Processing device for tea leaves

A processing device and tea technology, applied in tea treatment before extraction, etc., can solve problems such as poor slitting effect, loose tea strips, impossibility of infinite length of barrel wall, etc., and achieve easy control, uniform degree, and guaranteed appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

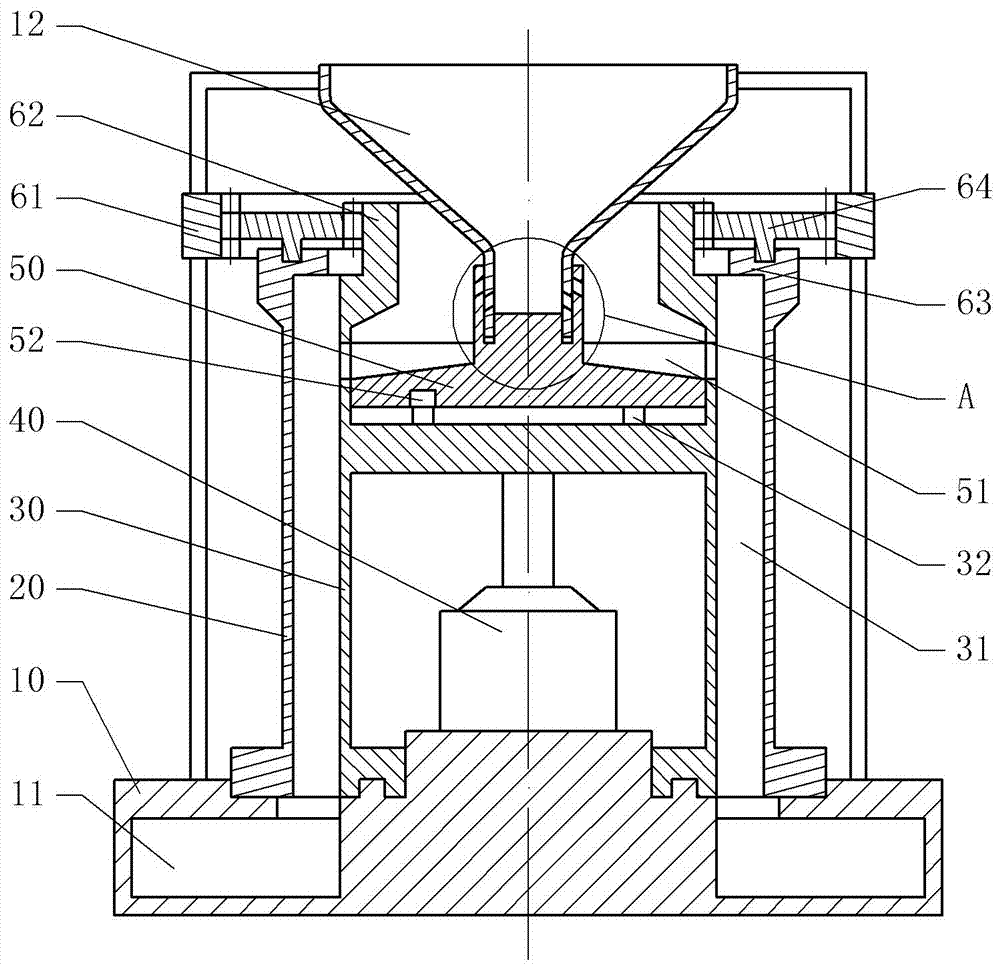

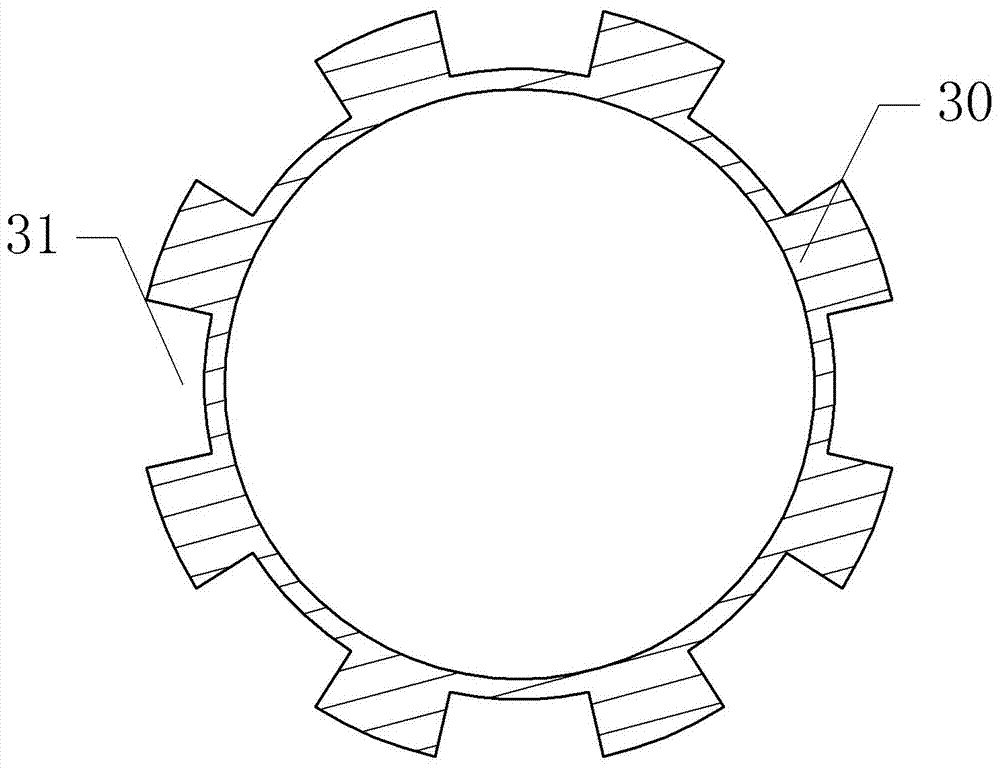

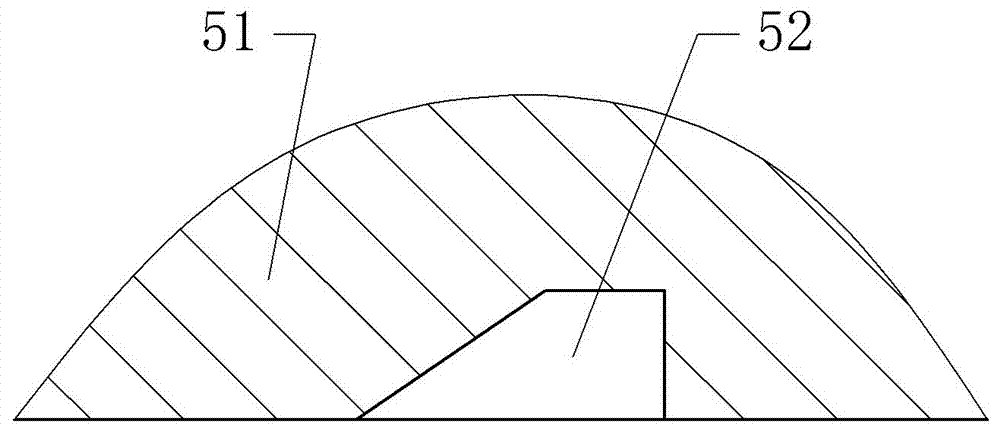

[0022] The reference numerals in the drawings of the description include: frame 10, collecting tank 11, feed hopper 12, material guiding cylinder 13, first discharge port 14, strip tube 20, kneading cylinder 30, kneading tank 31, wedge Block 32, drive motor 40, feed tray 50, feed trough 51, wedge groove 52, batching cylinder 53, second discharge port 54, ring gear 61, sun gear 62, planetary gear carrier 63, planetary gear 64.

[0023] The embodiment is basically as figure 1 , figure 2 , image 3 with Figure 4 Shown:

[0024] The tea processing device of the present embodiment includes a frame 10 , a sliver cylinder 20 , a kneading cylinder 30 , a feed hopper 12 , a feed tray 50 , a collection tank 11 and a driving motor 40 . The canister 20 and the kneading cylinder 30 are vertically arranged, the canister 20 is sleeved on the outside of the kneading canister 30, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com