Light-emitting diode (LED) for display screen and production method

A technology for light-emitting diodes and a manufacturing method, which is applied to instruments, electrical components, electrical solid-state devices, etc., can solve the problems of color, weather resistance, pixel resolution and color reproducibility, etc., and achieve uniform white balance, The picture is realistic and the effect of avoiding the phenomenon of overlapping lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

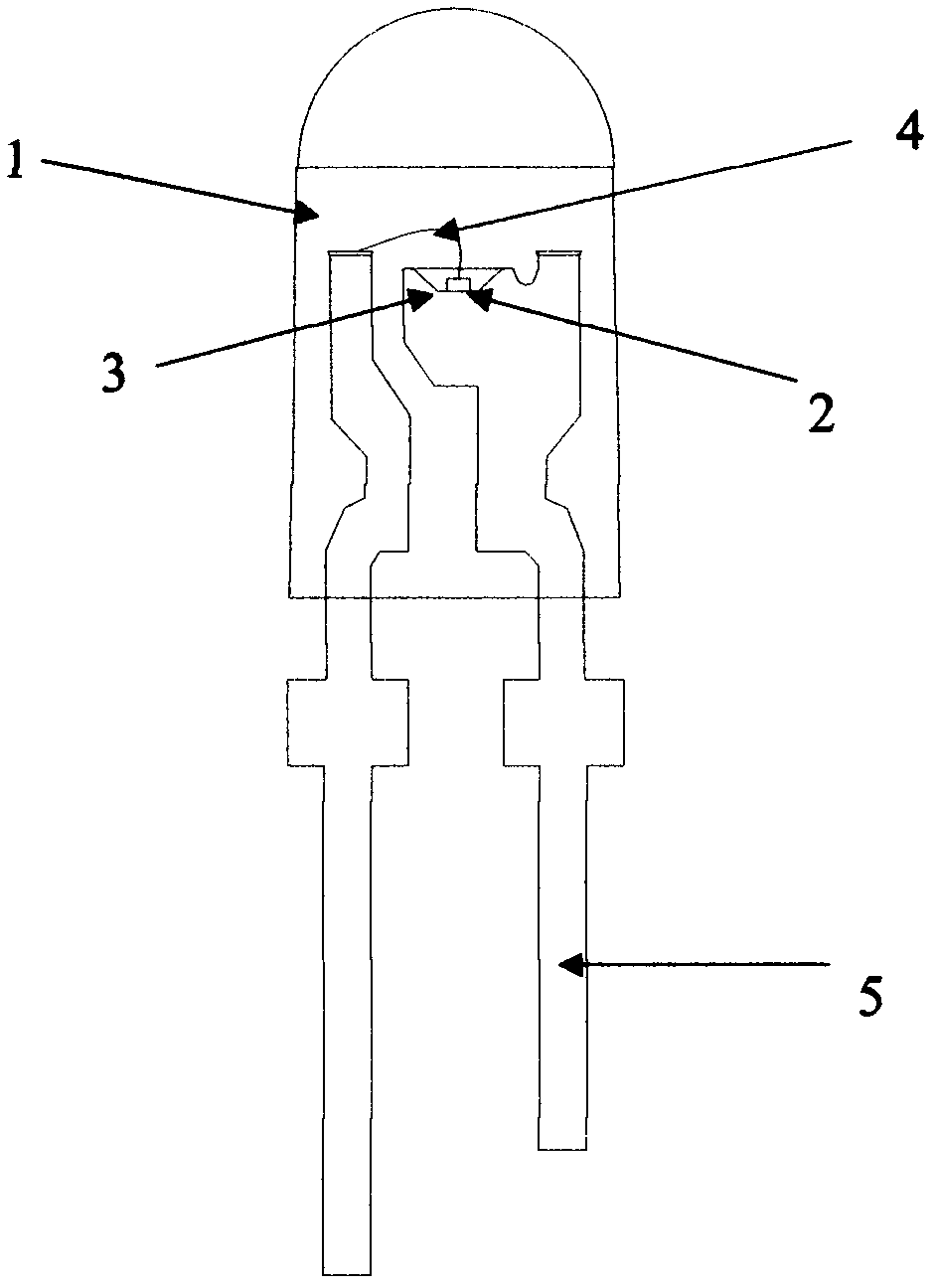

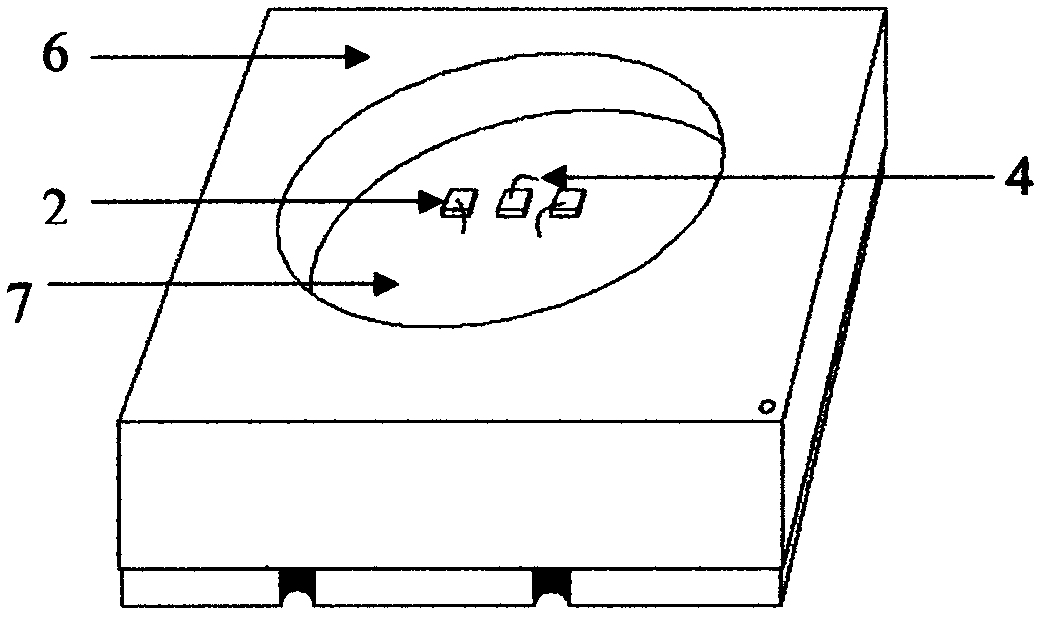

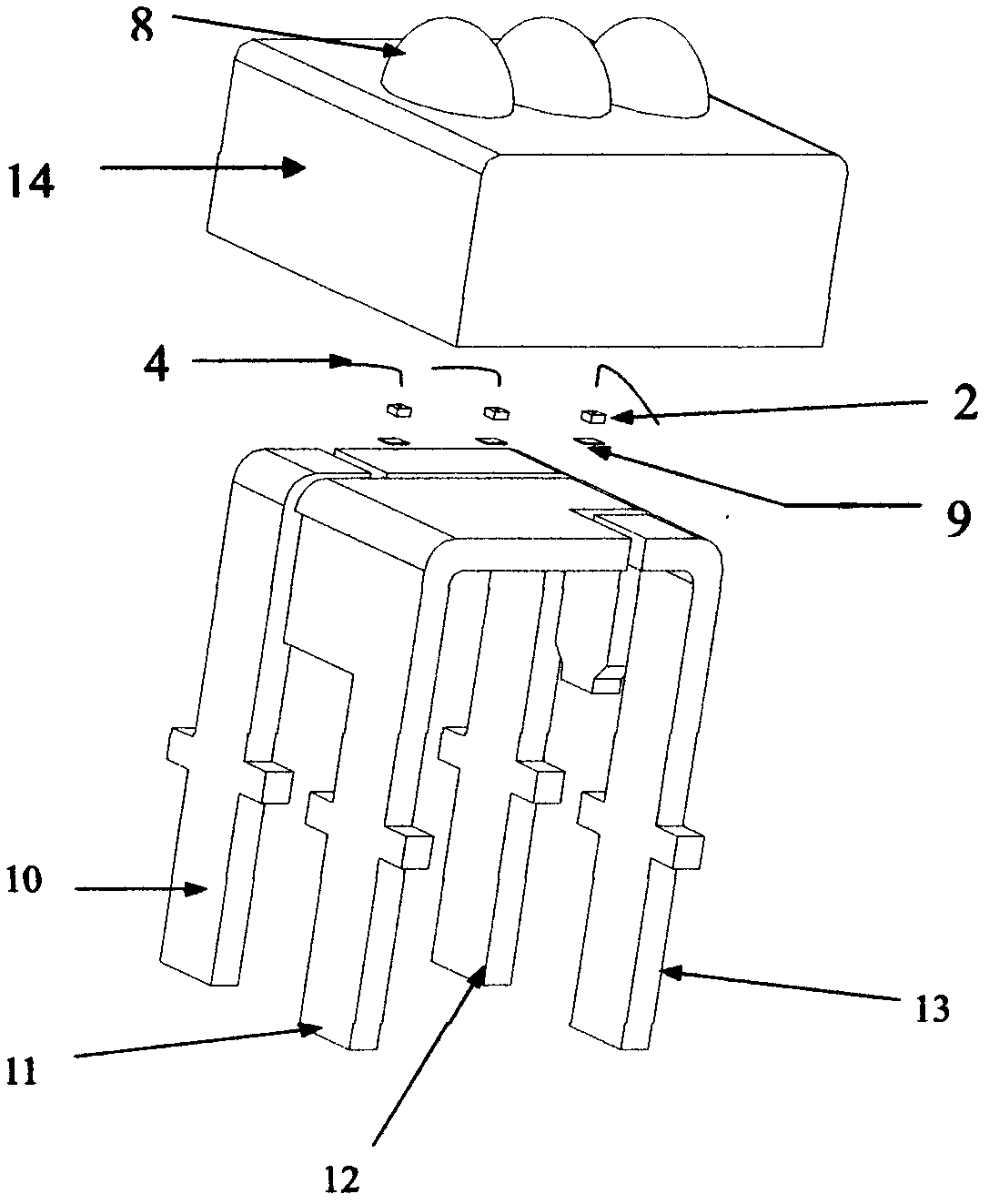

[0027] Welding areas (15, 16, 17, 18, 19) are set on the top of the outer pins of the support (28), and the crystal-bonding area (20); three groups of crystal-bonding glue (9) are connected on the crystal-bonding area (20), each Connect the LED chip (2) on the crystal solid glue (9), and the chip (2) is connected with the welding area (15, 16, 17, 18, 19) by the wire (4); seal. The three LED chips (2) are arranged equidistantly in a line. Three curved body optical structures (8) corresponding to the three LED chips (2) are arranged on the top of the epoxy resin cap (14).

[0028] Use the following process steps to complete:

[0029] First make the mold that is provided with guide post (21), curved surface cavity (22), limit card point (23), mold grain (24), steel sheet (25), fixed notch (26), direction recognition hole (27) strip;

[0030] Then make the bracket (28), set the welding area (15, 16, 17, 18, 19) on the upper plane of the bracket (28), fix the crystal area (20)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com