Ultrasonic wave flow rate metering device

A flow measurement and ultrasonic technology, applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems affecting measurement accuracy, manual hand-holding of gaskets, uncontrollable processing errors, etc., and achieve simple and safe sealing , good waterproof effect, avoiding the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

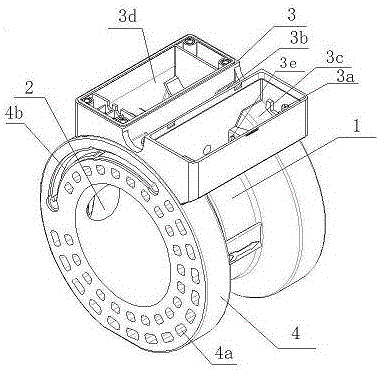

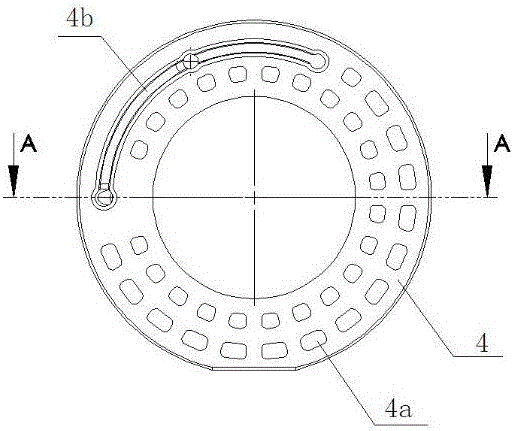

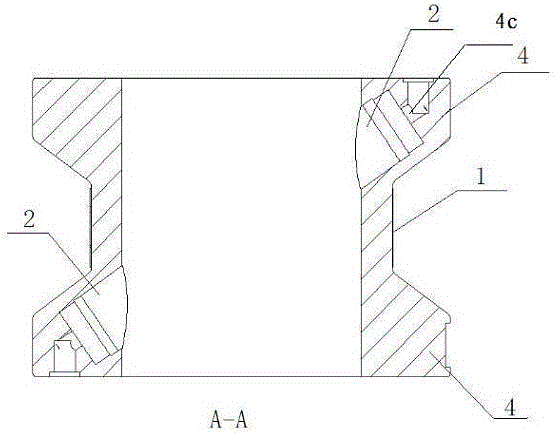

[0034] figure 1 It is an ultrasonic flow metering device of the present invention, which includes a measuring pipe body 1 and a signal processing device 3. Both ends of the measuring pipe body 1 have a boss sealing body 4 matching with the flange of the fluid pipeline to be measured. There are pairs of ultrasonic transducer mounting holes 2 on the inner side of the measuring tube body 1 respectively, and the ultrasonic transducer mounting holes 2 are arranged on the inner side of the measuring tube body 1 and extend to the space of the boss seal 4. Ultrasonic transducers are respectively installed in them, and the opening positions of the ultrasonic transducer installation holes 2 make the measurement signals of the two ultrasonic transducers realize direct radiation, and the measurement signals of the ultrasonic transducers are led to the signal processing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com