Cable for ship marine closed circuit television camera and manufacturing method thereof

A closed-circuit television and camera technology, which is applied in cable/conductor manufacturing, insulated cables, and coaxial cable manufacturing, etc. It can solve the problems of inconvenient on-site use, many supporting lines of closed-circuit television cameras, and easy to be messy, so as to reduce interference and signal noise, effect of good grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

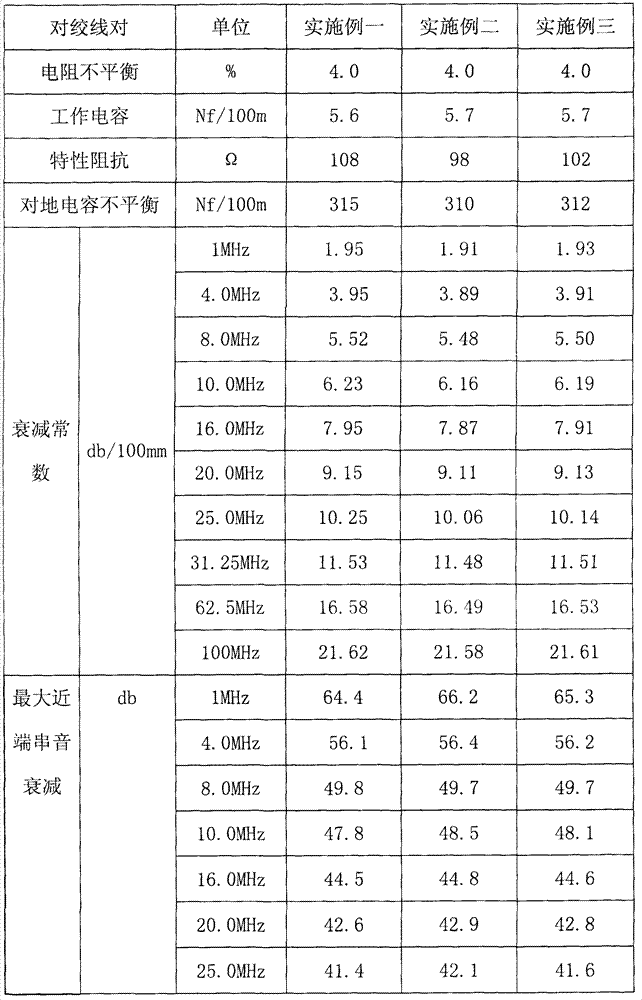

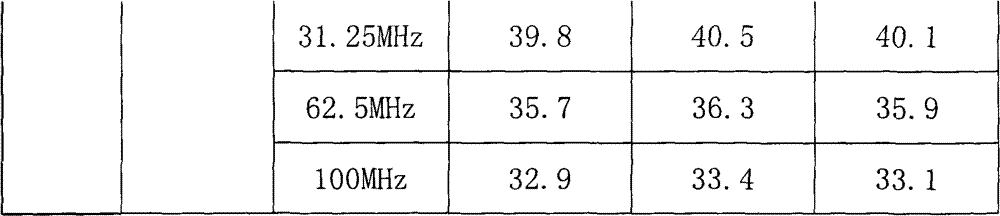

Embodiment 1

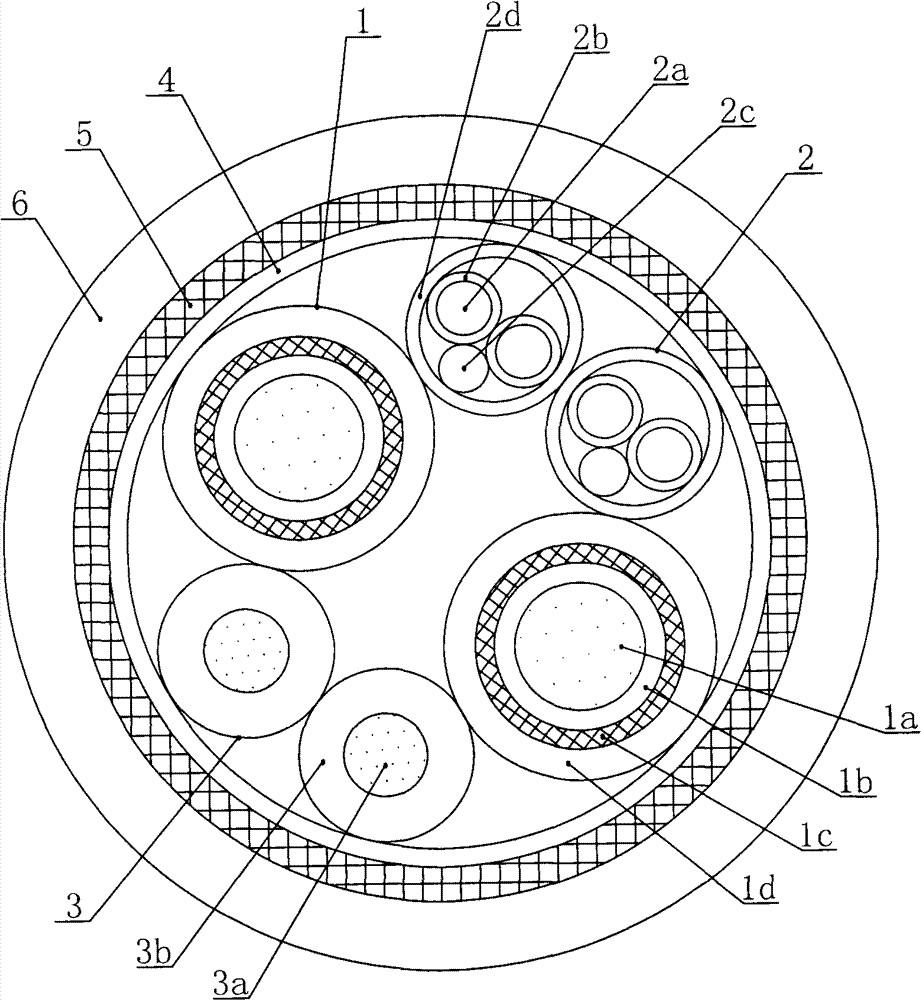

[0017] (1) Manufacture coaxial cable 1, twisted core wire 2 and power cable 3 respectively;

[0018] Take seven bare copper wire bundles with a diameter of 0.2mm and twist them into the central conductor 1a of the coaxial cable, and the stranding pitch ratio is 12; mm, the outer diameter of the coaxial cable insulating layer 1b after extrusion is 2.4mm; then, the outer diameter of the coaxial cable insulating layer 1b is braided with bare copper wires with a diameter of 0.12mm, the braiding density is 90%, and the mesh number is 94 mesh; The coaxial cable sheath 1d is extruded outside the coaxial cable shielding layer 1c, using halogen-free elastomer or thermosetting material, the thickness of the coaxial cable sheath 1d is 0.4mm, and the overall outer diameter of the formed coaxial cable is 3.8mm ;

[0019]Take seven tinned copper wire bundles with a diameter of 0.2mm and twist them into a twisted pair conductor 2a respectively, and the twisted pitch ratios are 8 and 10 resp...

Embodiment 2

[0026] (1) Manufacture coaxial cable 1, twisted core wire 2 and power cable 3 respectively;

[0027] Take seven bare copper wire bundles with a diameter of 0.2mm and twist them into the central conductor 1a of the coaxial cable, with a stranding pitch ratio of 15; mm, the outer diameter of the coaxial cable insulation layer 1b after extrusion is 2.5mm; then, the outer diameter of the coaxial cable insulation layer 1b is woven with bare copper wires with a diameter of 0.13mm, the braiding density is 90%, and the mesh number is 98 mesh; The coaxial cable sheath 1d is extruded outside the coaxial cable shielding layer 1c, using halogen-free elastomer or thermosetting material, the thickness of the coaxial cable sheath 1d is 0.45mm, and the overall outer diameter of the formed coaxial cable 1 is 4.0 mm;

[0028] Take seven tinned copper wire bundles with a diameter of 0.2 mm and twist them into a twisted pair conductor 2a respectively, and the twisted pitch ratios are 9 and 12 re...

Embodiment 3

[0035] (1) Manufacture coaxial cable 1, twisted core wire 2 and power cable 3 respectively;

[0036] Take seven bare copper wire bundles with a diameter of 0.2mm and twist them into the central conductor 1a of the coaxial cable, and the stranding pitch ratio is 13; mm, the outer diameter of the coaxial cable insulating layer 1b after extrusion is 2.45mm; then, the outer diameter of the coaxial cable insulating layer 1b is braided with bare copper wires with a diameter of 0.12mm, the braiding density is 90%, and the mesh number is 96 mesh; The coaxial cable sheath 1d is extruded outside the coaxial cable shielding layer 1c, using halogen-free elastomer or thermosetting material, the thickness of the coaxial cable sheath 1d is 0.42mm, and the overall outer diameter of the formed coaxial cable 1 is 3.9 mm;

[0037] Take seven tinned copper wire bundles with a diameter of 0.2mm and twist them into a twisted pair conductor 2a respectively, and the twisted pitch ratios are 8 and 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com