Demolding method and device for end plate of side plate of bilateral pre-tensioned pre-stressed concrete track plate

A demoulding device, track plate technology, applied in the direction of unloading device, manufacturing tools, etc., can solve the problems of partial cracks in the anchor hole, no extensive reports found, difficulty in controlling synchronization and levelness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

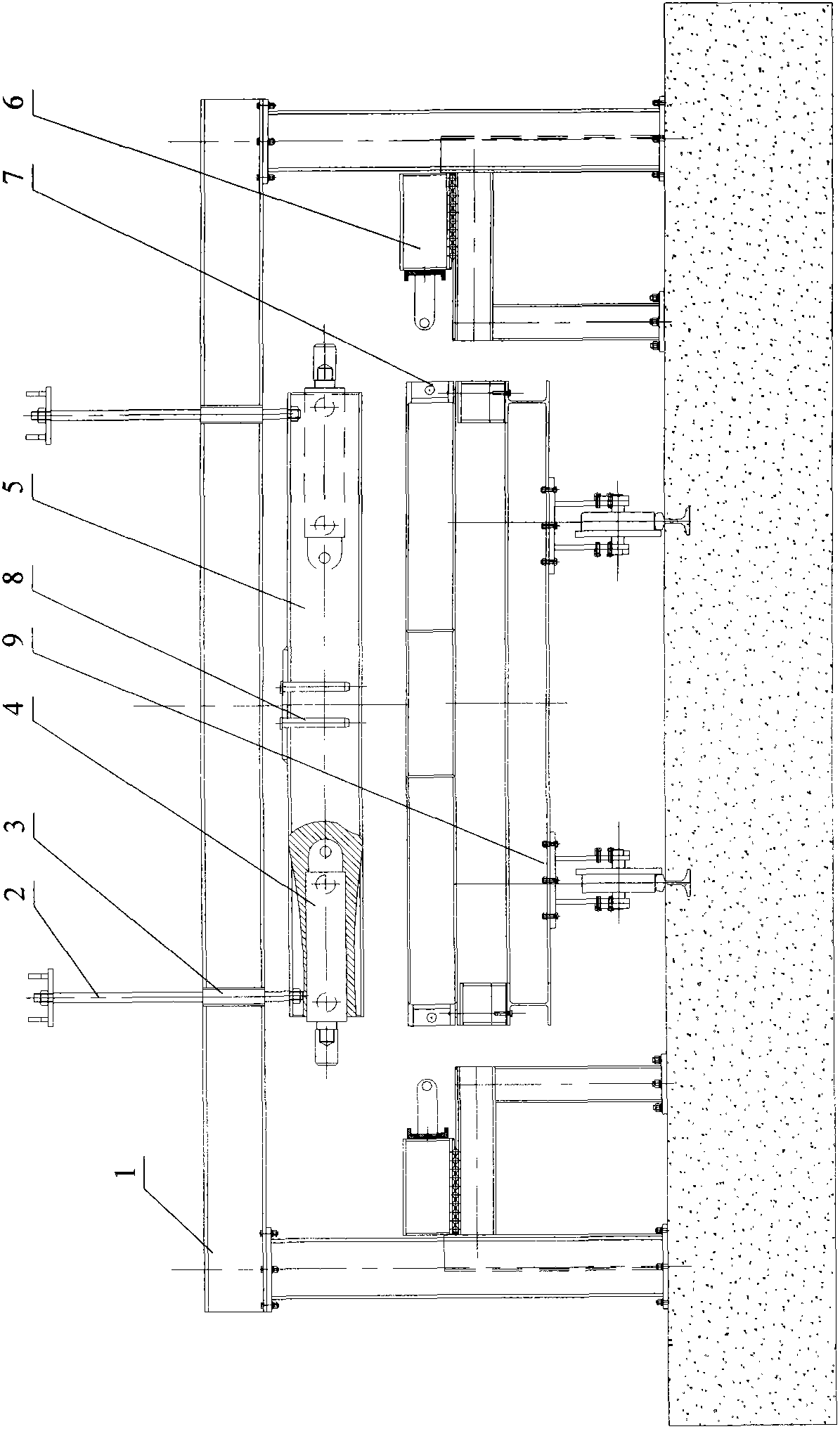

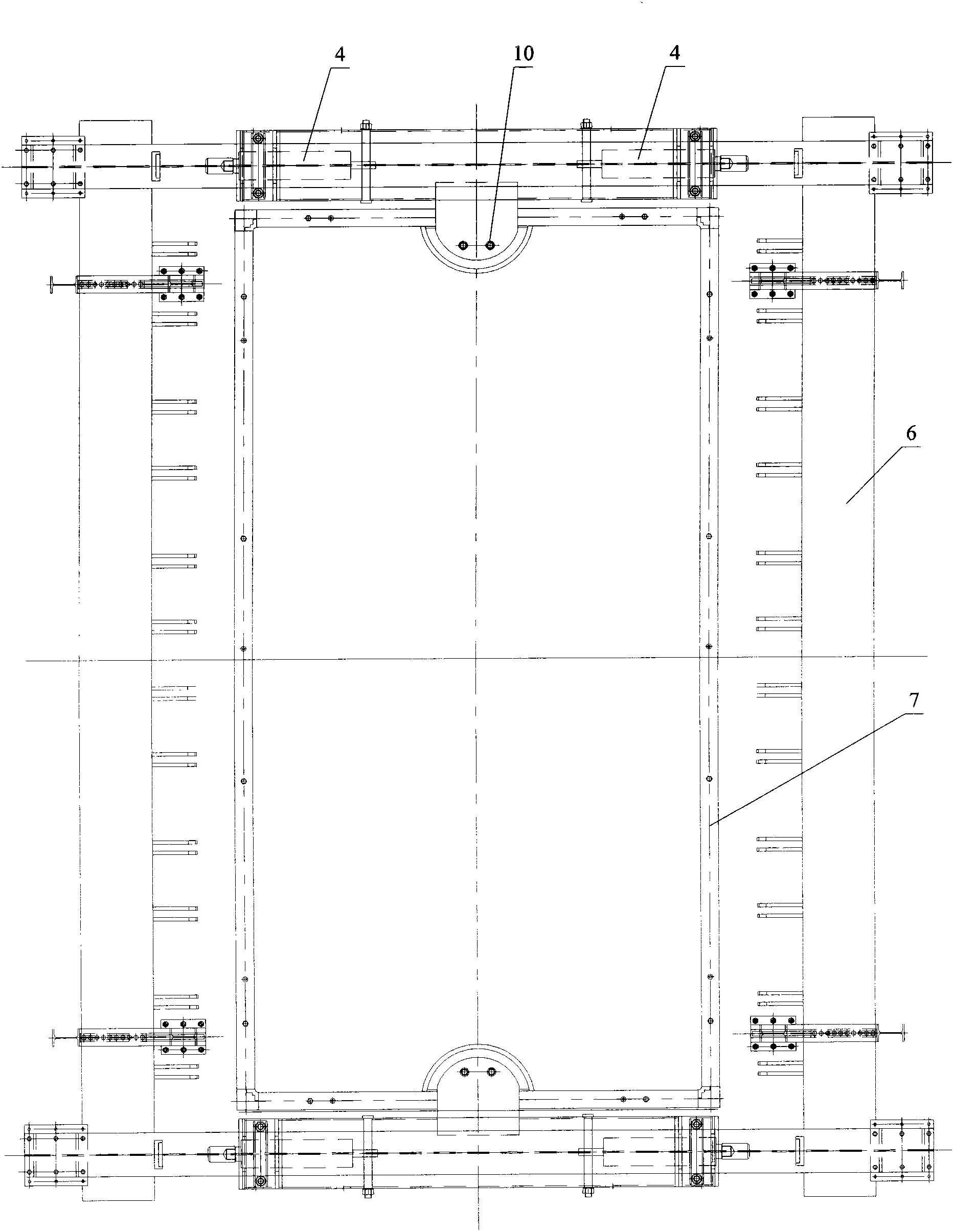

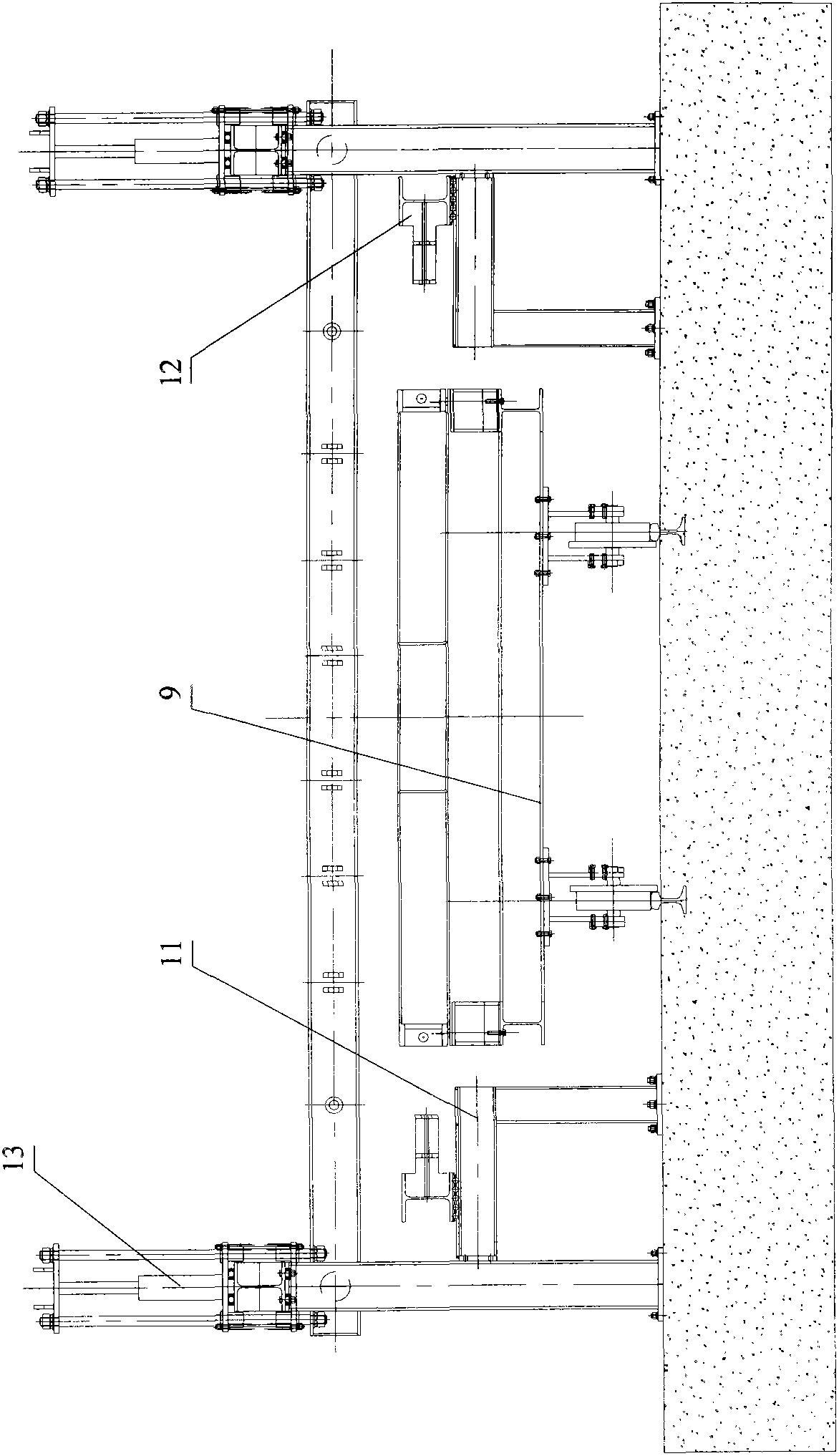

[0070] The demoulding device and method of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, so as to understand the features, details and advantages of the present invention more clearly and completely. It should be pointed out that those skilled in the art can easily understand that the following examples are only preferred exemplary examples given to facilitate the understanding of the present invention, and are not meant to limit the present invention in any way. On the contrary, on the basis of reading the present invention, those skilled in the art can make any modifications or changes to the following embodiments, and the features in different embodiments can be changed or combined as required. It should be understood that the present invention is not limited to the specific structures, devices, methods, etc. described and shown herein.

[0071] As mentioned above, the demoulding device of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com