Logistics loading and unloading operation equipment based on intelligent rail transportation device

A technology for rail transportation and operating equipment, which is applied in the directions of transportation and packaging, loading/unloading, and conveyor objects, etc. It can solve the problems of inconvenient classification and classification of loading and unloading goods, single discharge place, single transportation mode, etc., so as to facilitate classified transportation Product, the effect of changing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

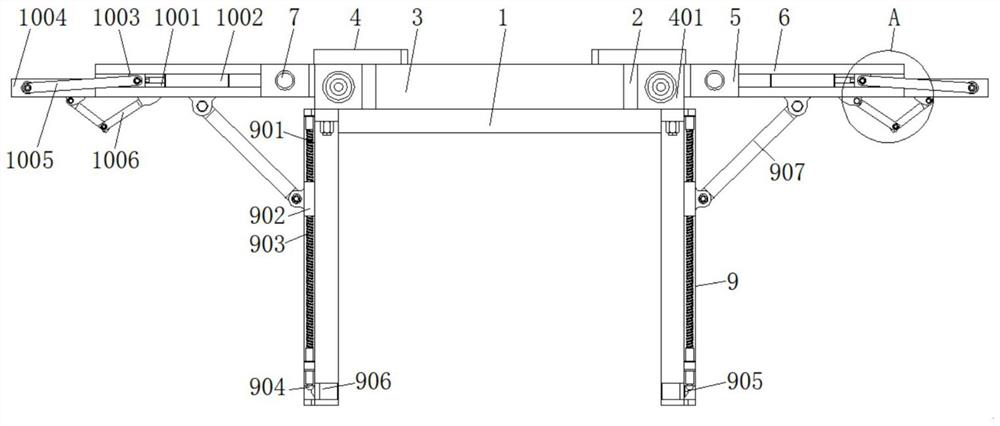

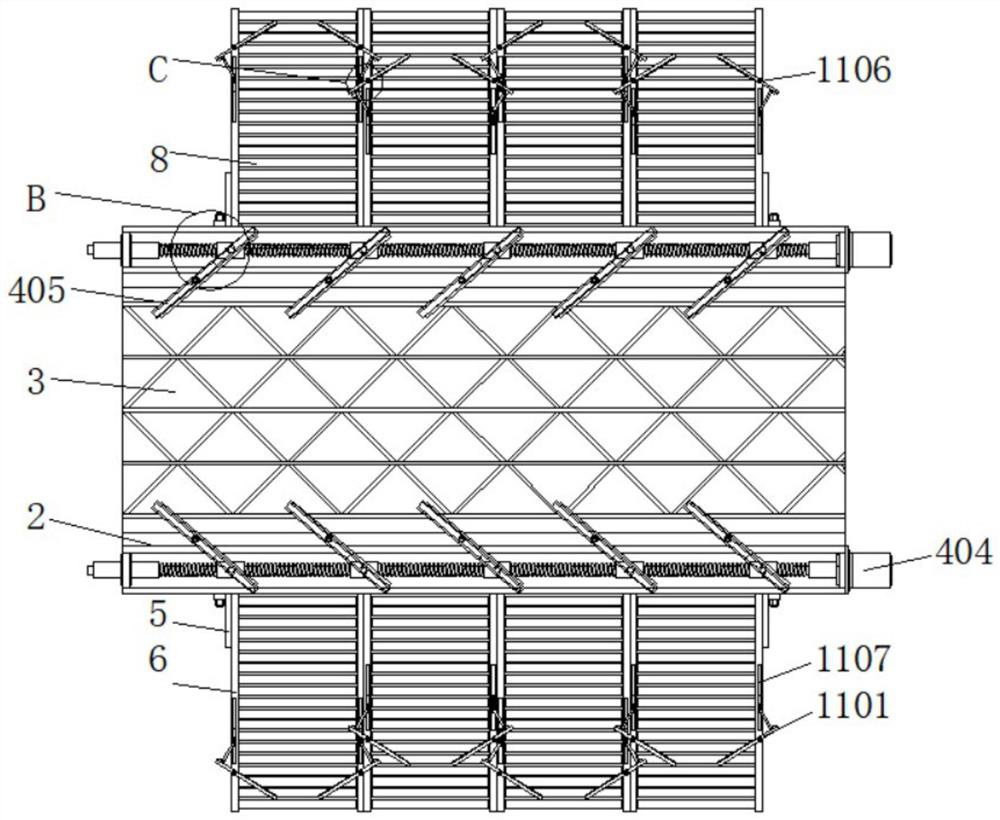

[0032] Such as figure 1 and figure 2 As shown, this embodiment proposes a logistics loading and unloading operation equipment based on an intelligent rail transport device, including a fixed support frame 1, a stand 2 installed on the fixed support frame 1, and a sorting mechanism installed at both ends of the stand 2 4. A conveyor belt 3 is provided on the platform 2, and two L-shaped fixing plates 5 are installed on the side far away from the platform 2 of the sorting mechanism 4, and several connecting frames 6 are arranged between the fixing plates 5, and the connecting frames 6 pass through The cooperation between the fixed plate 5 and the fixed shaft 7 is connected to the sorting and shifting mechanism 4, and the products on the conveyor belt 3 can be sorted and transferred to the rollers 8 of the connecting frame 6, which can be used for sorting and transporting different products. The connecting frame 6 and the connection of the fixed plate 5 are pierced with a fixed...

Embodiment 2

[0034] The solution in Embodiment 1 will be further introduced in combination with specific working methods below, see the following description for details:

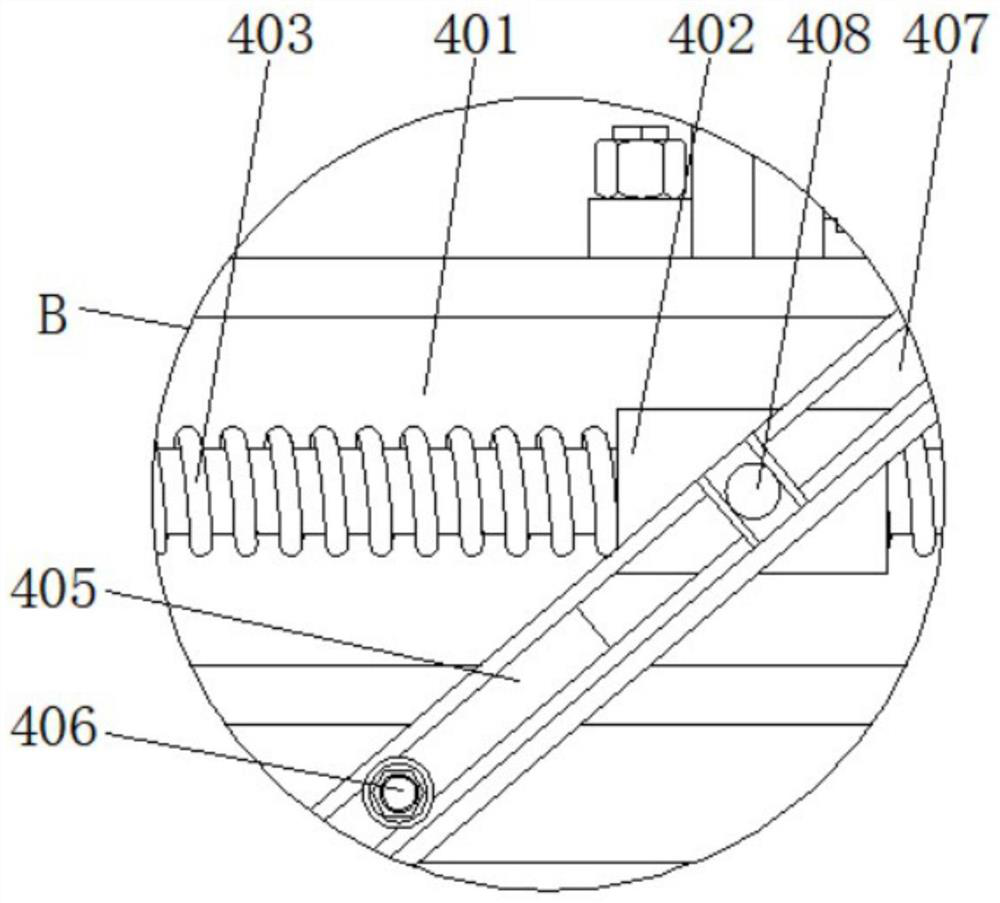

[0035] Such as figure 1 , figure 2 and image 3 As shown, as a preferred embodiment, on the basis of the above method, further, the classification dial mechanism 4 includes a fixed groove frame 401, a screw guide post 402, a lateral adjustment screw 403, a screw motor 404, and a driving rod 405 , fixed pin rod 406, limit notch 407 and limit rod 408, is provided with horizontal adjustment screw rod 403 in the fixed groove frame 401, and the axial direction of horizontal adjustment screw rod 403 is provided with several screw rod guide posts 402, and The rod guide post 402 is provided with a driving rod 405 corresponding to the screw guide post 402 one by one, and the driving rod 405 is pierced with a fixed pin rod 406, and the driving rod 405 is movably connected on the stand 2 through the fixed pin rod 406. A limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com