Rockfill dam face plate cushion layer and construction method

A construction method and technology of rockfill dams, applied in dams, barrages, water conservancy projects, etc., can solve problems such as construction joint opening and concrete damage, achieve convenient construction, ensure safety and durability, and avoid excessive cracks in the panel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

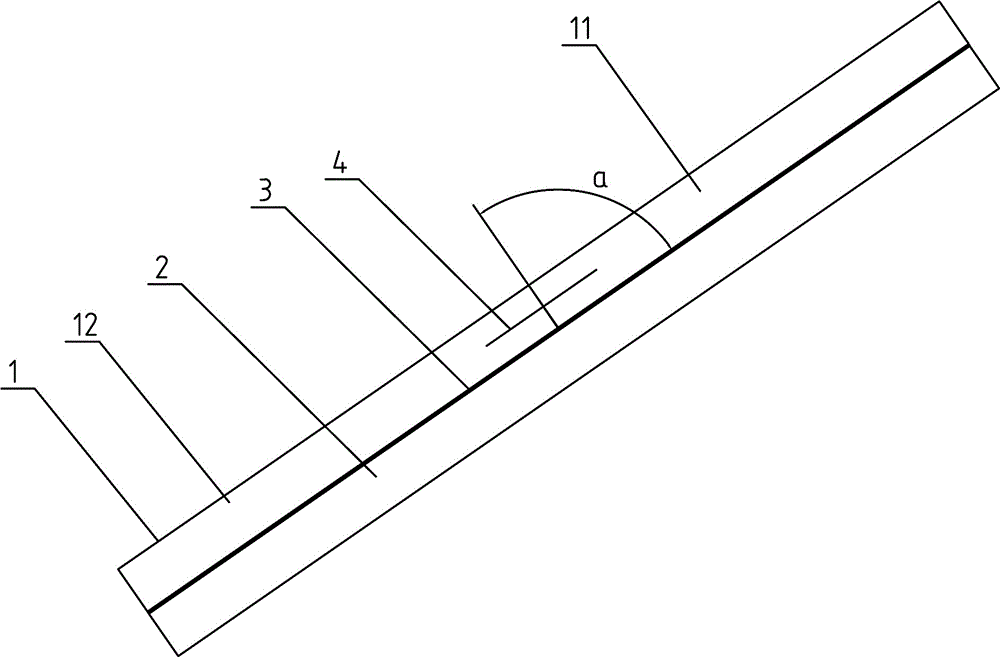

[0030] Such as figure 1 , 3 Among them, a face cushion of a rockfill dam, a membrane layer 3 is provided between the face plate 1 and the concrete foundation 2 . The restraint between the concrete of the face plate 1 and the concrete foundation 2 of the rockfill dam is reduced, and the probability of cracks is reduced.

[0031] The film layer 3 is a plastic film. Such as polyethylene film, and agricultural film.

[0032] The thickness of the film layer 3 is 0.05-0.15 mm. The preferred thickness in this example is 0.1 mm.

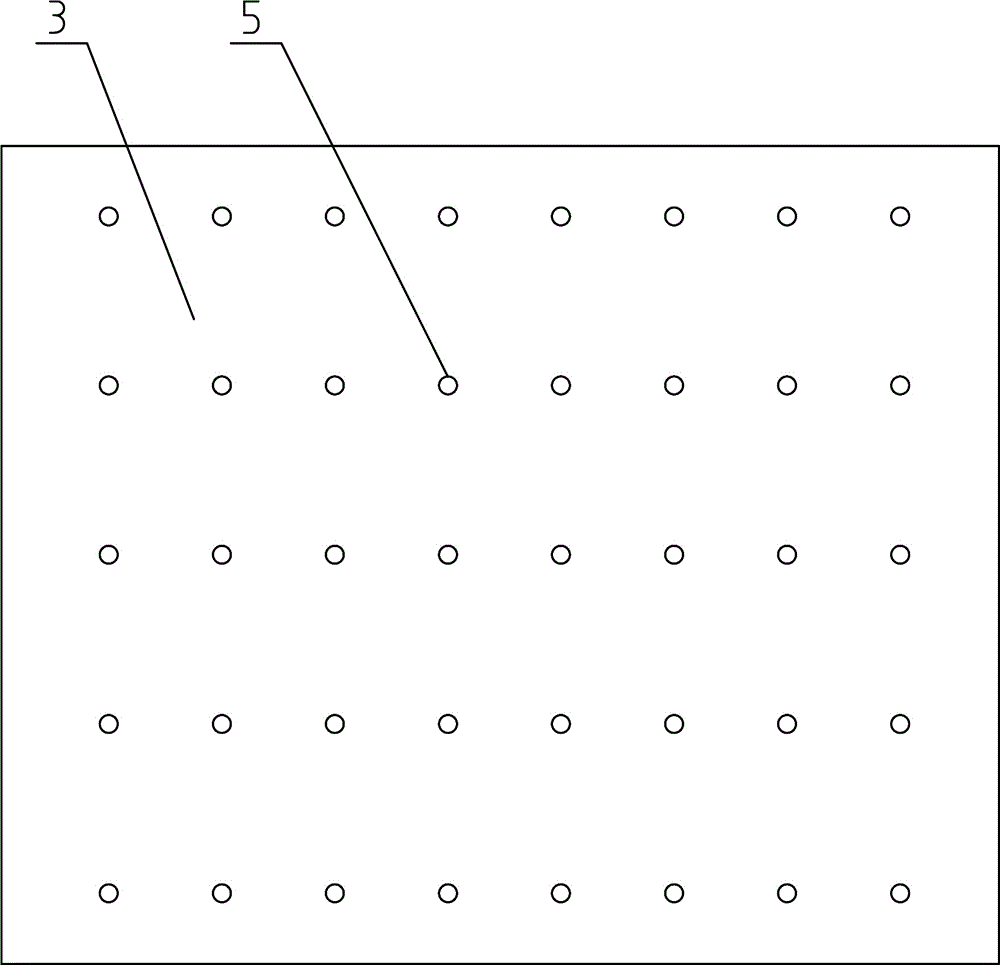

[0033] Such as figure 2 Among them, the membrane layer 3 is fixed on the concrete foundation 2 through a plurality of fixing pieces 5 . The fixing part 5 in this example adopts tall thumbtacks, and it is also feasible to use a similar tall staple as the fixing part 5 .

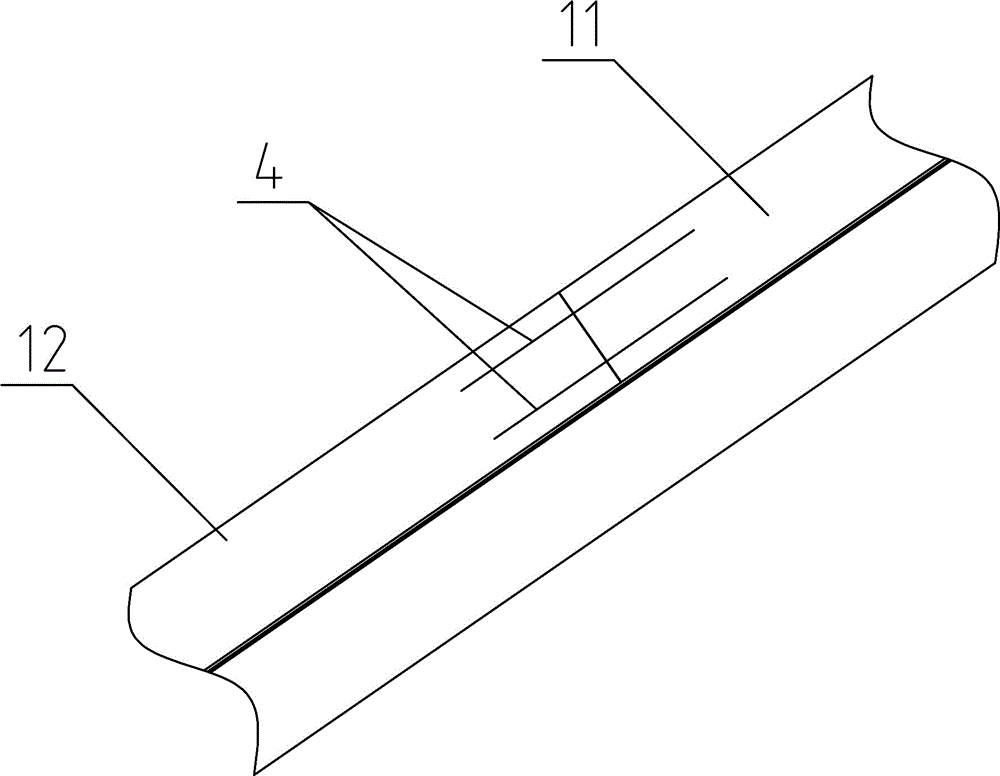

[0034] Such as figure 1 , 3 In ~5, a plurality of seam-passing steel bars 4 are provided between the pre-cast block 11 and the post-cast block 12 of the panel 1.

[0035] Such as ...

Embodiment 2

[0038] A construction method of the above-mentioned rockfill dam face cushion, comprising the following steps:

[0039] 1. Pouring concrete foundation 2;

[0040] Two, a layer of film layer 3 is set on the surface of the concrete foundation 2;

[0041] 3. The panel 1 is poured again, and the crack defects of the panel 1 are reduced through the above steps.

[0042] In step 2, when the film layer 3 is set, the film layer 3 is fixedly installed on the concrete foundation 2 with a plurality of fixing parts 5, i.e. high-foot push pins. In this example, an agricultural film is used; first, the film layer 3 is used with high-foot push pins 2 Fastened to concrete foundation 2. At the water-stop copper sheets on both sides of the panel, insert the film layer 3 under the water-stop copper sheets, and fix it firmly with tall thumbtacks.

[0043] Then install the panel steel bar, use the steel bar trolley as the working platform to drive the vertical bar into the concrete foundation 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com