Bridge bearing structure passing through huge karst cave and construction method of bridge bearing structure

A technology for load-bearing structures and bridge structures, which is used in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as affecting the safety of tunnel engineering operations, cracking and damage of tunnel structures, and uneven stress on tunnel structures, so as to avoid post-construction settlement. Large, high reliability, dynamic and static load transfer dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

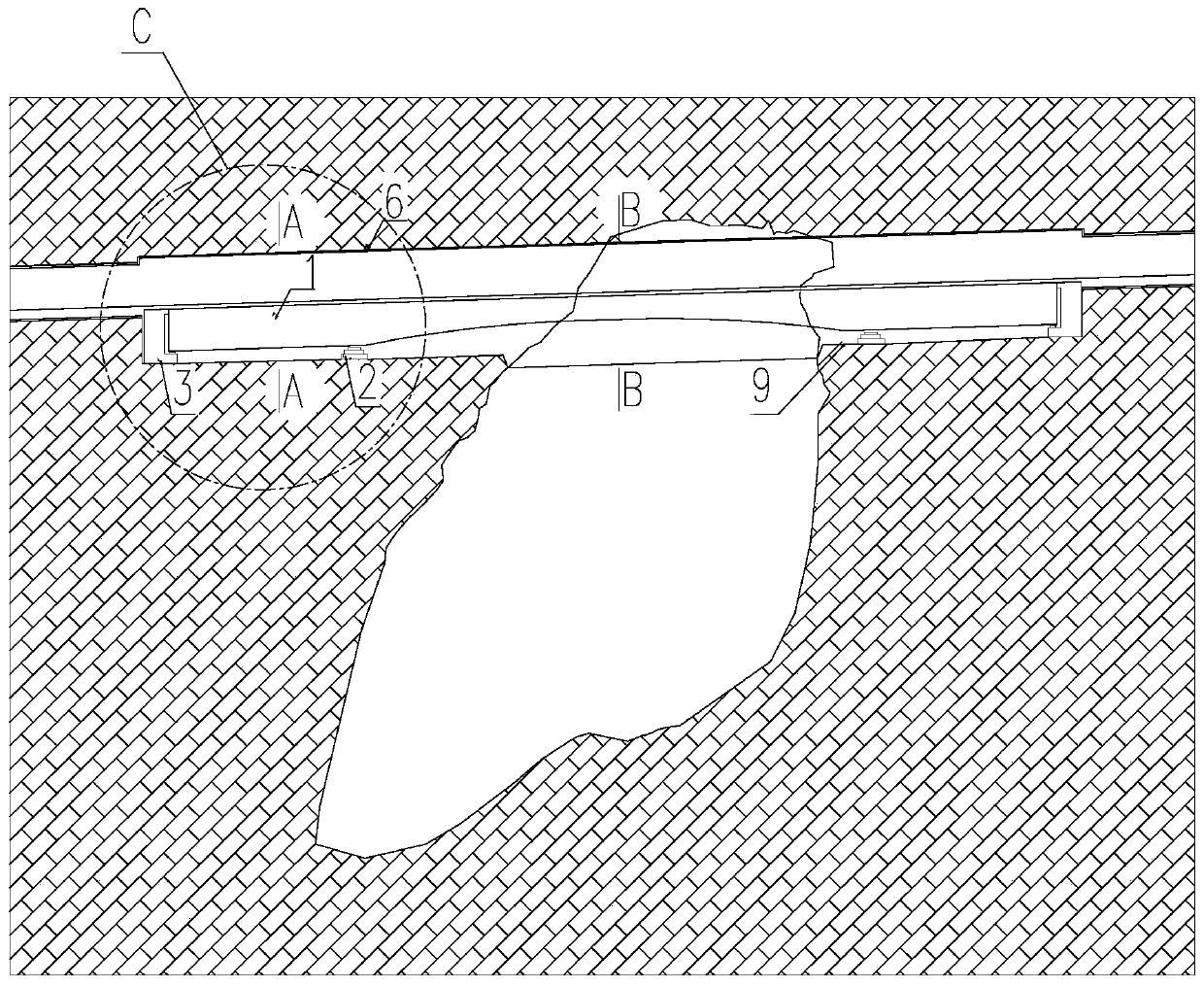

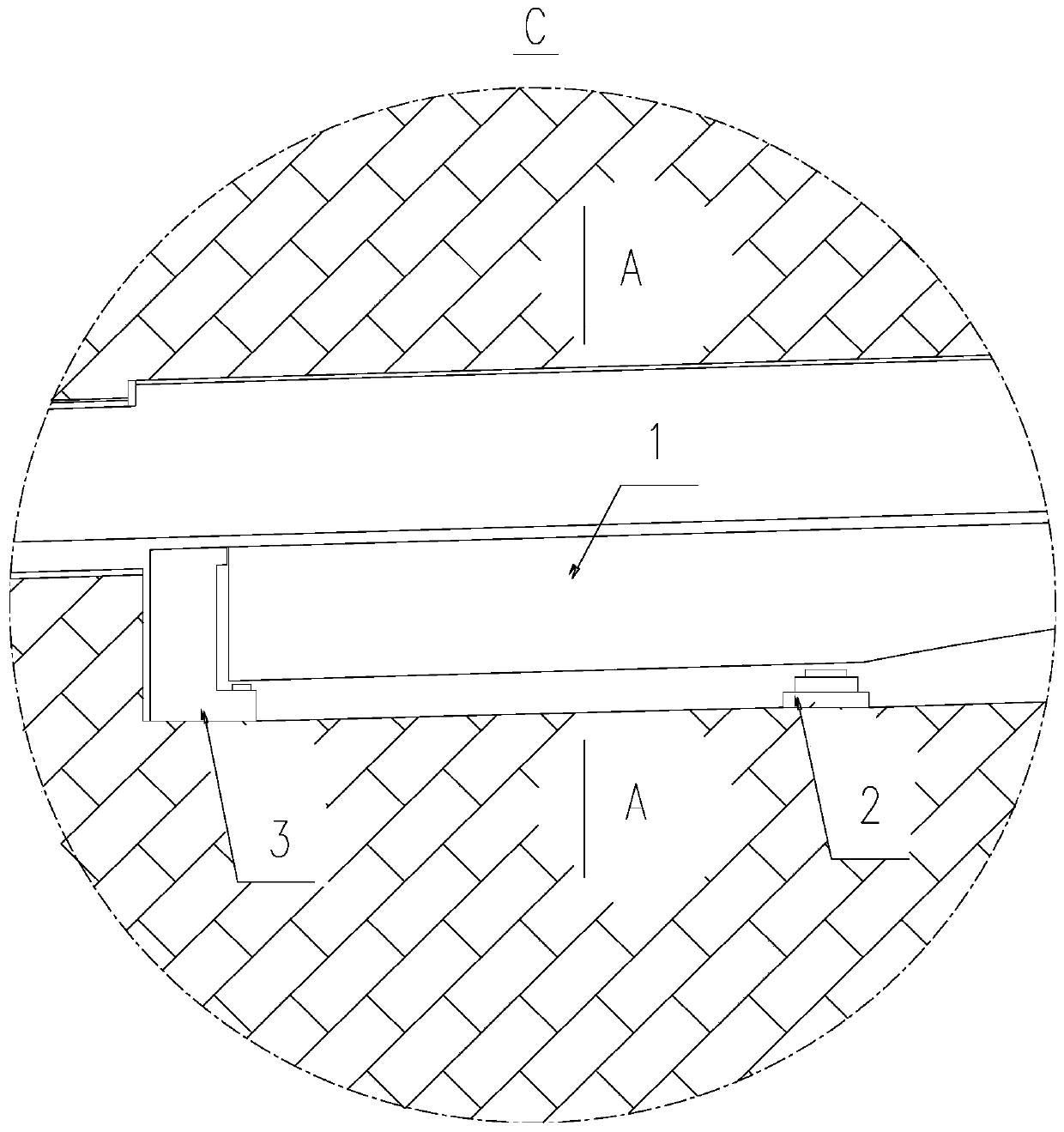

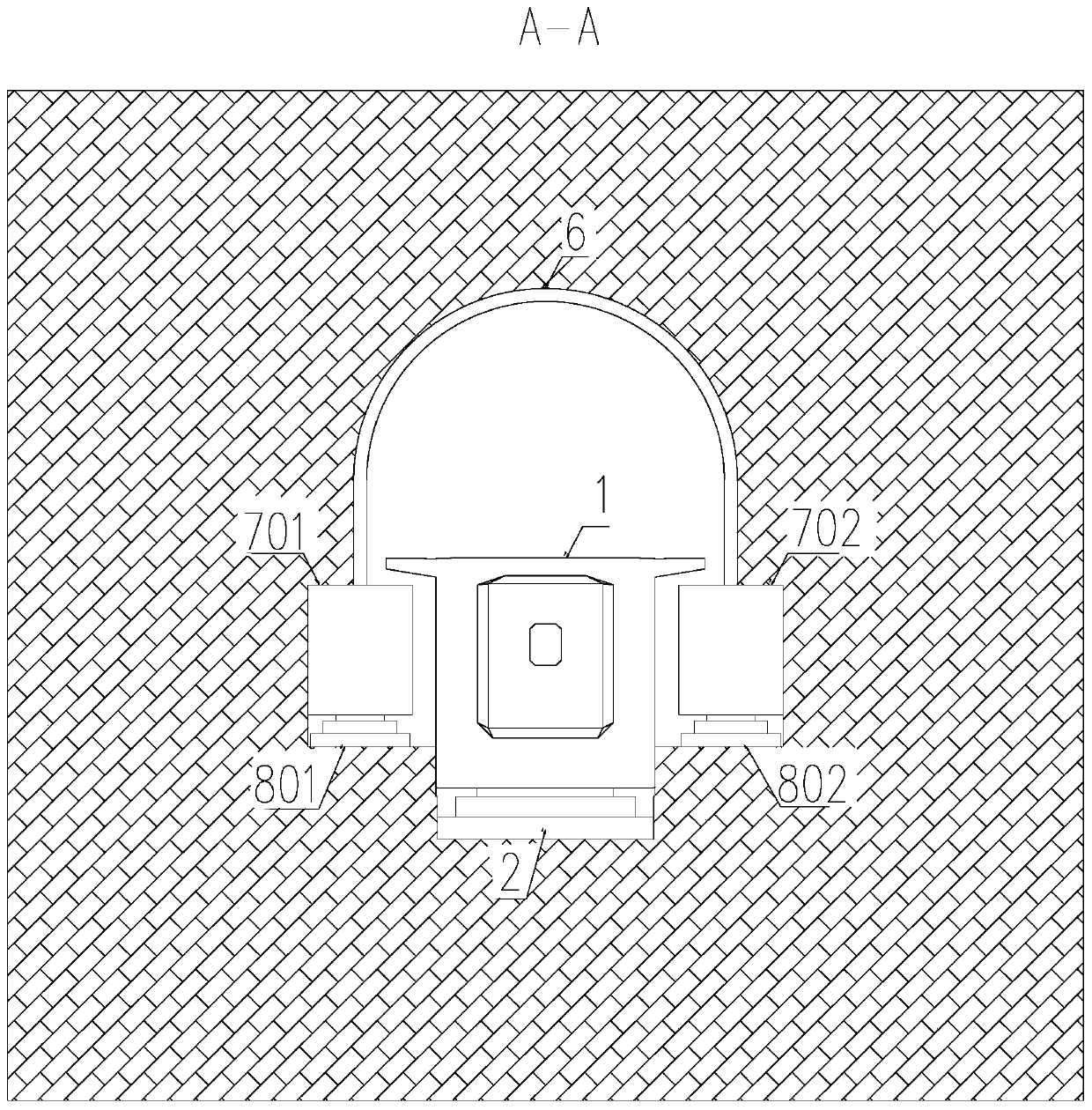

[0043] See Figure 1-Figure 9 . The embodiment of the present invention provides a load-bearing structure of a bridge passing through a giant karst cave 10, which includes a bridge structure 1 and a protective structure.

[0044] See image 3 and Figure 4 . Among them, the protective structure includes a first layer of protective structure and a second layer of protective structure. The first layer of protective structure includes open tunnel structure 6, support beam one 701, support beam two 702, support beam support one 801 and support beam support two. 802. The second layer of protection structure includes anchor net spray structure 4 and vertical long anchor cable 5 support.

[0045] Specifically, the anchor net and shotcrete structure 4 and the vertical long anchor cable 5 support the surrounding rock on the top of the cave 10. By setting the vertical long anchor cable 5, it is ensured that the large rock mass at the top of the cave 10 can be anchored. The combination of...

Embodiment 2

[0069] The embodiment of the present invention provides a load-bearing structure of a bridge passing through a giant karst cave 10. The difference from Embodiment 1 is that in this embodiment, a shed structure is used instead of the open cave structure 6 in Embodiment 1.

[0070] In this embodiment, the shed structure is a reinforced concrete member or a steel structural member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com