A kind of tea processing method

A processing method and tea technology, applied in the field of tea processing technology, can solve the problems of loose tea sticks, impossible infinite length of the barrel wall, poor strip arrangement effect, etc., and achieve the effect of ensuring the appearance and the degree of uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

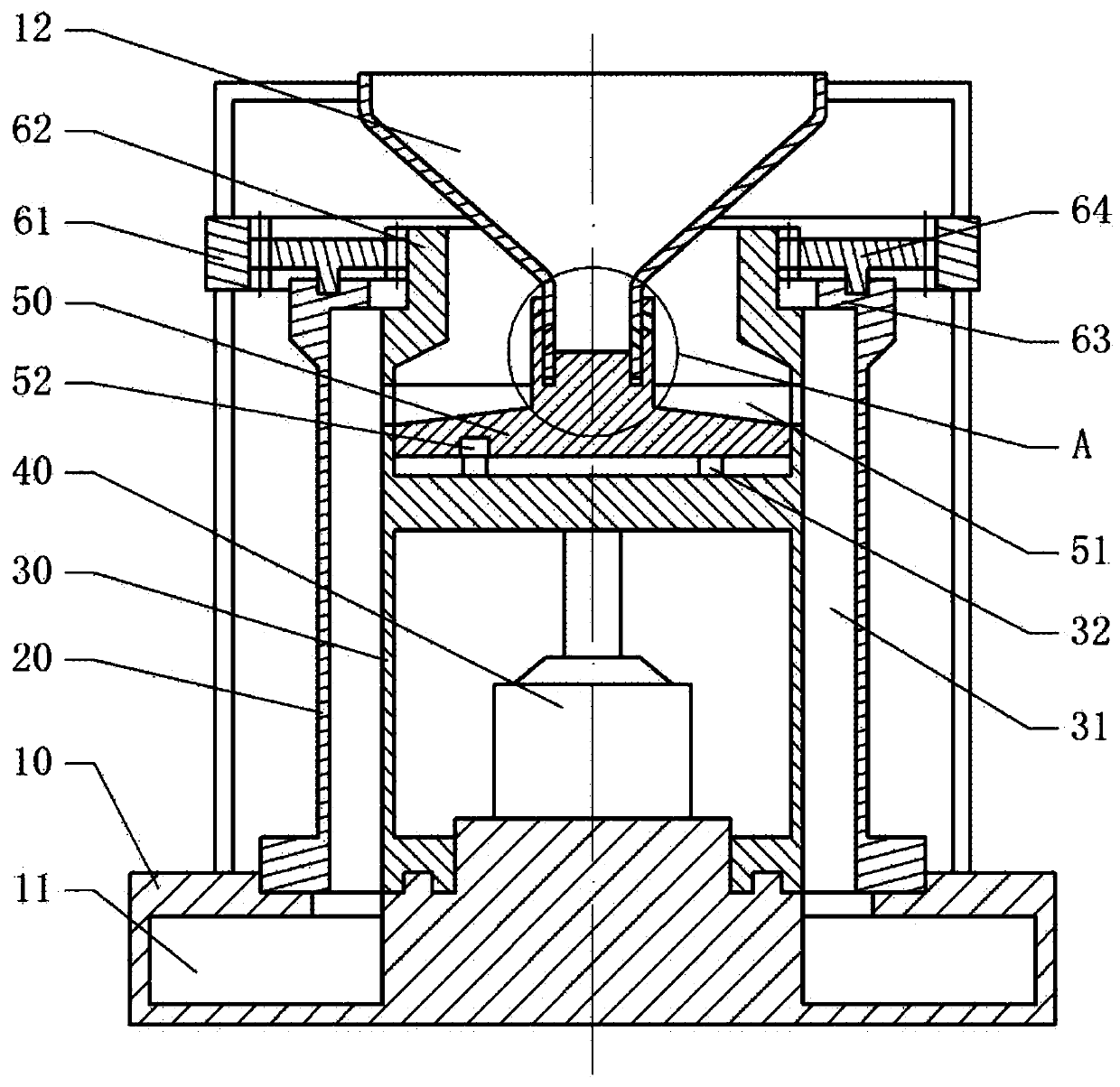

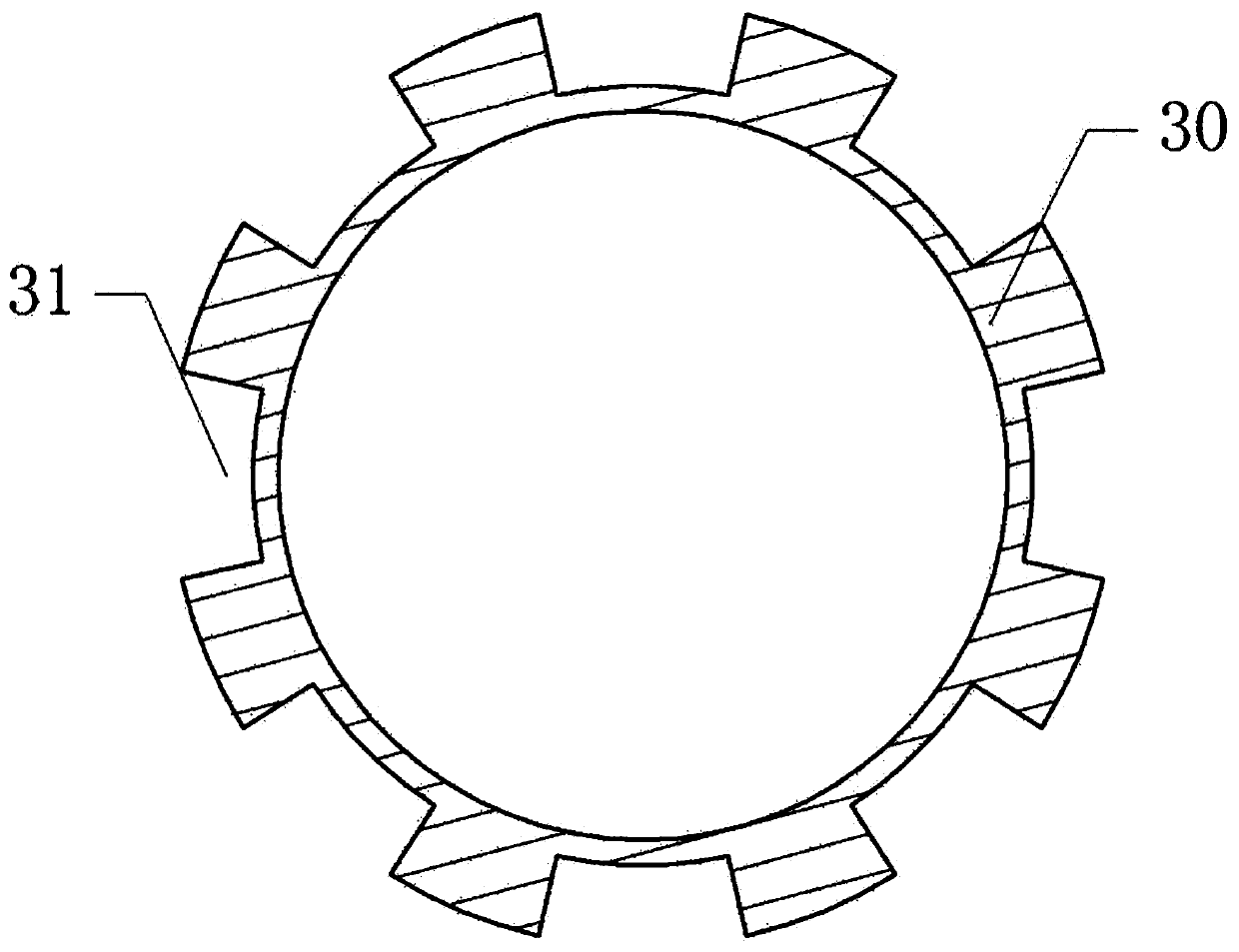

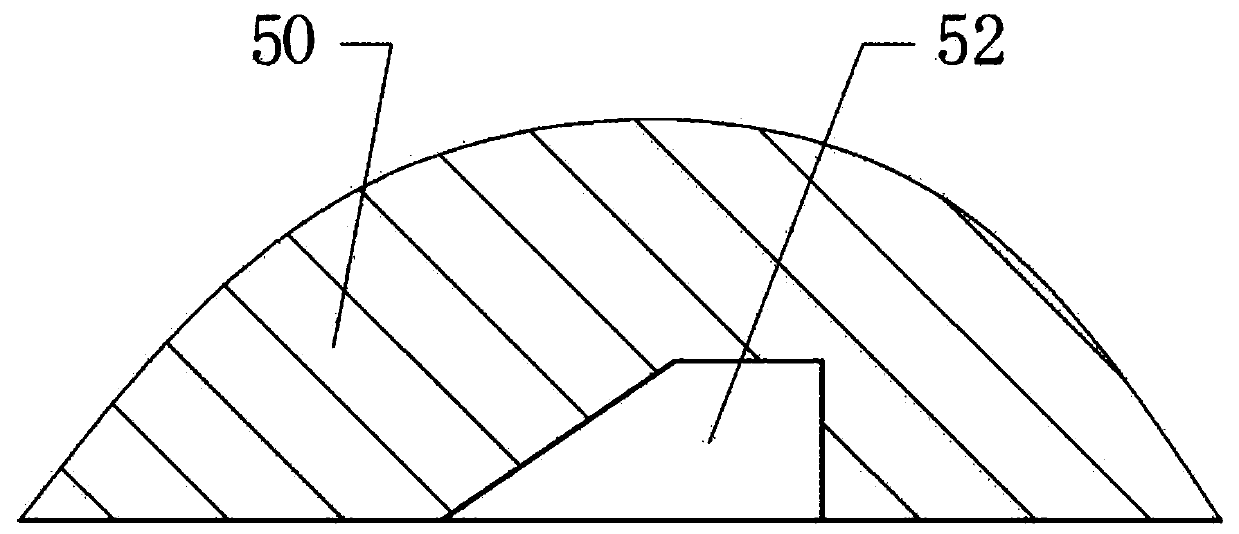

[0031] The tea processing method of the present embodiment adopts a tea stripping machine to strip the tea leaves. Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the tea carding machine includes a frame 10, a carding tube 20, a kneading tube 30, a feeding hopper 12, a feeding tray 50, a collection tank 11 and a driving motor 40. The strip tube 20 and the kneading tube 30 are vertically arranged, and the inner diameter of the strip tube 20 is 1.2m, and the strip tube 20 is sleeved on the outside of the kneading tube 30, and the strip tube 20 and the kneading tube 30 are all rotatably connected to the frame 10 Above, the outer circumference of the kneading cylinder 30 is attached to the inner wall of the slitting cylinder 20, and the driving motor 40 drives the slitting cylinder 20 and the kneading cylinder 30 to rotate in the same direction through a transmission mechanism. The transmission mechanism is a planetary gear 64 system, which is composed of a su...

Embodiment 2

[0044] The difference between the second embodiment and the first embodiment is that the tea slitting machine in the second embodiment is not provided with a transmission mechanism, the drive motor includes a first drive motor and a second drive motor, and the kneading drum is driven by the first drive motor, while the rationale The can is driven by a second drive motor, so that by controlling the first drive motor and the second drive motor respectively, the rotation direction and speed difference of the kneading can and the can can be controlled. In addition, in the second embodiment, the feeding tray is connected with a vibrator, and the vibrator can drive the feeding tray to vibrate up and down, and the vibration frequency of the feeding tray can be changed by changing the frequency of the vibrator.

[0045] In the present embodiment, the tea strips include the following steps:

[0046] (1) Connect the electromagnetic heating coil to the power supply, and heat the canister...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com