Strong abrasive belt base paper and preparation method

A technology of base paper and abrasive belt, which is applied in the papermaking industry, can solve problems such as flexibility, poor impermeability, low strength, and easy cracking, and achieve the effects of good impermeability, high strength, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

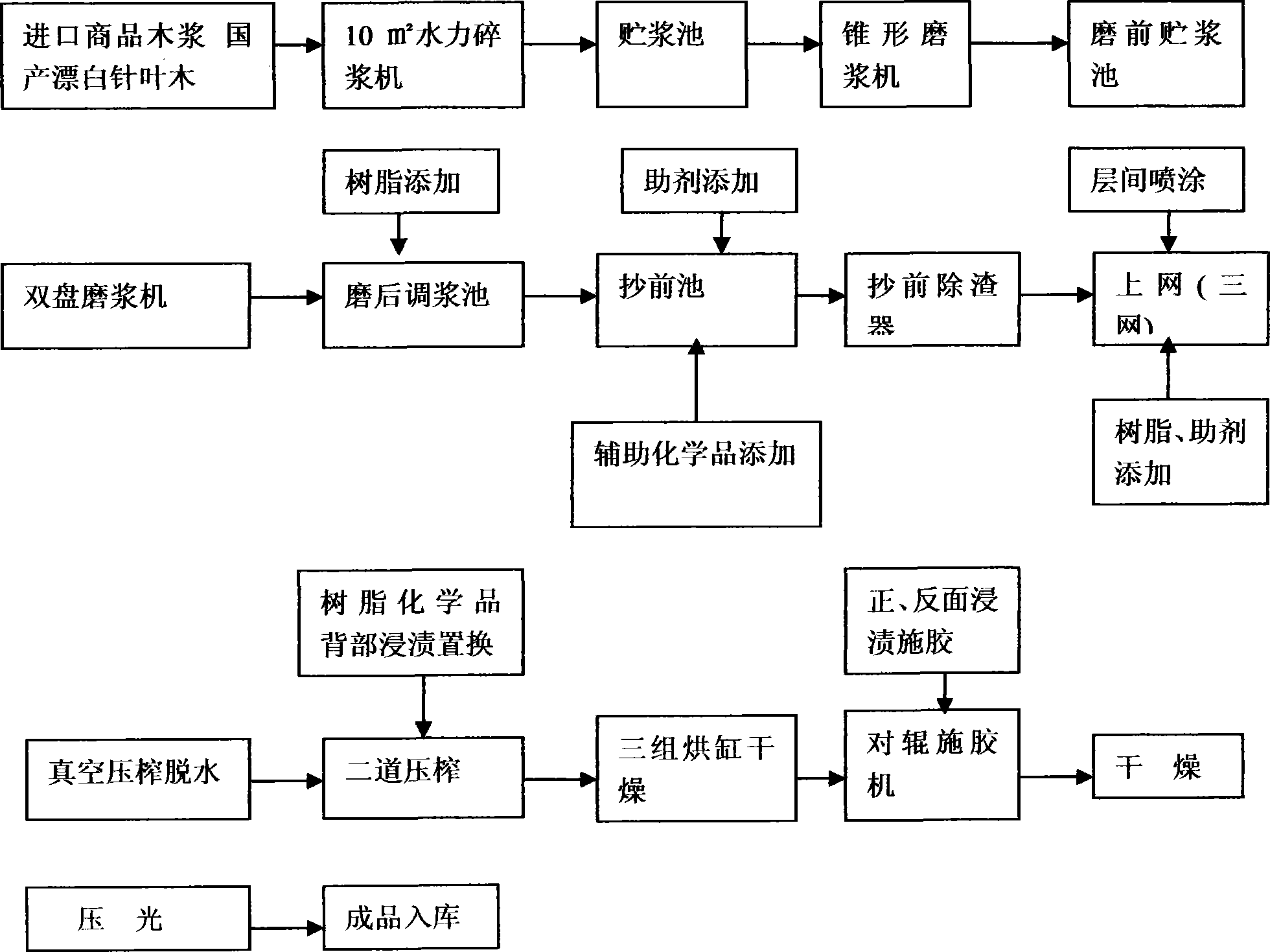

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the chemical composition of interlayer spraying:

[0078] Add oxidized starch to the diluted polyacrylate liquid;

[0079] Add accelerator or foam suppressor to the above mixed solution and stir continuously;

[0080] After the qualified mixed emulsion is filtered, the interlayer spraying is carried out.

[0081] Back Preload Replacement:

[0082] Mass percentage of chemical components replaced by pre-compression:

[0083] Resin 98~99.3%

[0084] Chemical additives 0%

[0085] Auxiliary chemicals 0.7~2%

[0086] In the composition of the chemical components of the pre-compression replacement, the resin is any two or combination of nitrile latex, PAE, and MF resin, and the auxiliary chemical is a foam suppressor;

[0087] The preparation method of the resin mixture in the back preload replacement process is:

[0088] Add diluting water to Nitrile Latex, and adjust the concentration at 15-25g / l;

[0089] Add PAE or / and MF resin to the adjus...

Embodiment 1

[0105] (1) strong abrasive belt base paper production process of the present invention, fiber proportioning actual control process:

[0106] Add 3 pieces of imported first-class bleached softwood pulp to 17 pieces of bleached domestic kraft softwood pulp, mix and feed, and store in two pulp tanks to fully mix and evenly.

[0107] (2) According to the above-mentioned proportioning process, the production process of the strong abrasive belt base paper of the present invention, the preparation steps of slurry seasoning, interlayer spraying, pre-pressing replacement, dipping and sizing process resin and auxiliary agents are as follows:

[0108] The beating time is 5 hours, and the pulp degree and wet weight index remain unchanged according to the same control index.

[0109] (3) The step of seasoning in the slurry is: add 30 parts of acrylate polymers to 15 parts of nitrile latex and mix them in the mixing tank, add 15 parts of oxidized starch to 2 parts of AKD and mix them in the...

Embodiment 2

[0126] (1) strong abrasive belt base paper production process of the present invention, the actual regulation and control process of fiber ratio:

[0127] Add 4 pieces of imported first-class bleached softwood pulp to 16 pieces of bleached domestic kraft softwood pulp, mix and feed, and store in two pulp tanks to fully mix and evenly.

[0128] (2) According to the above-mentioned proportioning process, the production process of the strong abrasive belt base paper of the present invention, the preparation steps of slurry seasoning, interlayer spraying, pre-pressing replacement, dipping and sizing process resin and auxiliary agents are as follows:

[0129] The pulping time is 6 hours, and the pulp degree and wet weight index are kept unchanged according to the same control index.

[0130] (3) The seasoning steps in the slurry are:

[0131] ①, 40 parts of acrylic polymers are mixed with 15 parts of nitrile latex,

[0132] ②. Add 10 parts of cationic polyacrylamide solution to ①...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com