Reinforced structure for coupling beam of reinforced concrete

A reinforced concrete and reinforced structure technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems that the coupling beam cannot meet the seismic design requirements, the rigidity of the lateral force resistance system increases greatly, and the ductility and deformation capacity are ignored. The effects of shortening the reinforcement construction period, improving engineering efficiency, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

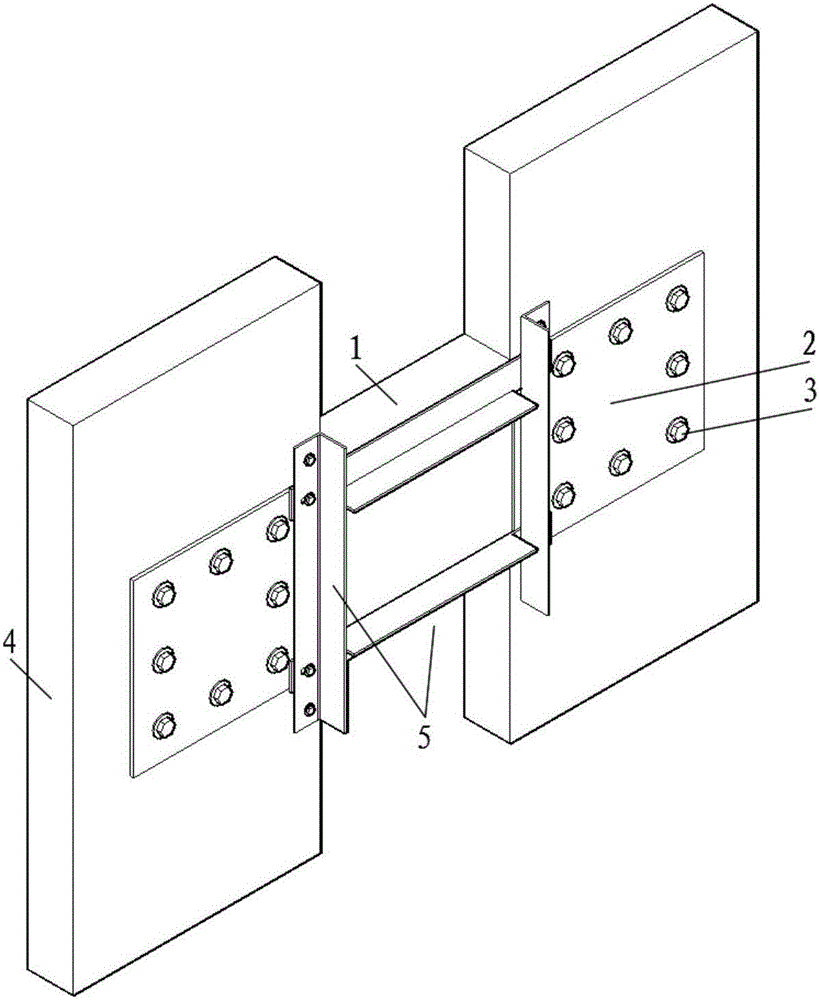

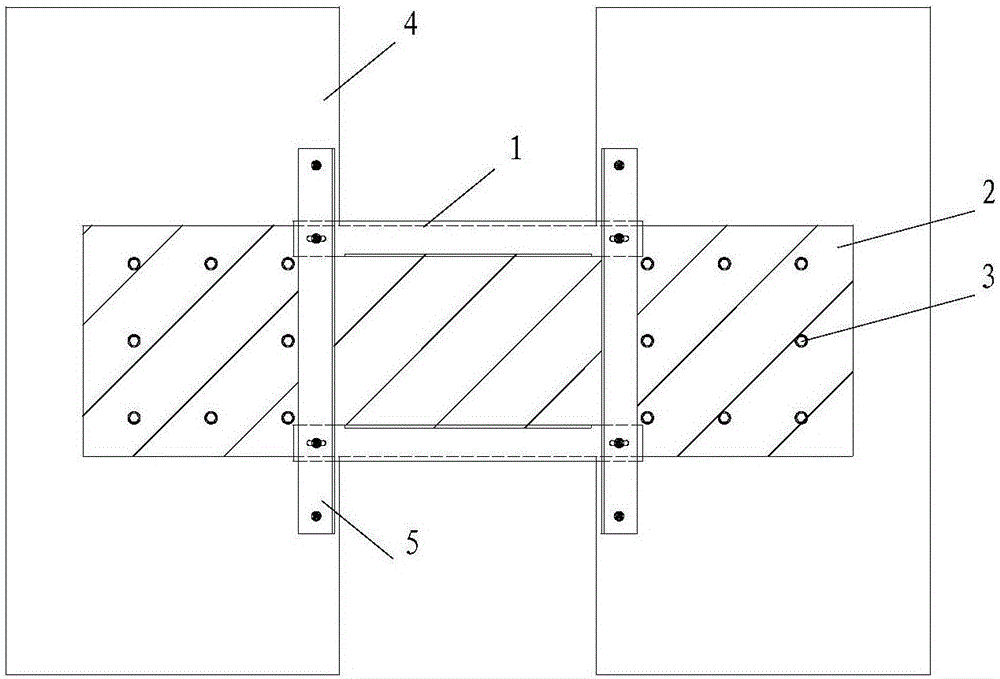

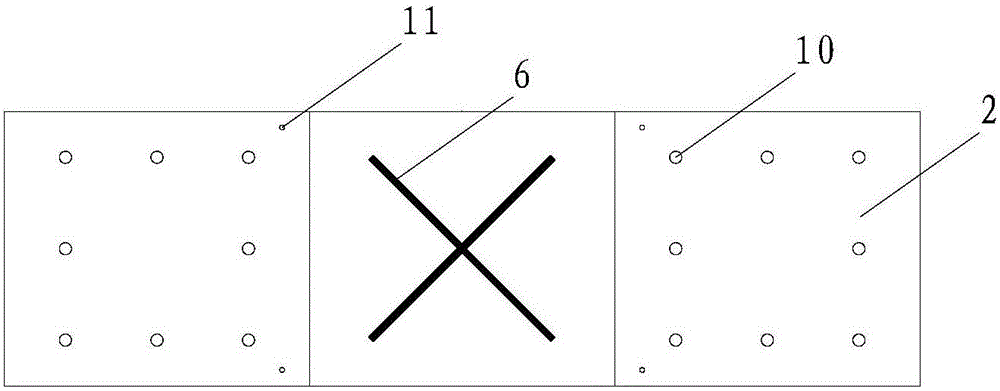

[0032] Such as figure 1 , figure 2 As shown, a reinforced concrete coupling beam reinforcement structure includes a coupling beam 1, a steel plate 2, a shear wall 4 at both ends of the coupling beam, and a buckling restraint frame 5. The steel plate 2 is connected to the shear walls 4 at both ends of the connecting beam through chemical anchor bolts, and the gap between the screw rod of the chemical anchor bolt and the wall of the bolt hole is filled with chemical adhesive. The vertical frames on both sides of the buckling restraint frame 5 are respectively connected to the steel plates 2 on the shear wall 4 through bolts, and the vertical frames extend from the upper and lower ends of the steel plate 2 to connect with the corresponding shear wall 4 connection, the joint between the vertical frame of the buckling constrained frame 5 and the steel plate 2 is provided with a horizontally arranged oblong hole, the joint between the transverse frame of the buckling constrained f...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described: , the vertical frame and the horizontal frame are welded to form the buckling restraint frame (5), and the thickness of the contact part of the steel plate (2) with the shear wall (4) is greater than that of the contact part with the coupling beam (1) thickness.

[0048]Specifically: the thickness of the contact part between the steel plate 2 and the shear wall 4 at both ends of the connecting beam is 9 mm, and the thickness of the contact part between the steel plate 2 and the connecting beam 1 is 4.5 mm.

[0049] In this embodiment, in order to meet different needs for strengthening the connecting beam, by increasing the thickness of each part of the steel plate, the strength of the connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com