Radome and embedded metal ring connection structure and connection method

A technology of connecting structure and radome, applied in the direction of radiation unit cover and other directions, to achieve the effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

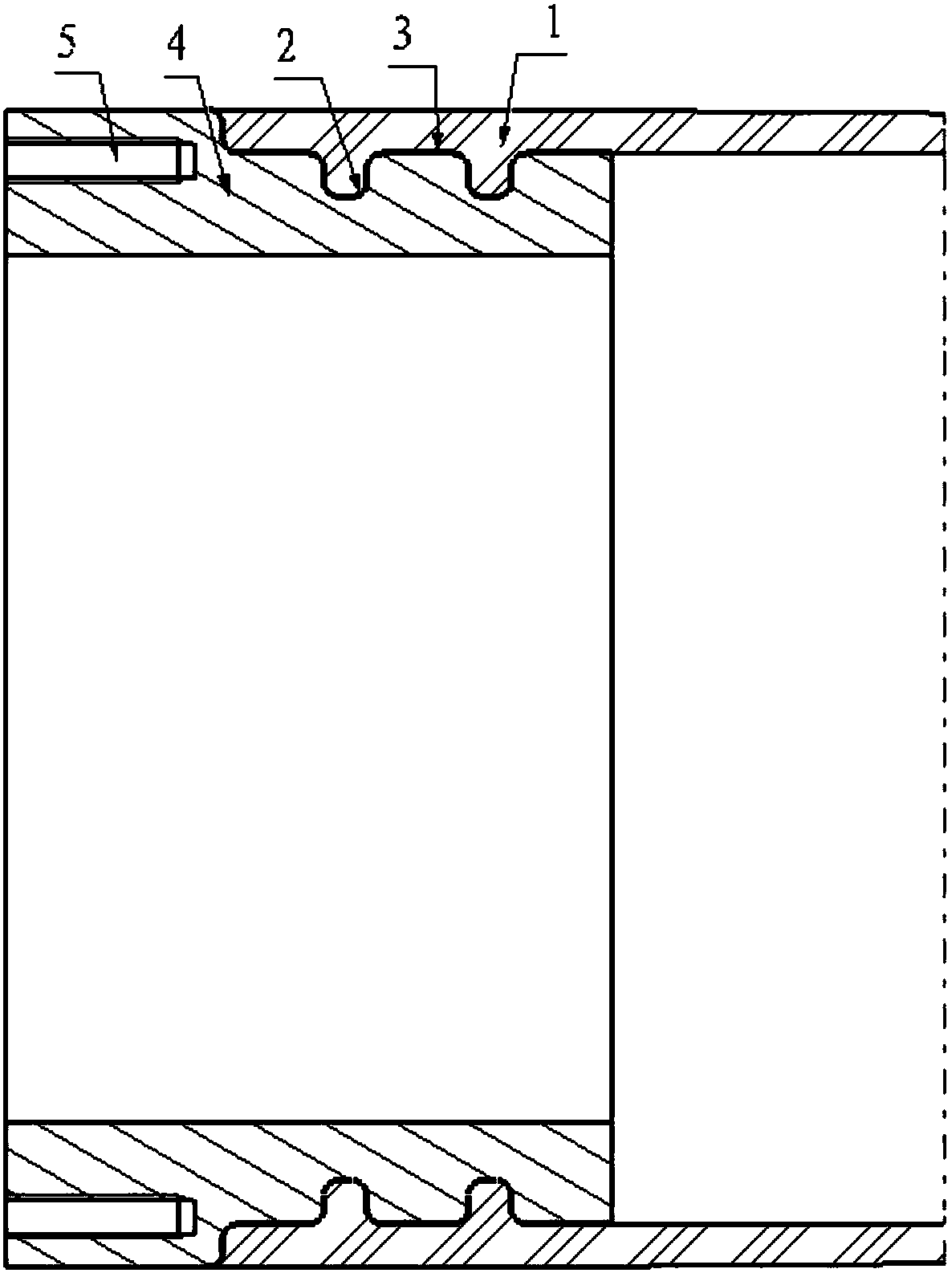

[0008] The connection structure between the radome and the embedded metal ring, the radome 1 is made of composite material, there is a protrusion on the inner surface of the root of the radome 1, and there is a groove 2 matching the protrusion on the outer surface of the embedded metal ring 4, There is an adhesive 3 on the connecting surface of the two, and they are fixed to each other during the forming process of the radome 1 . There is also a threaded hole 5 on the outer end surface of the embedded metal ring 4 .

[0009] The connection method between the pre-embedded metal ring and the composite material radome at its root is: when the radome 1 is formed, the pre-embedded metal ring 4 is used as a part of the mold, and when demoulding, the pre-embedded metal ring 4 and the radome 1 are demoulded . In order to avoid the mismatch caused by inconsistent thermal expansion coefficients during the molding process, an adhesive 3 is applied between the radome 1 and the embedded m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com