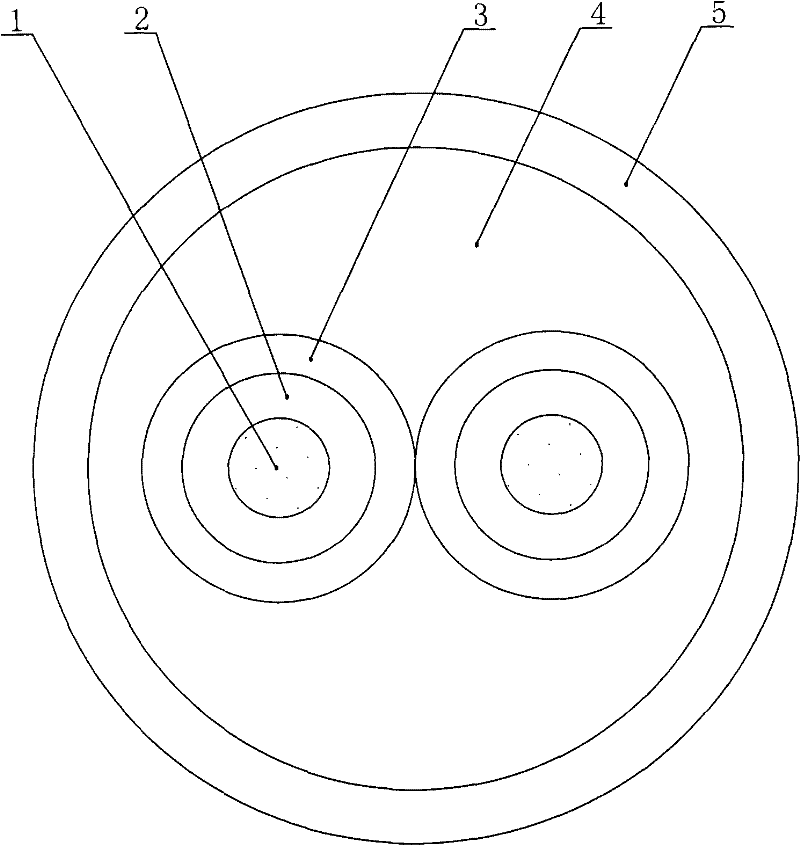

Ship underwater sonar transducer cable and manufacturing method thereof

An underwater sonar and manufacturing method technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of great difference in insulation performance of ethylene-propylene rubber, short service life of cables, poor waterproof performance, etc., and achieve mechanical Excellent performance, guaranteed waterproof performance, and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

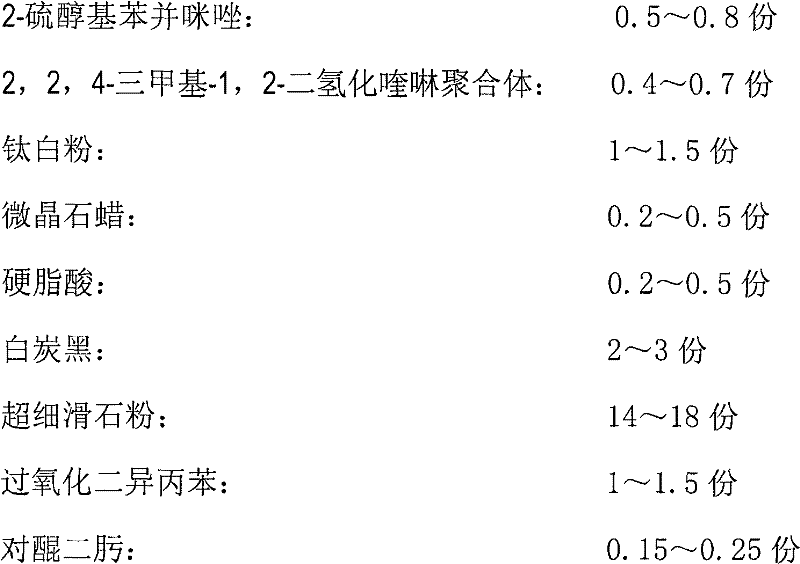

[0021] First prepare insulating rubber for use, the steps are as follows: (1) Prepare the raw materials of insulating rubber according to the following components and weight content: ethylene propylene rubber 2470: 11 parts; ethylene propylene rubber 578K: 7 parts; dibenzothiazole disulfide (commonly known as DM ): 0.1 parts; zinc oxide: 1.5 parts; 2-mercaptobenzimidazole (antiaging agent MB): 0.5 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer (antiaging agent RD, resinous): 0.4 parts; titanium dioxide: 1 part; microcrystalline paraffin: 0.2 parts; stearic acid: 0.2 parts; white carbon black: 2 parts; superfine talcum powder: 14 parts; Benzene (DCP): 1 part; p-quinonedioxime (GMF): 0.15 part;

[0022] (2) First mix ethylene propylene rubber 2470 and ethylene propylene rubber 578K evenly, then add zinc oxide, 2-thiolbenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline Polymer, titanium dioxide, microcrystalline paraffin, stearic acid, white carbon black, superfine talcum p...

Embodiment 2

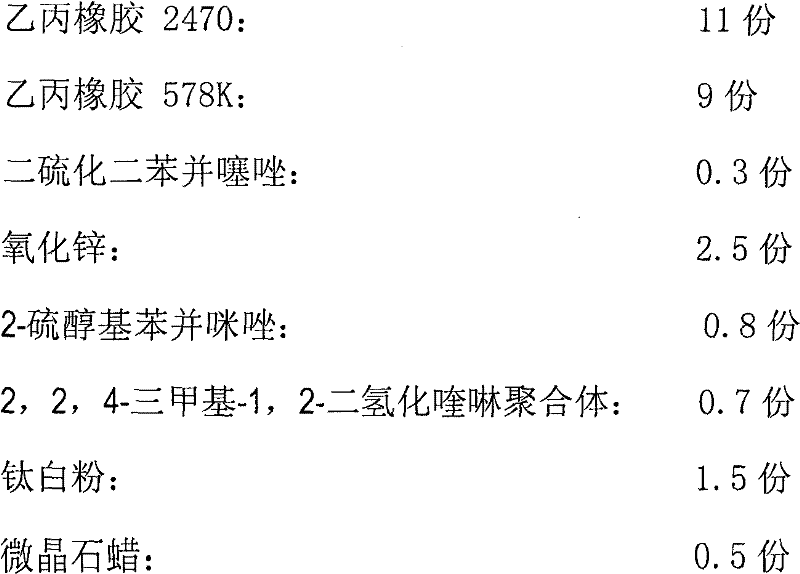

[0032] First prepare the insulating rubber for use, the steps are as follows: (1) Prepare the raw materials of the insulating rubber according to the following components and weight content: ethylene propylene rubber 2470: 11 parts; ethylene propylene rubber 578K: 9 parts; dibenzothiazole disulfide: 0.3 parts ; Zinc oxide: 2.5 parts; 2-mercaptobenzimidazole: 0.8 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 0.7 parts; Titanium dioxide: 1.5 parts; Crystal paraffin: 0.5 parts; stearic acid: 0.5 parts; white carbon black: 3 parts; superfine talcum powder: 18 parts; dicumyl peroxide: 1.5 parts; p-quinonedioxime: 0.25 parts;

[0033] (2) First mix ethylene propylene rubber 2470 and ethylene propylene rubber 578K evenly, then add zinc oxide, 2-thiolbenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline Polymer, titanium dioxide, microcrystalline paraffin, stearic acid, white carbon black, superfine talcum powder, knead for 11 minutes; then use 20 mesh + 40 mesh + 56 mesh three-l...

Embodiment 3

[0043] First prepare the insulating rubber for use, the steps are as follows: (1) Prepare the raw materials of the insulating rubber according to the following components and weight content: ethylene propylene rubber 2470: 11 parts; ethylene propylene rubber 578K: 8 parts; dibenzothiazole disulfide: 0.2 parts ; Zinc oxide: 2.0 parts; 2-mercaptobenzimidazole: 0.6 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 0.6 parts; Titanium dioxide: 1.3 parts; Crystal paraffin: 0.4 parts; stearic acid: 0.3 parts; white carbon black: 2.5 parts; superfine talcum powder: 16 parts; dicumyl peroxide: 1.3 parts; p-quinonedioxime: 0.18 parts;

[0044] (2) First mix ethylene propylene rubber 2470 and ethylene propylene rubber 578K evenly, then add zinc oxide, 2-thiolbenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline Polymer, titanium dioxide, microcrystalline paraffin, stearic acid, white carbon black, superfine talc powder, knead for 10 minutes; then use 20 mesh + 40 mesh + 56 mesh three-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com