The lowering method of the steel casing

A steel casing and steel platform technology, applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of increased cost and high rental cost of large-scale hoisting equipment, and achieve the effect of increasing hoisting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

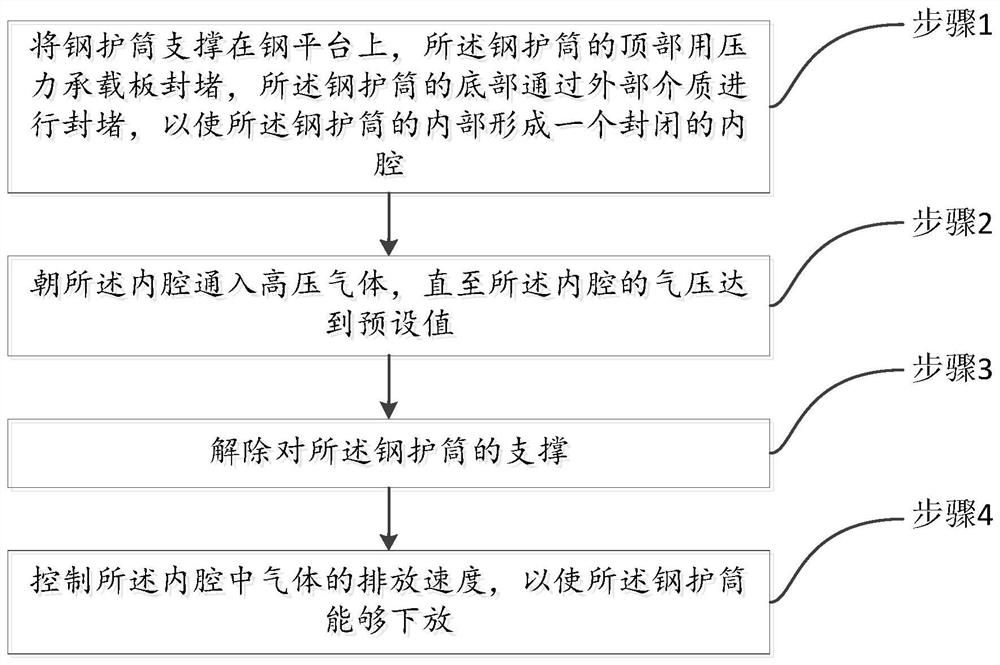

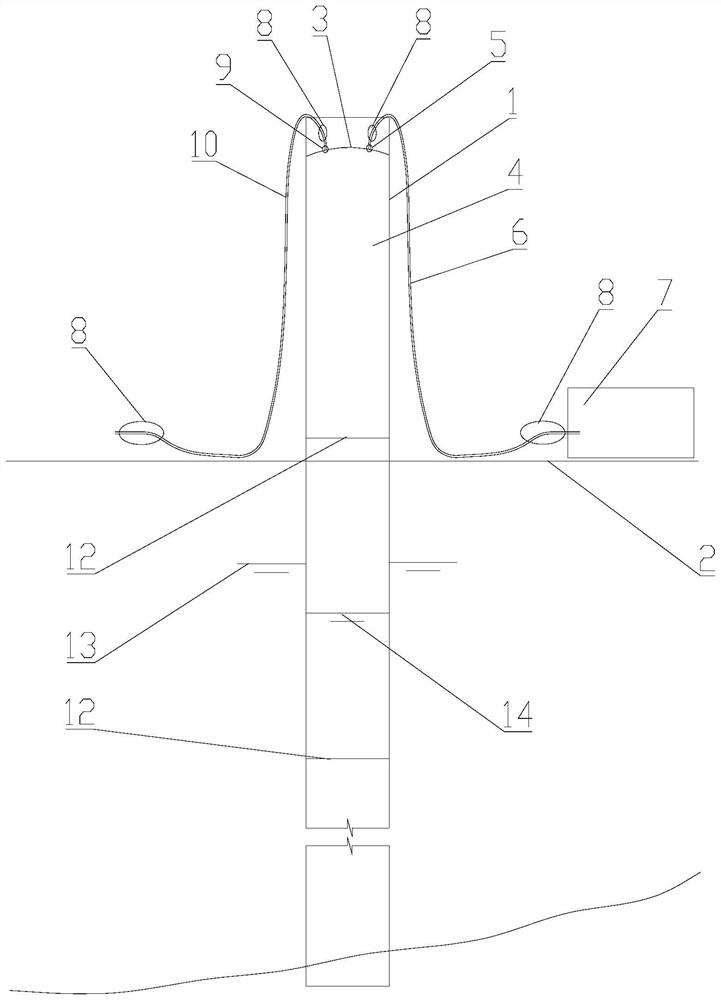

[0044] Please refer to figure 1 and figure 2 , the present embodiment provides a method for lowering the steel casing 1, which includes the following steps:

[0045] Step 1, supporting the steel casing 1 on the steel platform 2, the top of the steel casing 1 is sealed with a pressure bearing plate 3, and the bottom of the steel casing 1 is blocked by an external medium, so that the A closed cavity 4 is formed inside the steel casing 1 .

[0046] The method provided in this embodiment is used to lower the steel casing 1. First, the steel casing 1 needs to be supported on the steel platform. The specific support method can be that the steel casing 1 is directly welded on the steel platform 2, or it can be connected A support 11 welded on the steel platform 2 is fixedly connected; after the steel casing 1 is supported on the steel platform 2, the end near the top of the steel platform 2 is the top of the steel casing 1, and the end near the bottom of the steel platform 2 It i...

no. 2 example

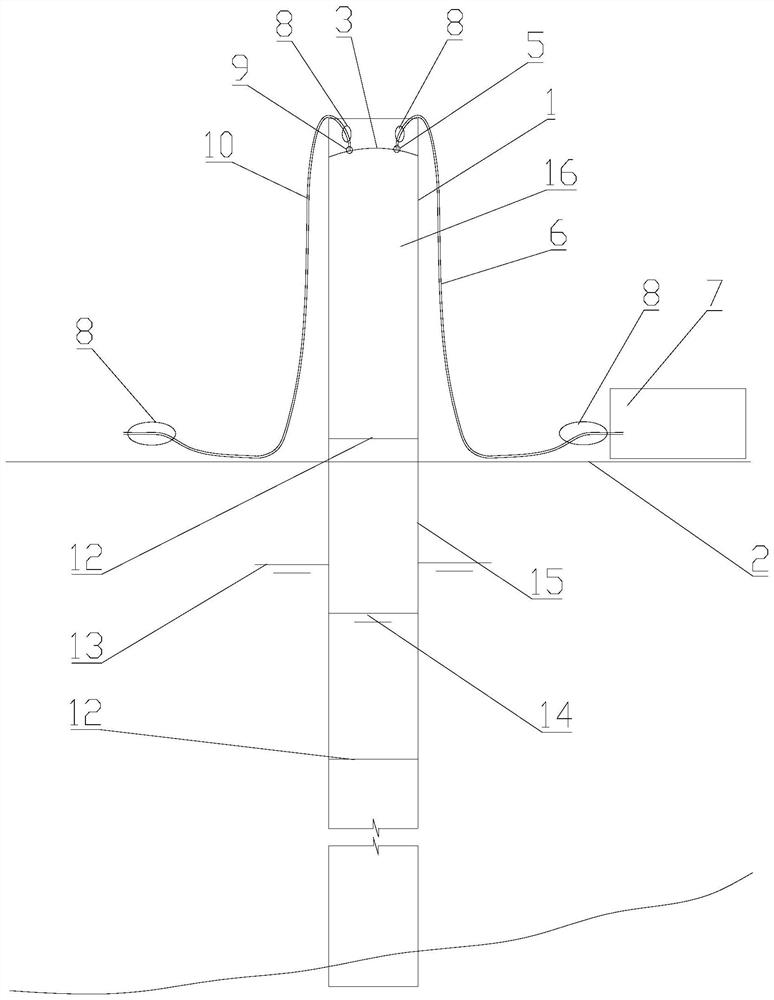

[0075] Please refer to image 3 , the present embodiment provides a method for lowering a steel casing, which is applied to lowering a multi-section steel casing by a crane with limited lifting capacity. Assuming that the lifting capacity of the crane is n steel casings, the first n steel casings are lowered in the original way, and the first embodiment is adopted from the n+1th steel casing 16 to the n+ith steel casing The method for lowering the steel casing is provided, so the method for lowering the steel casing in the first embodiment also belongs to this embodiment, and will not be repeated here.

[0076] The lowering method of the front n section steel casing comprises the following steps:

[0077] Step 1, measurement and setting out: accurately set out the position of the steel casing on the steel platform 2.

[0078] Step 2, install the guide frame: fix the guide frame on the steel platform 2.

[0079] Step 3, lowering the first section of steel casing: the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com