Assembly and container system for pressurized fluids and its manufacturing method and device

A pressurized fluid and container technology, applied in the installation device of the container structure, the manufacture of the container structure, the geometry/arrangement/size of the container structure, etc., can solve the problem of not having burst resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Detailed description of the preferred embodiment

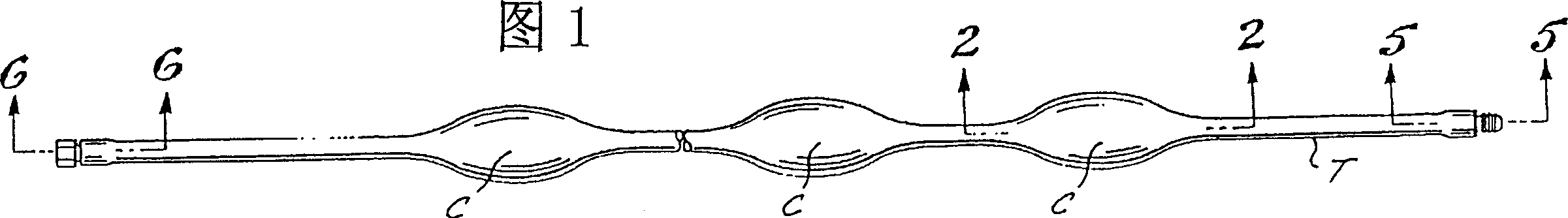

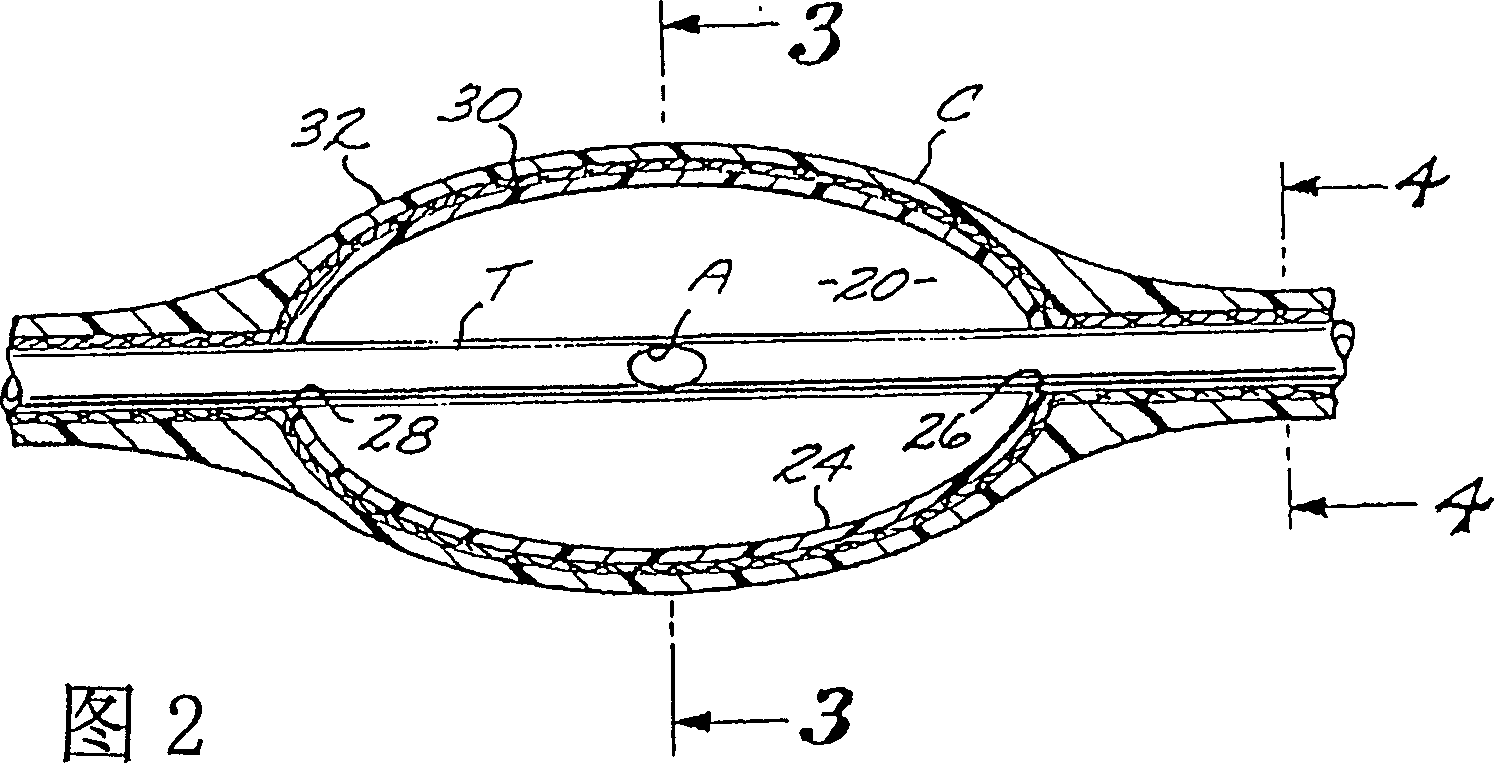

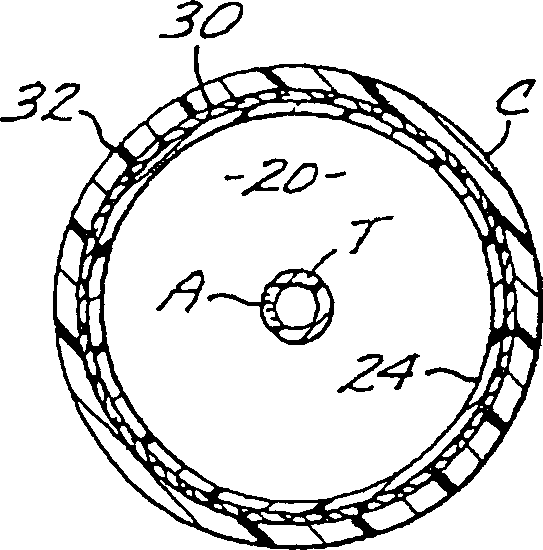

[0027] Referring to the drawings, and in particular FIGS. 1-6, a pressurized vessel system embodying the invention includes a plurality of conformal, generally elliptical chambers C and tube cores T coaxially and hermetically secured to the chambers. C on. The die T is provided with a plurality of longitudinally equidistantly spaced holes A which communicate with the fluid conveyed within the interior 20 of each cavity C along its length. The size of the holes A is selected to control the rate of discharge of the pressurized fluid from the chamber C such that a very low rate of fluid discharge can be produced thereby avoiding large and potentially energy leaks when one or more chambers C are perforated, explosion occurs.

[0028] Referring now to Figures 2 and 3, each chamber C includes a generally oval shell 24 molded from a suitable synthetic plastic having open front and rear ends 26 and 28 . Holes 26 and 28 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com