Wind-supplying pipe heat insulation device inside carbon element calcining rotary kiln and its preparation and method for using

A technology of air supply pipe and rotary kiln, which is applied in the application field of refractory materials, and can solve problems such as difficulty in guaranteeing performance, short service life of air supply pipe, and insufficient air supply in the kiln, so as to improve service life, prolong service life, connect Strong and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

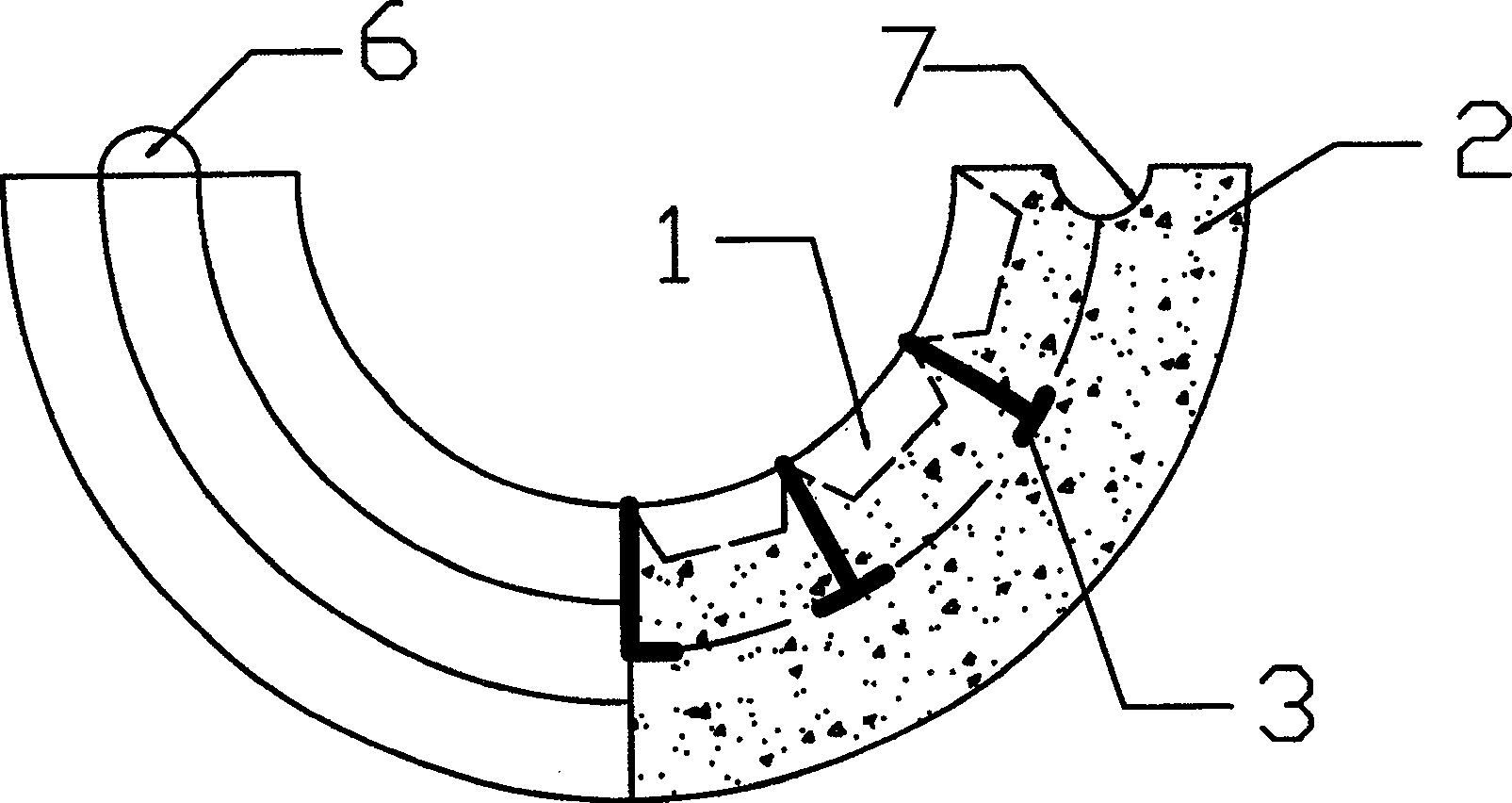

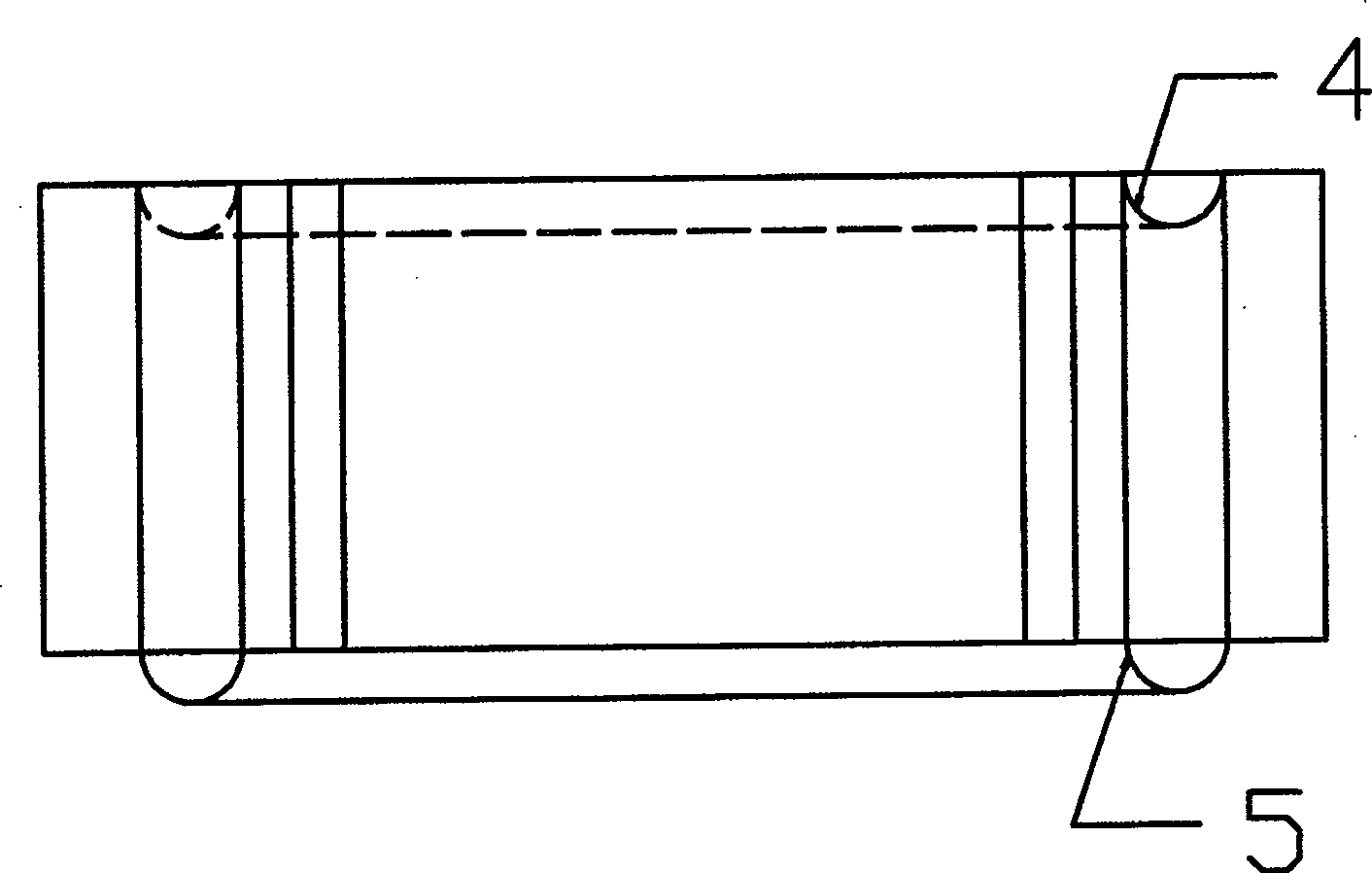

Embodiment 1

[0018] The size of the rotary kiln is φ2.84×55m, used for calcining petroleum coke, the speed is 2-3rmp / min, the output is 9-12t / h clinker, and the air supply volume is 16000-1700Nm 3 / h, the air supply ratio between primary air, secondary air and tertiary air is 2:3:5, the air supply pipe is made of φ108×4mm seamless steel pipe, and the wind speed in the pipe is 45-55m / s. The combined heat-insulating wrapping block is mainly composed of pad iron 1, castable material 2, and anchor nail 3, and is hollow and semi-cylindrical, with pad iron 1 arranged on the inner wall. Weld a T-shaped anchor piece 3 every 30mm on one side of the heat insulation prefabricated block on the pad iron 1, and set an outwardly convex semi-circle II6 and semi-circular type on both ends of the combined heat insulation prefabricated block. The inner groove II7 is provided with an outer convex semicircular ring I5 and a semicircular inner groove I4 corresponding to each other on the side. The size and tec...

Embodiment 2

[0022] Rotary kiln size φ2.2×45m, self-weight 214.8t, used for calcining petroleum coke, rotating speed 3-4rmp / min, output 6-9t / h clinker, air supply volume 14000-1500Nm 3 / h, the air supply ratio between primary air, secondary air and tertiary air is 1:3:6, the air supply pipe is made of φ89×4.5mm seamless steel pipe, and the wind speed in the pipe is 40-45m / s. The combined heat-insulating wrapping block is composed of pad iron 1, castable material 2, and anchor nail 3, and is hollow and semi-cylindrical, with pad iron 1 arranged on the inner wall. Weld a V-shaped anchor piece 3 every 30mm on the side of the heat insulation prefabricated block on the pad iron 1, and set a convex semicircular ring II6 and a semicircular annular shape on the two ends of the combined thermal insulation prefabricated block. The inner groove II7 is provided with an outer convex semicircular ring I5 and a semicircular inner groove I4 corresponding to each other on the side. The size and technical p...

Embodiment 3

[0026] Rotary kiln size φ2.5×55m, self-weight 274.8t, used for calcining petroleum coke, speed 3-4rmp / min, output 11-12t / h clinker, air supply volume 17000-1800Nm 3 / h, the air supply ratio between primary air, secondary air and tertiary air is 1:3:6, the air supply pipe is made of φ89×4.5mm seamless steel pipe, and the wind speed in the pipe is 450-55m / s. The combined heat-insulating wrapping block is composed of pad iron 1, castable material 2, and anchor nail 3, and is hollow and semi-cylindrical, with pad iron 1 arranged on the inner wall. Weld a T-shaped anchor piece 3 every 30mm on one side of the heat insulation prefabricated block on the pad iron 1, and set an outwardly convex semi-circle II6 and semi-circular type on both ends of the combined heat insulation prefabricated block. The inner groove II7 is provided with an outer convex semicircular ring I5 and a semicircular inner groove I4 corresponding to each other on the side. The size and technical parameters of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com