Method for connecting Fe-based high-temperature alloy ring with internal characteristics and Cu-Ag alloy

A technology of iron-based high-temperature alloy and copper-silver alloy, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of delamination and high porosity of the connecting layer, peeling of the connecting layer, etc., to increase the scope of application, avoid peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for diffusion bonding copper-silver alloy of the iron-based superalloy ring member with internal features provided by the present invention will be described in detail below with reference to the drawings and specific examples.

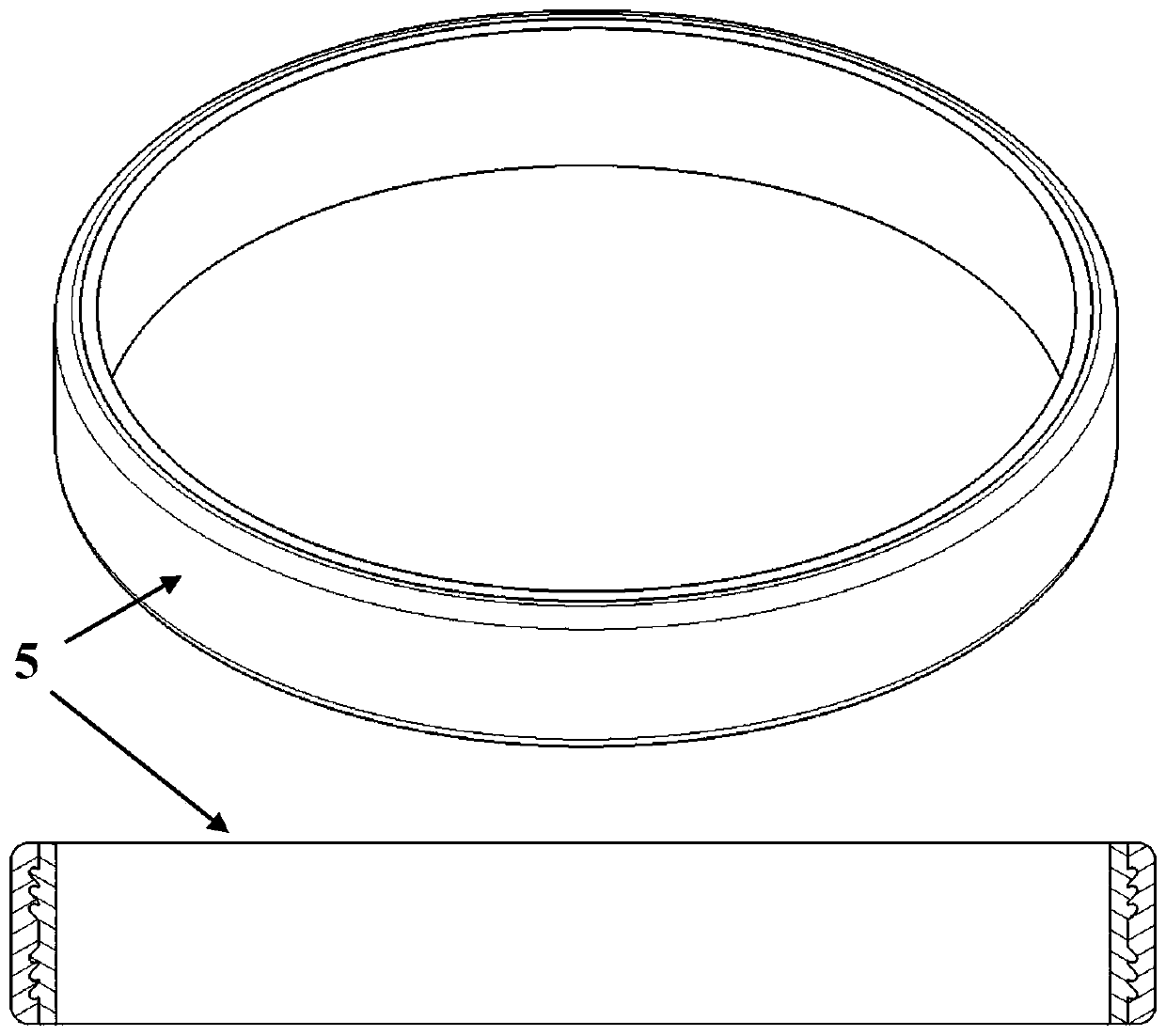

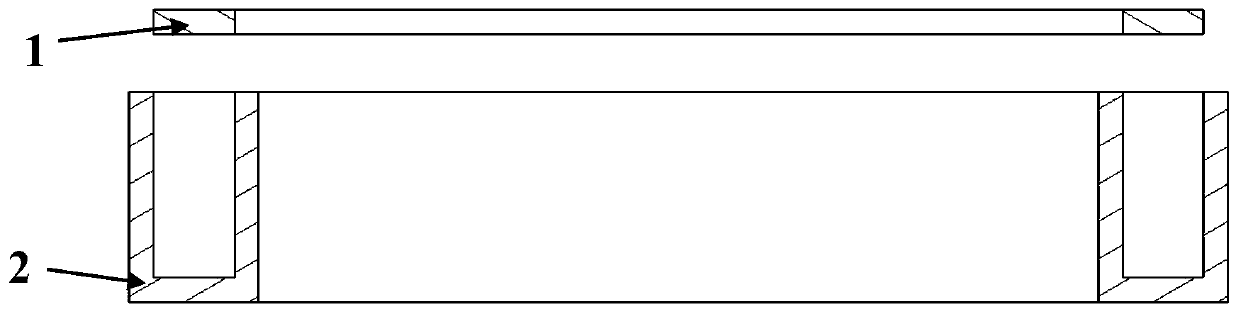

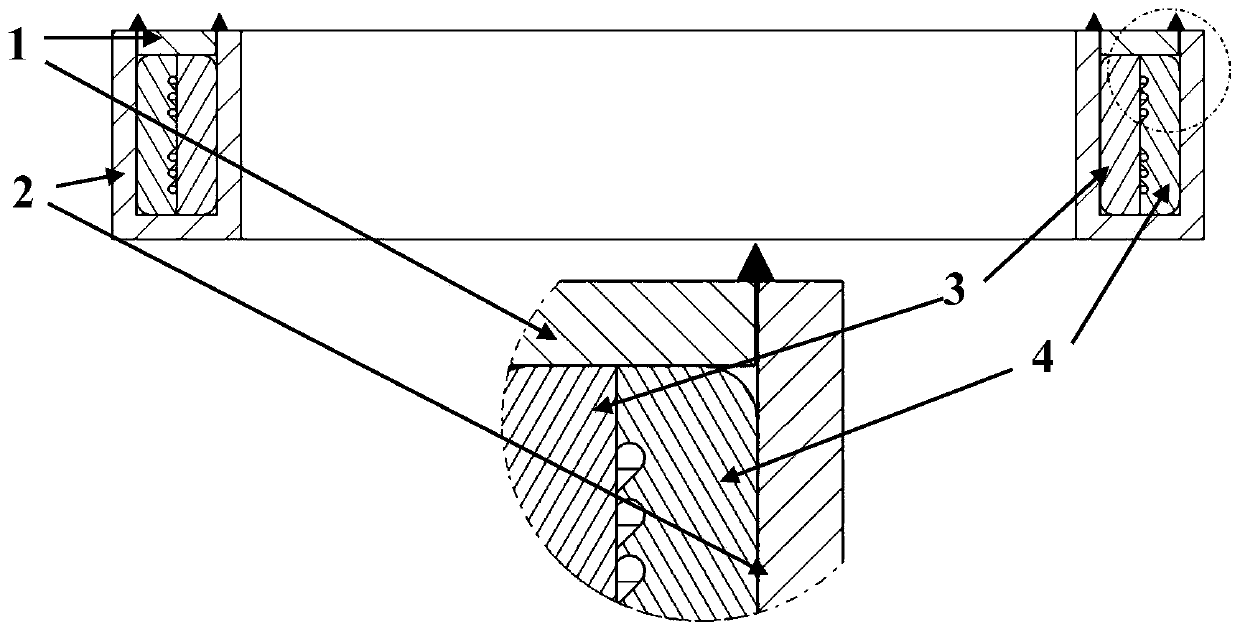

[0022] Such as figure 1 — Figure 4 As shown, the method for diffusion bonding copper-silver alloy with iron-based superalloy ring parts with internal features provided by the present invention includes

[0023] The following steps in order:

[0024] 1) According to the structural characteristics of the final annular connecting piece 5, an iron-based superalloy ring piece 4 and a copper-silver alloy ring piece 3 with internal characteristics are prepared. In order to ensure the dimensional accuracy of the connecting piece, the copper-silver alloy ring piece 3 is processed based on the inner diameter of the iron-based superalloy ring piece 4, which conforms to the clearance fit. That is, a certain gap is left between the outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com