Polishing pads and chemical mechanical polishing equipment

A polishing pad and polishing layer technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding tools, etc., can solve the problems of wasting polishing liquid, reducing the utilization rate of polishing liquid, and destroying, so as to control the residence time and maintain excellent Performance, the effect of maintaining the polishing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

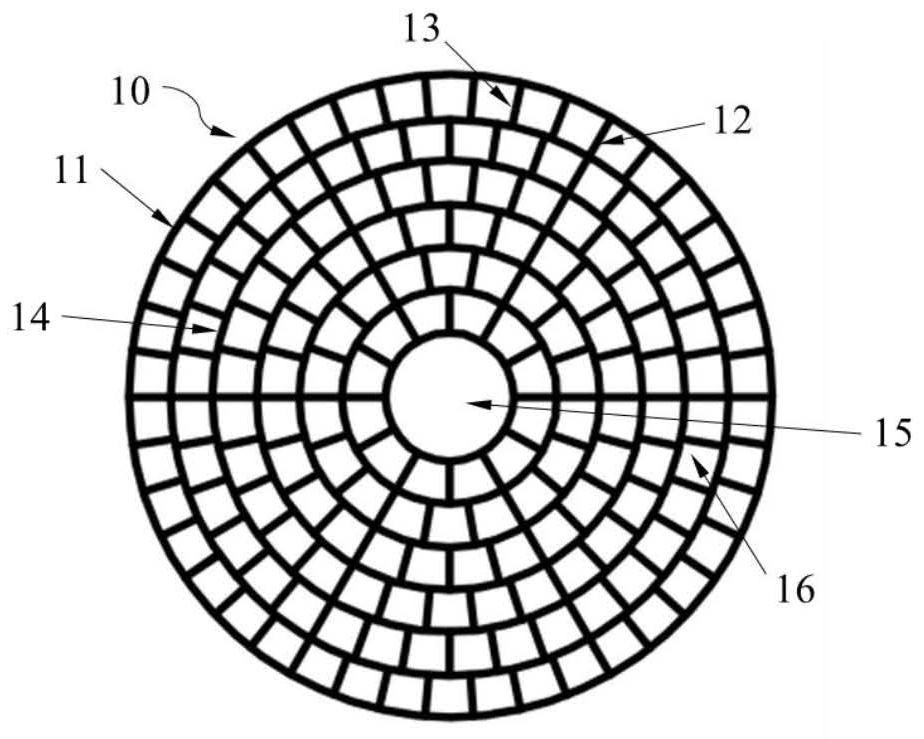

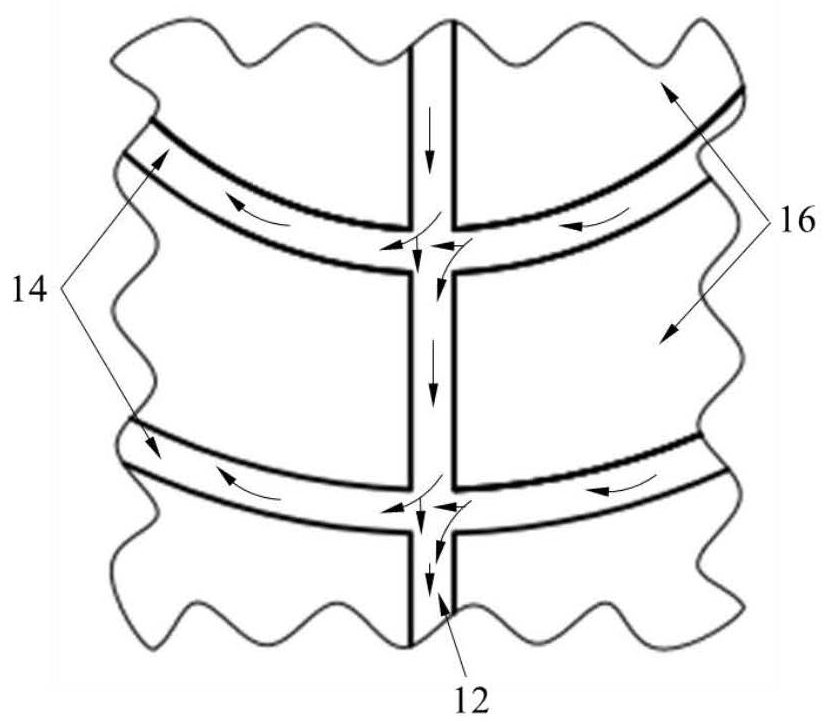

[0090] This example figure 1 with Figure 2a As shown, the polishing pad 10 includes a substrate layer and a polishing layer, and the polishing layer includes at least three circumferential grooves 14 arranged in sequence from the center 15 to the circumference 11 along the circumferential direction and a first radial groove 14 arranged along the radial direction. Groove 12 and second radial groove 13; Described first radial groove 12 connects circle center 15 and circumference 11, divides the area 16 between circle center 15 and circle 11 into circle sectors, the number of circle sectors Equal to the number of grooves of the first radial groove 12; said circle sector divides the polishing zone 16 between the adjacent circumferential grooves 14 evenly with an arithmetic progression from the center 15 to the circumference 11, forming a second diameter groove 13, the second radial groove 13 evenly divides the area between the k-1th circumferential groove and the kth circumferen...

Embodiment 2

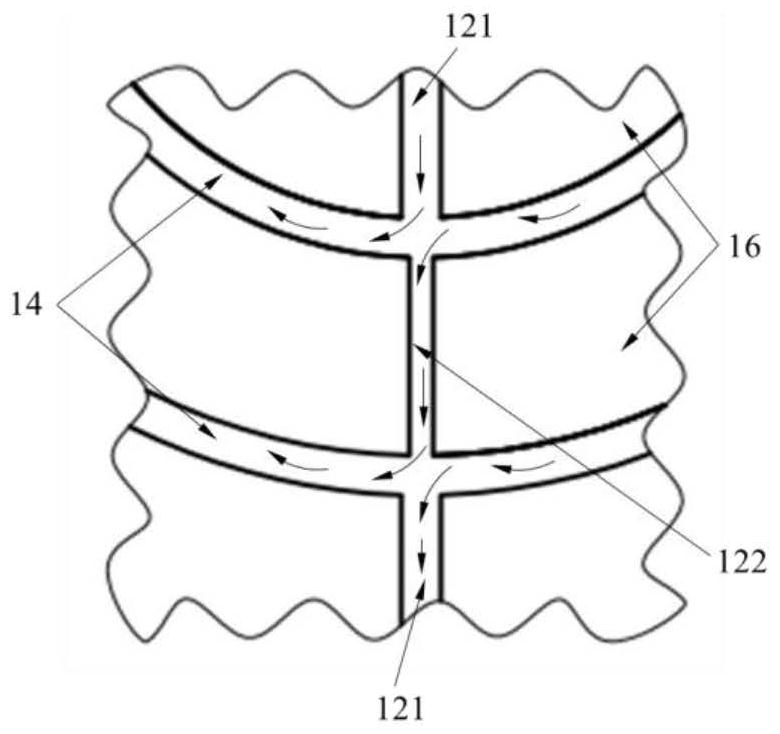

[0093] This embodiment is based on Embodiment 1, changing the width of the first radial groove 12, and dividing the first radial groove 12 into the first radial groove wide groove 121 and the first radial groove narrow groove 122, the first radial groove wide groove 121 and the first radial groove narrow groove 122 appear alternately along the radial direction as Figure 2b As shown, the width of the wide groove 121 of the first radial groove is equal to the width of the circumferential groove 14, and the width of the wide groove 121 of the first radial groove is greater than that of the narrow groove 122 of the first radial groove width. Dividing the first radial groove 12 into wide grooves and narrow grooves and alternately distributing them along the radial direction is beneficial to control the speed at which the polishing liquid flows out along the first radial groove 12, promotes uniform distribution of the polishing liquid as a whole, and maintains a stable polishing en...

Embodiment 3

[0095] This example image 3As shown, the polishing pad 210 includes a substrate layer and a polishing layer, and the polishing layer includes at least three circumferential grooves 214 arranged in sequence from the center 215 to the circumference 211 along the circumferential direction and a second radial groove 214 arranged along the radial direction. Groove 213, the second radial groove 213 from the center of circle 215 to the circumference 211 in an equiproportional sequence gradually increases and evenly divides the polishing zone 216 between adjacent circumferential grooves 214 and connects with the outer radial direction of the circumferential groove 214 The second radial groove 213 is evenly distributed on both sides of the inner second radial groove 213, the width of the circumferential groove 214 is equal to the width of the second radial groove 213 in the radial direction, and the second radial groove 213 The area between the k-1th circumferential groove and the kth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com