Tea leaf strip tidying device

A technology of tea stripping and tea, which is applied in the field of tea stripping devices, which can solve problems such as poor stripping effect, impossibility of infinitely long barrel wall, loose tea strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below by specific embodiments:

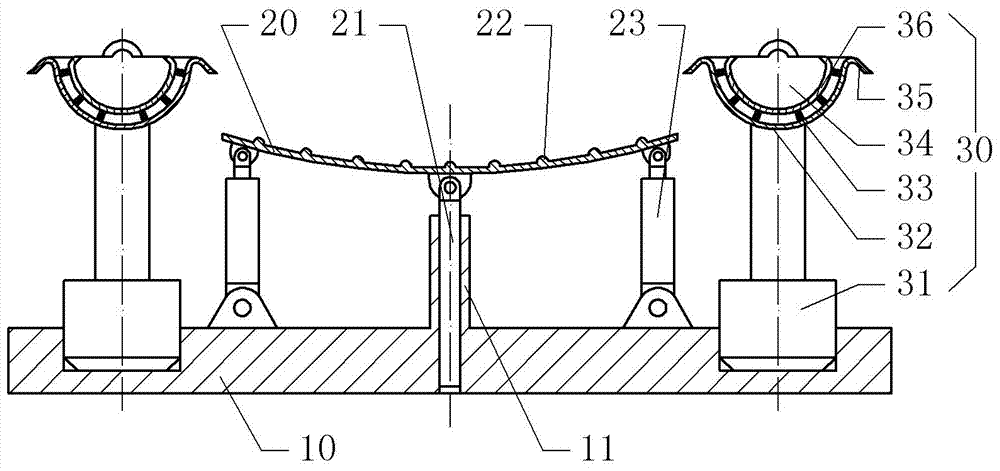

[0017] Reference numerals in the accompanying drawings include: frame 10, sliding cylinder 11, strip-arranging table 20, sliding rod 21, arc-shaped ridges 22, air cylinder 23, kneading and pressing mechanism 30, frame body 31, kneading and pressing groove 32, Brush 33 , collecting trough 34 , arc-shaped lug plate 35 , rubbing shaft 36 .

[0018] The example is basically as figure 1 shown:

[0019] The tea strip sorting device of this embodiment includes a frame 10, a strip sorting table 20, a kneading and pressing mechanism 30, a driving mechanism and a heating mechanism; The sliding cylinder 11 and the sliding rod 21 are slidably connected to the sliding cylinder 11 , so that the sliding rod 21 is vertically slidably connected to the rack 10 . The frame 10 is provided with air cylinders 23 corresponding to both ends of the rule table 20 . When the two cylinders 23 expand and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com