Patents

Literature

34results about How to "Control discharge rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

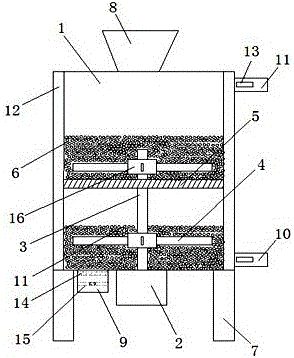

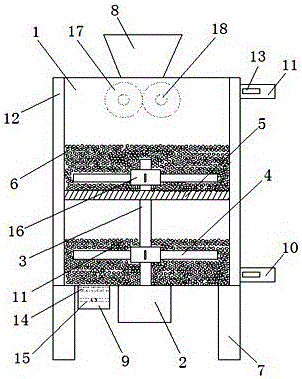

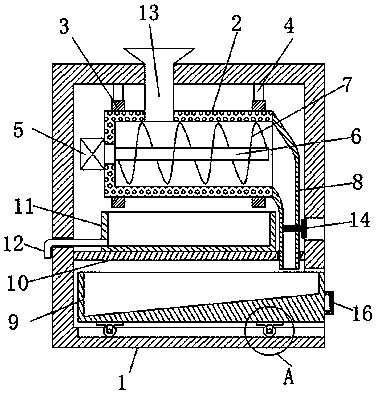

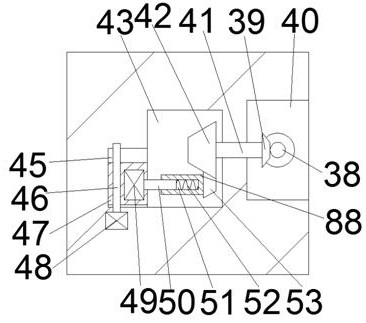

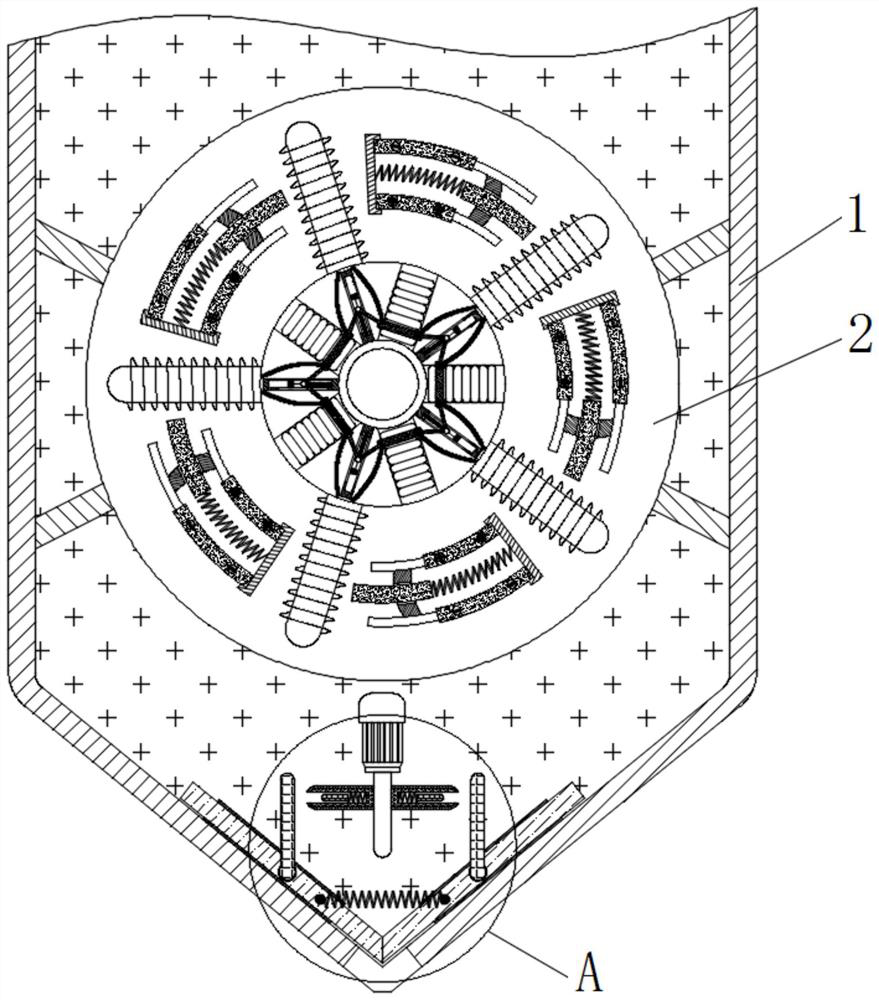

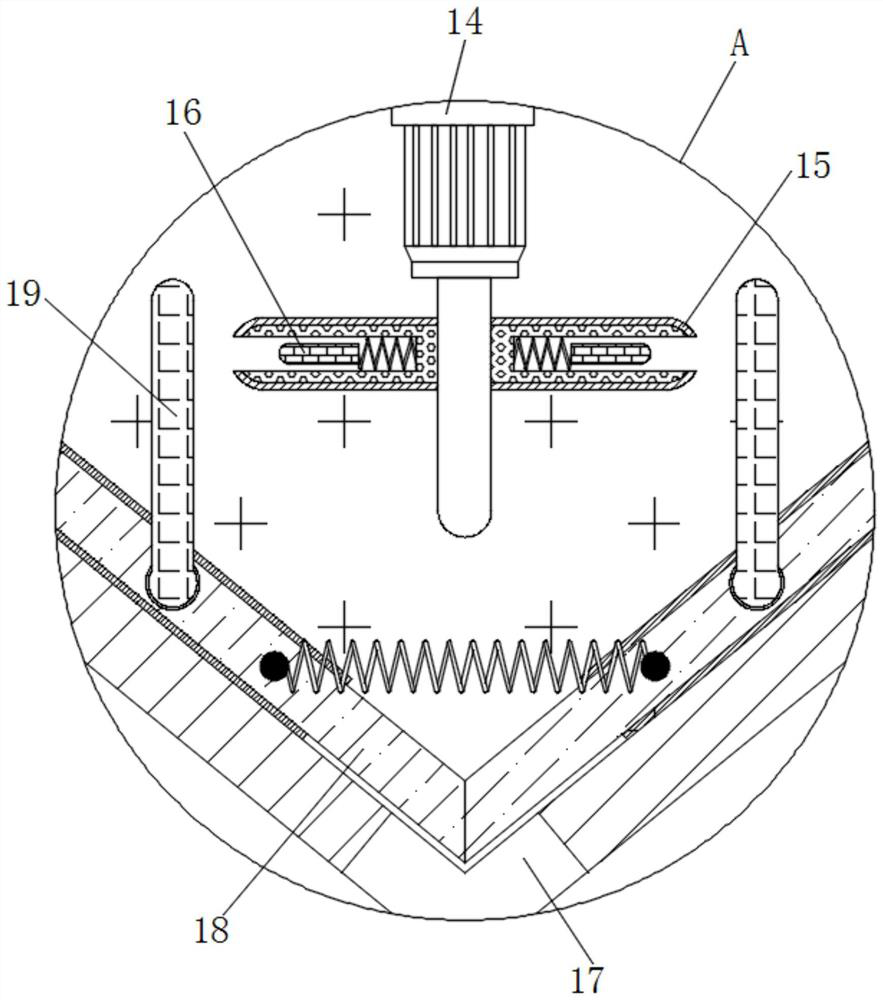

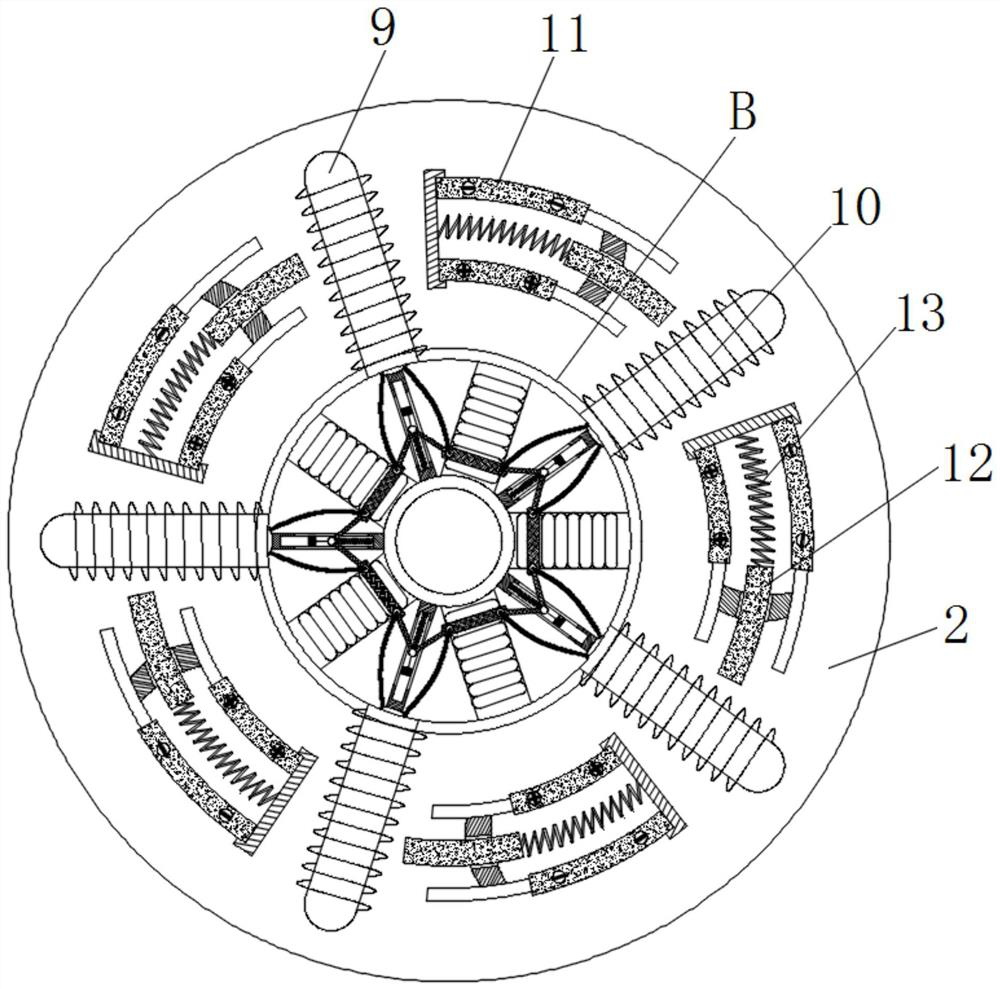

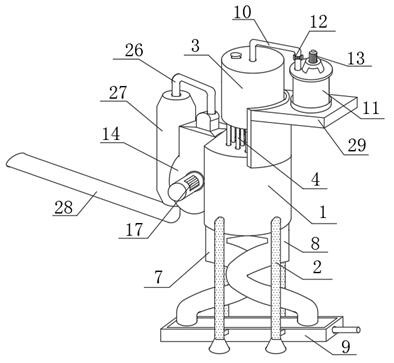

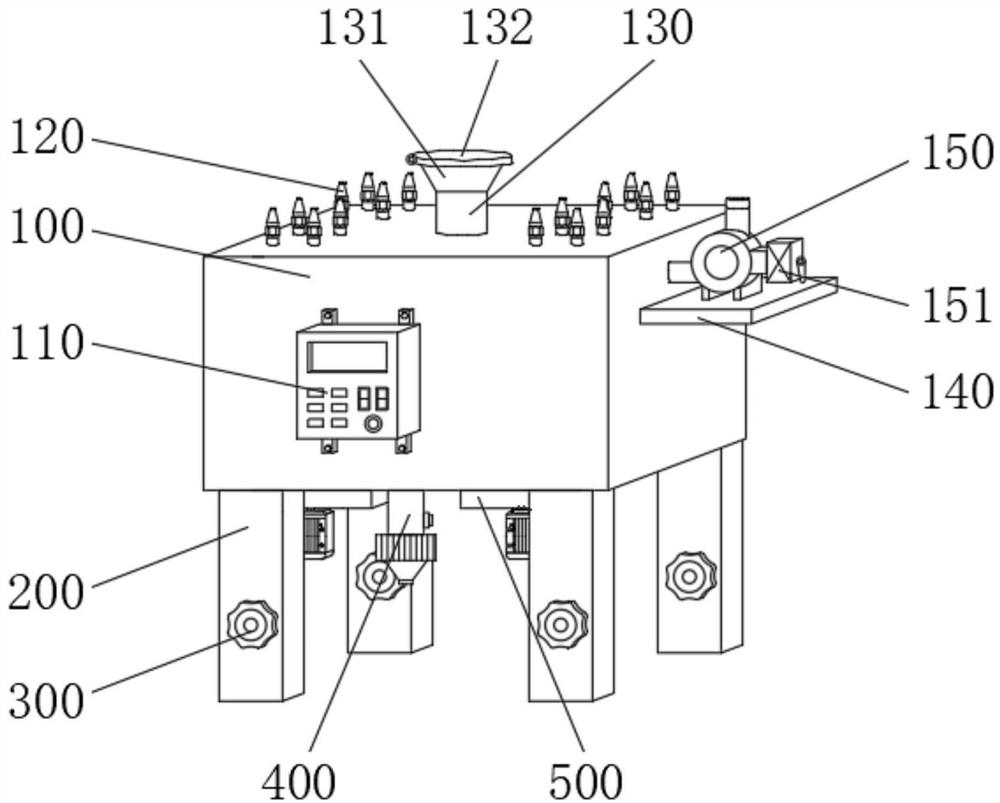

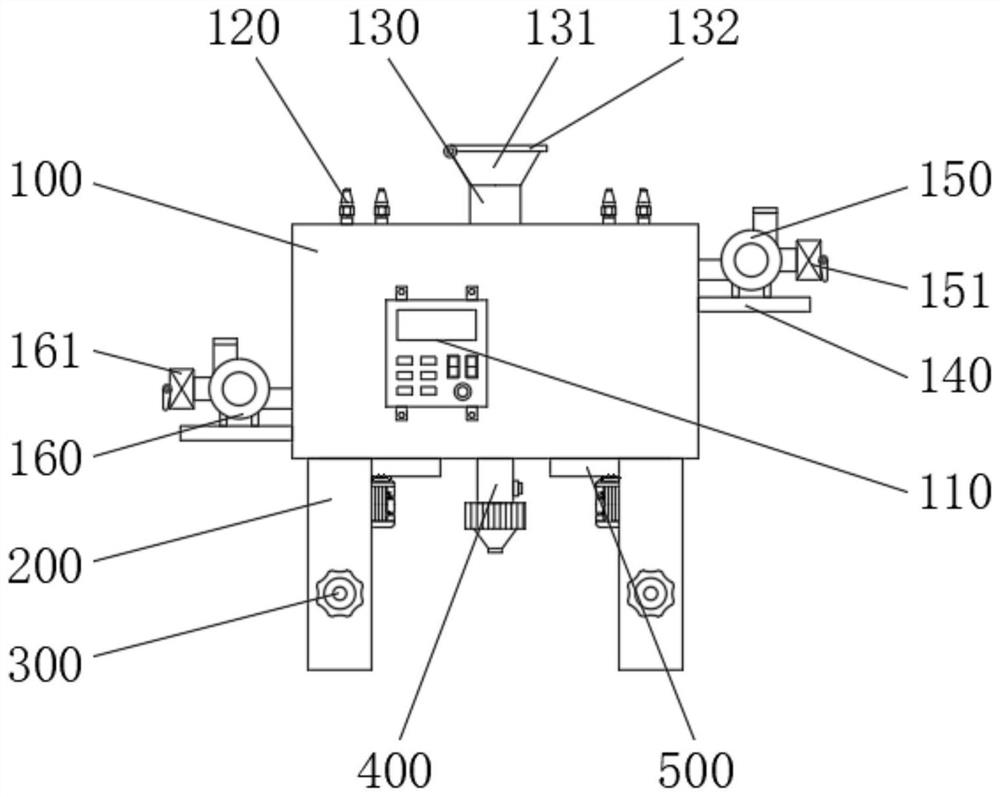

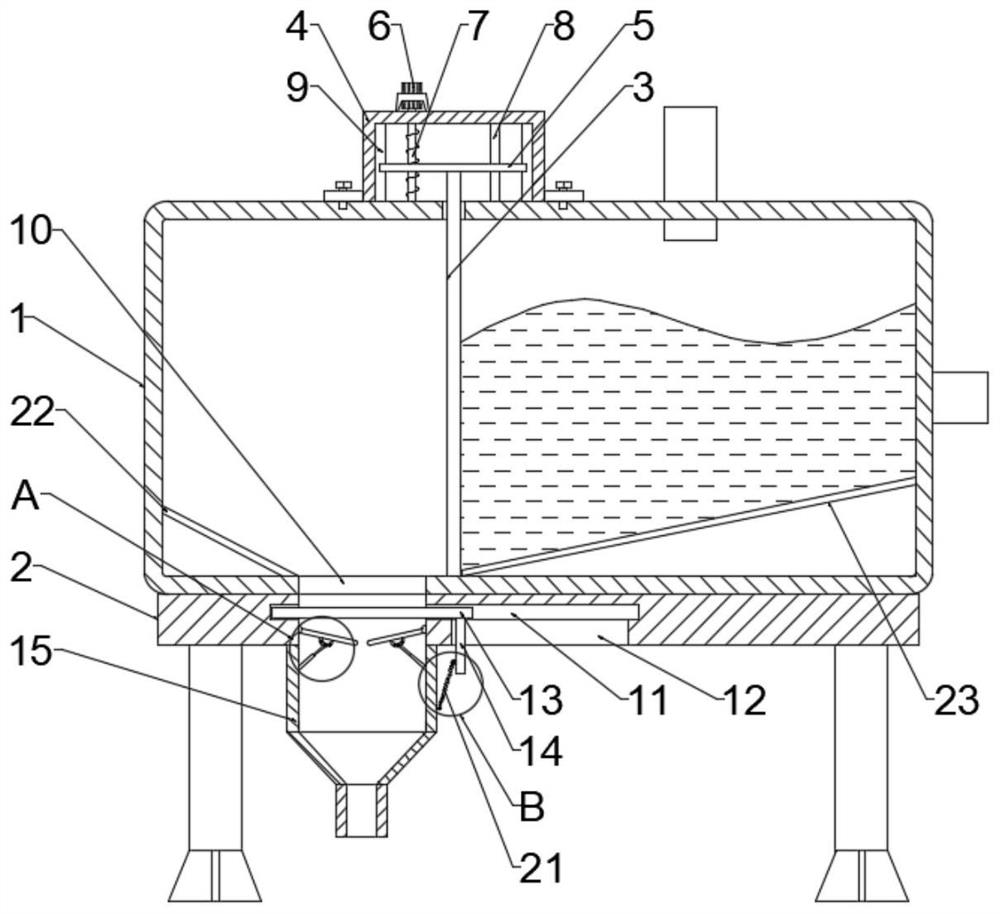

Stirring device capable of adjusting stirring degree and controlling discharging

PendingCN112657415AImprove stirring efficiencyIncrease the resistance valueRotary stirring mixersTransportation and packagingPhysicsElectric machinery

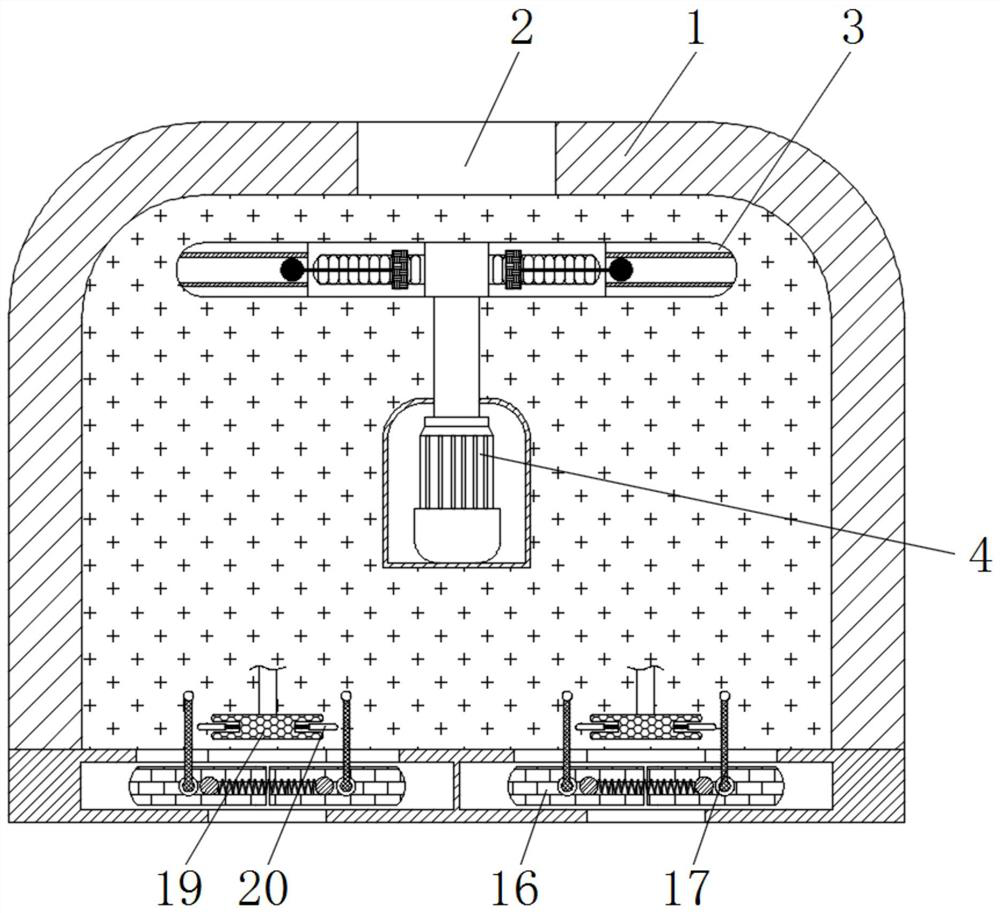

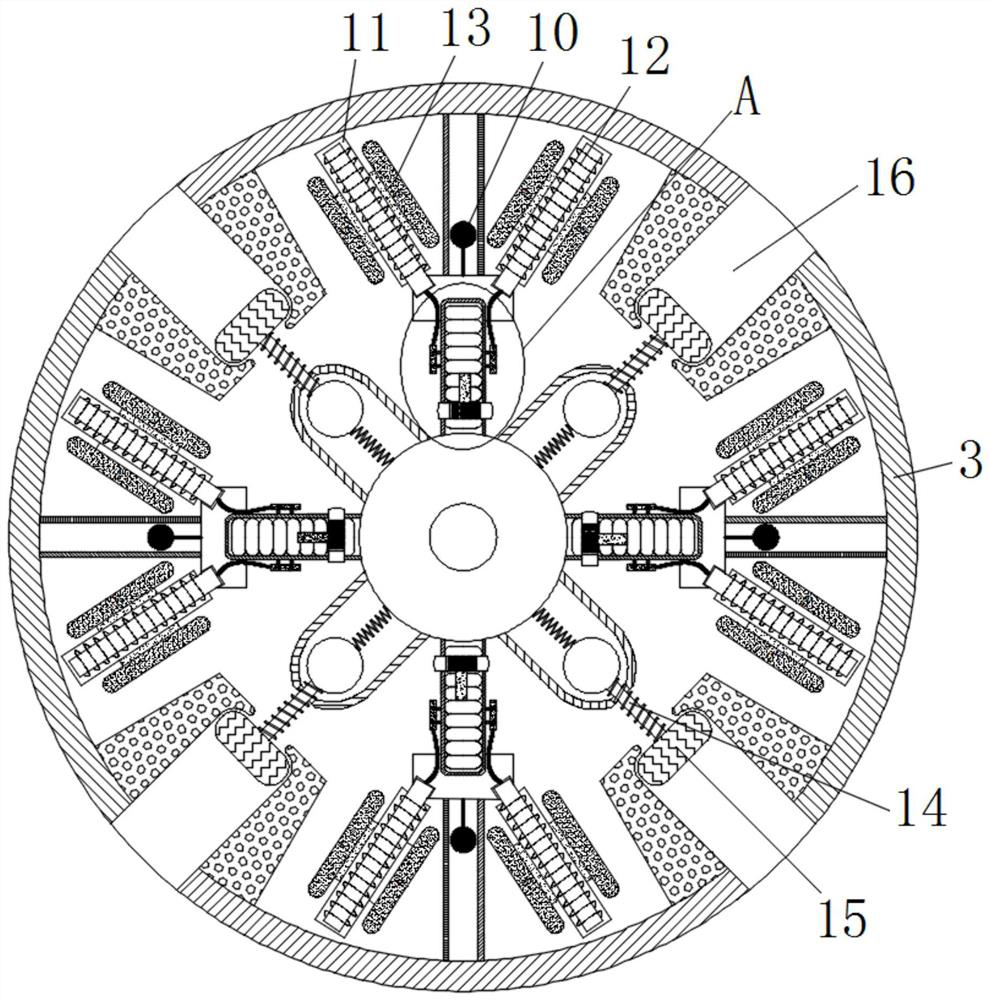

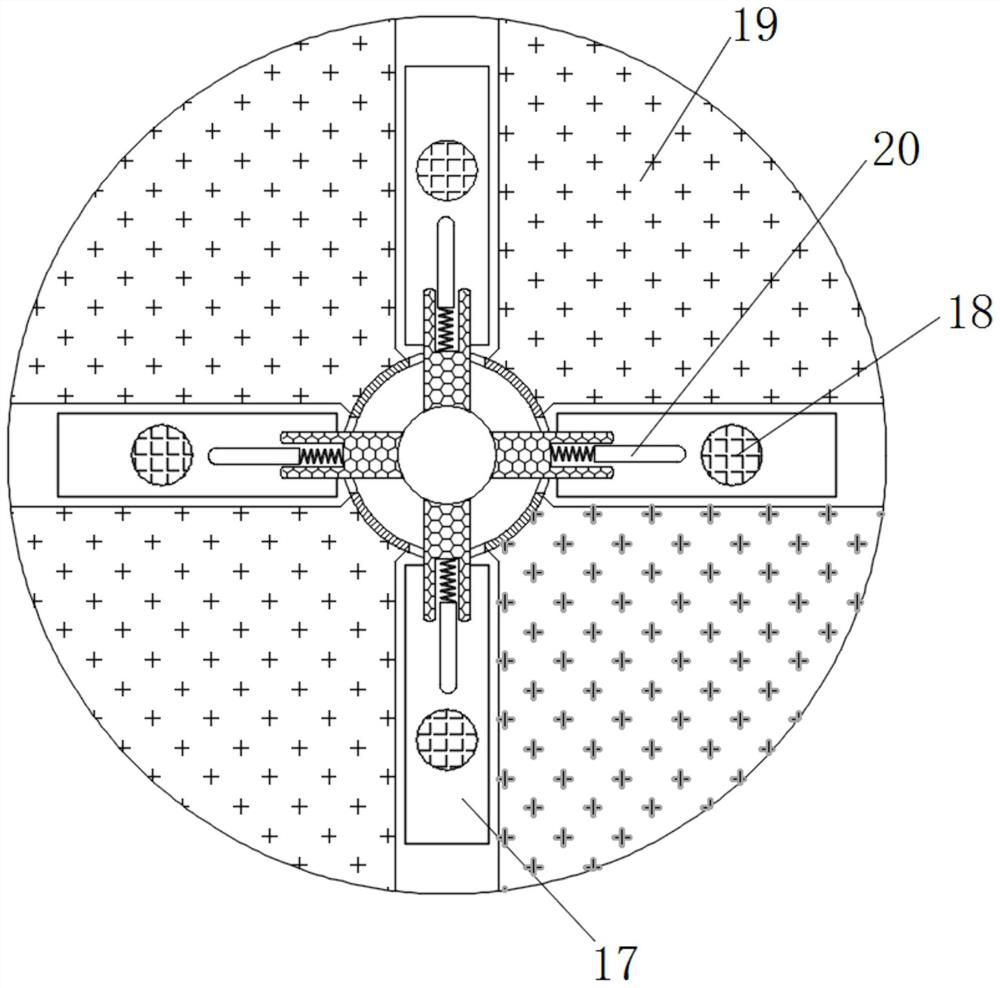

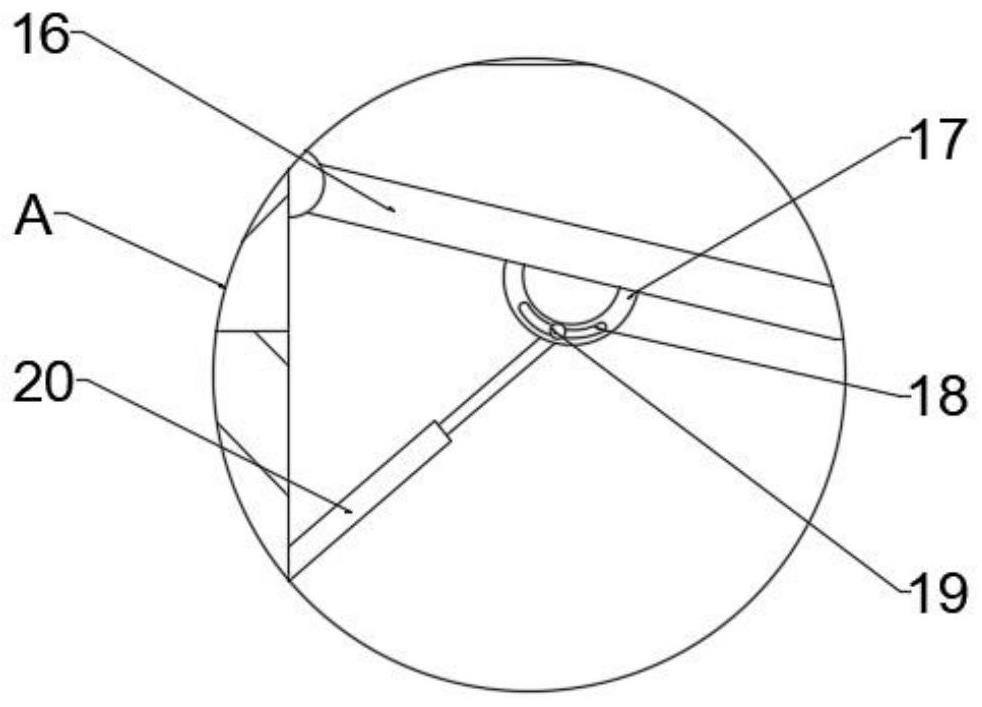

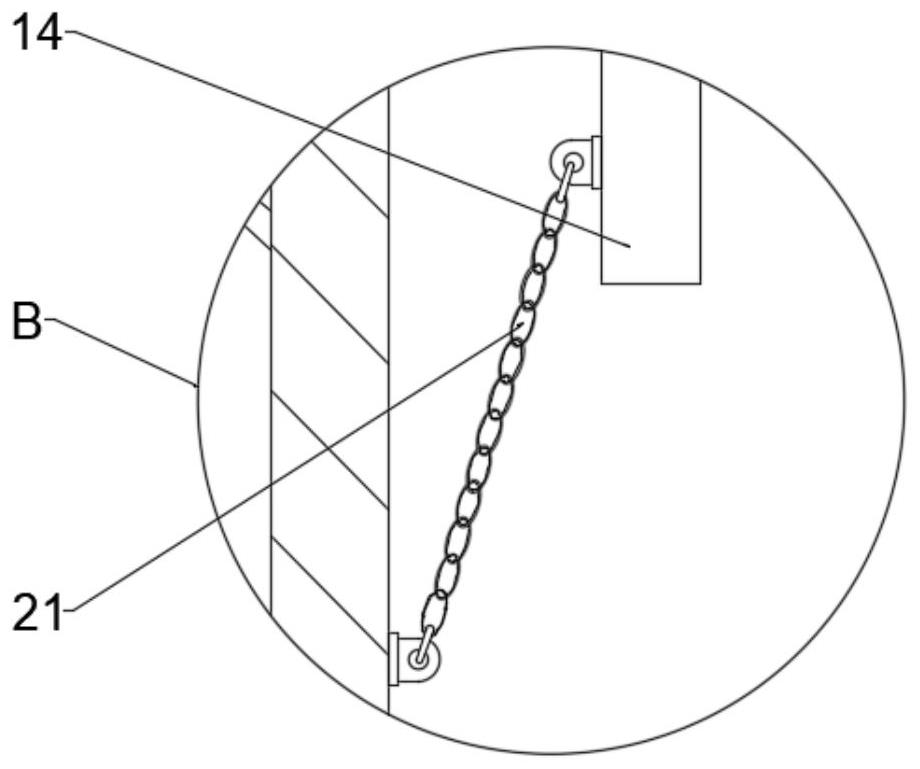

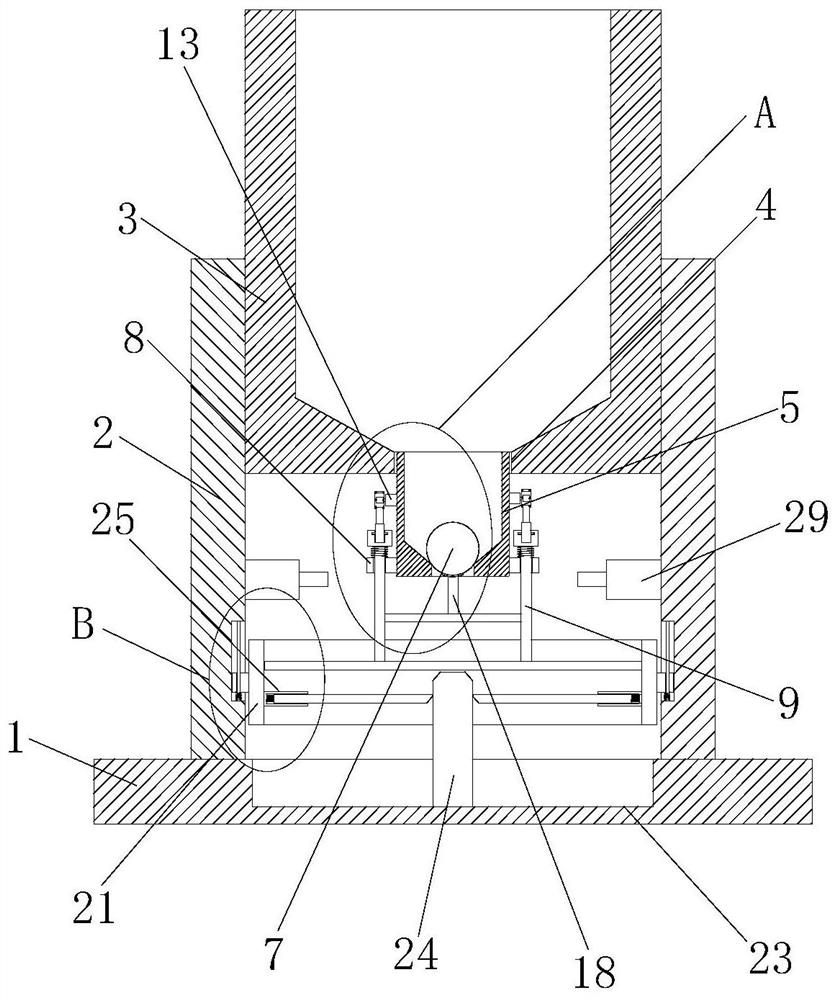

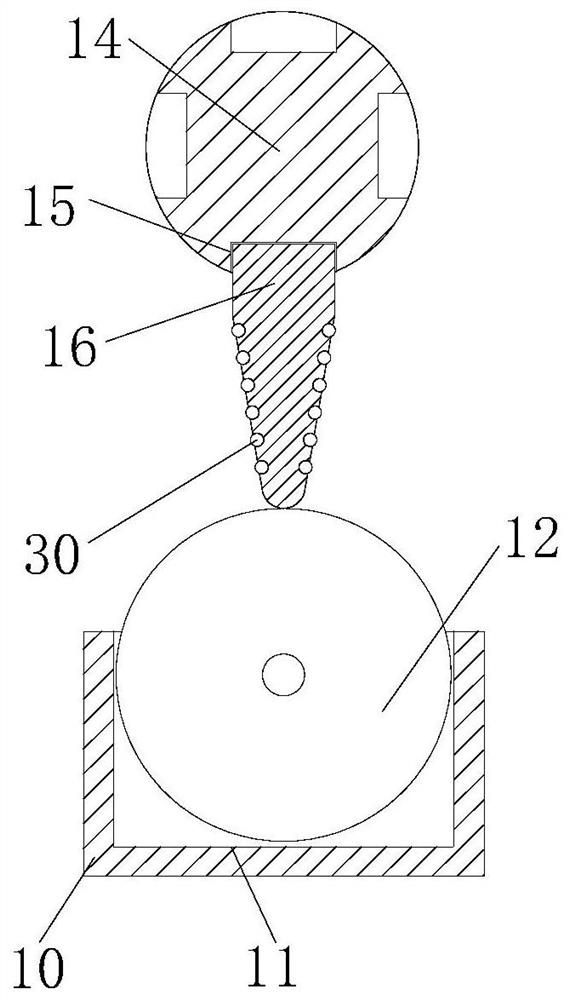

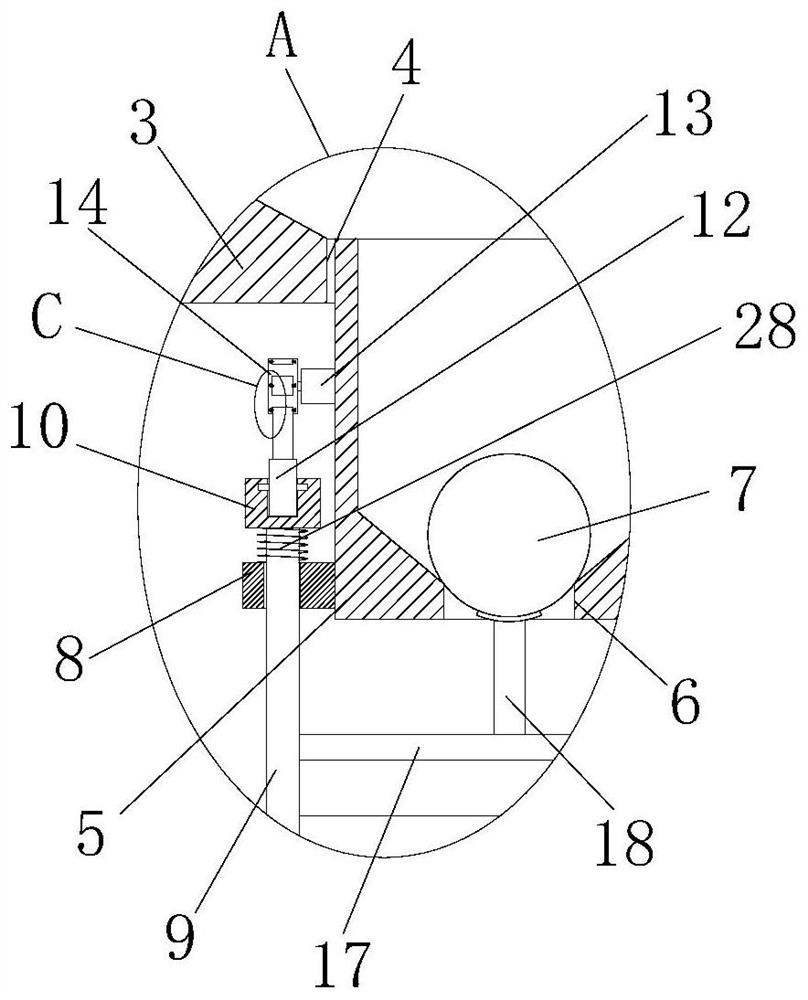

The invention relates to the technical field of chemical equipment, and discloses a stirring device capable of adjusting the stirring degree and controlling discharging. The stirring device comprises a shell, a feeding port is formed in the top end of the shell, a stirring disc is rotatably connected to the lower portion of the feeding port in the shell, and the bottom end of the stirring disc is in transmission connection with a motor; a heating groove is fixedly formed in the surface of the stirring disc, a heating resistor strip is fixedly installed in the heating groove, a contact is installed on the surface of the heating resistor strip in a sliding mode, and a dielectric substance is fixedly installed at the end, close to the edge of the stirring disc, of the contact. According to the stirring device capable of adjusting the stirring degree and controlling discharging, stirred materials guided into the shell are preheated, stirring is conducted after the preheating temperature reaches an expected value, the stirring efficiency is improved, the stirring speed can be adjusted according to the preheating effect, the stirring efficiency is improved, and the discharging speed is adjusted according to the stirring speed of current equipment; the discharging efficiency is improved; and material blockage can be prevented.

Owner:郑有东

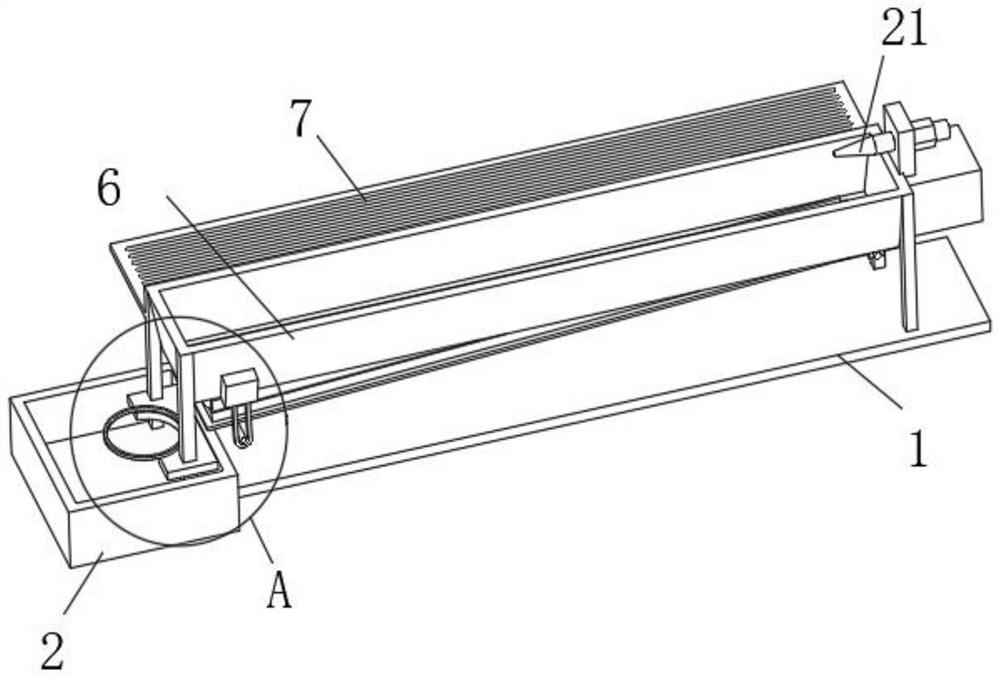

Processing device for tea leaves

ActiveCN107348037AGood for tightAchieve the effect achievedPre-extraction tea treatmentEngineeringDrive motor

The invention discloses a processing device for tea leaves and relates to the processing equipment for tea leaves. The processing device comprises a frame, a strip-tidying drum, a rolling drum, a feeding hopper, a feeding plate and a driving motor, wherein the strip-tidying drum sleeves the exterior of the rolling drum; the strip-tidying drum and the rolling drum are both rotatably connected with the frame; the rotating speed of the rolling drum is more than that of the strip-tidying drum; a plurality of vertically arranged rolling slots are formed in an outer side wall of the rolling drum; the feeding hopper is arranged above the rolling drum; the feeding plate is capable of sliding along the vertical direction of the frame; the feeding plate is arranged on the upper part of the rolling drum and is located in the rolling drum; a plurality of feeding slots which are tilted along the radial direction of the feeding plate are formed on the upper surface of the feeding plate; a plurality of wedge slots which are uniformly formed along the peripheral direction are formed on the lower surface of the feeding plate; wedge blocks which can be embedded into the wedge slots are fixed in the rolling drum; a feeding port which is connected with the rolling slots is formed in the rolling drum; the feeding port is connected with the rolling slots. The rolling slots can drive the tea leaves to rotate, the tea leaves can be rolled relative to the side wall of the strip-tidying drum and the tea leaves are rolled toward one direction, so that the tea strips are tightly rolled.

Owner:浮梁县瑶里茶叶有限公司

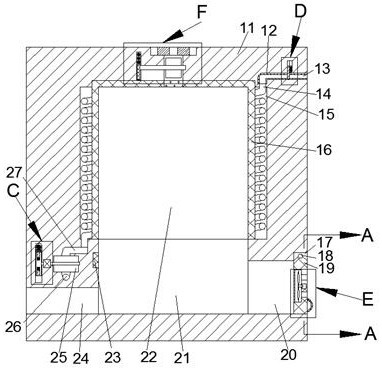

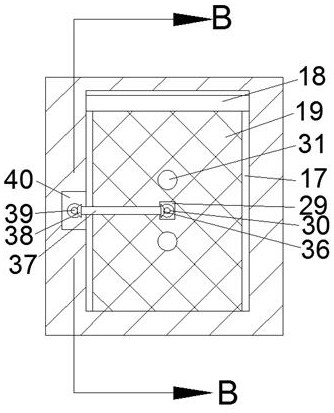

Grinding device for coating processing and operation method of grinding device

InactiveCN106362834AImprove grinding qualityQuality improvementGrain treatmentsDrive shaftElectric machinery

The invention discloses a grinding device for coating processing. The grinding device comprises a grinding barrel, a motor, a transmission shaft, a stirring rod, a filtering plate and grinding balls; the grinding device is characterized in that the grinding barrel is arranged on a support, a feeding bin, a discharging bin, a water inlet pipe and a water outlet pipe are arranged on the grinding barrel, the motor is arranged at the bottom of the grinding barrel, the transmission shaft is arranged in the grinding barrel, and one end of the transmission shaft is connected with the motor; and the stirring rod is arranged on a connecting block, the filtering plate is arranged in the grinding barrel, and the grinding balls are arranged at the bottom of the grinding barrel and the position, above the filtering plate, in the grinding barrel. According to grinding device, the filtering plate is arranged in the grinding barrel, the grinding balls are arranged at the bottom of the grinding barrel and the position, above the filtering plate, in the grinding barrel, and therefore a coating raw material can be repeatedly ground, and the coating grinding quality is improved; and an interlayer is arranged on the grinding barrel, cooling water is injected into the interlayer, coating in the grinding process can be cooled, and the coating quality is further improved.

Owner:芜湖瑞德机械科技有限公司

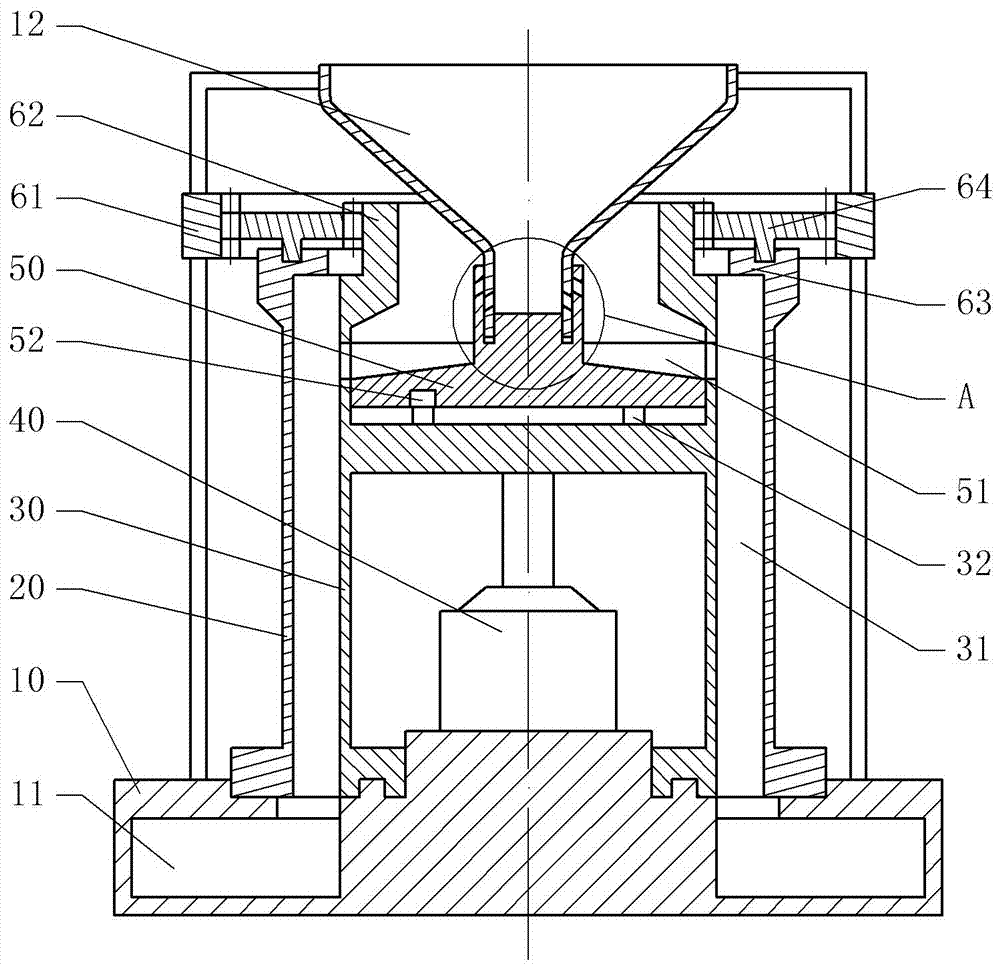

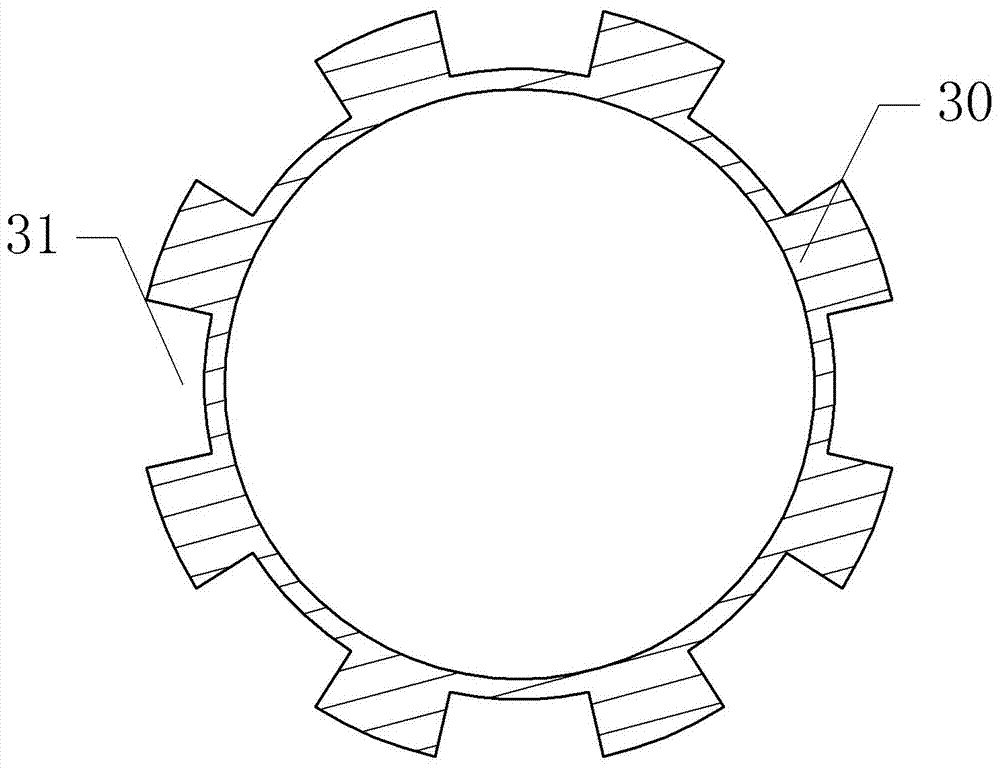

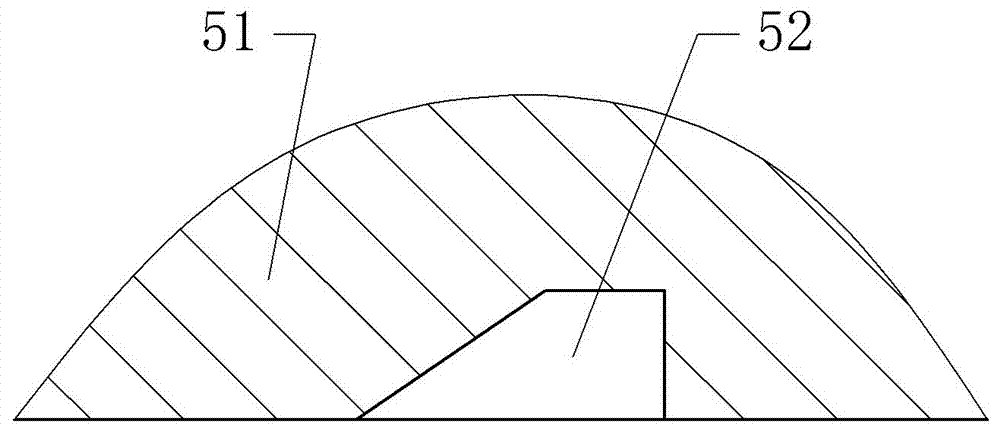

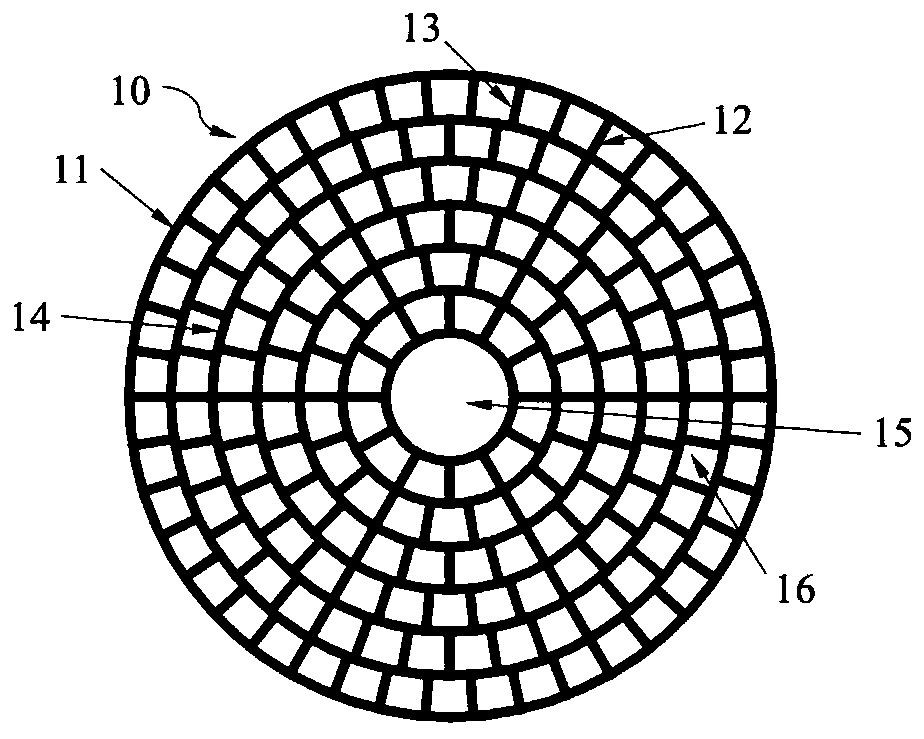

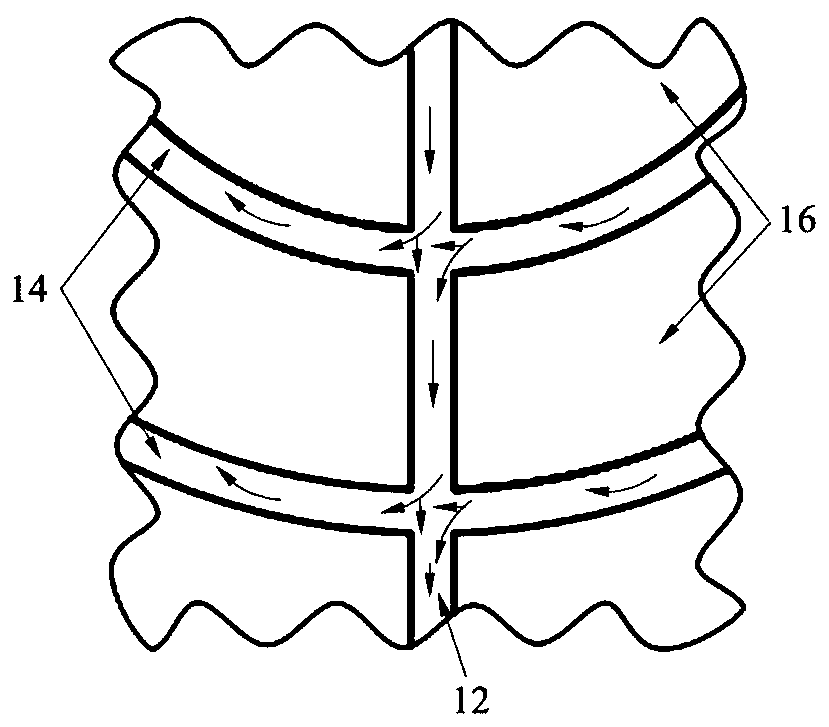

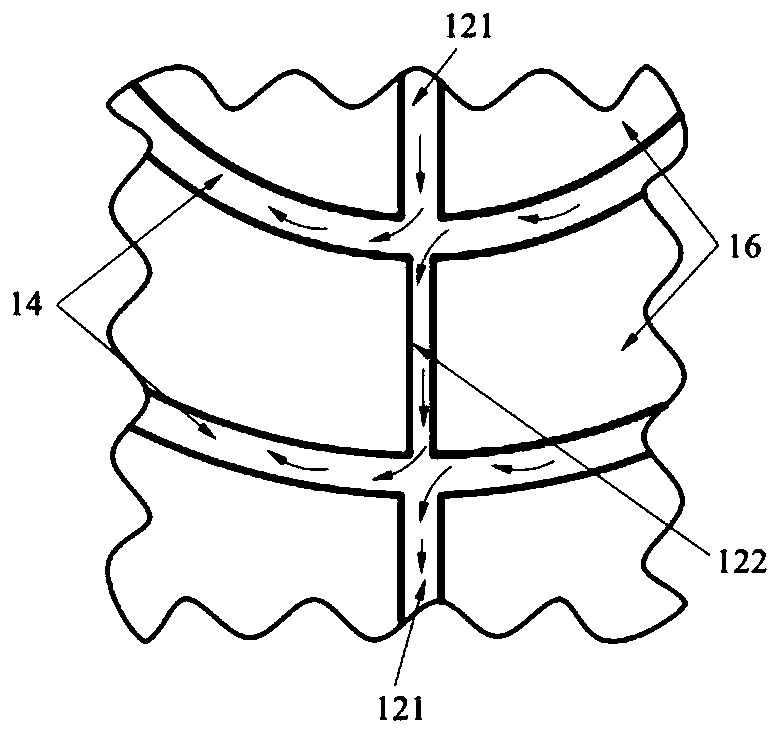

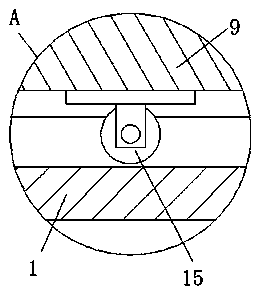

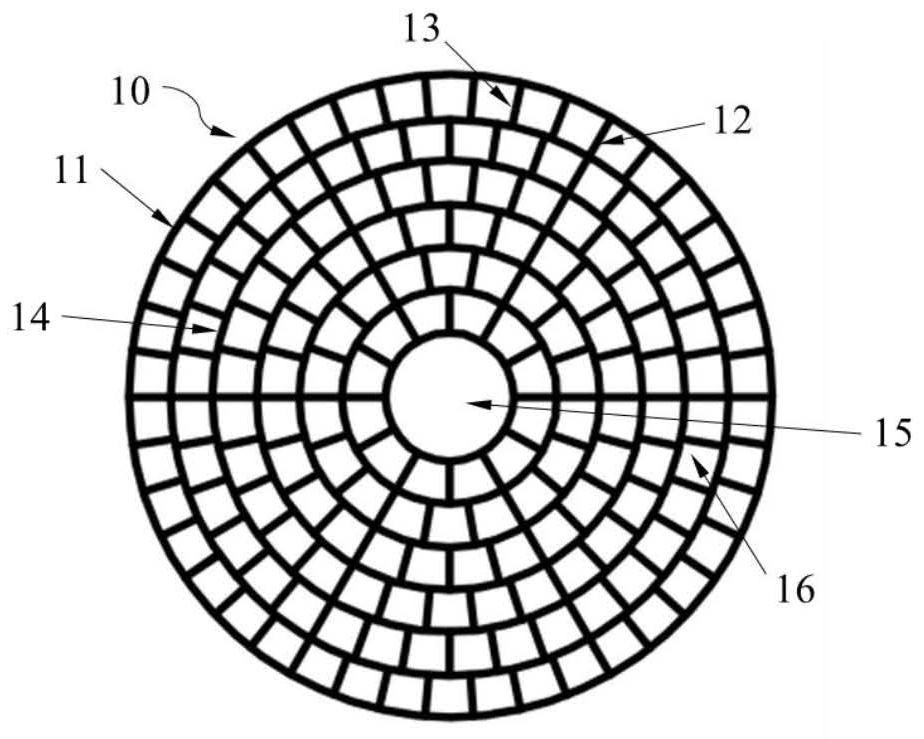

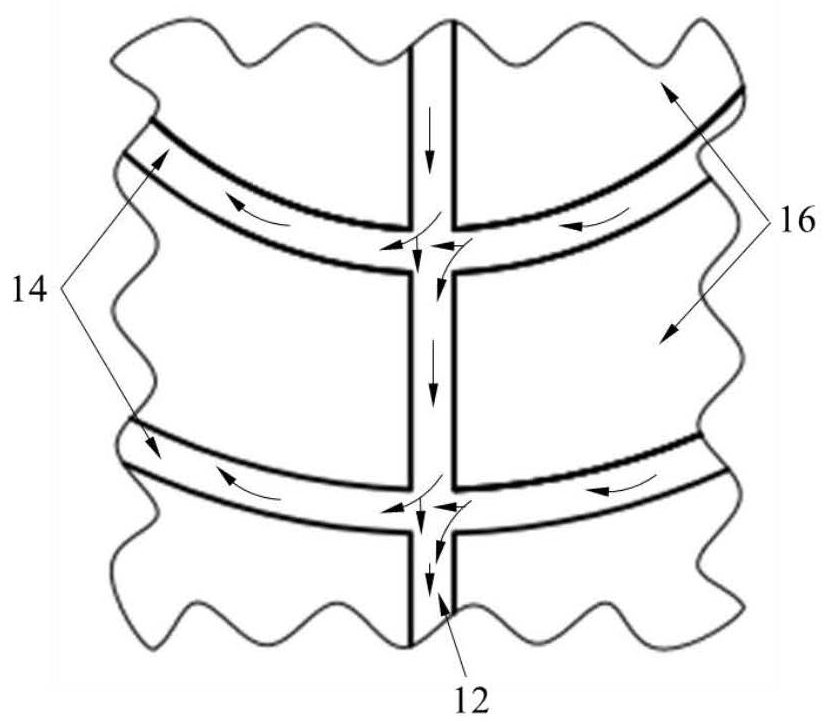

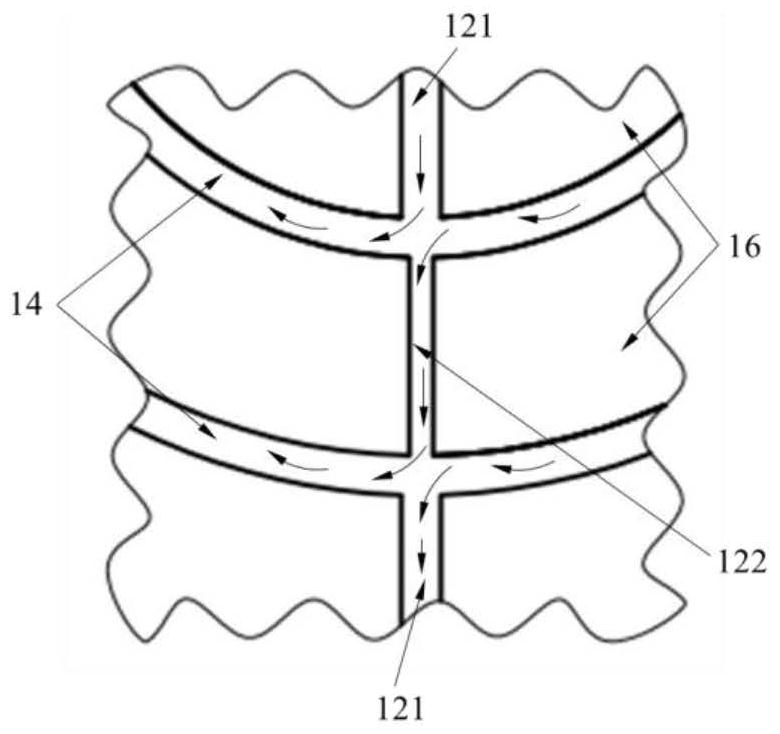

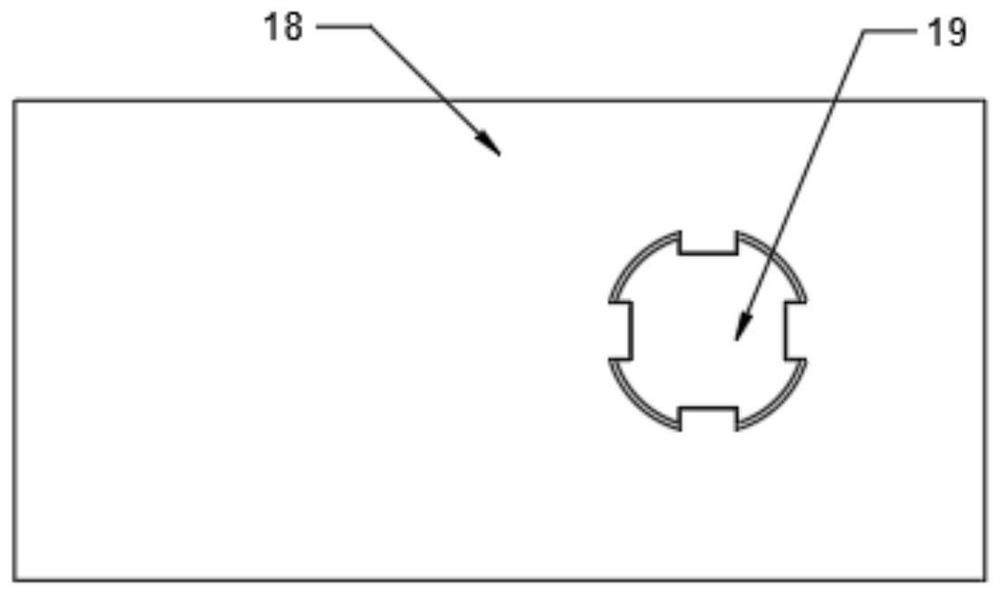

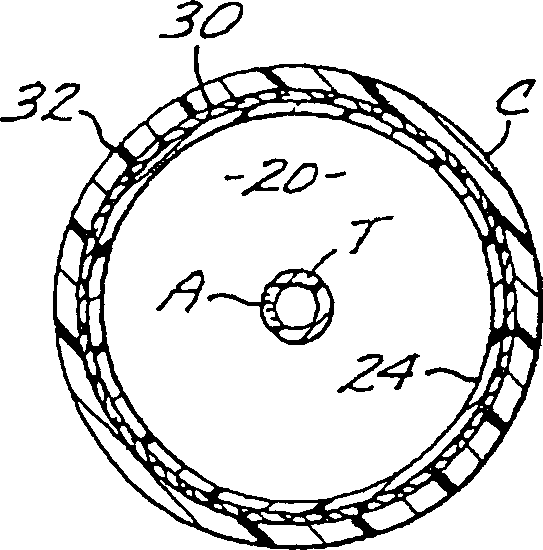

Polishing pad and chemical-mechanical polishing equipment

ActiveCN110802508AConsiderable storage capacityLarge storage capacityLapping toolsGrinding/polishing apparatusPolishingEngineering

The invention provides a polishing pad and chemical-mechanical polishing equipment, and belongs to the technical field of semiconductors. The polishing pad comprises a substrate layer and a polishinglayer located on the substrate layer, wherein the polishing layer comprises a plurality of concentric circumferential trenches formed in the circumferential direction and a plurality of radial trenches which are formed in the radial direction and communicate with the adjacent trenches in the circumferential direction. By means of the polishing pad and the chemical-mechanical polishing equipment, the utilization rate of polishing liquid can be increased, the service life of the polishing pad can be prolonged, and the polishing quality can be improved.

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

Environmental protection equipment for sludge treatment

The invention discloses environmental protection equipment for sludge treatment. The equipment includes a tank; a transversely arranged filter cartridge is arranged in the tank; lifting rings fixedlysleeve the two ends of the side wall of the filter cartridge; the upper ends of the two lifting rings are fixedly connected with the upper side wall of the tank through fixing rods; a driving motor isfixedly connected to the left end outside the filter cartridge; the output end of the driving motor is rotationally connected with a rotating rod through a coupler; the end, away from the driving motor, of the rotating rod penetrates through the side wall of the filter cartridge and is rotationally connected with the filter cartridge through a rolling bearing; the rod wall of the rotating rod isfurther fixedly connected with spiral blades; an opening is formed in the side, away from the driving motor, of the filter cartridge; a sludge pipe is fixedly connected to the opening; and a sludge box is movably arranged below the interior of the tank. According to the environmental protection equipment, solid-liquid separation can be effectively carried out on sludge, so that filtered water andsludge can be respectively treated, secondary pollution of the sludge to the environment is avoided, and the environmental protection equipment is convenient for people to use.

Owner:江都区武坚兴业机械厂

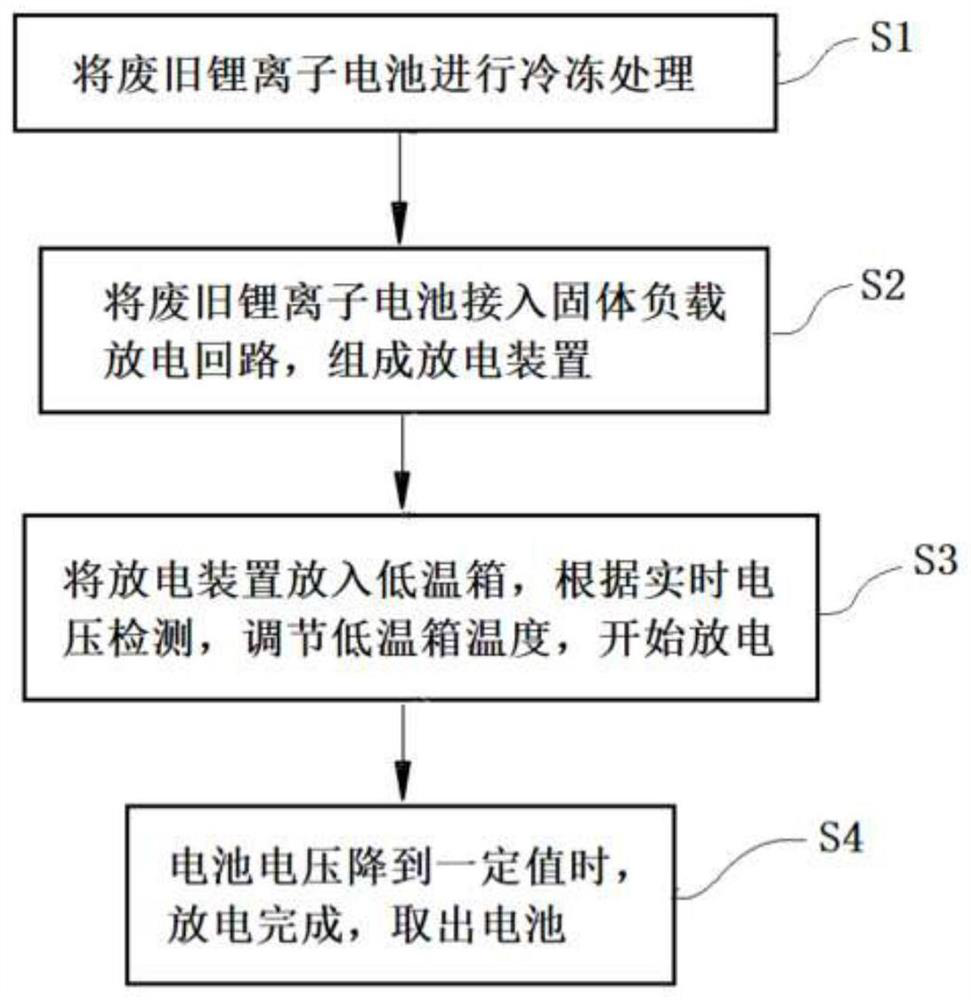

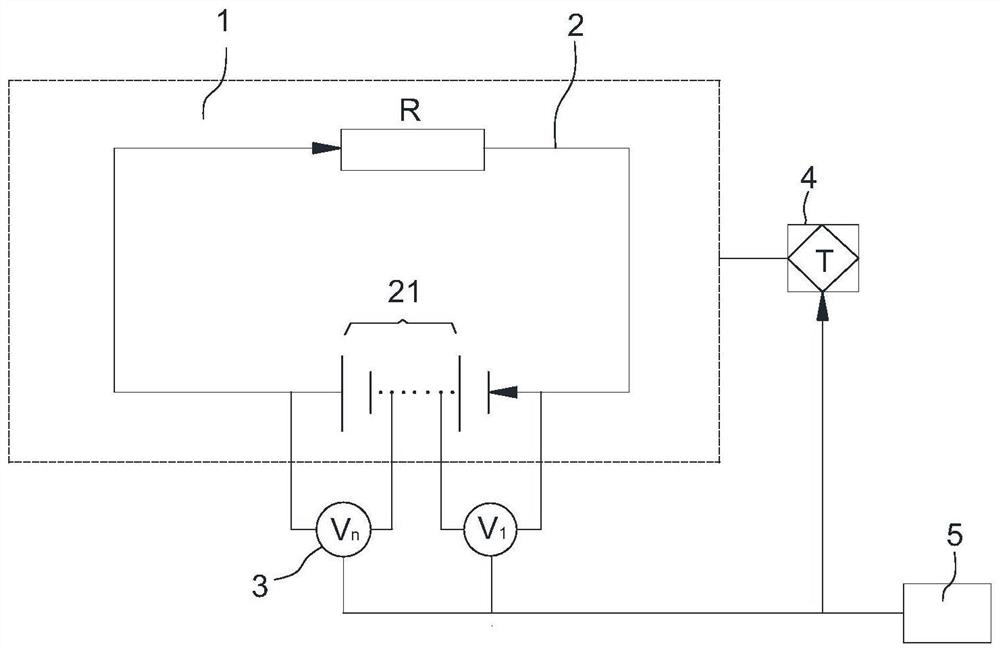

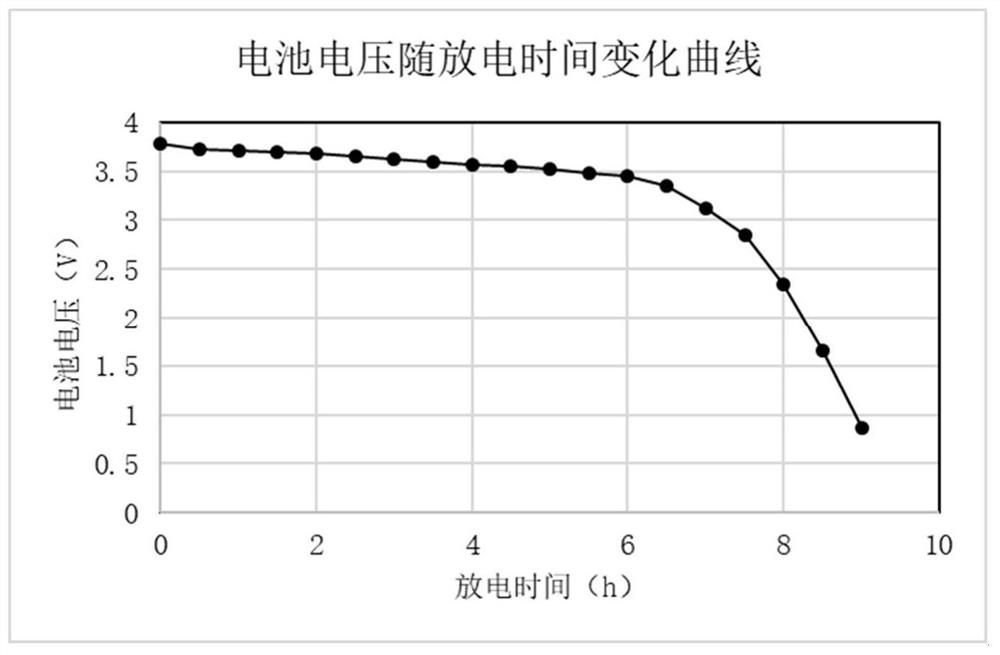

Safe discharging method for waste lithium ion battery

ActiveCN113161639ADischarge safetyEfficient dischargeSecondary cells charging/dischargingWaste accumulators reclaimingProcess engineeringEnvironmental engineering

The invention provides a safe discharging method for a waste lithium ion battery, which comprises the following steps of: freezing a waste lithium ion battery to temporarily inactivate the battery; connecting the frozen battery to a solid load discharging loop to form a discharging device; putting the discharging device into a low-temperature box, carrying out real-time voltage detection on the waste lithium ion battery to be discharged, adjusting the temperature of the low-temperature box according to the detected voltage value, controlling the discharging rate of the battery, and starting discharging; and when the voltage of the battery drops below a set value, stopping discharging, taking the battery out, and entering a subsequent procedure. The waste lithium ion battery connected with the discharging loop is put into the low-temperature box, the temperature during discharge is adjusted in a segmented manner according to the voltage monitored in real time, the discharge rate at the initial stage of discharge can be reduced, the safety during discharge is ensured, the discharge degree is judged through a battery voltage detection controller, the discharge rate at the later stage of discharge is improved, and safe and efficient discharging of the waste lithium ion battery is realized.

Owner:SHENZHEN QINGYAN EQUIP TECH CO LTD

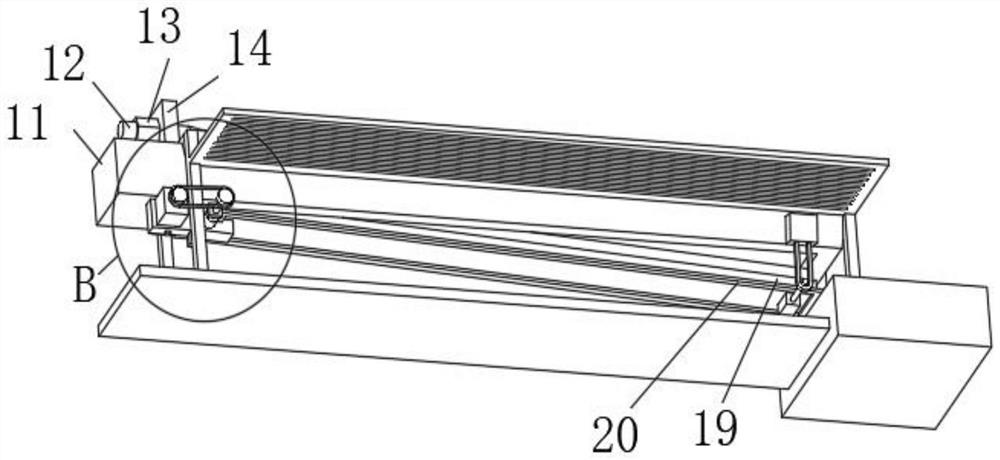

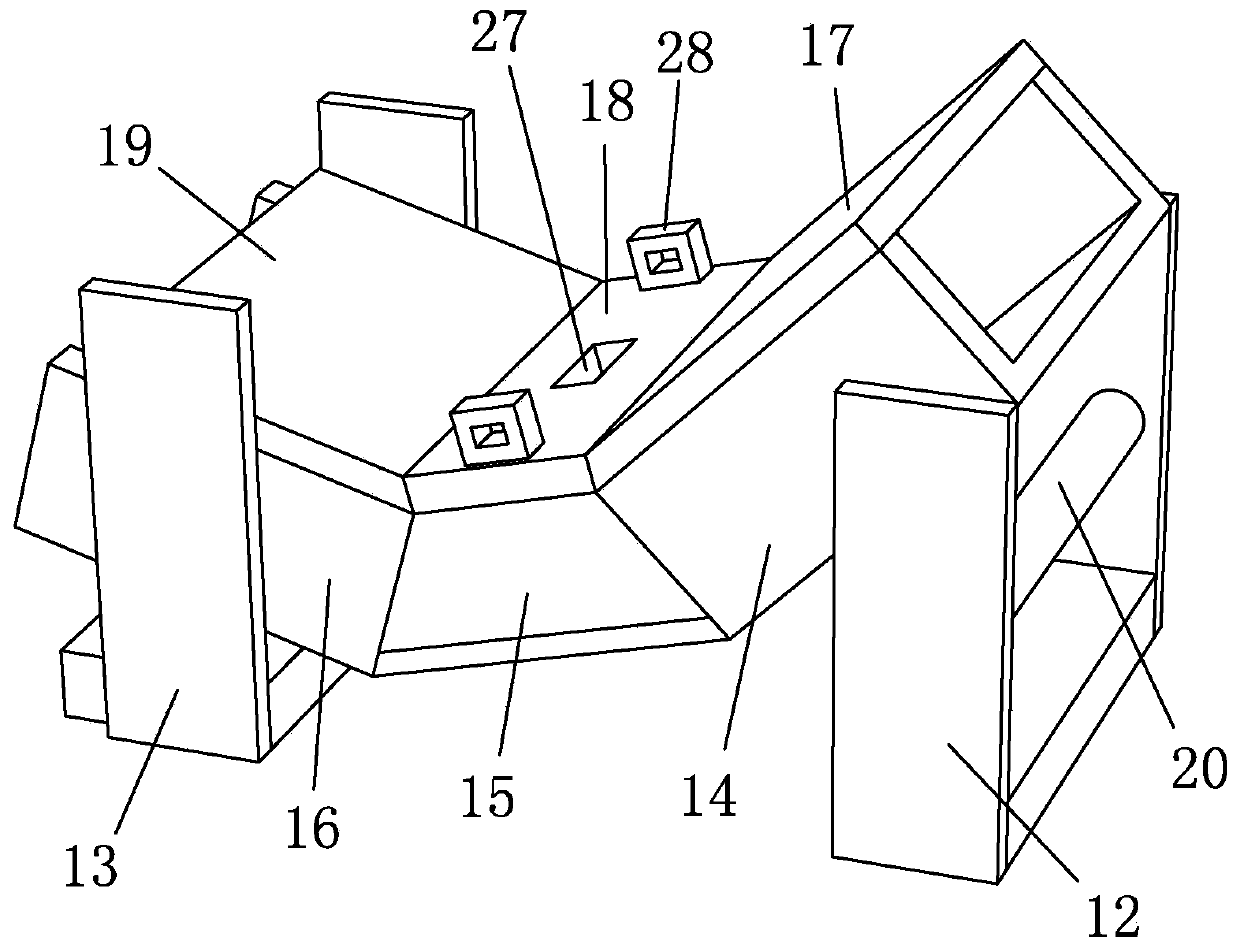

Logistics loading and unloading operation equipment based on intelligent rail transportation device

ActiveCN113636271ALimit positionChange the angle of rotationConveyorsLoading/unloadingLogistics managementBraced frame

The invention discloses logistics loading and unloading operation equipment based on an intelligent rail transportation device, and relates to the technical field of logistics loading and unloading operation, in particular to the logistics loading and unloading operation equipment based on the intelligent rail transportation device, the logistics loading and unloading operation equipment comprises a fixed supporting frame, a rack mounted on the fixed supporting frame and classifying and shifting mechanisms mounted at the two ends of the rack, a conveying belt is arranged on the rack, and two L-shaped fixing plates are mounted on the sides, away from the rack, of the classifying and shifting mechanisms. According to the logistics loading and unloading operation equipment, the classifying and shifting mechanisms are arranged, a lead screw motor can push a lead screw guide column to reciprocate in a fixed groove frame through a transverse adjusting lead screw, a limiting rod on the lead screw guide column can be inserted into a limiting notch, the lead screw guide column can move in the central axis direction of the limiting notch through the limiting rod, a shifting rod can be pushed to rotate along the outer part of a fixed pin rod, so that the pushing force can be applied to transported products until the product is pushed to a roller column, and the logistics loading and unloading operation equipment can be used for dispersing the products.

Owner:成都工贸职业技术学院

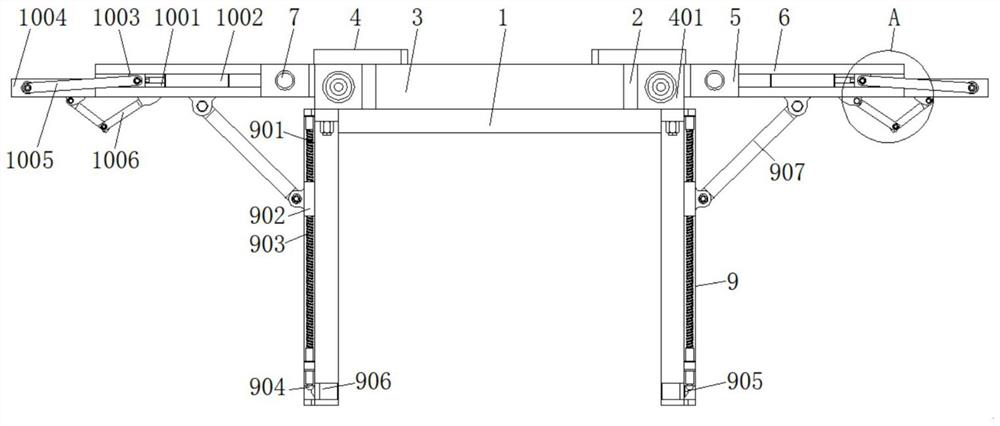

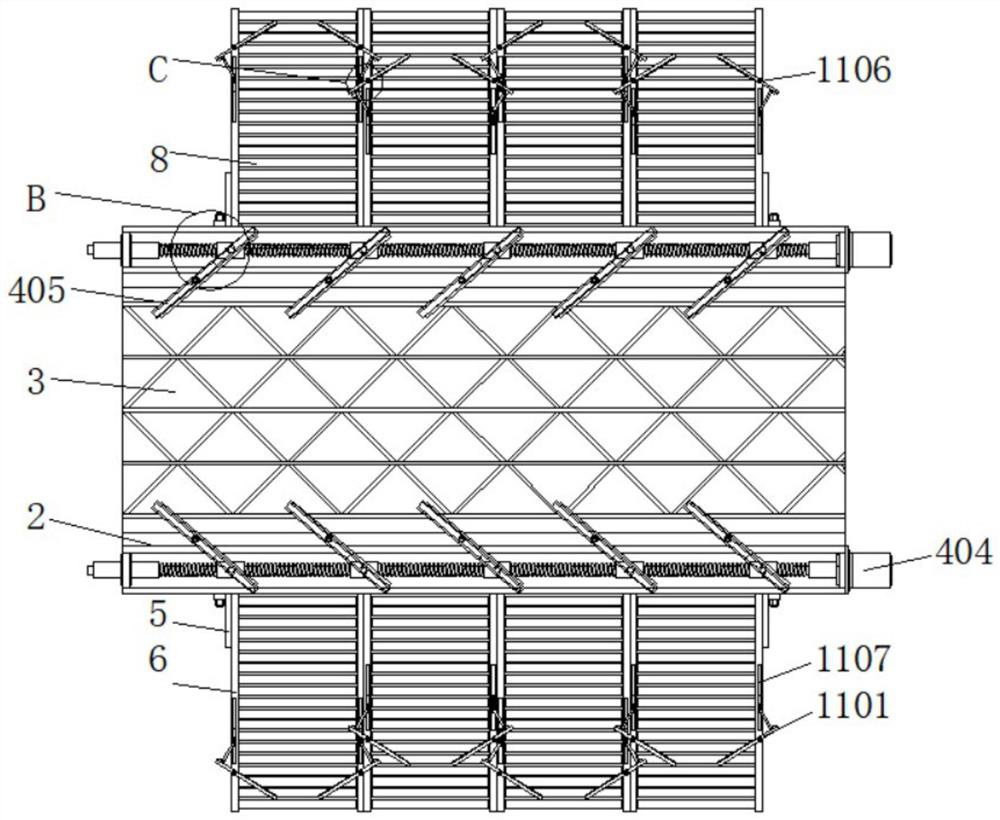

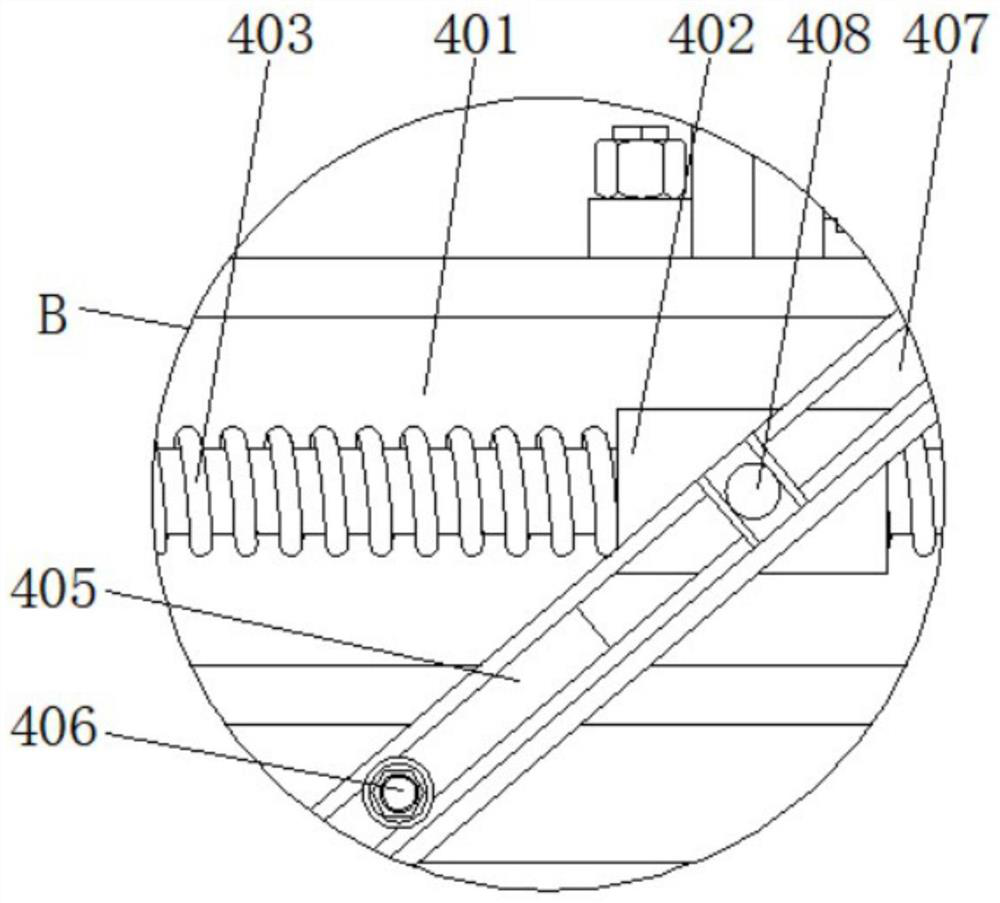

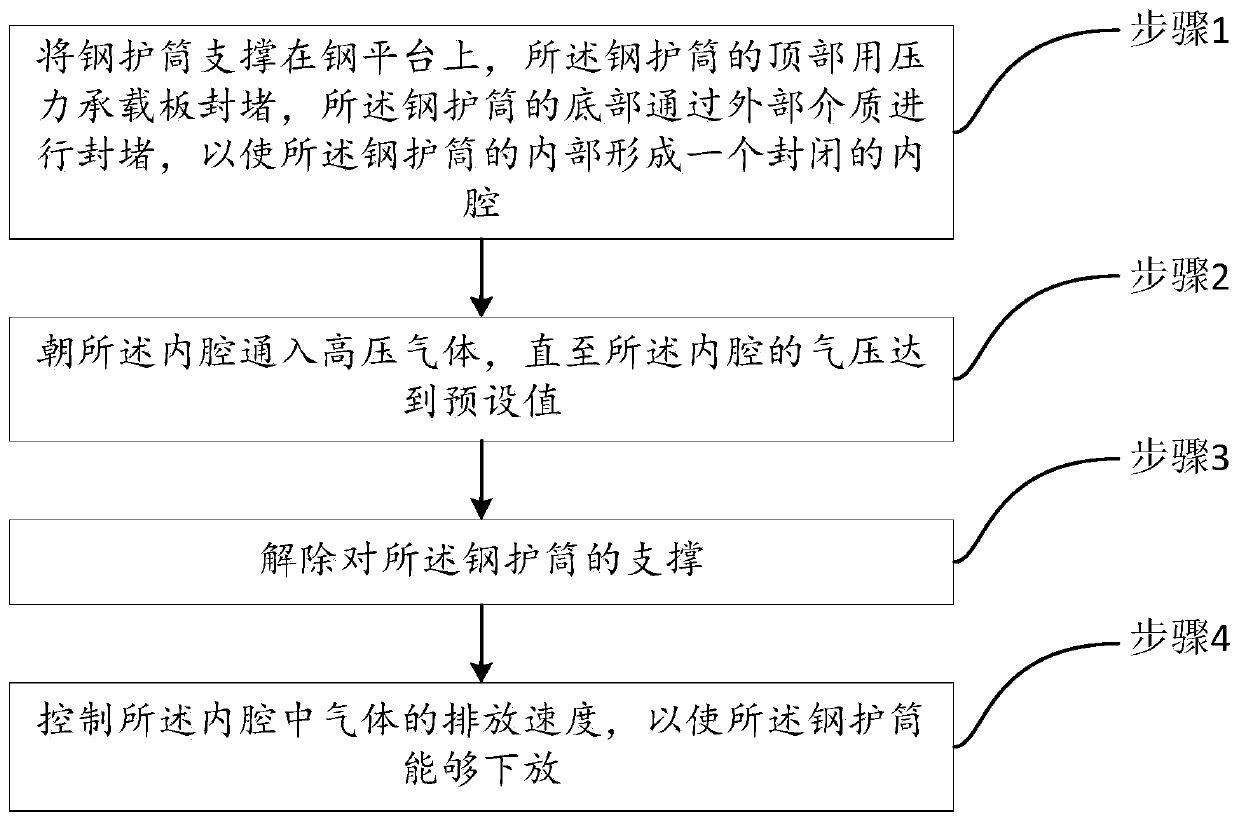

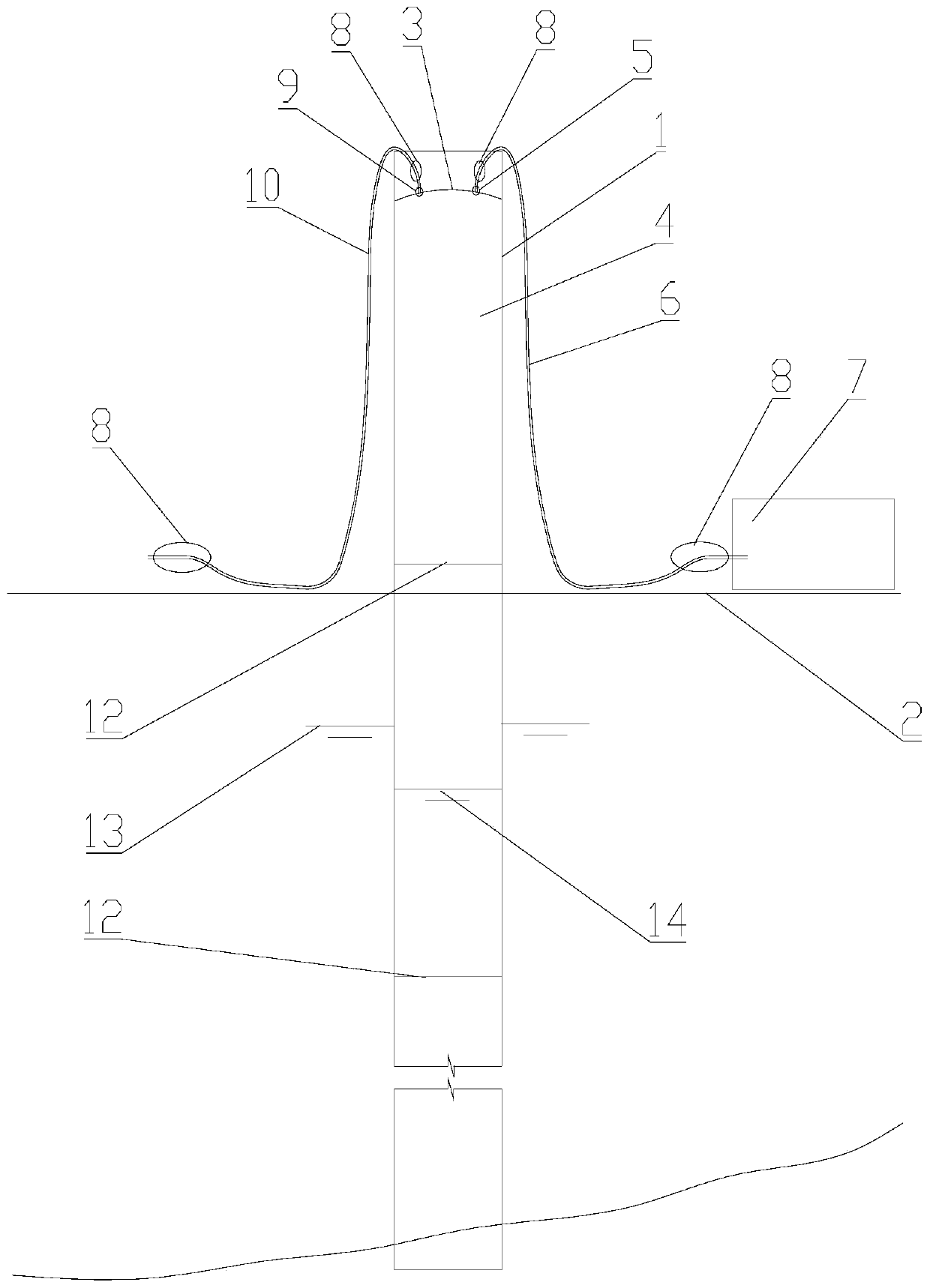

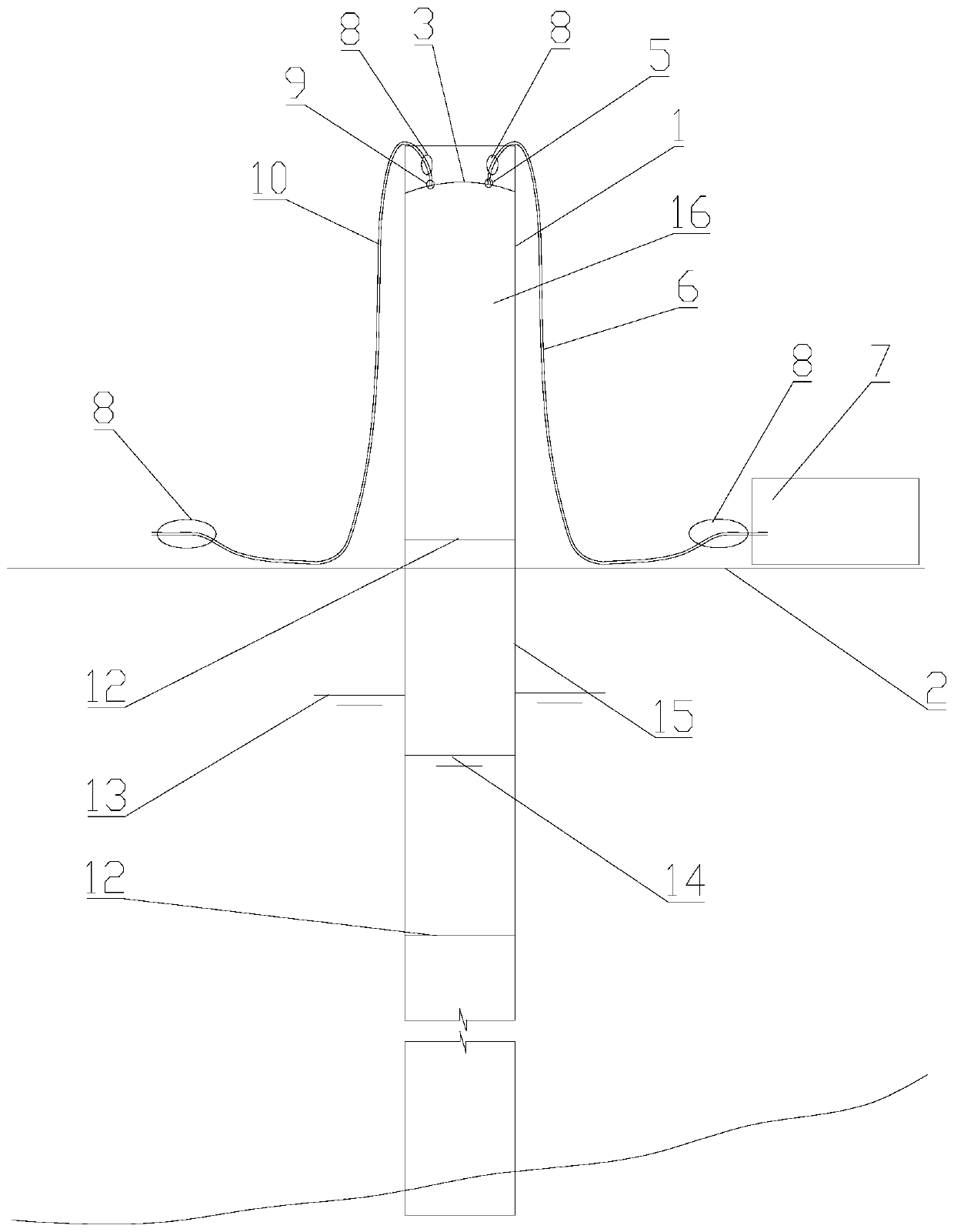

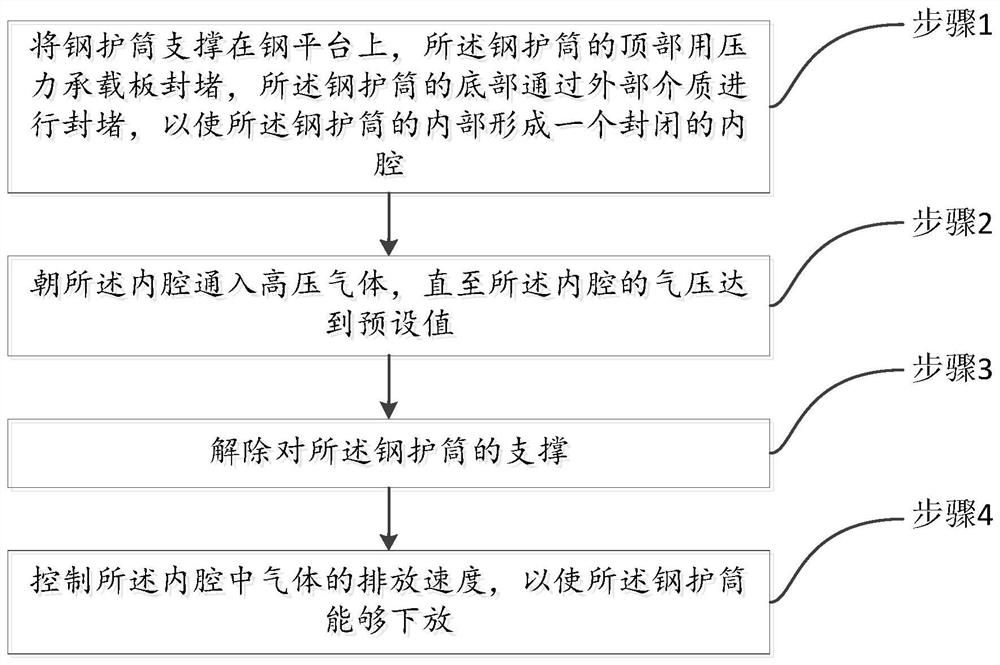

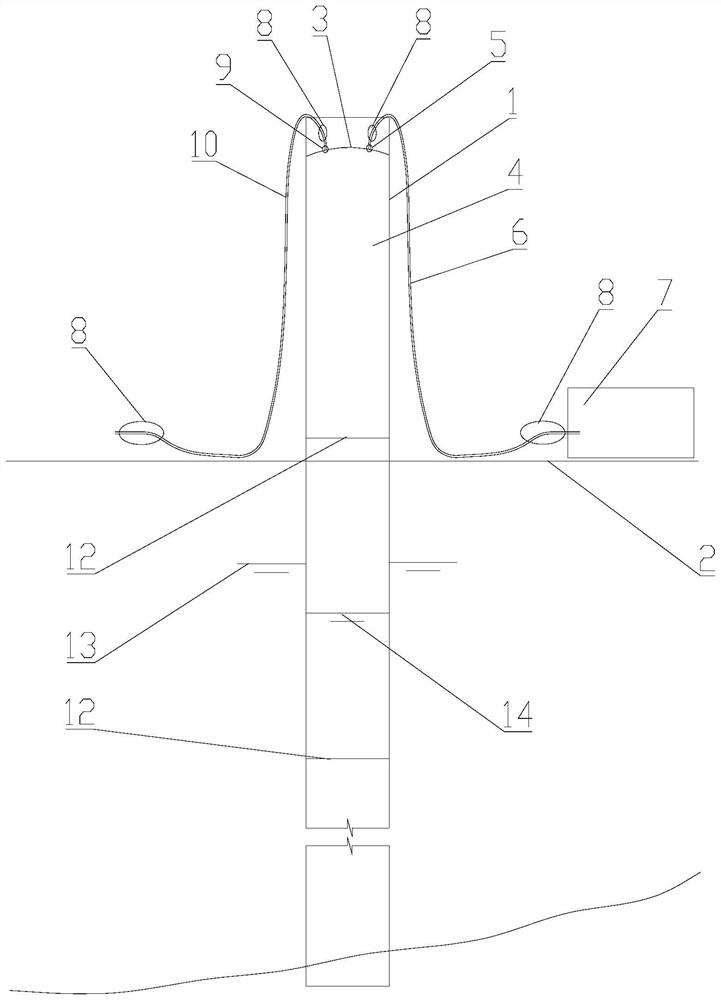

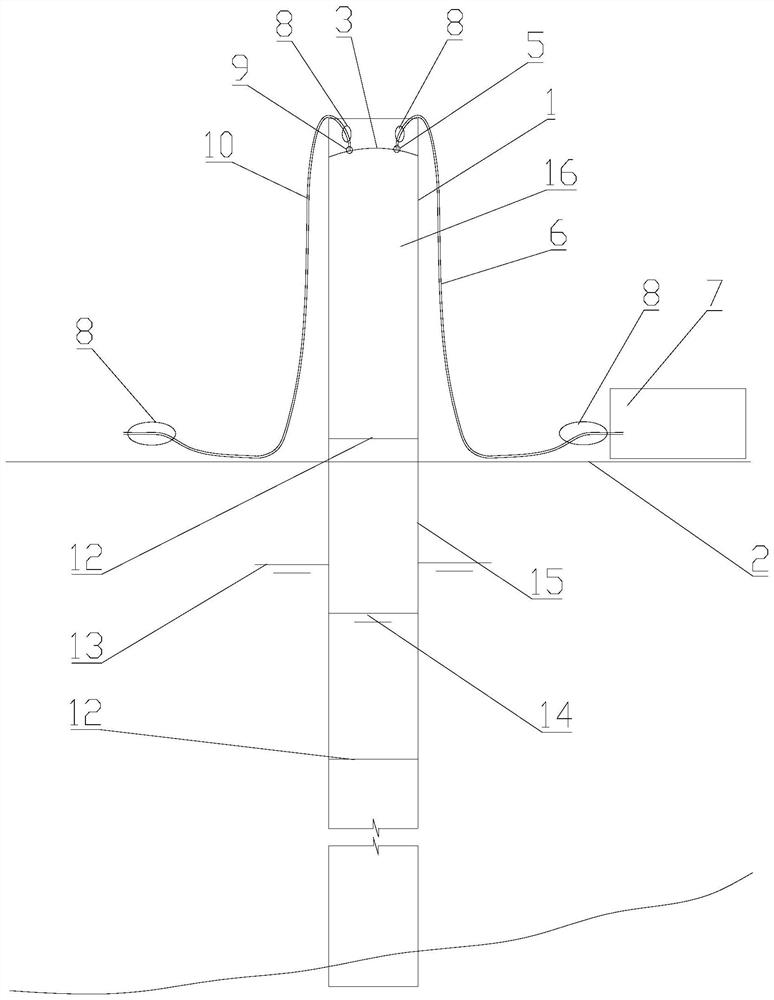

Lowering method of steel protection casing

ActiveCN110616711AControl discharge rateIncreased lifting capacityBulkheads/pilesMaterials scienceAtmospheric pressure

The invention provides a lowering method of a steel protection casing, and relates to the hoisting technology field of the steel protection casing. The lowering method of the steel protection casing includes: step 1, supporting the steel protection casing on a steel platform, using a pressure bearing plate for blocking the top of the steel protection casing, blocking the bottom of the steel protection casing through an external medium so as to form a sealed inner cavity in the steel protection casing; step 2, inflating the inner cavity until air pressure Pi of the inner cavity reaches a presetvalue; step 3, relieving support for the steel protection casing; and step 4, controlling discharge speed of gas in the inner cavity so as to lower the steel protection casing. The lowering method ofthe steel protection casing forms the sealed inner cavity in the steel protection casing by sealing two ends of the steel protection casing, and then inflates the inner cavity until the air pressurePi reaches the preset value, and meanwhile the pressure bearing plate at the top of the steel protection casing is subject to upward pressure, and the pressure can counteract a part or all of the gravity of the steel protection casing, thereby improving hoisting capacity of a hoisting device.

Owner:CCFEB CIVIL ENG

Efficient industrial boiler pre-combustion chamber

InactiveCN112555805AImprove work efficiencyControl recyclingSolid fuel combustionCasings/liningsCombustion chamberExhaust gas emissions

The invention discloses an efficient industrial boiler pre-combustion chamber which comprises a pre-combustion chamber body. A pre-combustion cavity is formed in the pre-combustion chamber body, the upper side of the pre-combustion cavity communicates with a heat removal cavity, heat exchange plates made of heat transfer materials are fixedly arranged on the inner wall and the upper wall of the heat removal cavity, an annular water-cooling heat exchange cavity is formed in the outer side of the heat removal cavity, and a spiral water-colling pipeline is arranged in the water-cooling heat exchange cavity. The rotating speed of a water pump is controlled and reduced at the initial stage of ignition of the pre-combustion chamber through temperature detection, so that the flowing of cooling water in the water-cooling pipeline is further slowed down, the heat exchange in the pre-combustion chamber is reduced, and the combustion efficiency of fuel is improved; and then, through temperature detection, when the temperature rises, flowing of cooling water is accelerated, heat energy recovery is improved, meanwhile, the area of a waste gas exhaust port is controlled through the exhaust amount of waste gas, the effect of controlling the exhaust rate of the waste gas is achieved, the heat exchange efficiency in the pre-combustion chamber is further improved, and the overall working efficiency of the pre-combustion chamber is improved.

Owner:上海窍妙科技有限公司

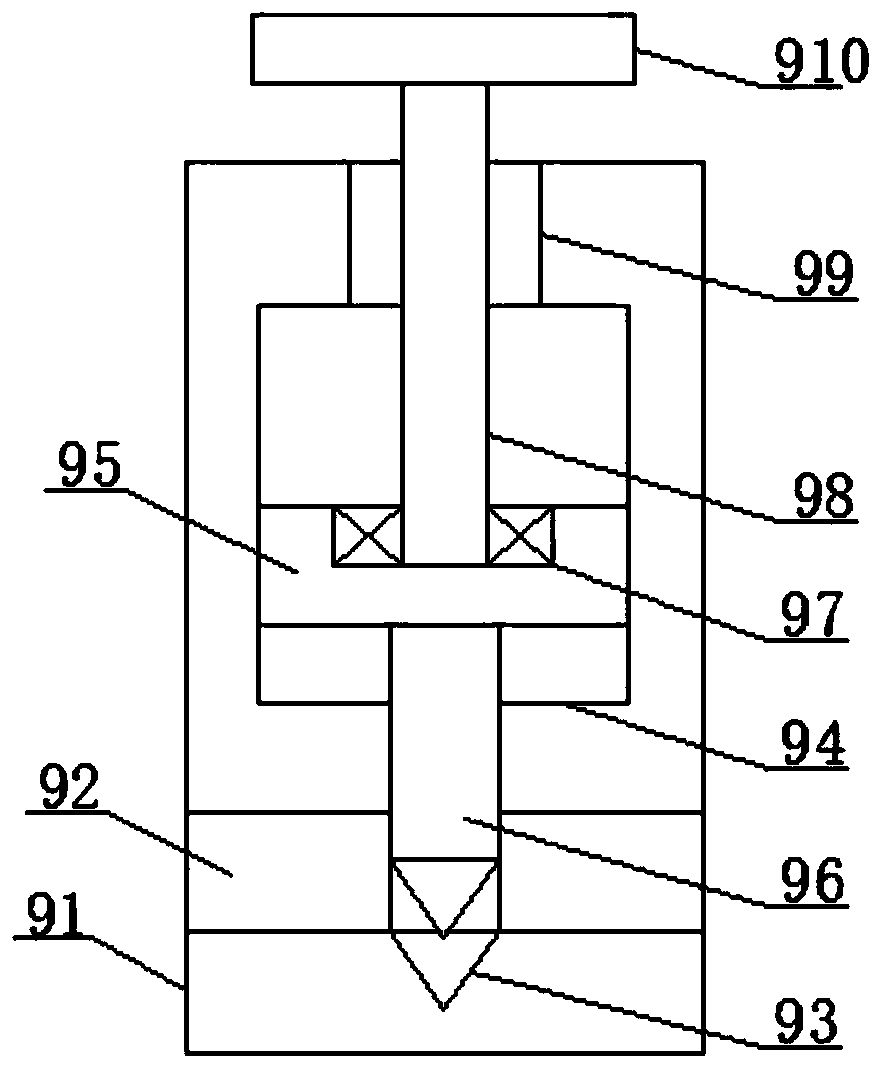

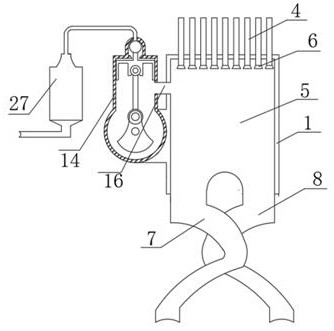

Efficient dewatering device for textiles

ActiveCN111089456AControl discharge rateHigh kinetic energy utilizationDrying solid materials with heatDrying solid materials without heatElectric machineryProcess engineering

The invention discloses an efficient dewatering device for textiles. The efficient dewatering device comprises a main body shell. According to the efficient dewatering device, a power source generatedby a driving motor can be utilized for achieving both the effects of generation of high-pressure gas and jet dewatering, and the function of centrifugal dewatering, in this way, the textiles can be subjected to high-pressure air jetting and centrifugal dewatering, and thus the accelerated and effective dewatering effect can be achieved. Moreover, power of the driving motor is effectively and sufficiently utilized, and the utilization rate of kinetic energy is high. Besides, the efficient dewatering device is provided with a rotation-type air flow speed control mechanism of a thread structureso that discharge speed of air can be controlled to form wind power with proper strength. In addition, the efficient dewatering device is provided with a hollow-shaft-type wind power switching and guiding mechanism which can achieve position switching on the space, and the air is converted to the mode of blowing the textiles via wind power to achieve wind-driven dewatering. The efficient dewatering device is furthermore provided with a gear-meshing-type rotation function conversion mechanism, which can increase the rotation speed and then achieve a better centrifugal effect.

Owner:安徽湖晟纺织科技有限公司

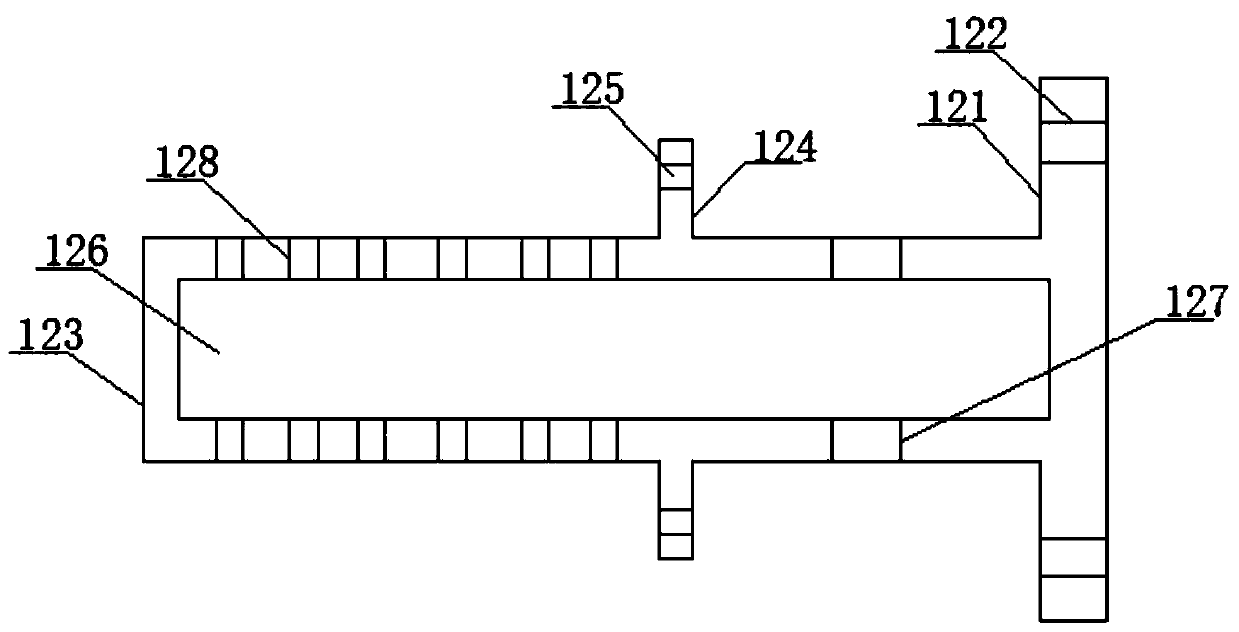

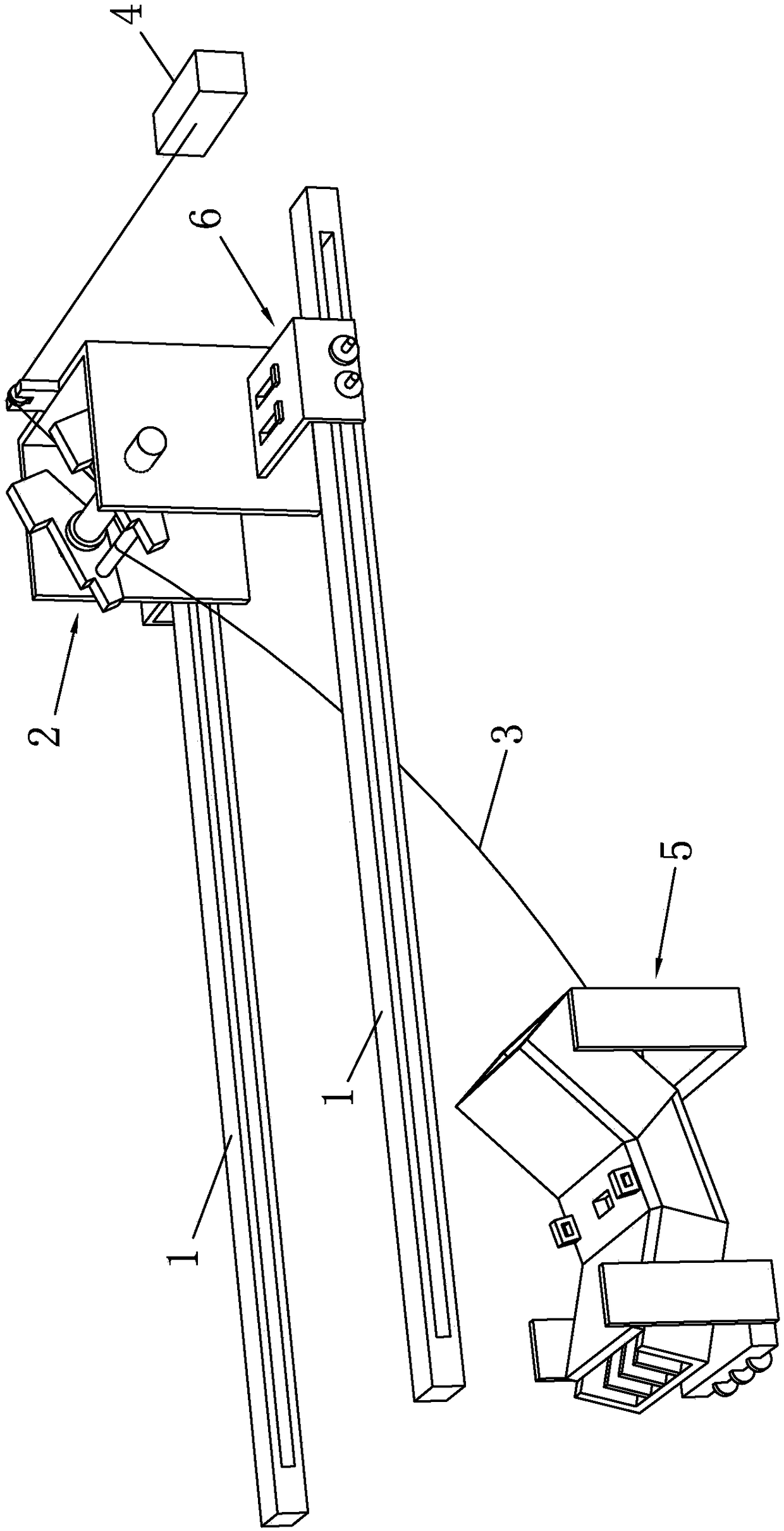

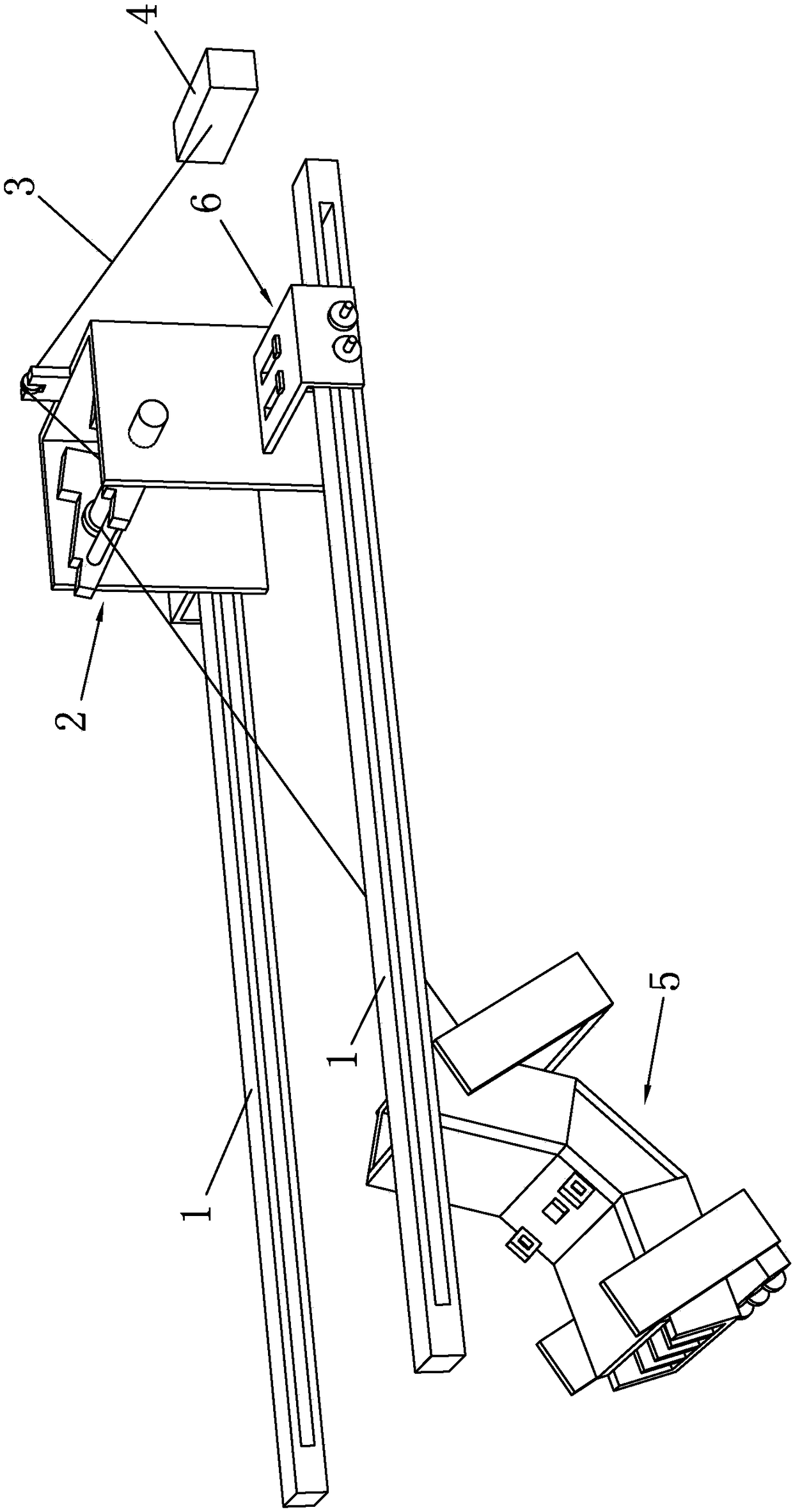

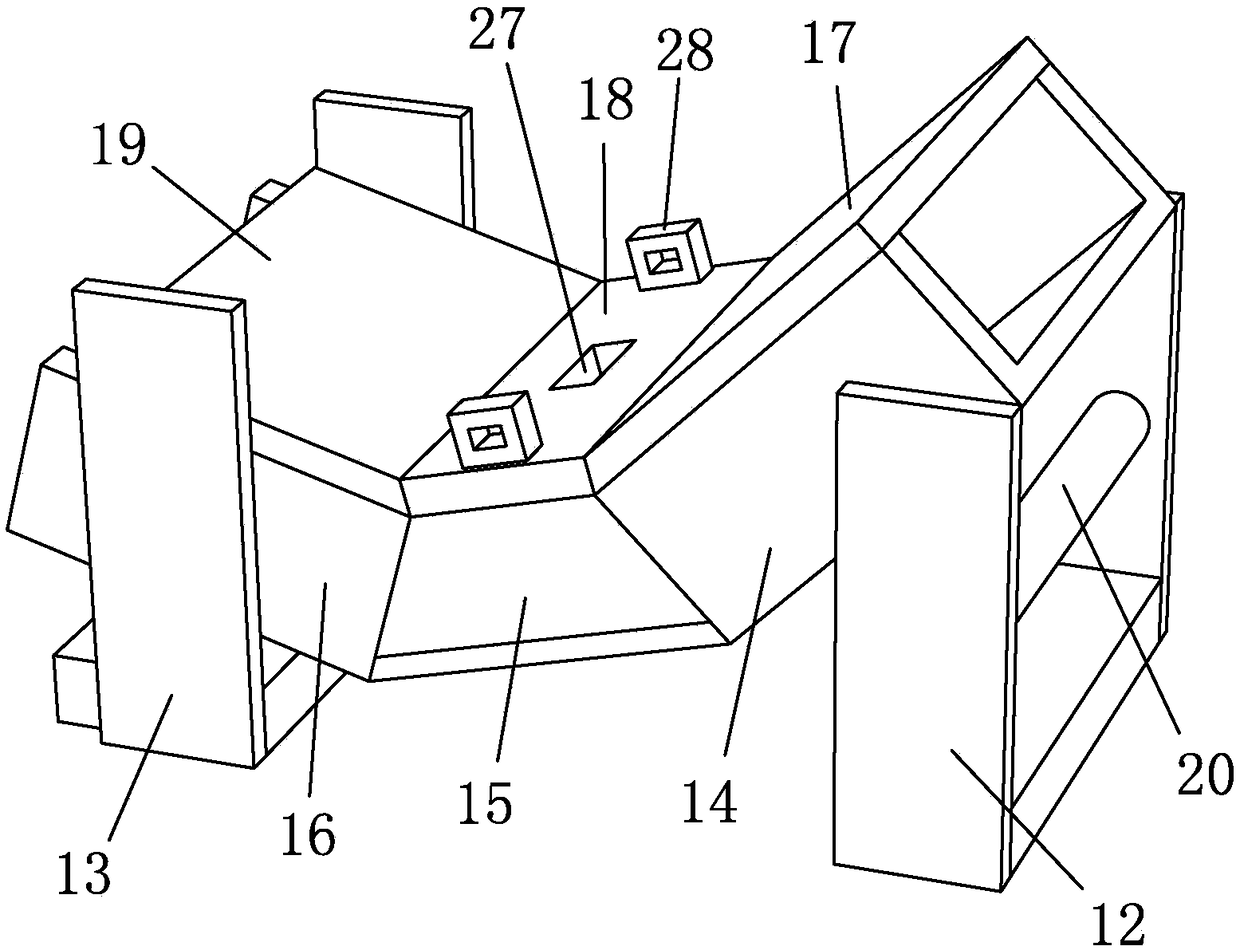

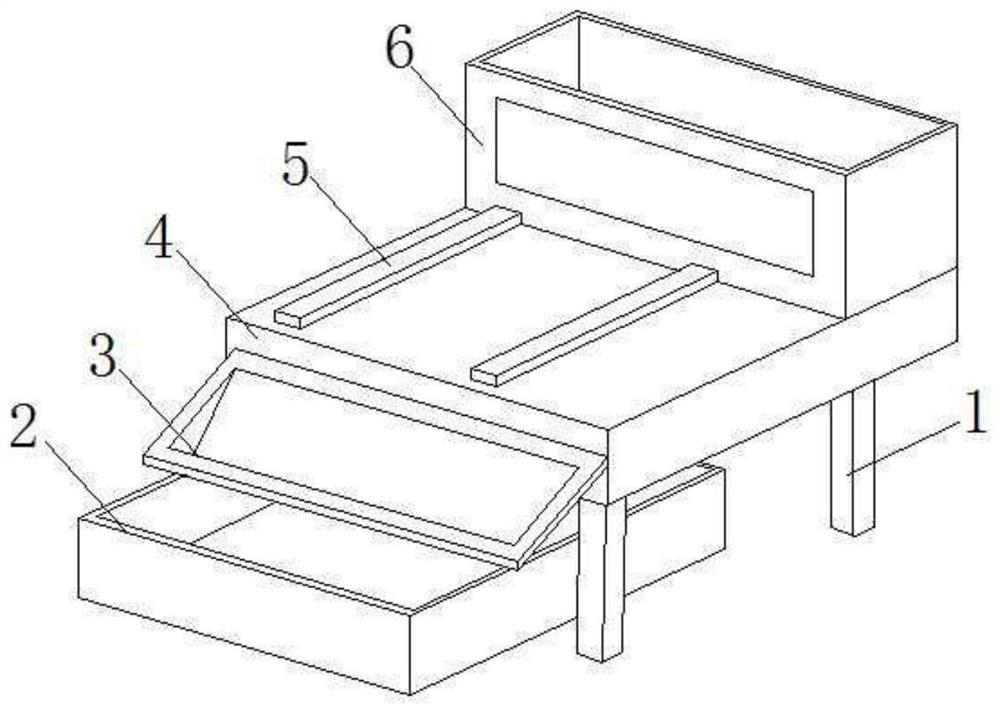

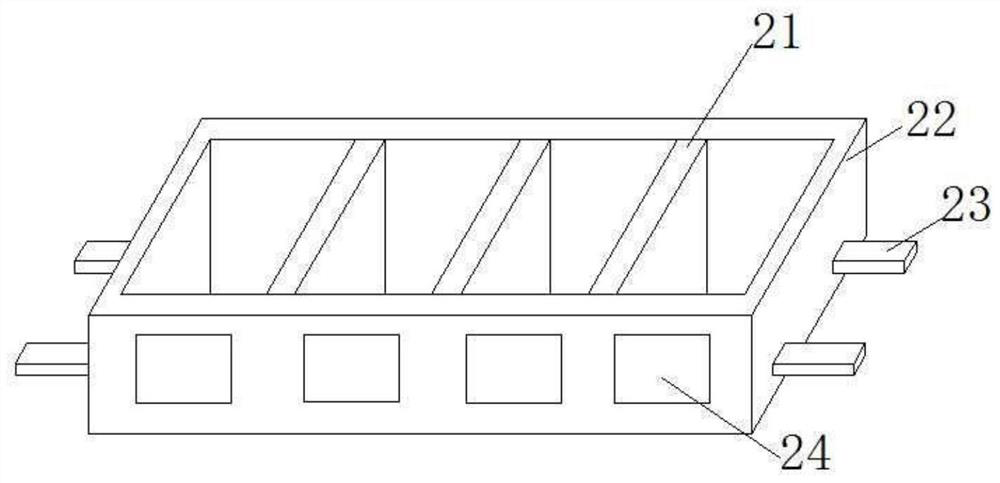

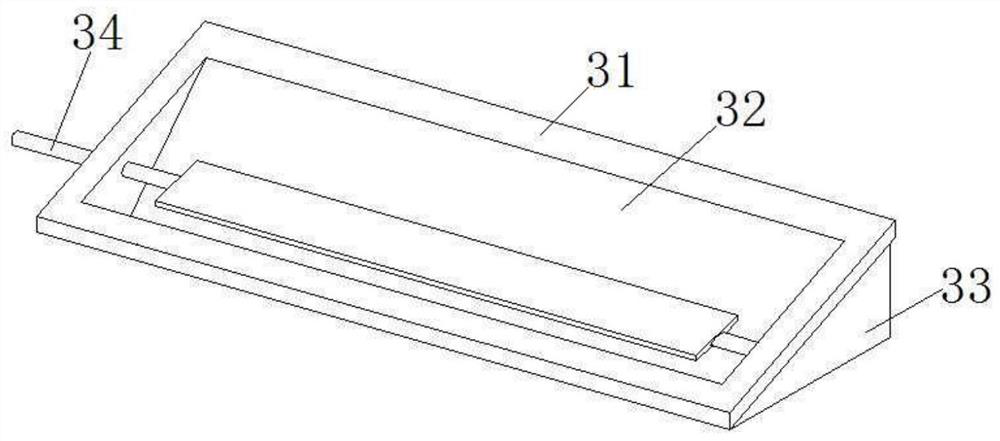

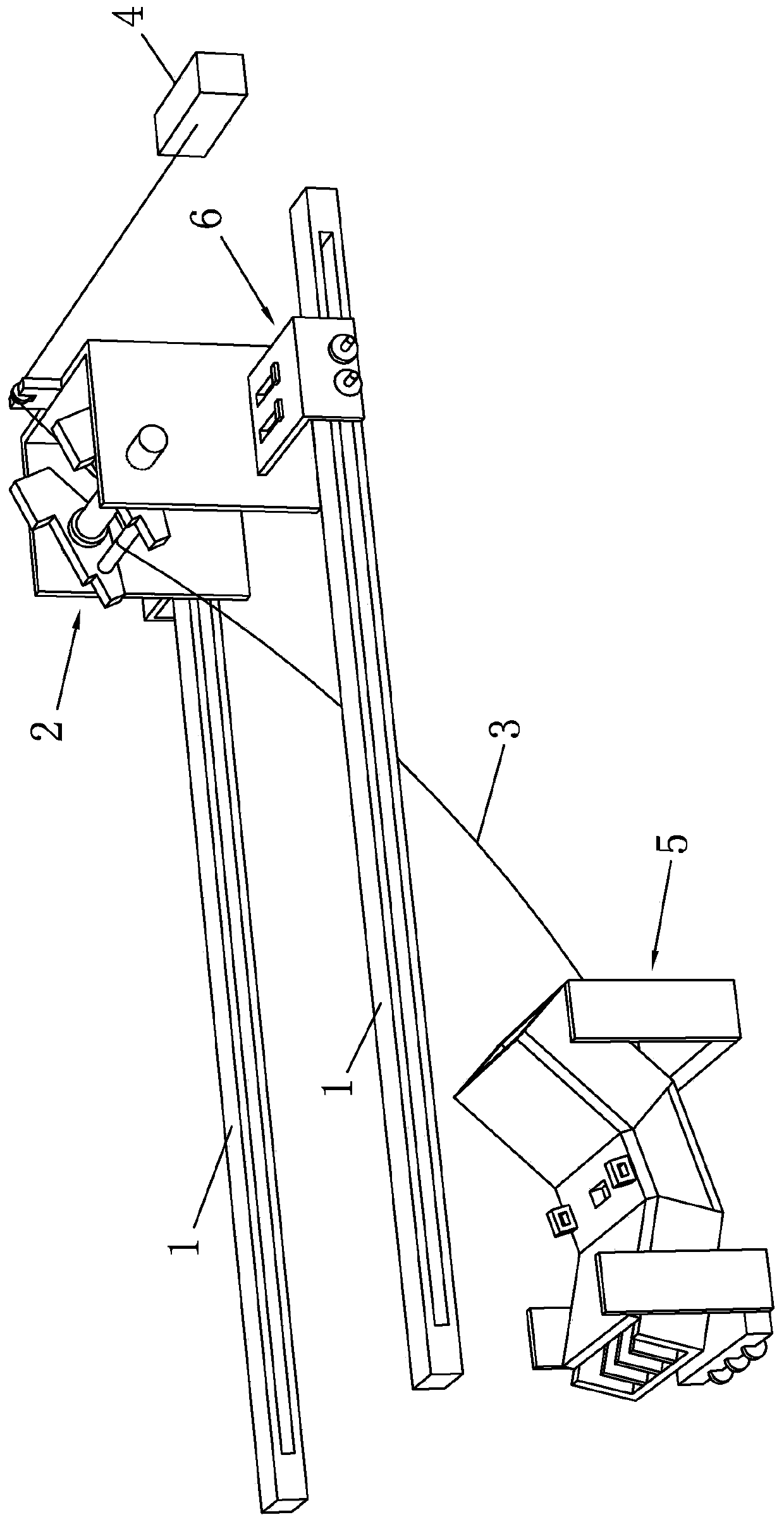

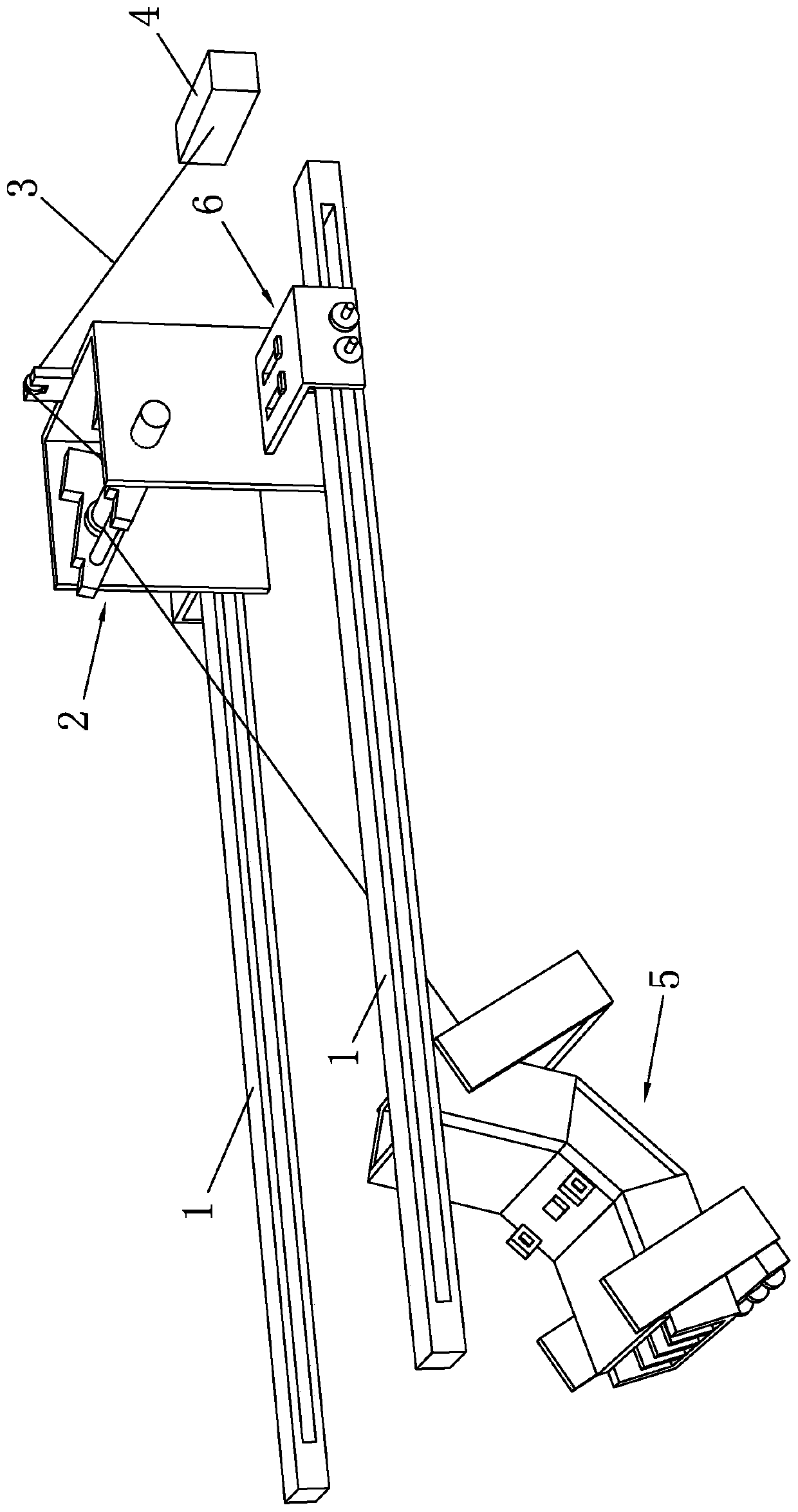

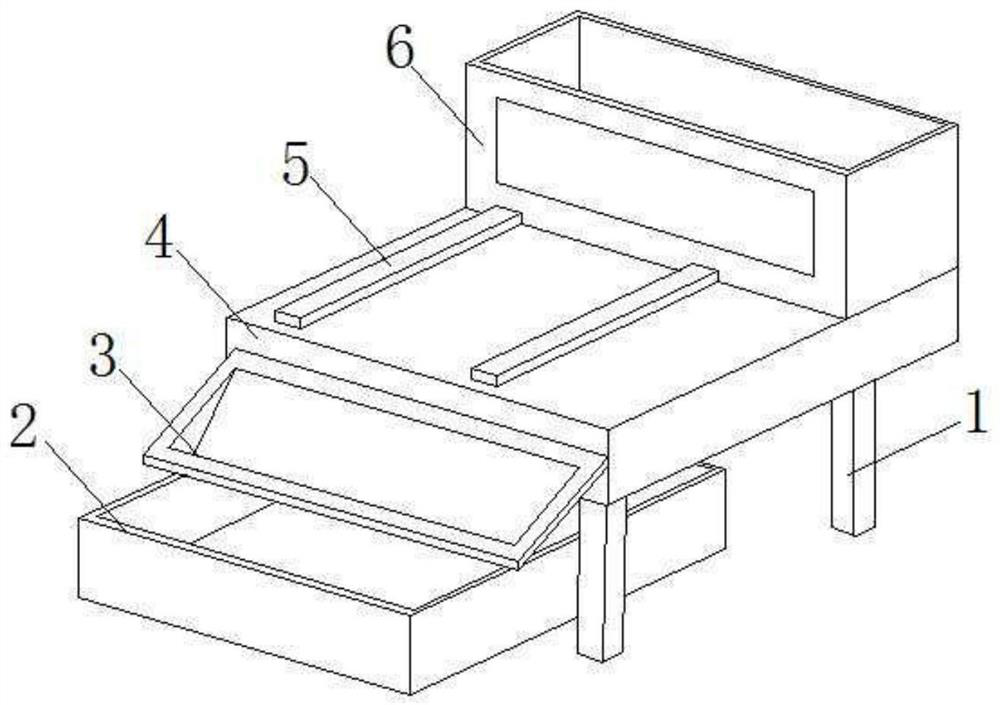

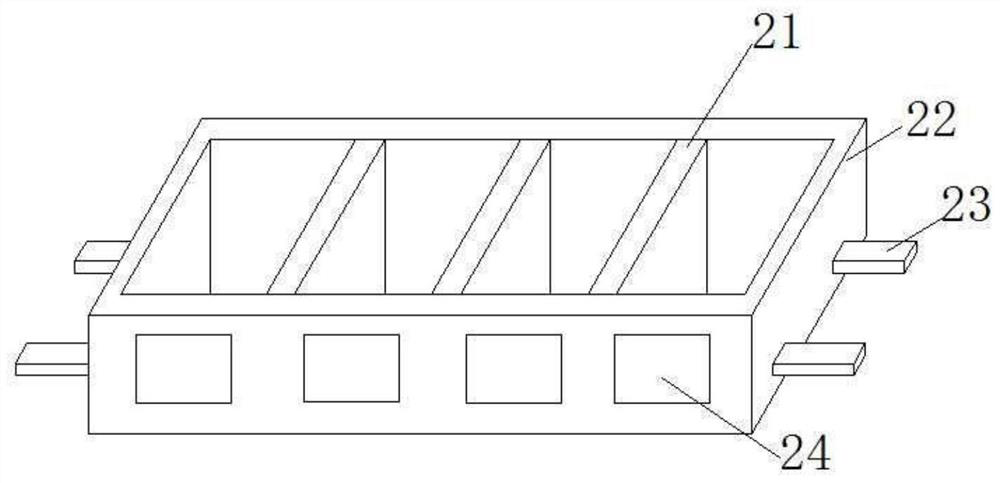

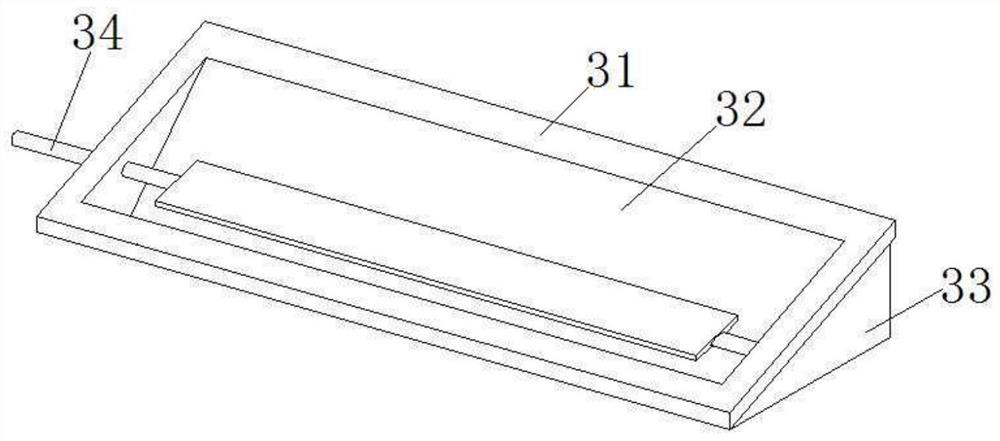

Compaction-type sand gravel filling device and construction method

The invention discloses a compaction-type sand gravel filling device and a construction method. The compaction-type sand gravel filling device comprises two tracks, an adjustment device, a traction rope, a traction device and a sand gravel filling box. The adjustment device comprises an adjustment frame, a rotary rod and an adjustment rod. The sand gravel filling box comprises a first mounting support, a second mounting support, a feeding part, a buffering part and a discharging part. The construction method comprises the steps of a, digging of a sand gravel filling pit; b, arrangement of thetracks; c, arrangement of the adjustment device; d, arrangement of the traction device; e, hoisting and placing of the sand gravel filling box; f, sand gravel filling; g, repeating of the step e and the step f; and h, compaction of a sand gravel layer. By adoption of the compaction-type sand gravel filling device and the construction method, the sand gravel filling pit can be orderly filled with sand gravels in one direction, so that the structure of the sand gravel filling pit is prevented from being damaged; the construction difficulty is lowered, and the construction quality of an ecological retaining wall is improved; and meanwhile, the sand gravel layer can be laid rapidly by only one person, so that the labor cost is reduced, and the construction process of the whole ecological retaining wall is shortened.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Polishing pads and chemical mechanical polishing equipment

ActiveCN110802508BConsiderable storage capacityLarge storage capacityLapping toolsGrinding/polishing apparatusEngineeringMechanical engineering

The invention provides a polishing pad and chemical mechanical polishing equipment, belonging to the technical field of semiconductors. The polishing pad includes a substrate layer and a polishing layer on the substrate layer, the polishing layer includes a plurality of concentric circumferential grooves arranged in the circumferential direction, and a plurality of grooves arranged in the radial direction and connected to adjacent circumferential directions Groove radial groove. The invention can improve the utilization rate of the polishing liquid, the service life of the polishing pad and the polishing quality.

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

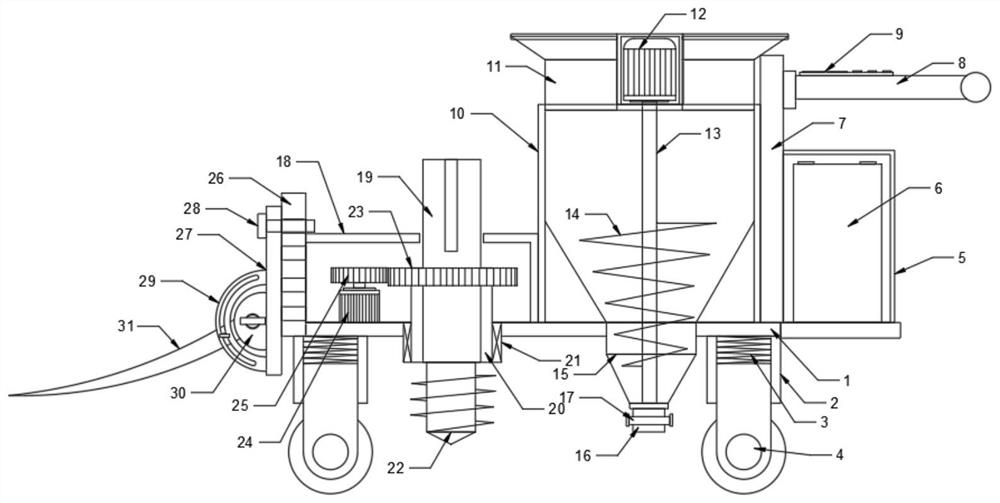

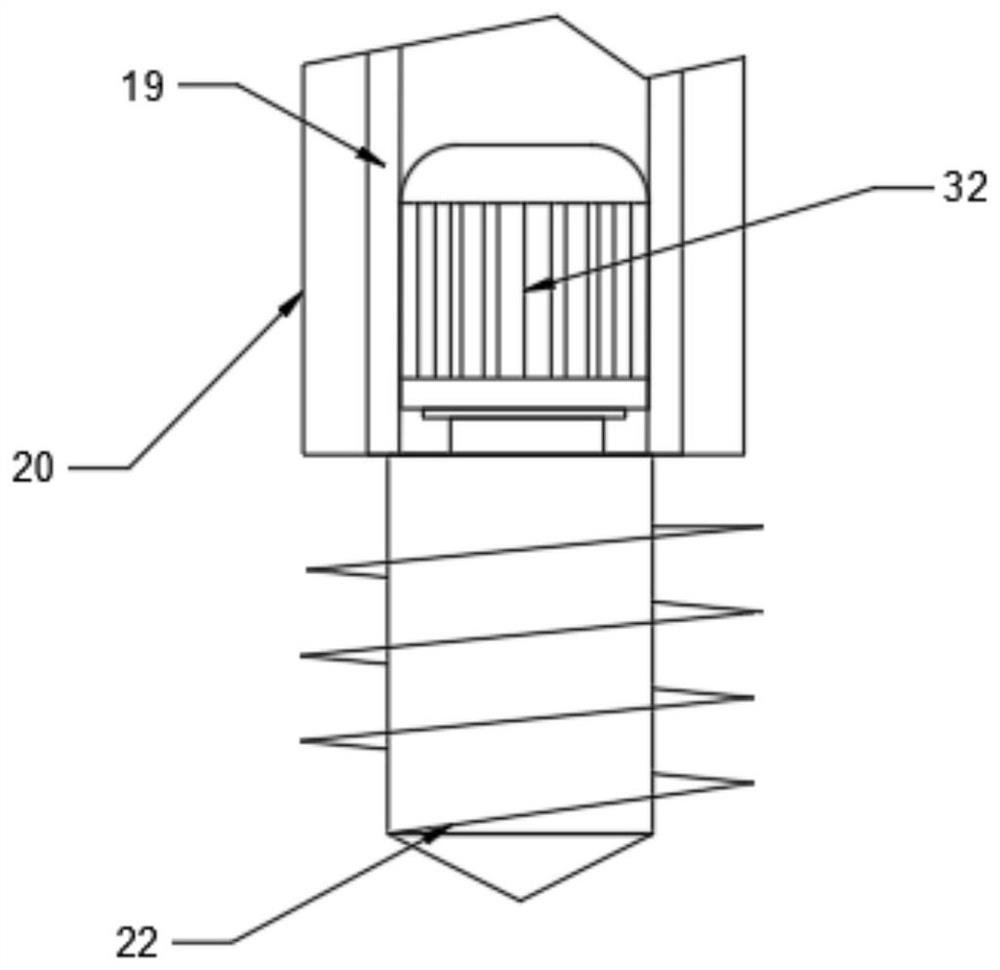

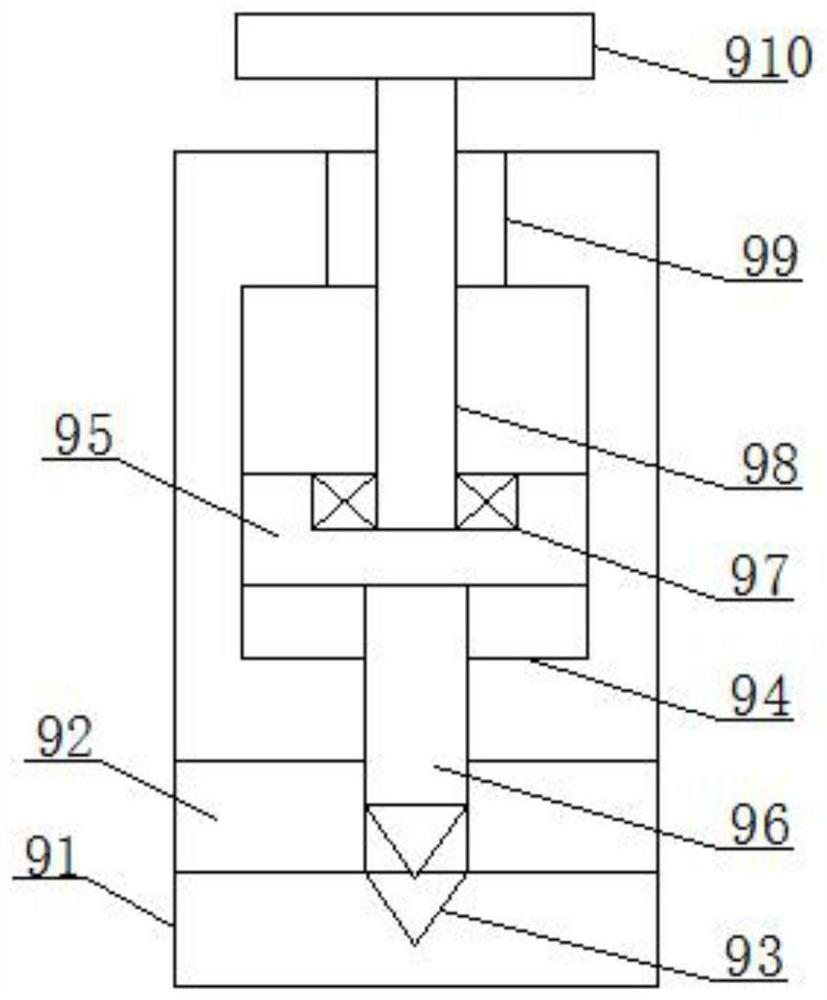

Pit digging and planting apparatus for agricultural production

InactiveCN111771476ADepth is easy to controlImprove planting efficiencyPlantingDibble seedersHelical bladeElectric machine

The present invention discloses a pit digging and planting apparatus for agricultural production. The pit digging and planting apparatus includes a bottom plate, a storage box and a pit digging head;the right side of the upper end of the bottom plate is provided with a vertical plate, the left side of the vertical plate is provided with the storage box, the middle of the top end of the storage box is provided with a first motor, the front end of a rotating shaft of the first motor is provided with a stirring rod and a helical blade, and the bottom end of the storage box is provided with a hopper and an electromagnetic valve; the left side of the upper end of the bottom plate is provided with a fixed plate, the right side of the fixed plate is provided with a fixed frame, the bottom end ofthe inner side of the fixed frame is provided with a second motor and a gear, the right side of the second motor is provided with a limiting cylinder, the outer side of the upper end of the limitingcylinder is provided with a gear ring, the inner side of the limiting cylinder is provided with a fixed cylinder, and the bottom end of the inner side of the fixed cylinder is provided with a third motor and the pit digging head; and the left side of the fixed plate is provided with a supporting plate, the bottom end of the supporting plate is provided with a fixed mount, the outer side of the fixed mount is provided with a limiting frame, and the inner side of the fixed mount is provided with a furrowing blade. The pit digging and planting apparatus is reasonable in structure and capable of facilitating digging pits for sowing, furrowing, relieving the working intensity of a farmer and increasing the work efficiency.

Owner:张国进

Automatic water changing drinking trough for pigeon feeding

InactiveCN113841634AControl discharge rateAchieve dischargeAvicultureWater storage tankPotable water

The invention discloses an automatic water changing drinking trough for pigeon feeding, and relates to the field of agricultural breeding. The automatic water changing drinking trough comprises a supporting base, wherein a waste water storage tank is fixedly mounted at one end of the supporting base, a supporting plate is fixedly mounted at the top end of the waste water storage tank, two supporting rods are fixedly mounted at the top end of the supporting plate, the same water injection tank is fixedly mounted at the top ends of the two supporting rods, and two limiting blocks are fixedly mounted on the two sides of the water injection tank respectively. When drinking water for pigeons needs to be replaced, an output shaft of a servo motor rotates to drive a first roller to rotate, the first roller rotates to drive a belt to rotate, the belt rotates to drive a second roller to rotate, the second roller rotates to drive a rotating tank to rotate, after the rotating tank is inclined for a certain angle, waste water in the tank is discharged into the waste water storage tank, the servo motor is controlled through an electric control program, so that the inclination angle of the rotating tank is further controlled, and the discharging speed of the waste water can be controlled.

Owner:ANHUI UNIV OF SCI & TECH

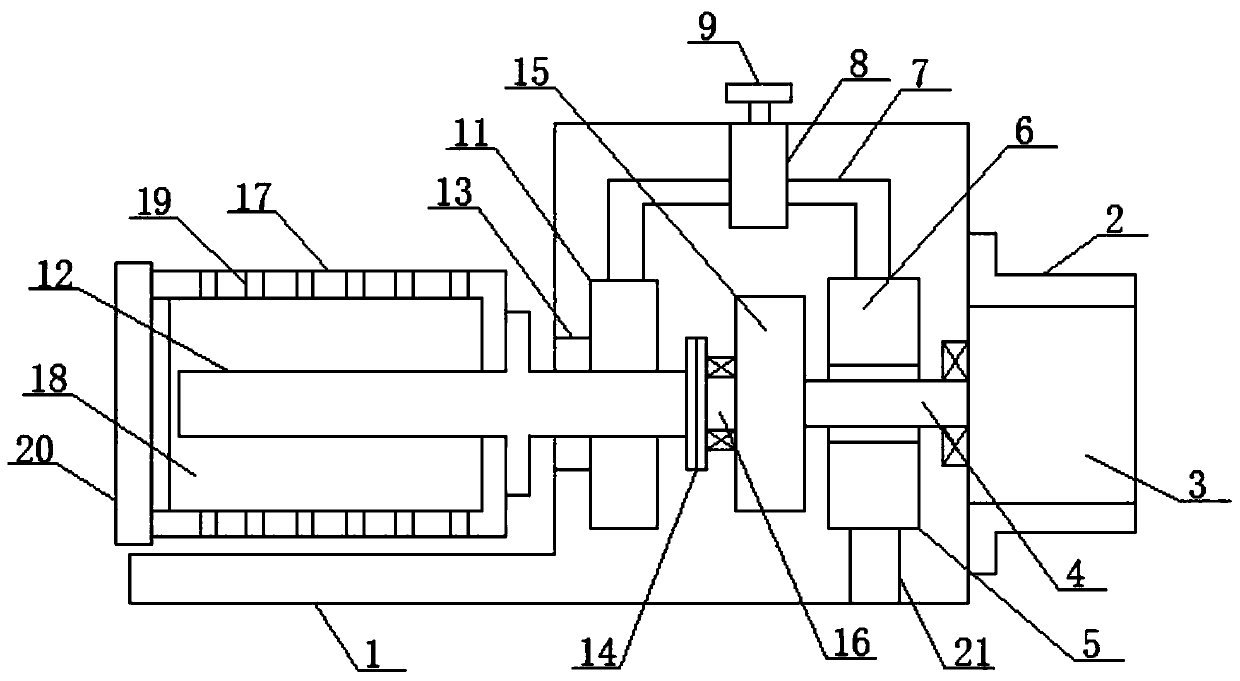

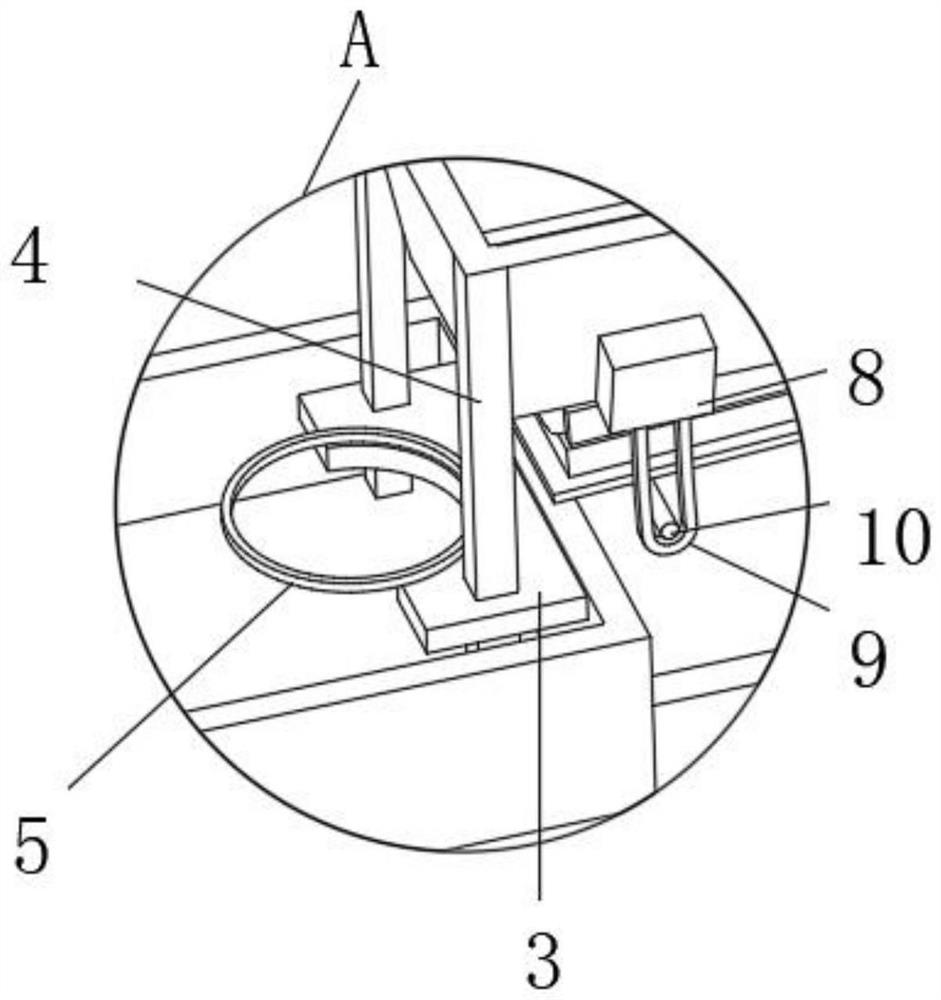

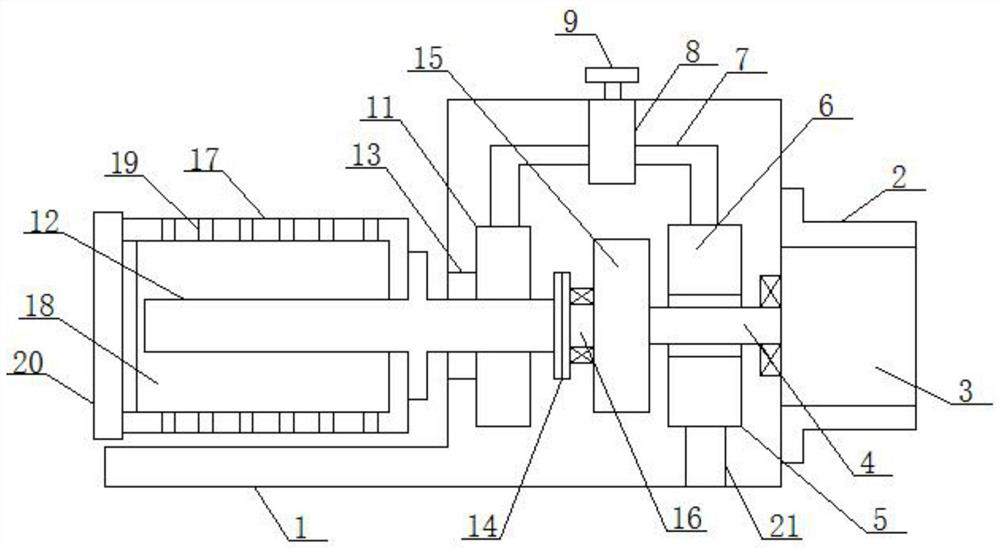

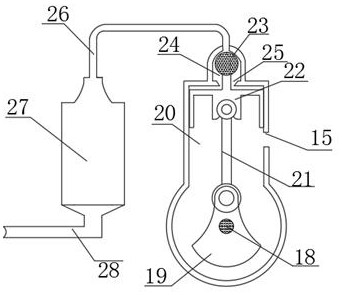

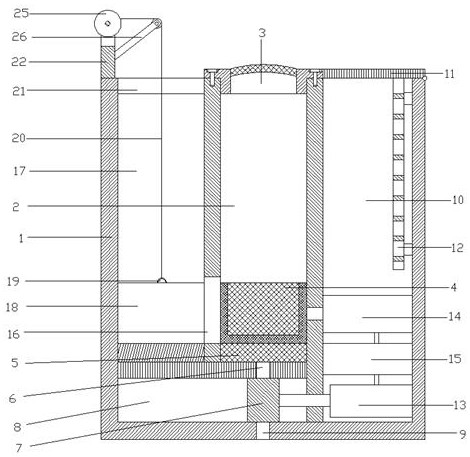

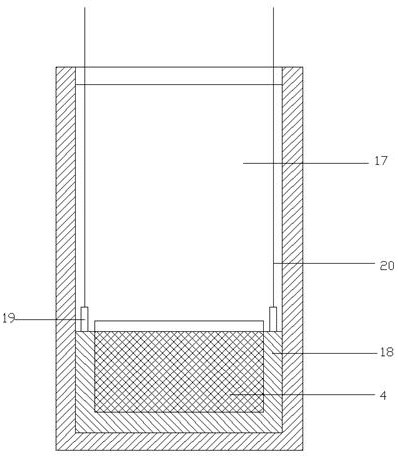

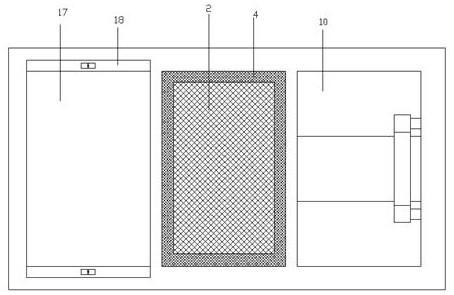

Intelligent manufacturing device capable of guaranteeing slurry uniformity and discharging quality

InactiveCN112877969AGuaranteed uniformityGuaranteed output qualityTextile treatment machine arrangementsFiberCarbon fibers

The invention relates to the technical field of carbon fiber production, and discloses an intelligent manufacturing device capable of guaranteeing the slurry uniformity and the discharging quality. The device comprises a shell; a stirring disc is rotatably mounted in the shell; a driving rod is fixedly mounted in the center of the stirring disc; a resistor stripe is fixedly connected to the outer portion of the driving rod on the surface of the stirring disc; a contact rod is slidably connected to the surface of the resistor stripe; a sliding groove is fixedly formed in the outer portion of the driving rod on the surface of the stirring disc; a sliding block is slidably connected to the inner portion of the sliding groove; and a connecting rod is rotatably connected to the bottom end of the sliding block. According to the intelligent manufacturing device capable of guaranteeing the slurry uniformity and the discharging quality, the stirring speed and the internal temperature are adjusted according to the uniformity of internal slurry, so that the quality of the stirred slurry is guaranteed, energy waste caused by overhigh equipment power is prevented; and meanwhile, the size of a discharging port is adjusted according to the slurry uniformity, so that the discharging quality is guaranteed, and the phenomenon that the working efficiency is reduced due to the too low discharging speed is avoided.

Owner:吴敏

A high-efficiency dehydration device for textile articles

ActiveCN111089456BControl discharge rateHigh kinetic energy utilizationDrying solid materials with heatDrying solid materials without heatElectric machineGear wheel

The invention discloses a high-efficiency dehydration device for textile articles, which comprises a main body shell. The present invention utilizes a power source generated by a driving motor, which can be used not only for high-pressure gas generation and spray dehydration, but also for centrifugal force dehydration, so that textiles can be subjected to high-pressure air spray and centrifugal force dehydration, thereby achieving fast and efficient Effective dehydration, and effectively and fully utilize the power of the drive motor, the kinetic energy utilization rate is high, and the device has a threaded structure rotary air flow speed control mechanism, which can control the air discharge speed and form a suitable wind force , in addition, the device has a hollow shaft type wind conversion guide mechanism, which can make the position of the space change, convert the air into the wind blowing effect on the textile, and realize the wind dehydration. In addition, the device has a gear meshing rotary function conversion mechanism, The rotation speed can be increased to achieve a strong centrifugal force.

Owner:安徽湖晟纺织科技有限公司

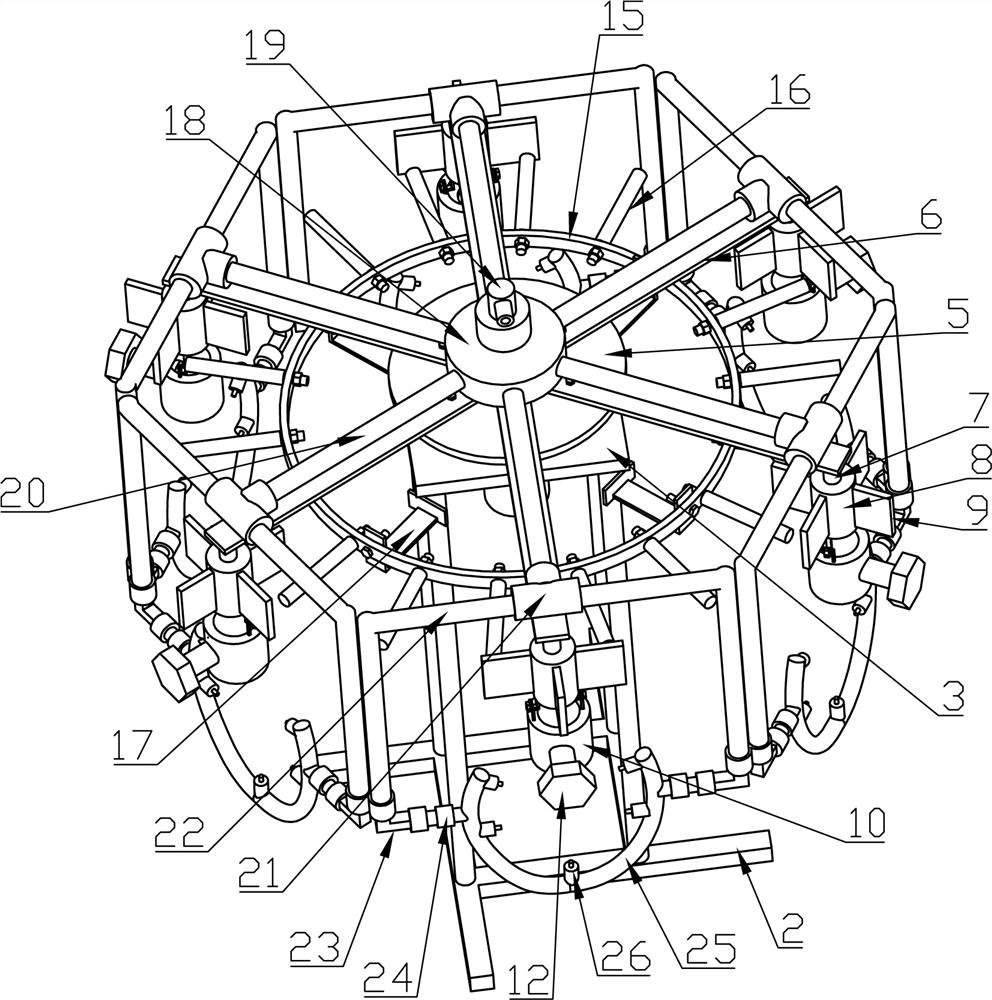

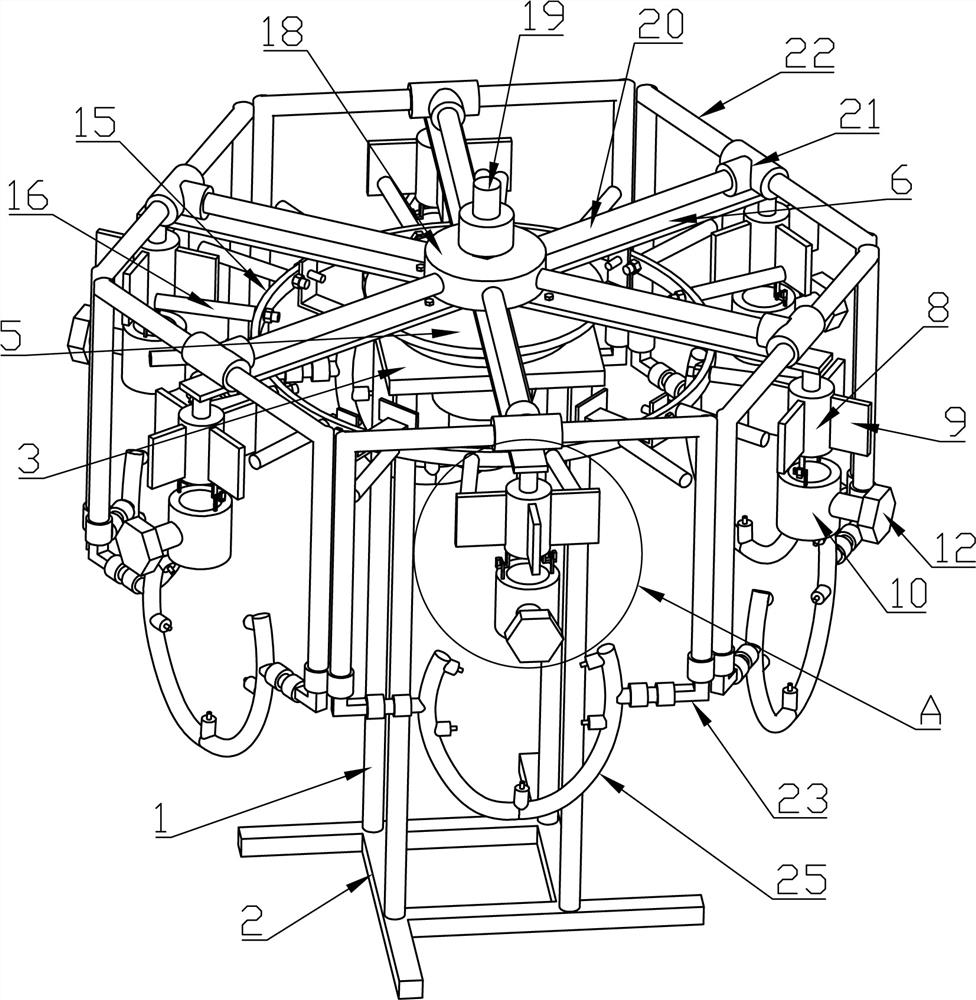

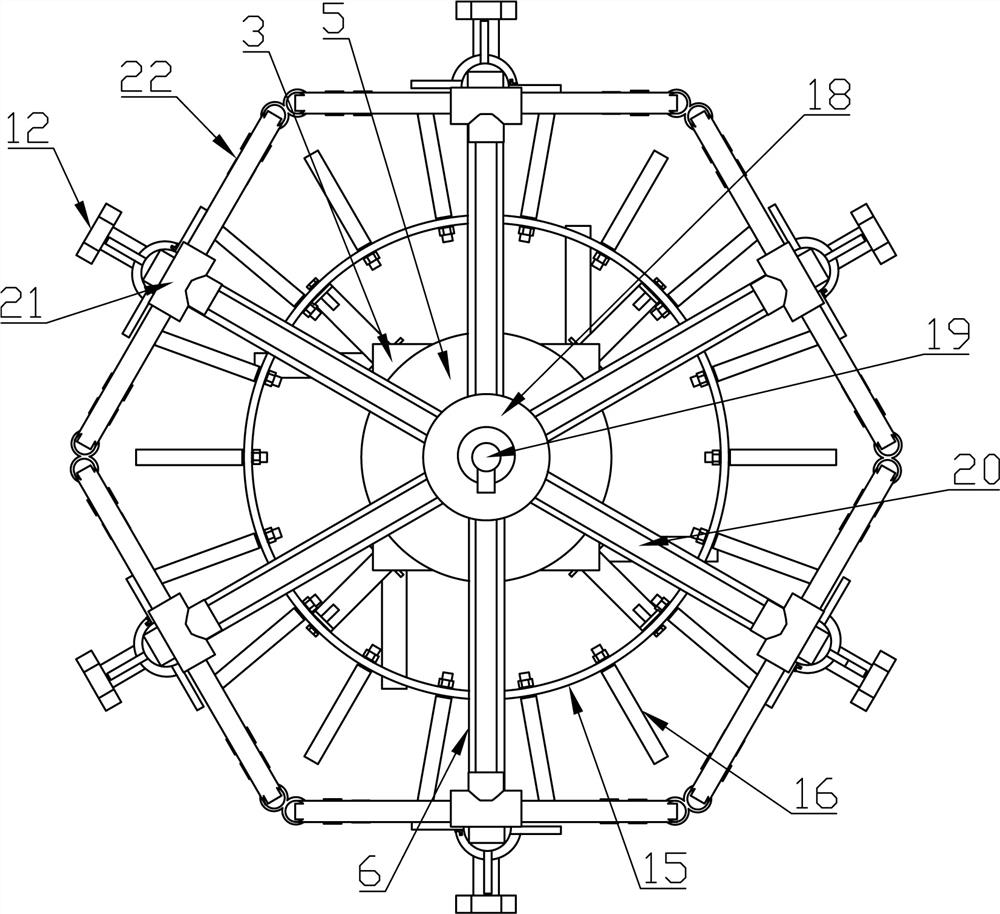

A fully automatic root washing equipment

ActiveCN112474516BGuaranteed independenceIntegrity guaranteedCleaning using liquidsStationary filtering element filtersEngineeringMechanical engineering

The invention relates to a fully automatic root washing equipment, which comprises a base, a mounting plate is rotatably arranged on the top of the base, a driving device is provided on the base to drive the horizontal rotation of the mounting plate, and the circumferential direction of the mounting plate is uniform. There are a number of installation strips arranged along the radial direction of its radius, and the bottom of the free end of the installation strip is rotatably provided with a cylinder, the side of the cylinder is provided with a number of blades in the circumferential direction, and a rhizome clamping device is provided under the cylinder ; The outer periphery of the base is horizontally fixed with a mounting ring, and the outer circumference of the mounting ring is provided with a number of driving rods arranged along the radial direction of its radius, and the driving rods are matched with the blades; A water-distributing chamber, the water-distributing chamber is provided with a rotary joint, and the side of the water-dividing chamber is provided with a number of water-distributing pipes arranged along the radial direction of its radius and communicating with it, and the water-distributing pipes are arranged on the installation strip , the free end of the water distribution pipe communicates with two L-shaped water pipes through a three-way joint.

Owner:石家庄益康农科技发展有限公司 +2

Efficient water curtain dust remover and using method thereof

InactiveCN111888858AControl discharge rateImprove absorption efficiencyUsing liquid separation agentFlue gasDust control

The invention discloses an efficient water curtain dust remover which comprises a dust removal box and supporting legs, the four sets of supporting legs are welded to the lower end of the dust removalbox. A water supply tank is fixedly connected to the upper part of the dust removal tank; the bottom of the water supply tank is communicated with a plurality of groups of spraying pipes; the plurality of groups of spraying pipes extend downwards into the D-shaped dust removal cavity of the dust removal box; and the lower end of the spraying pipes is in threaded connection with a pressure spray head, the bottom of the dust removal box is symmetrically connected with a first spiral pipe and a second spiral pipe, a liquid collecting tank is arranged below the first spiral pipe and the second spiral pipe, and the upper end of the water supply box is connected with an air storage tank through an air inlet pipe. According to the efficient water curtain dust remover and the using method thereof, the effect of controlling the flue gas emission rate is achieved by designing the sliding block with the crank connecting rod moving and cooperating with the valve effect of the spherical check block so that the effect is matched with the fixed flow rate of a water curtain, the absorption efficiency of absorption liquid is improved, the dust remover is suitable for different working conditions,and better use prospects are brought.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

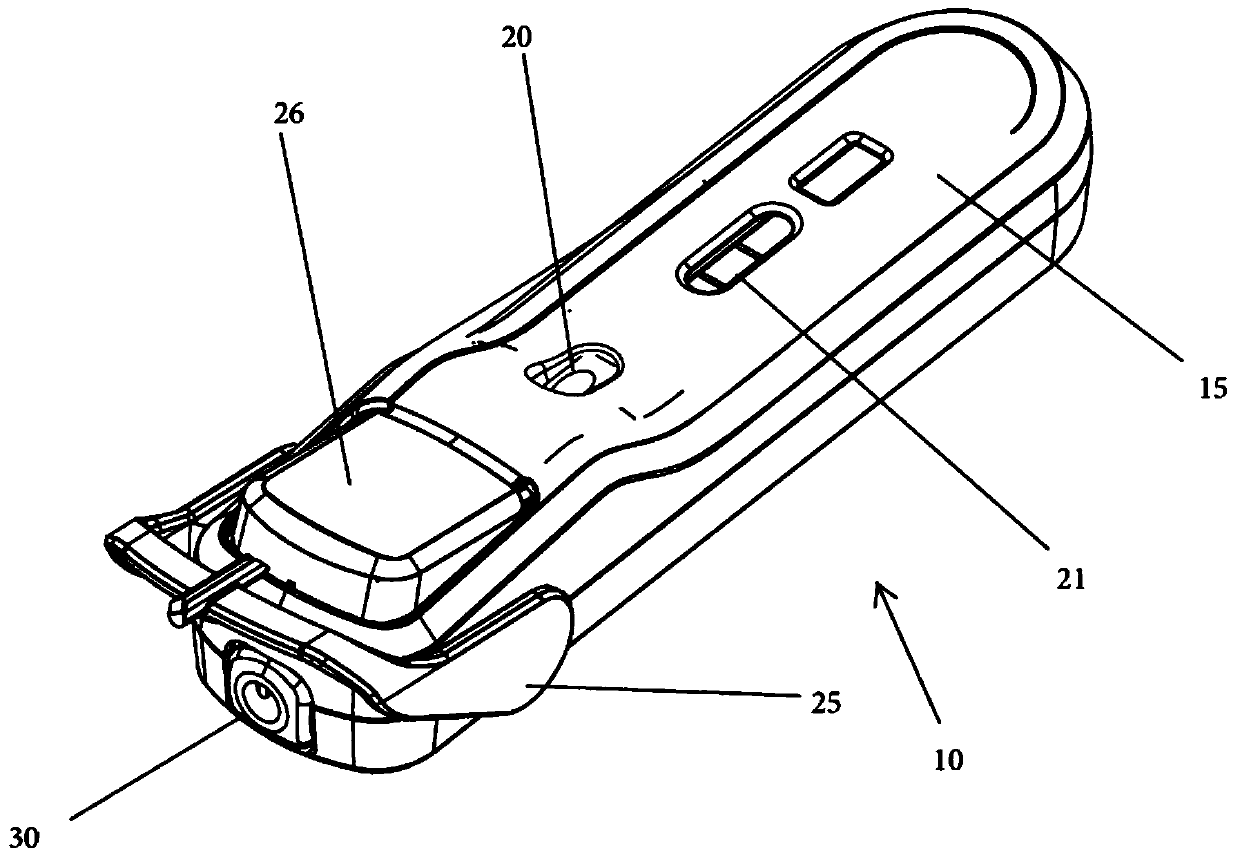

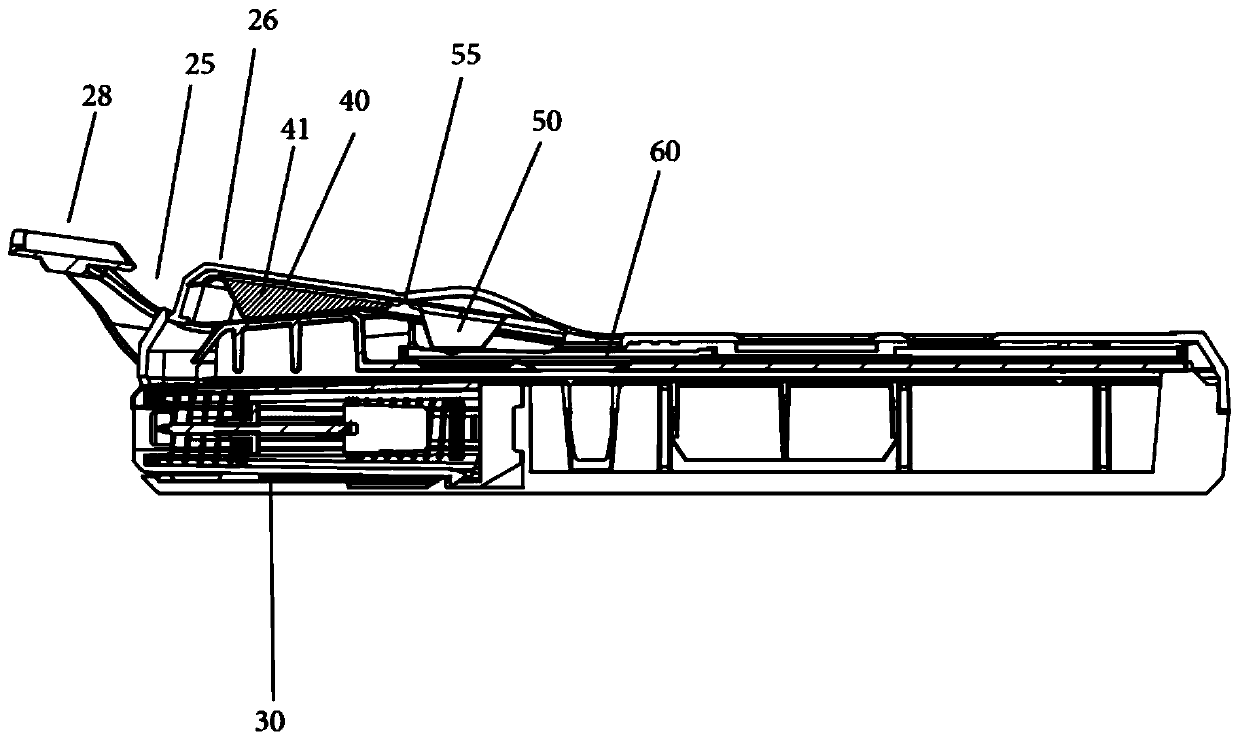

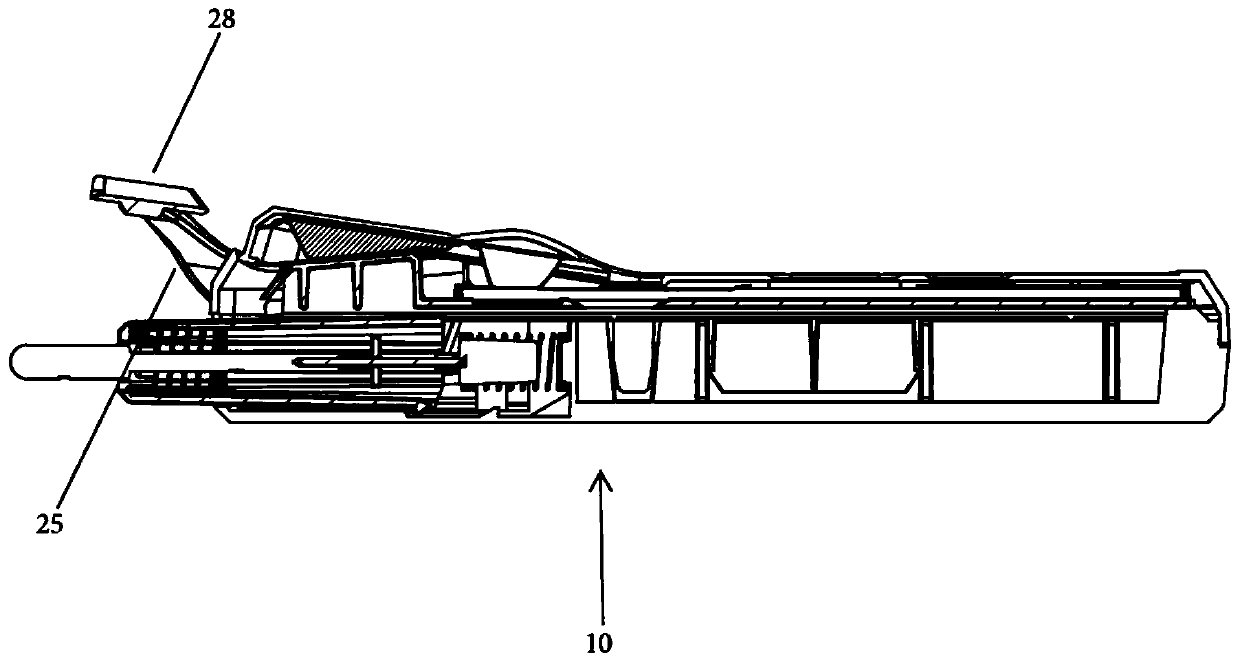

Integrated fluid module and test device

ActiveCN110234577AReduce flow rateControl discharge rateVaccination/ovulation diagnosticsCatheterEngineeringMechanical engineering

Owner:ATOMO DIAGNOSTICS PTY LTD

Machining waste material collecting device

ActiveCN112372366AIncrease elasticityAvoid damageMaintainance and safety accessoriesStructural engineeringMachine

The invention discloses a machining waste material collecting device, the device comprises supporting legs and further comprises a machine frame which is in a cuboid shape and is fixed to the upper ends of the supporting legs, a collecting box is arranged below the machine frame in a penetrating manner, a guide frame is pivoted to the end part of the machine frame and is placed above the collecting box, first guide rails are fixed to the top end of the machine frame in the length direction of the machine frame, the two first guide rails are arranged in parallel, a material box is supported atthe upper end of the machine frame and slides along the first guide rails, a guide frame comprises a rectangular frame, a supporting block is triangular and is fixed on the lower side of the end partof the frame, a conveying frame is pivoted in an inner cavity of the frame, a shifting piece is pivoted in the frame in the axial direction of the frame, a material box comprises a shell which is in acuboid shape, a discharge window is rectangular and is pivoted to the side wall of one side of the shell, a material removing piece is fixed on the side wall of the other side of the shell, and therefore, the machining waste material collecting device can collect waste materials and meanwhile has good self-buffering protection capacity.

Owner:嘉兴沃瑞科技有限公司

A dense sand and gravel filling device and construction method

The invention discloses a compaction-type sand gravel filling device and a construction method. The compaction-type sand gravel filling device comprises two tracks, an adjustment device, a traction rope, a traction device and a sand gravel filling box. The adjustment device comprises an adjustment frame, a rotary rod and an adjustment rod. The sand gravel filling box comprises a first mounting support, a second mounting support, a feeding part, a buffering part and a discharging part. The construction method comprises the steps of a, digging of a sand gravel filling pit; b, arrangement of thetracks; c, arrangement of the adjustment device; d, arrangement of the traction device; e, hoisting and placing of the sand gravel filling box; f, sand gravel filling; g, repeating of the step e and the step f; and h, compaction of a sand gravel layer. By adoption of the compaction-type sand gravel filling device and the construction method, the sand gravel filling pit can be orderly filled with sand gravels in one direction, so that the structure of the sand gravel filling pit is prevented from being damaged; the construction difficulty is lowered, and the construction quality of an ecological retaining wall is improved; and meanwhile, the sand gravel layer can be laid rapidly by only one person, so that the labor cost is reduced, and the construction process of the whole ecological retaining wall is shortened.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

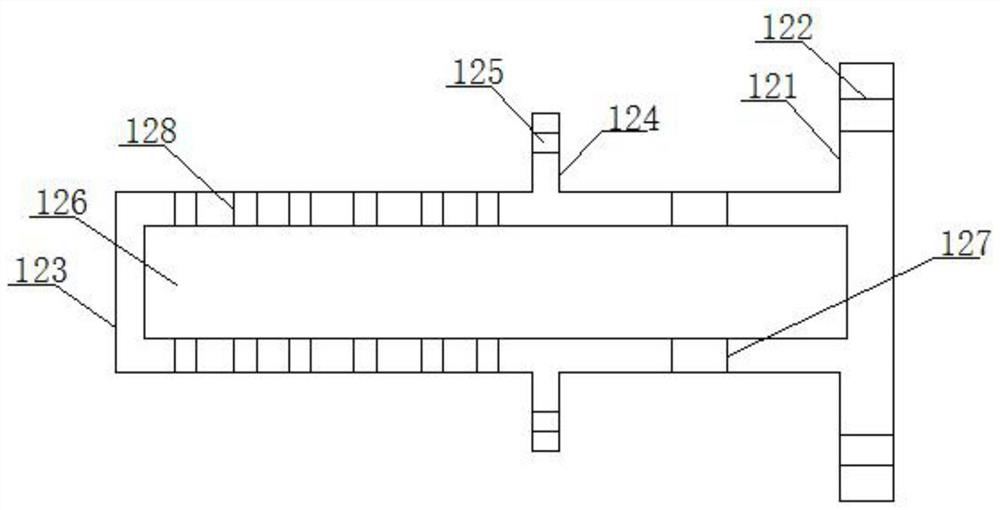

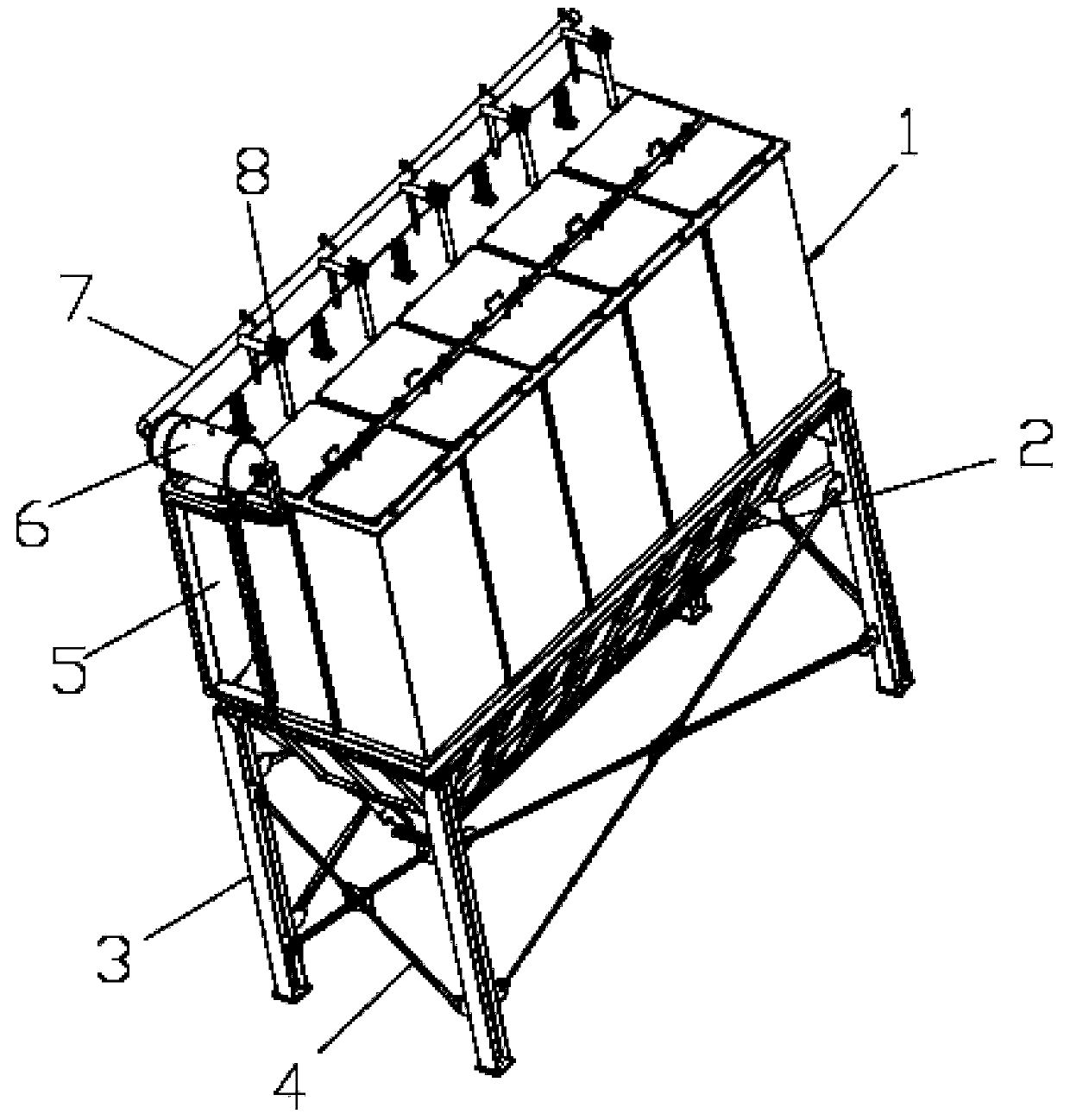

Convenient-to-maintain pulse bag type dust remover for processing glutinous rice

PendingCN110694368AImprove air tightnessEasy to maintain laterDispersed particle filtrationBiotechnologyAgricultural science

The invention discloses a convenient-to-maintain pulse bag type dust remover for processing glutinous rice. The pulse bag type dust remover comprises a dust removing mechanism; a dust collecting hopper is arranged at the bottom end of the dust removing mechanism; one side surface of the dust removing mechanism is provided with an air inlet; the other side surface of the dust removing mechanism issymmetrically provided with an air outlet; an air pump is arranged at the upper part of the left side of the dust removing mechanism; the air pump is provided with an air pipe; and the air pipe is provided with a plurality of groups of pulse solenoid valves at equal intervals. A dust removal cavity has good air tightness and obvious dust-containing gas purification effect; two adjacent groups of maintenance plates can be pulled apart by rotating movable clamping plates, so that later maintenance and overhaul of maintenance personnel are facilitated, and maintenance and overhaul are convenientand rapid; dust-containing gas can be prevented from being mixed with the purified gas, so that quality of the purified gas is ensured; dust attached to the filter plate can be better removed, so thatthe dust removal effect is better; and the dust discharge rate of dust can be controlled, so that the dust can be conveniently collected and treated by workers in a centralized manner.

Owner:毛学兰

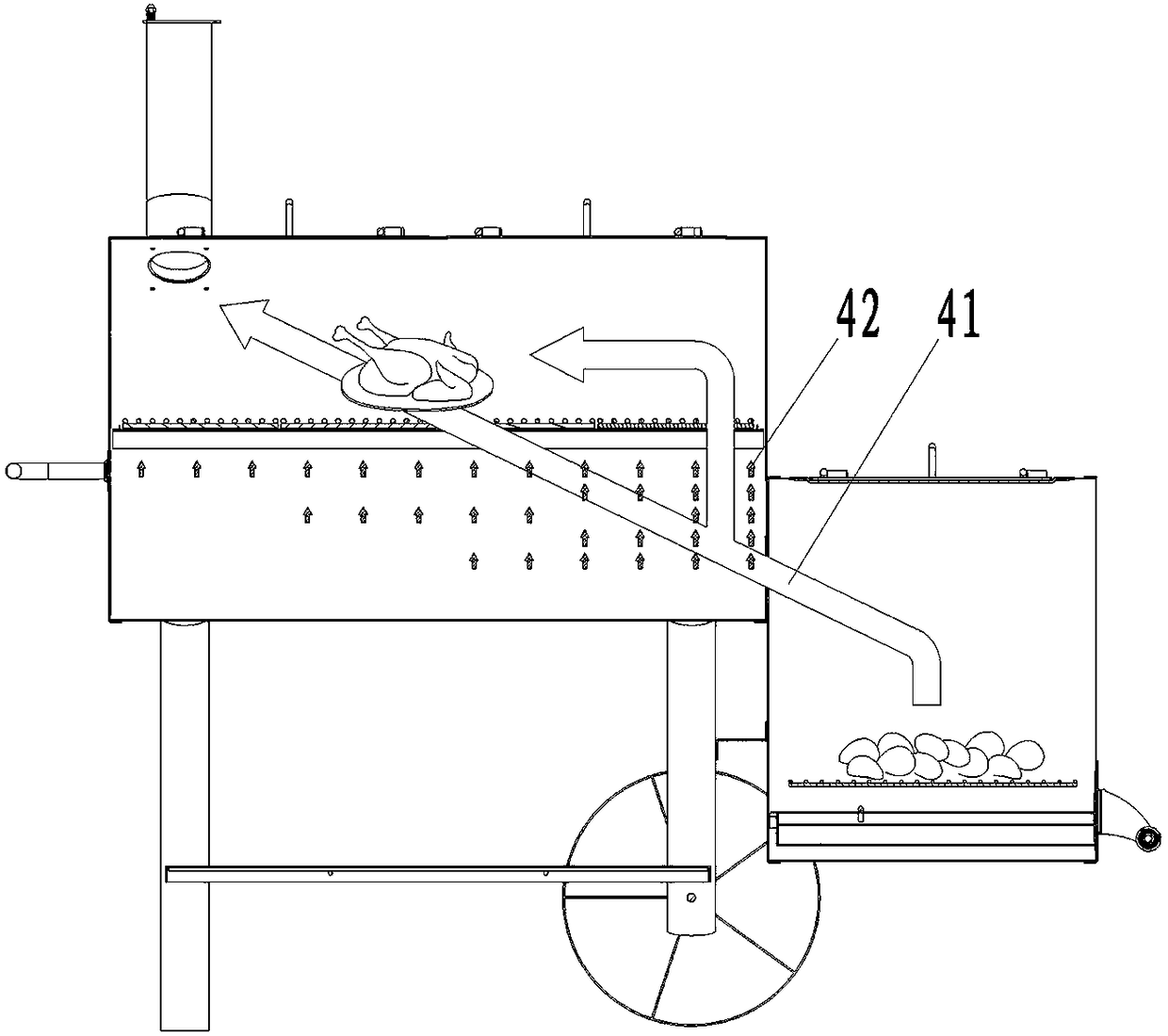

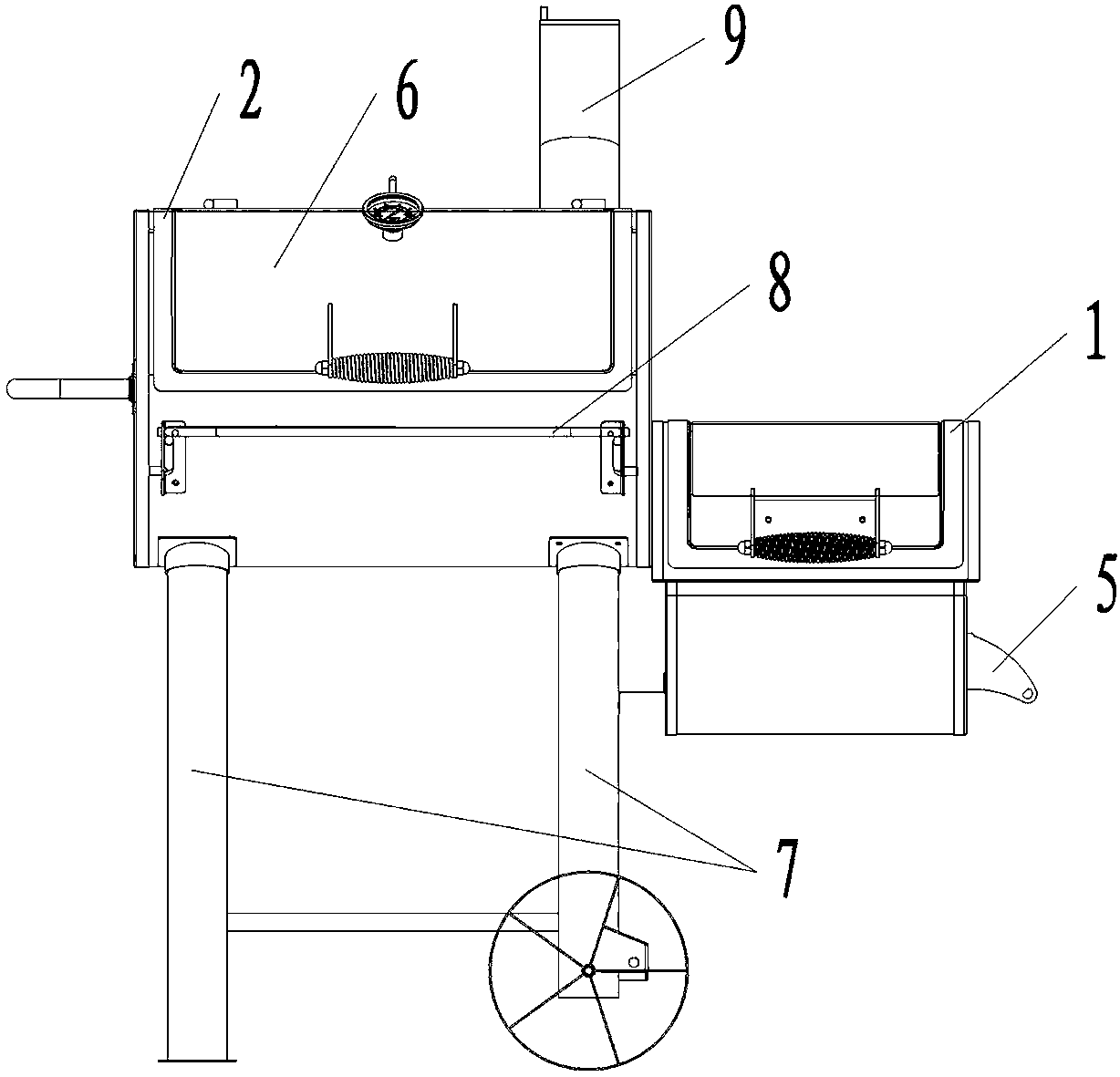

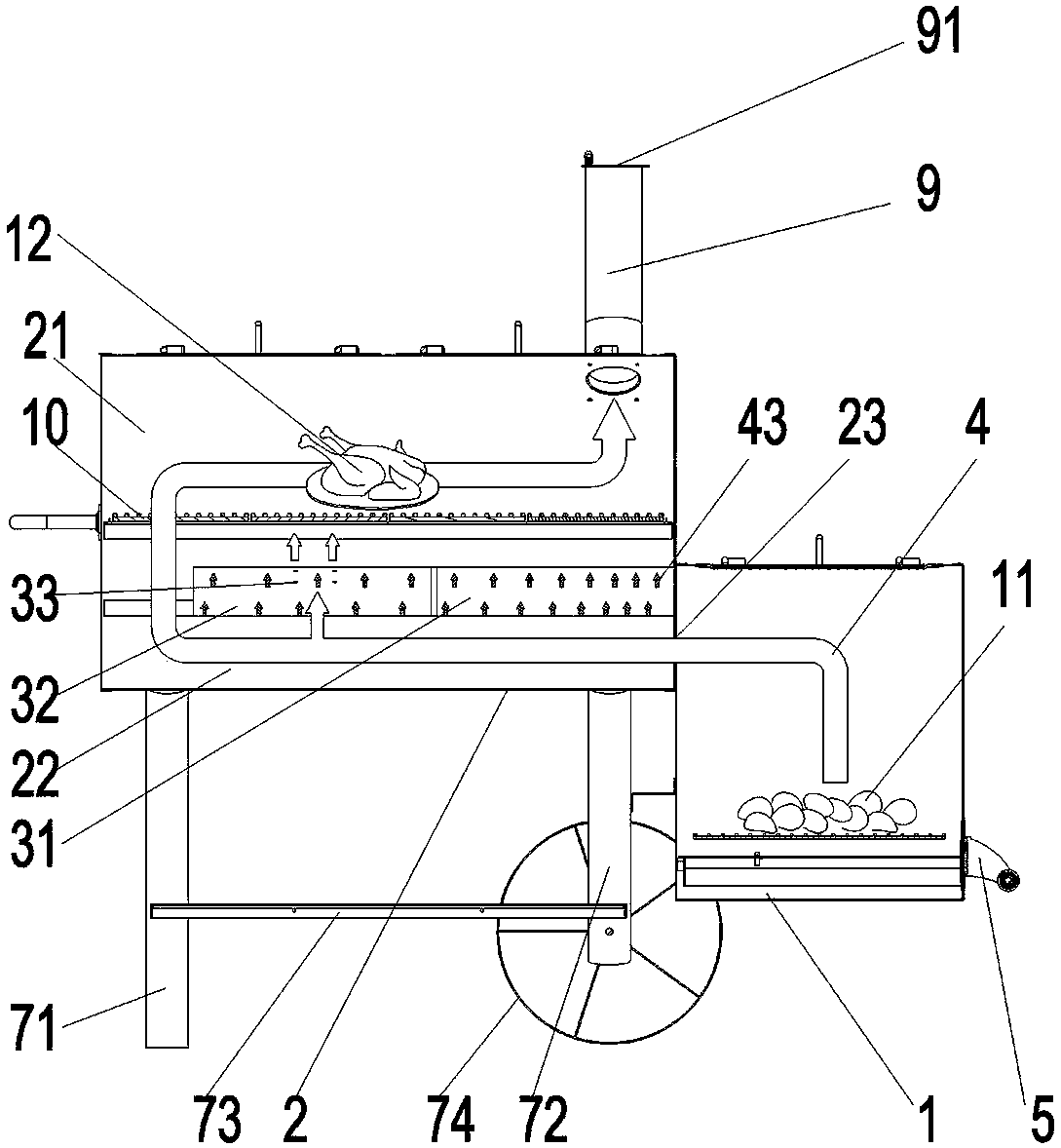

Fumigation equipment and its smoke baffle, flue

The invention discloses a barbecuing device and a smoke baffle plate as well as a flue thereof. The smoke baffle plate comprises a first smoke baffle sub-plate and a second smoke baffle sub-plate, wherein the first smoke baffle sub-plate and the second smoke baffle sub-plate are movably connected end to end; the flue comprises an upper cavity, a lower cavity and a smoke gas hole; a smoke gas flows through the lower cavity, the smoke gas hole and the upper cavity in sequence and flows in a C shape; the right end of the lower cavity is communicated with the top of a smoke gas generating furnace through a smoke gas inlet; the right end of the upper cavity is connected with an atmosphere through a chimney; the chimney and the smoke gas inlet are arranged at a same end. The smoke baffle plate and the flue are arranged in the barbecuing device; the barbecuing device also comprises a folding table-board, a rack, a drip-proof covering door and an ash receiving disc. By using the smoke baffle plate provided by the invention, temperatures at the two ends of the barbecuing device are balanced; the flue is increased by one time in length in comparison with the prior art; a barbecuing speed is quickened; the operation convenience is increased.

Owner:永康市东街五金机械有限公司

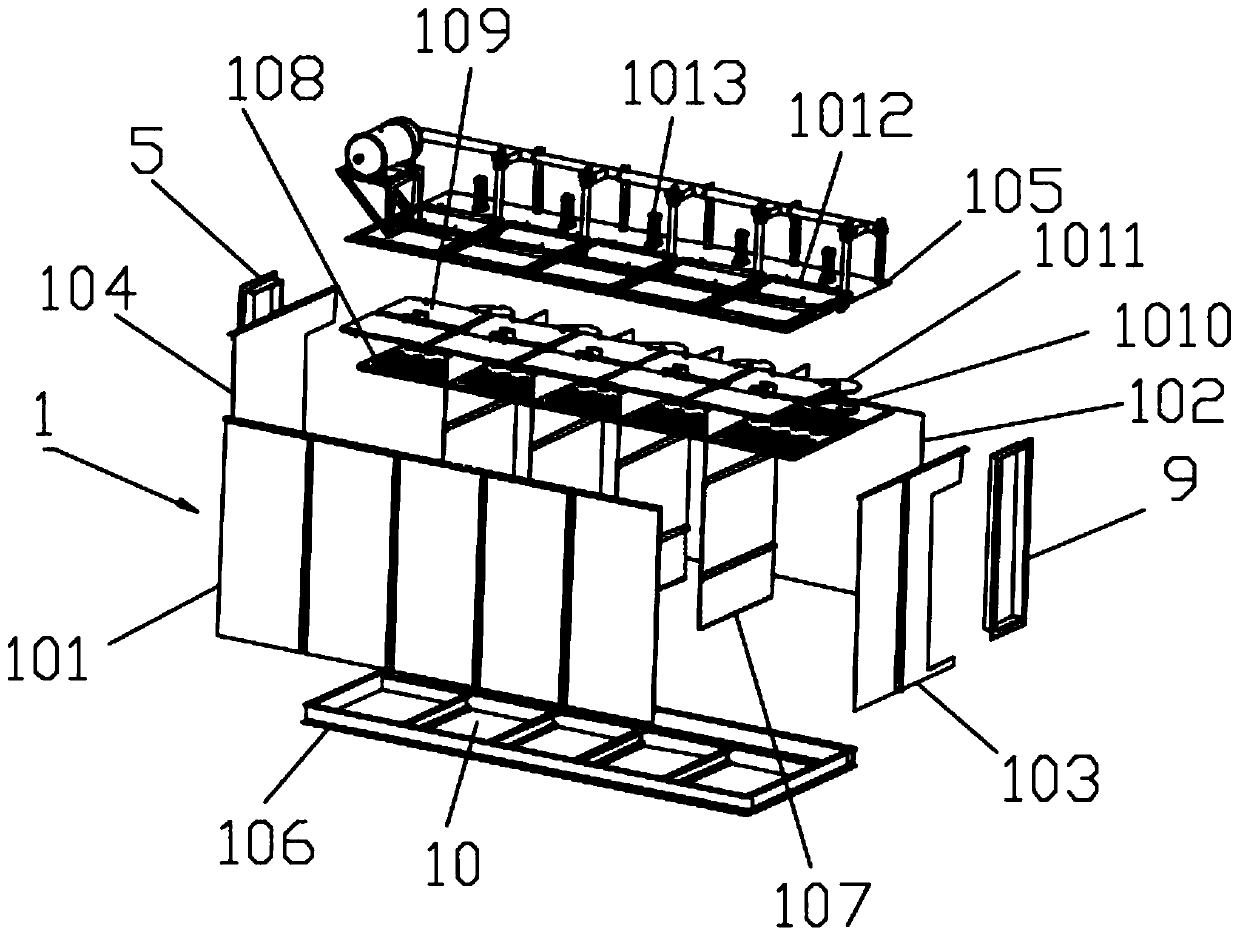

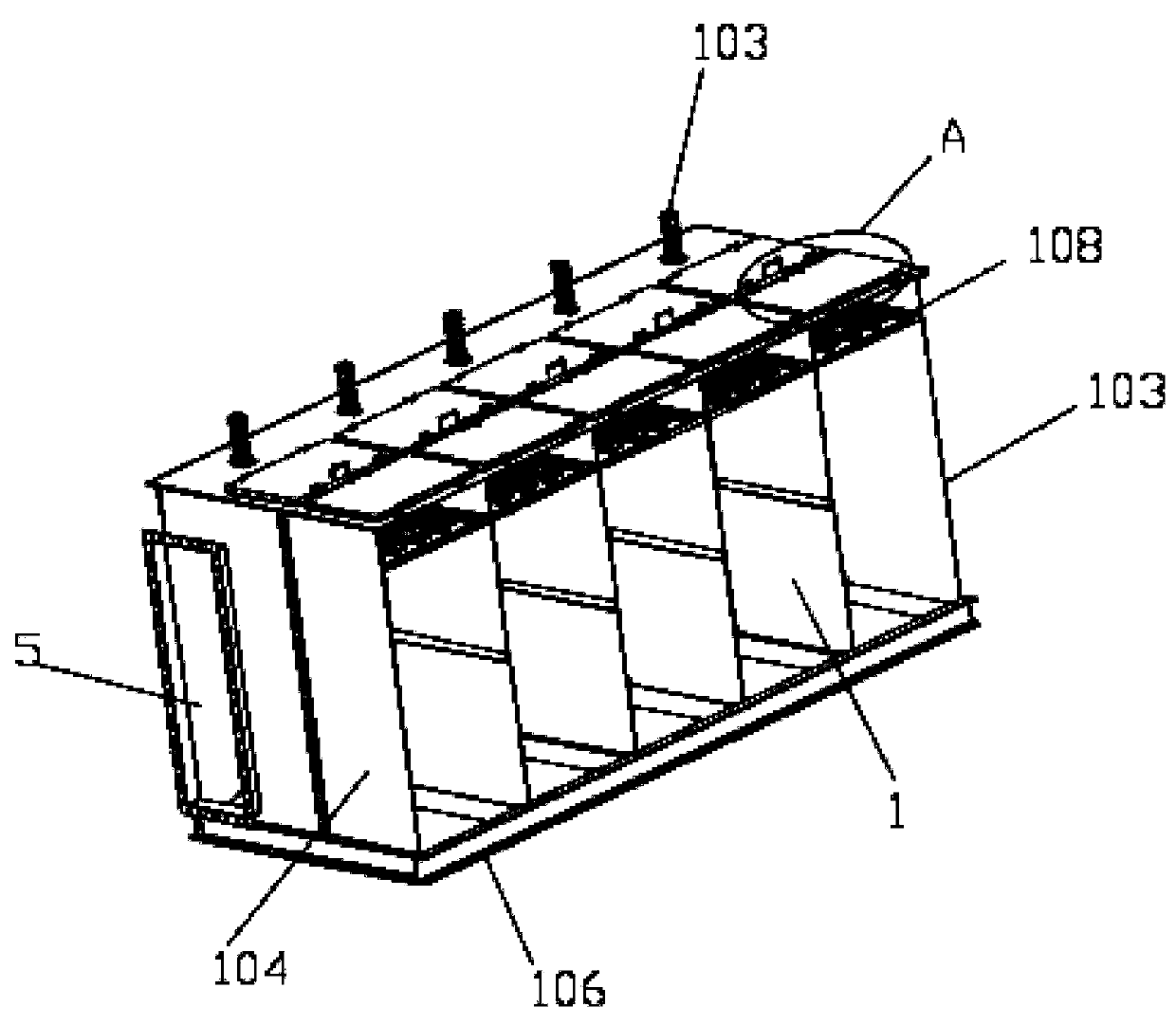

Cooling device for rice processing

PendingCN113019508AImprove cooling effectEnsure full accessDispersed particle filtrationGrain treatmentsAgricultural engineeringAgricultural science

The invention discloses a cooling device for rice processing in the technical field of rice processing equipment. The cooling device comprises a box body, supporting columns, a sliding mechanism, a discharging mechanism and an exhaust mechanism, the supporting columns are welded to four corners of the bottom of the box body, and the sliding mechanism is connected to the lower sides of inner cavities of the supporting columns in a sliding mode. According to the cooling device for the rice processing, the structure design is reasonable, the airflow blowing-in direction is changed while the airflow flowing speed is not reduced, the airflow makes full contact with rice, the cooling time of the rice is effectively shortened, a temperature sensor is arranged to detect the residual temperature in a rice pile, workers do not need to take out the rice and then detect the temperature, the actual operation steps of the rice cooling device are greatly reduced, then a one-way exhaust valve and a plate type filter element are used in cooperation, gas in the box body is exhausted, meanwhile, residual air in the box body is purified, the rice cooling efficiency is further improved, and meanwhile, impurities left on the surface of rice are effectively reduced.

Owner:安徽稼仙金佳粮集团股份有限公司

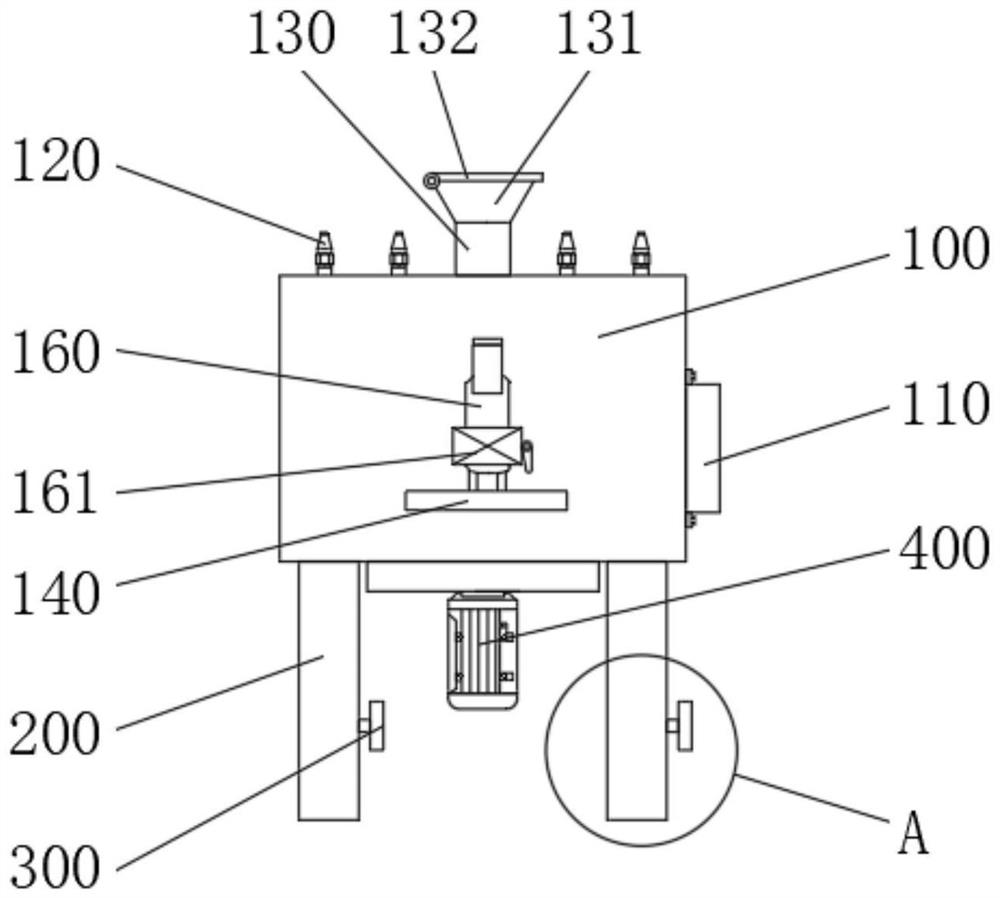

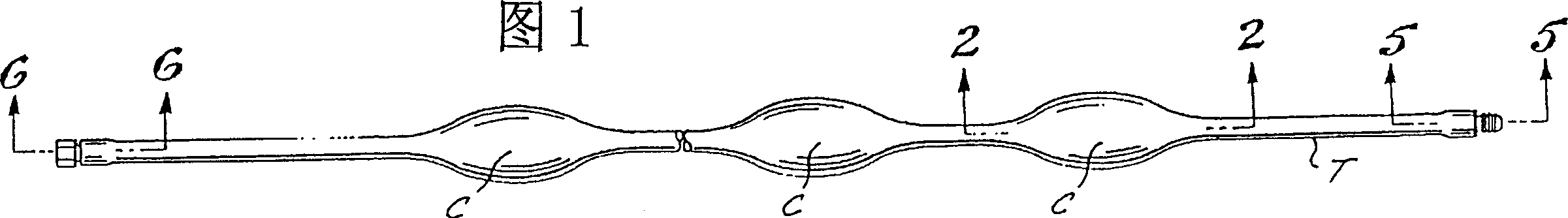

Assembly and container system for pressurized fluids and its manufacturing method and device

InactiveCN1107024CControl discharge rateReduce discharge rateAircraft componentsVessel mounting detailsEngineeringMechanical engineering

A container system for pressurized fluids that includes a plurality of generally ellipsoidal chambers connected by a tubular core. The tubular core is formed along its length with a plurality of apertures each of which is positioned within one of the chambers. The apertures are of comparatively small size so as to be able to control the rate of evacuation of pressurized fluid should a chamber be ruptured.

Owner:ECC SYST

A kind of rainwater overflow well in residential area green space with filtering and water storage functions

ActiveCN110541465BEasy to storePrevent precipitationFatty/oily/floating substances removal devicesSewerage structuresWater storageFiltration

The invention relates to the field of environmental protection, in particular to a rainwater overflow well in residential areas with functions of filtering and storing water. The inner lower end of the well is provided with a filter cover, the filter cover is provided with a filter screen, the filter screen is provided with a drain outlet, the drain outlet is provided with a baffle plate, the left side of the filter cover is provided with a first opening, and the left side of the first opening is A connecting frame is provided, connecting ears are arranged at the front and rear ends of the upper side of the connecting frame, a steel wire rope is arranged on the upper side of the connecting ears, a second opening is arranged at the upper end of the water storage well, a connecting seat is arranged at the upper left end of the second opening, and the inner upper end of the connecting seat A rotating shaft is installed, and the rear side of the rotating shaft is connected with the servo motor through a bearing seat. Take-up rollers are respectively installed at the front and rear ends of the rotating shaft, and steel wire ropes are wound on the take-up rollers. This invention can effectively store and filter rainwater, which is convenient for filtering discharge of impurities.

Owner:易晓艳

The lowering method of the steel casing

ActiveCN110616711BControl discharge rateIncreased lifting capacityBulkheads/pilesMechanical engineeringHoist device

The invention provides a method for lowering a steel casing and relates to the technical field of steel casing hoisting. The method includes: step 1, supporting the steel casing on a steel platform, the top of the steel casing is sealed with a pressure bearing plate, and the bottom of the steel casing is blocked by an external medium, so that the inside of the steel casing forms a Closed lumen; step 2, pass gas into the lumen until the air pressure in the lumen P 1 Reach the preset value; step 3, release the support to the steel casing; step 4, control the discharge speed of the gas in the inner cavity, so that the steel casing can be lowered. The lowering method of the steel casing adopted in the present invention is to form a closed cavity inside the steel casing by closing the two ends of the steel casing, and then pass the gas in the cavity until P i When the preset value is reached, the pressure bearing plate on the top of the steel casing is under upward pressure, which can offset part or all of the gravity of the steel casing itself, thereby increasing the hoisting capacity of the hoisting equipment.

Owner:CCFEB CIVIL ENG

Boiler device with self-blowdown structure

PendingCN114294640AEasy to drainControl discharge rateBoiler cleaning apparatusEngineeringMechanical engineering

The invention is suitable for the technical field of boilers, and provides a boiler device with a self-pollution-discharge structure, which comprises a base, a boiler body is arranged on the top surface of the base, a box body is arranged on the top surface of the boiler body, a partition plate is arranged in the boiler body, the top of the partition plate penetrates through the top surface of the boiler body and extends into the box body, and the bottom of the partition plate is provided with a water inlet. A partition plate is arranged at the top of the box body, a transverse plate is arranged at the top of the partition plate, a threaded rod is arranged at one end of the transverse plate in a penetrating mode, and the threaded rod is rotationally connected with the top face and the bottom face of the box body. According to the boiler, pollution discharge can be conveniently carried out, the discharge rate can be conveniently controlled, the sealing performance between the boiler body and the outside is guaranteed through multiple measures, use is convenient, and the use effect of the boiler is greatly improved.

Owner:无锡锡成锅炉有限公司

Grain discharge system for grain dryer

ActiveCN109911660BSpeed up opening and closing timesIncrease the feeding speedDrying gas arrangementsDrying chambers/containersMetallurgyAgricultural engineering

The invention belongs to the field of grain processing equipment, and particularly relates to a grain discharging system for a grain drying machine. The problems that the function of an existing graindischarging mechanism is single, grains which are stacked together cannot be completely dried, the grains cannot be filtered while the grains are discharged, and the grain quality is influenced are solved. The grain discharging system comprises a collecting base, wherein two side plates are welded to the top of the collecting base, a same drying machine is welded to one sides, close to each other, of the two side plates, a fixing box is fixedly installed in a discharging hole of the drying machine, a blocking ball is movably installed in the fixing box, and the discharging hole is formed in the inner wall of the bottom of the fixing box. The grain discharging system is simple in structure and convenient to operate; and the grain discharging mechanism is rich in function, the discharging speed of the grains can be controlled, different processing requirements can be met, the grains can be dried again when the grain discharging mechanism is discharged, the grain can be filtered and screened while the grains are discharged, debris and impurities mingled in the grains can be filtered out, and the production quality of the grains is improved.

Owner:际华(芜湖)农业科技发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com