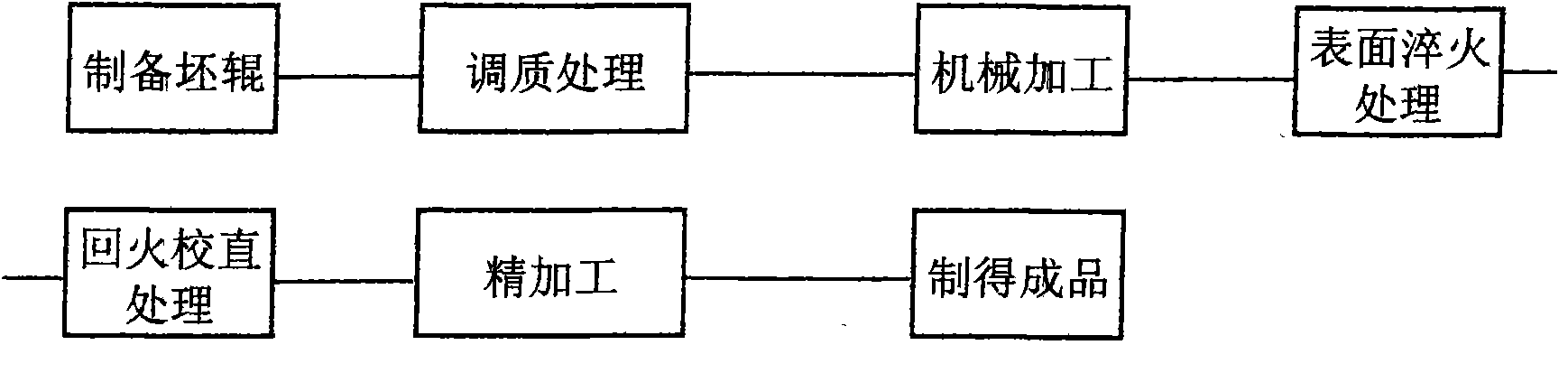

[0050] A method for preparing a hot-rolled hot straightening roll as described in Example 1, followed by the steps of preparing blank roll, quenching and tempering treatment, machining, surface quenching treatment, tempering treatment, and finishing step to obtain a hot-rolled hot-rolled straightening roll Straight rolls which:

[0051] The material used for the roll body is the modified H13 hot work die steel;

[0052] The surface quenching treatment adopts the method of vertical 2500-3000HZ intermediate frequency induction rapid heating and pressure water spray rapid cooling, and the quenching temperature is controlled within the range of 1130-1170°C;

[0053] The tempering treatment is performed twice in the tempering furnace, the tempering temperature is controlled within the range of 520°C to 580°C, and the tempering time of each tempering treatment is ≥10h;

[0054] The tempering treatment also includes the straighte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com