Processing method of tippy tea, and tippy tea

A processing method and technology of Maojian tea, which are applied to the processing method of Maojian tea and the field of Maojian tea, can solve the problems of difficult dissolution of brewed tea, long processing cycle, less material degradation, etc., and achieve the effects of reducing the broken broken rate and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A processing method of Maojian tea, comprising the following steps:

[0030] (1) Harvesting: picking tea greens with one bud and one leaf at the beginning or one bud and one leaf at the beginning or one bud and two leaves at the beginning of development without insect damage, fat and hairy tea buds;

[0031] (2) Green spreading: spread the tea green evenly on a bamboo curtain or a bamboo sieve, place it in a cool and dry place for air circulation, and spread it in a cool and dry place, with a thickness of 5 cm, until the surface of the green tea loses luster and feels soft to the touch, making the dark green The green grass gas subsides to produce a delicate fragrance, and there is a fruity or floral fragrance;

[0032] (3) Finishing: put the green tea into the hot air stove, the temperature of finishing is 135°C, and the finishing time is 5 minutes;

[0033] (4) Cooling: Shake the green tea immediately after killing green, spread it thinly in bamboo curtains or bamboo...

Embodiment 2

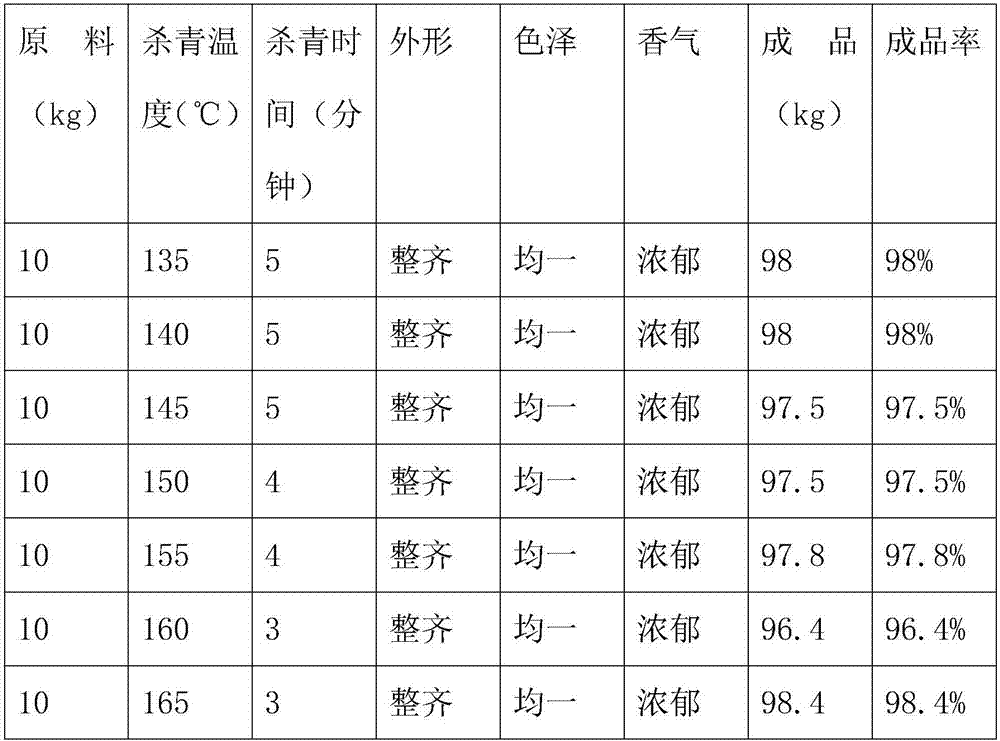

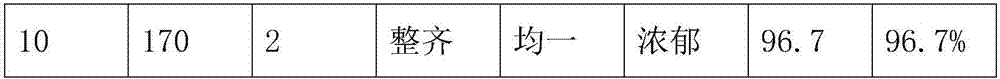

[0044] On the basis of Example 1, other steps and parameters remain unchanged. (3) In the deenzyming step, the deenzyming temperature can be 140°C, 145°C, 150°C, 155°C, 160°C, 165°C, 170°C.

[0045] In this embodiment, the temperature of the above-mentioned hot air stove for finishing greens will not cause the tea leaves to lose water too quickly and cause scorching, destroy and passivate the oxidase activity in the green tea, and inhibit the enzymatic oxidation of tea polyphenols in the green tea. Evaporate part of the water in the green tea, making the green tea soft, easy to knead and shape, and promote the formation of good aroma.

[0046] For verifying the beneficial effect of present embodiment, the performance of Maojian tea is as follows

[0047]

[0048]

Embodiment 3

[0050] As in Example 1, wherein (5) the parameters in the kneading step are as follows: the green leaves are put into the kneading machine kneading bucket, and the amount of leaf throwing is based on naturally filling the kneading bucket; the kneading time is 29 minutes; when kneading, follow the following order Pressing: Knead with air pressure for 4 minutes → knead with light pressure for 3 minutes → knead with light pressure for 3 minutes → knead with light pressure for 1 minute → knead with light pressure for 4 minutes → knead with light pressure for 1 minute → knead with light pressure for 3 minutes → knead with light pressure for 1 minute Minutes → Slightly press and knead for 3 minutes → Lightly press and knead for 1 minute → Slightly press and knead for 4 minutes → Lightly press and knead for 1 minute.

[0051] Above-mentioned whole kneading time can be 30 minutes, 31 minutes, 32 minutes, 33 minutes, 34 minutes

[0052] In this embodiment, in the rolling step, the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com