Method for connecting nickel-based high-temperature alloy annular piece with copper-silver alloy through partial diffusion bonding

A nickel-based superalloy, copper-silver alloy technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of high porosity, delamination, and peeling of the connecting layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for local diffusion bonding copper-silver alloy of the nickel-base superalloy ring provided by the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

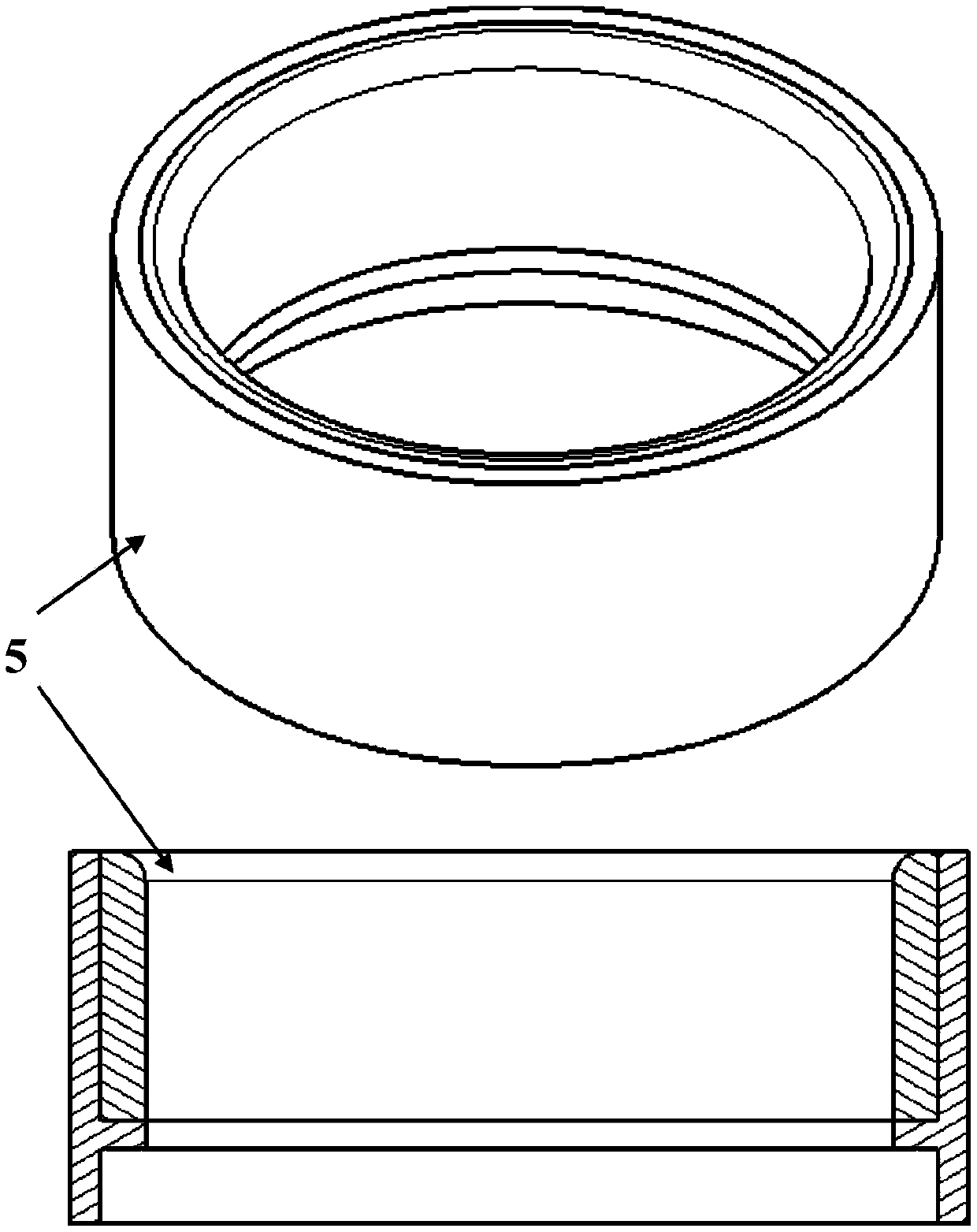

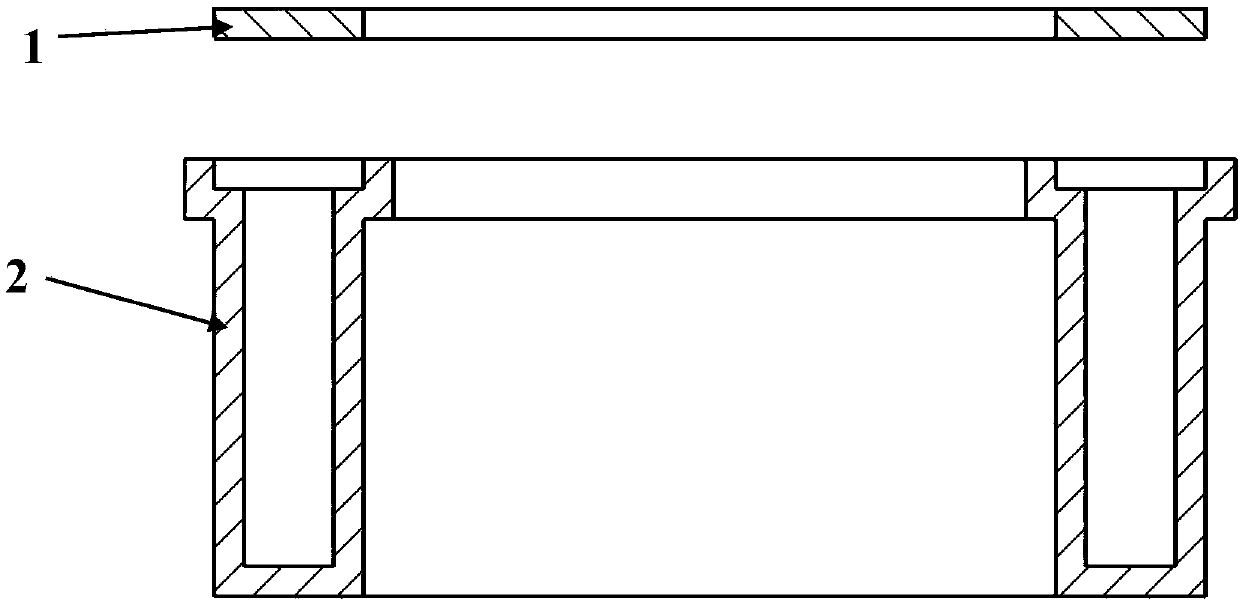

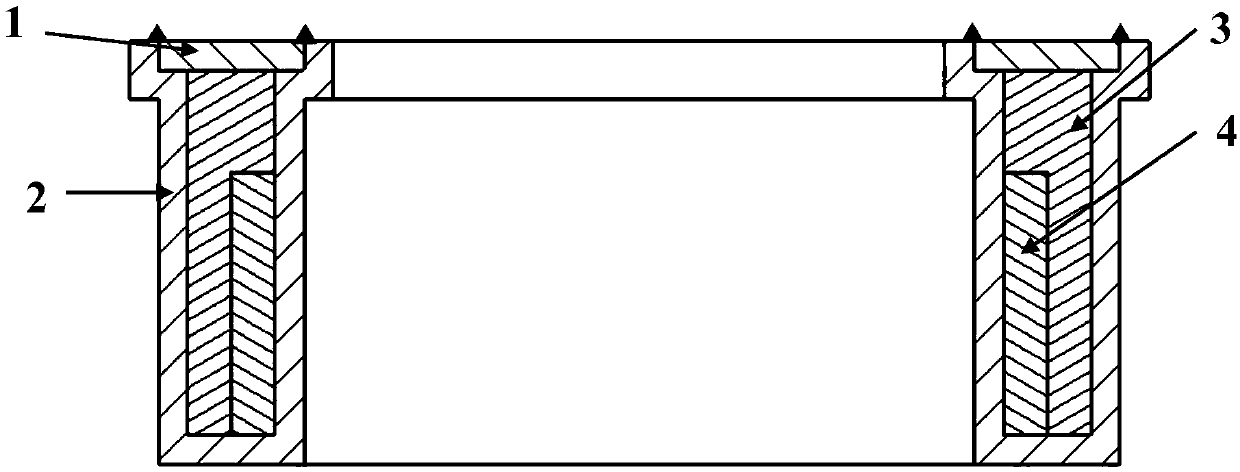

[0021] Such as figure 1 — Figure 4 As shown, the method for the local diffusion connection copper-silver alloy of the nickel-base superalloy annular piece provided by the invention comprises the following steps carried out in order:

[0022] 1) According to the structural features of the final connecting piece 5, a nickel-based superalloy ring piece 3 and a copper-silver alloy ring piece 4 are prepared. The material of the nickel-based superalloy ring 3 can be GH4169, GH600, etc., and the ratio of copper to silver in the copper-silver alloy material can be changed. In order to ensure the dimensional accuracy of the connecting parts, the copper-silver alloy ring 4 is processed based on the inner diameter of the nickel-based high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com