Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

A hot-dip galvanizing and characteristic technology, which is applied in the field of cold-rolled high-strength sheet for automobiles, can solve the problems of poor flanging performance, large difference in hardness between two phases, and poor hole expansion rate, and achieve the effect of avoiding the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

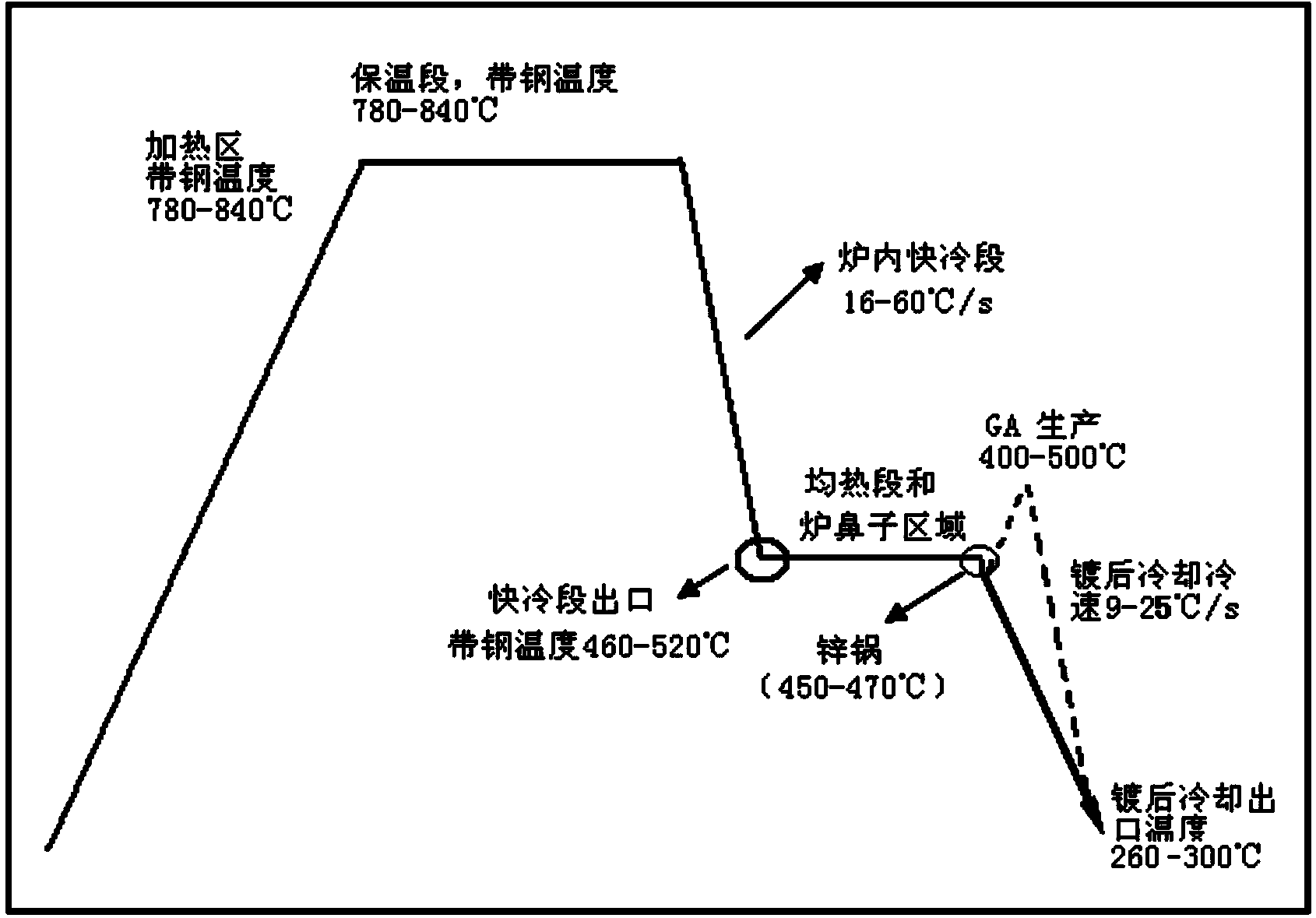

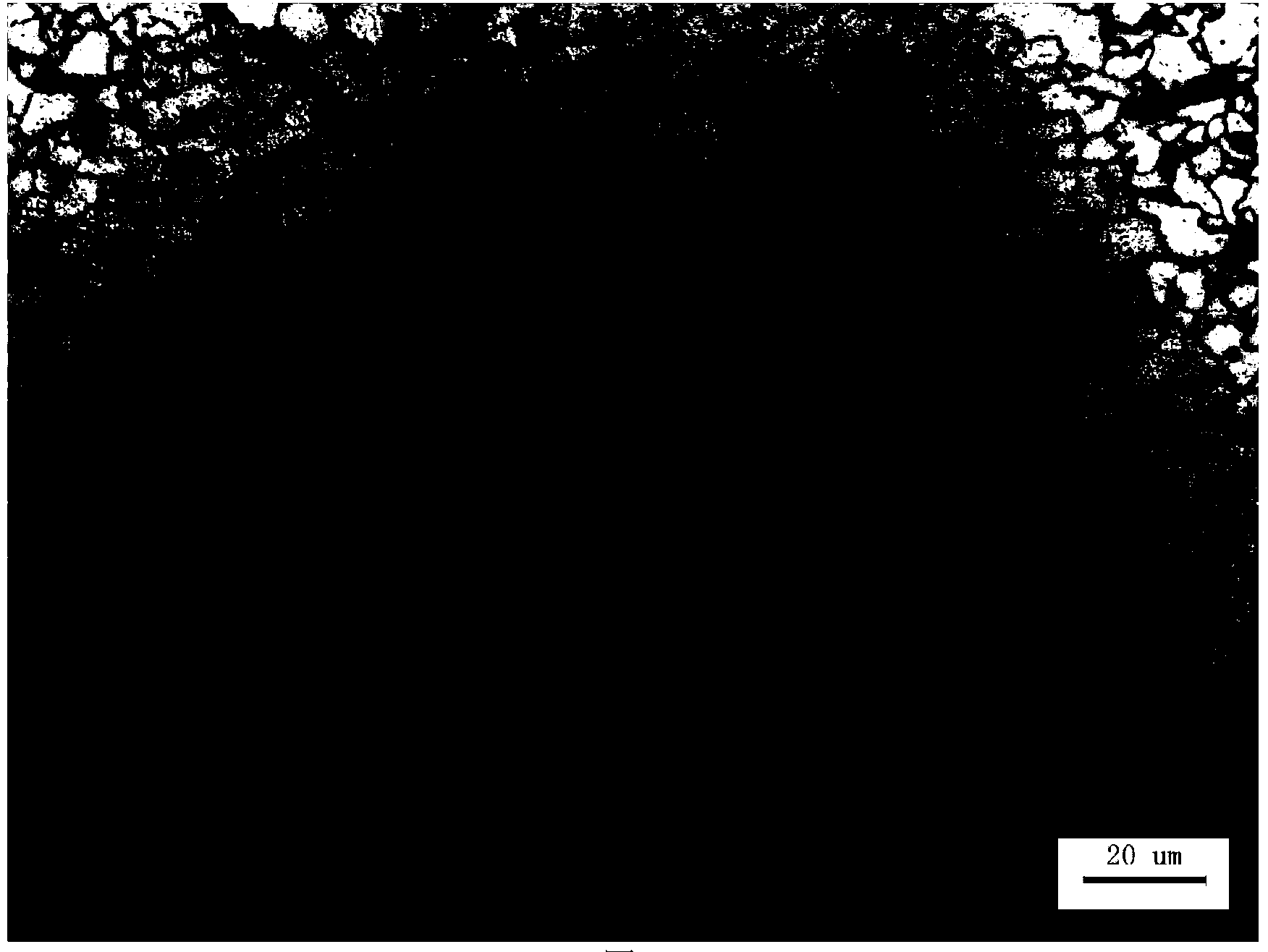

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0020] See Figure 1-Figure 3 , a cold-rolled hot-dip galvanized dual-phase steel sheet with flanging characteristics, and its chemical composition weight percentages are: C0.06%-0.095%, Si0.3%-0.6%, Mn1.4%-1.8%, 0< P≤0.02%, 0<S≤0.01%, Al0.02%-0.05%, Cr0.35-0.55%, Nb0.02-0.04%, 0<N≤0.005%, and the rest are Fe and unavoidable impurities.

[0021] Preferably, the composition contains by mass percentage:

[0022] C0.065%~0.085%, Si0.4%~0.55%, Mn1.55%~1.65%,

[0023] The steel composition control principle of the present invention is as follows:

[0024] C: It is the most effective strengthening element and the main element ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com