Patents

Literature

211results about How to "Same angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

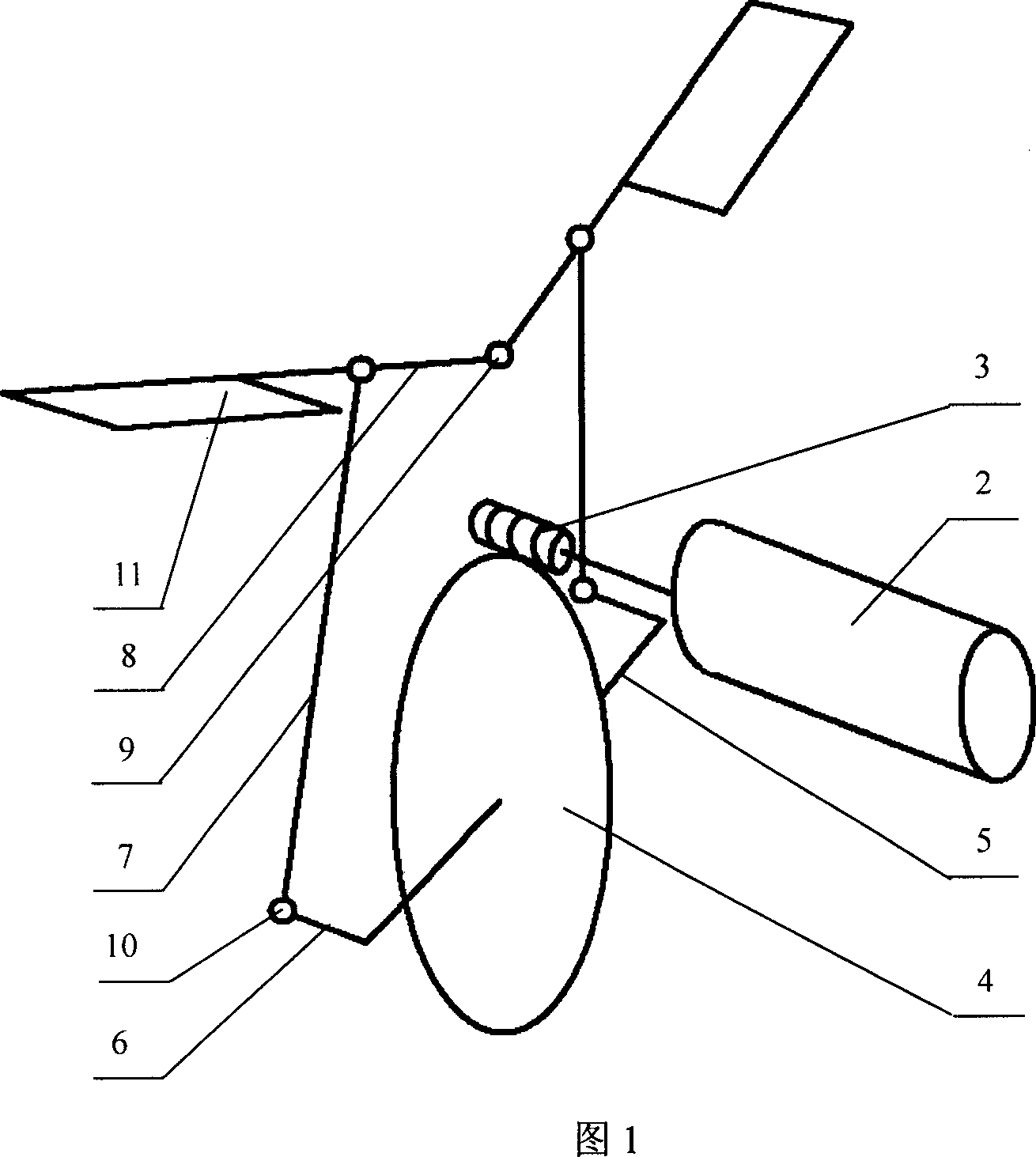

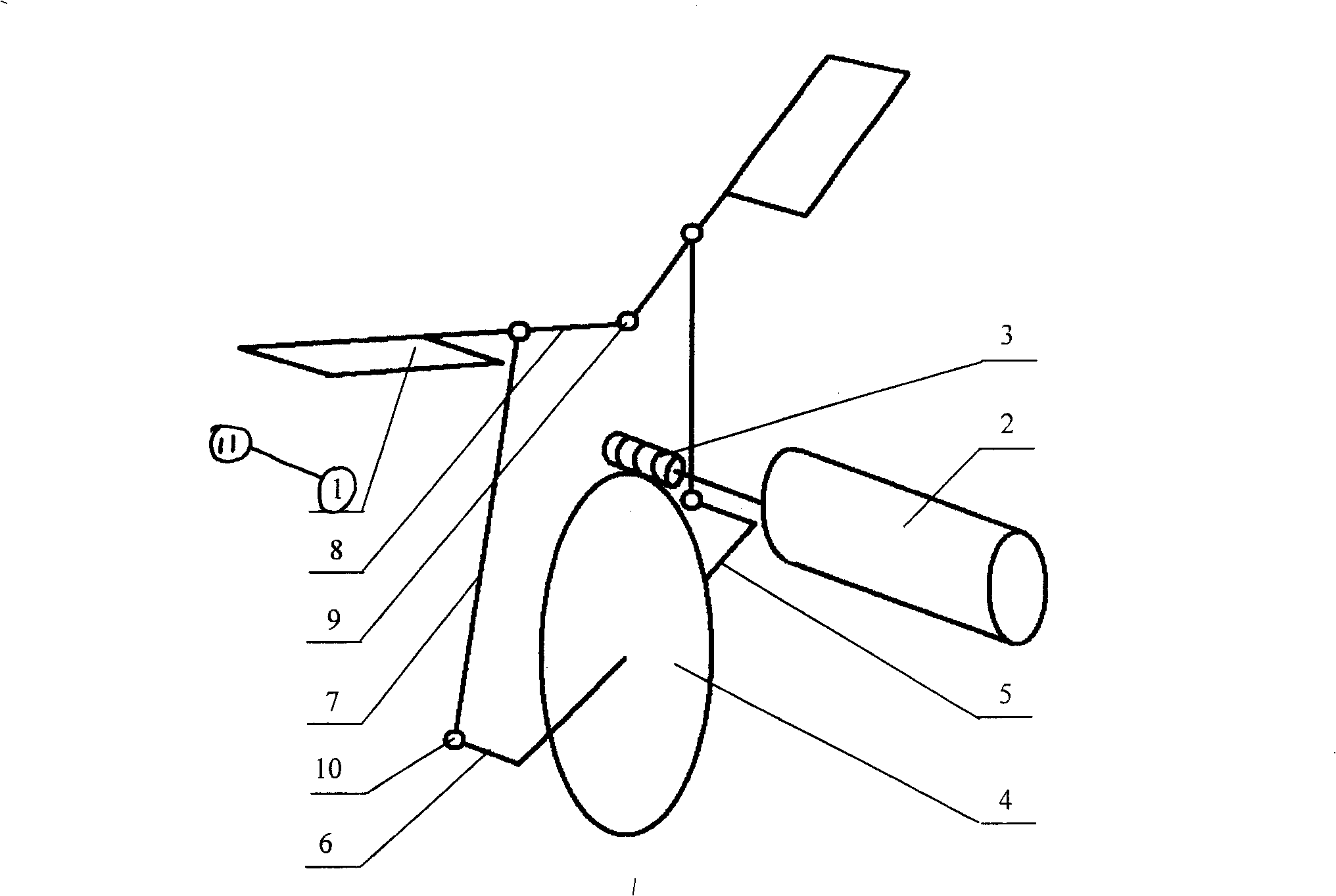

Driving mechanism for wings of minitype ornithopter

InactiveCN101049858AOvercoming the disadvantages of asymmetric flutterOvercoming complexityOrnithoptersFlapping wingGear wheel

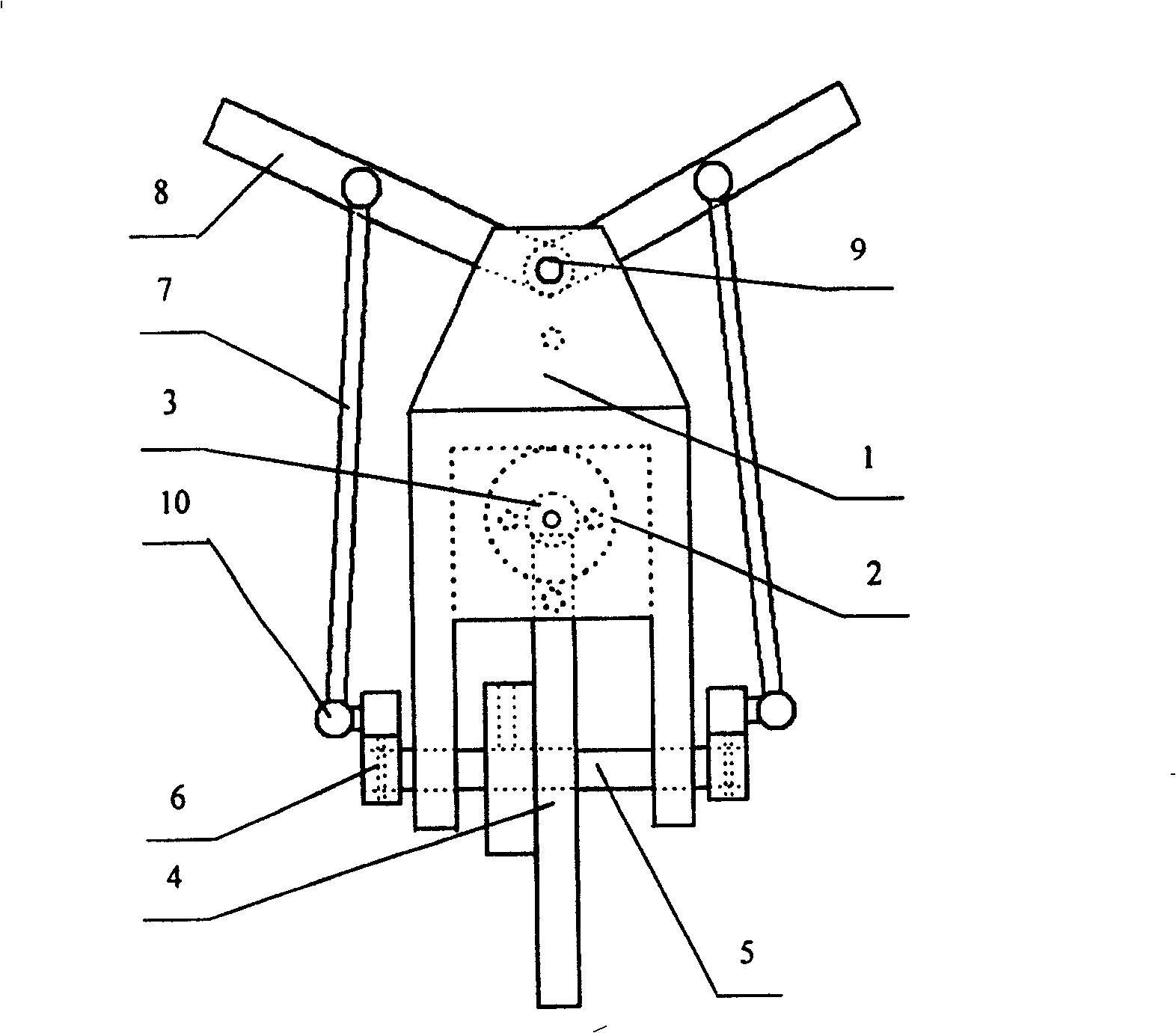

A drive mechanism for the wings of miniature ornithopter is composed of a worm-gear speed reducer and two sets of 4-connection-rod unit consisting of crank with one end fixed to the axle of worm gear, connection rod with one end linked to crank, and rocker arm linked between rocker arm and wing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

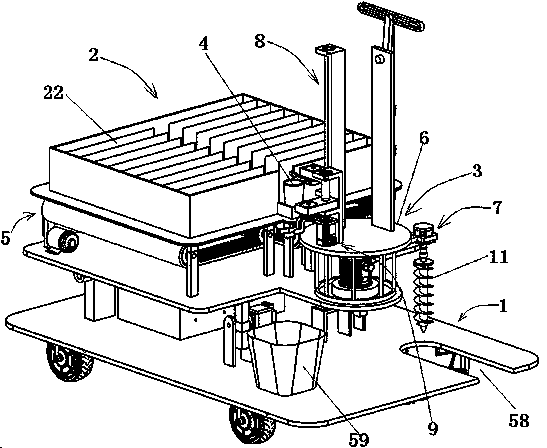

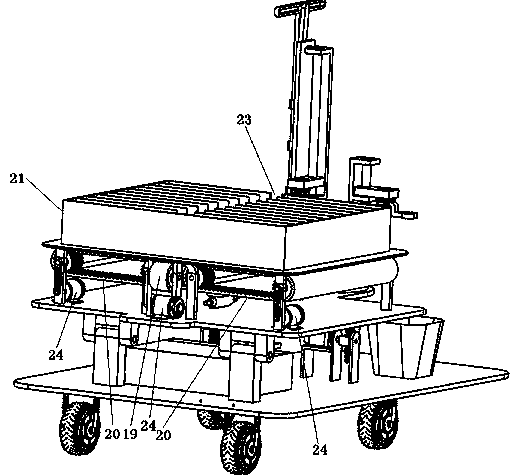

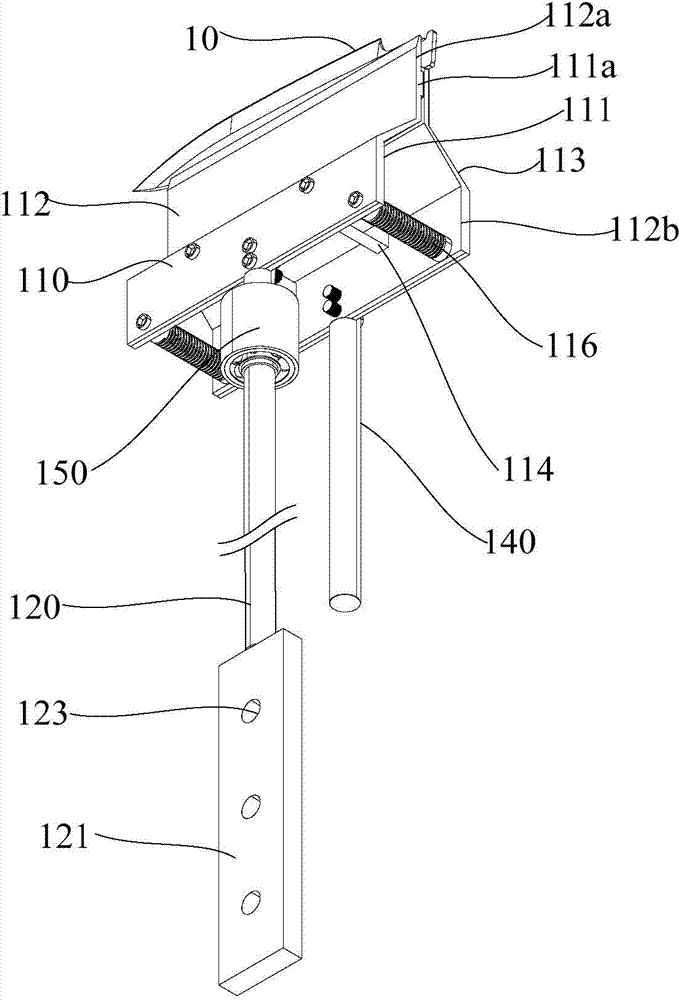

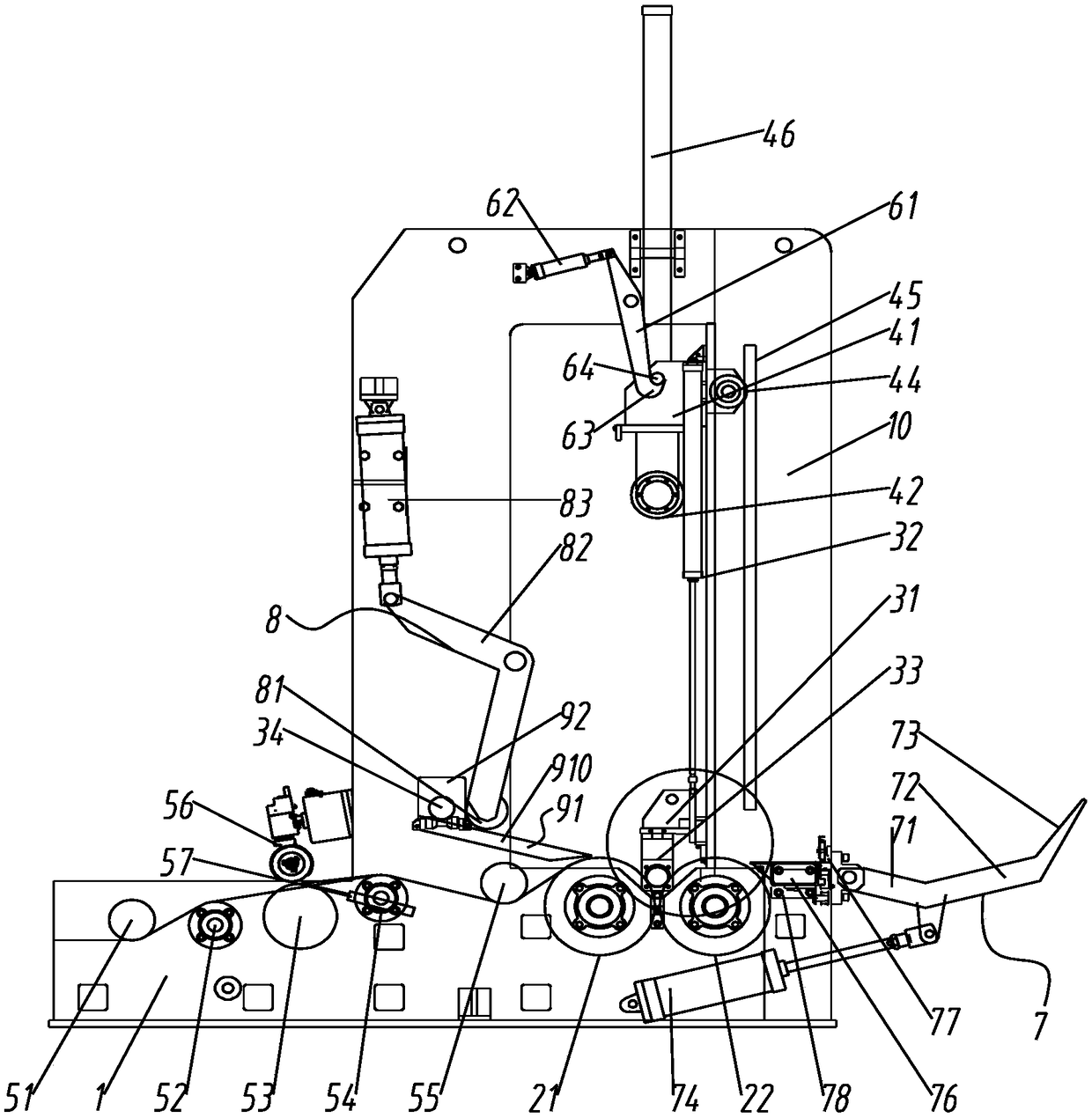

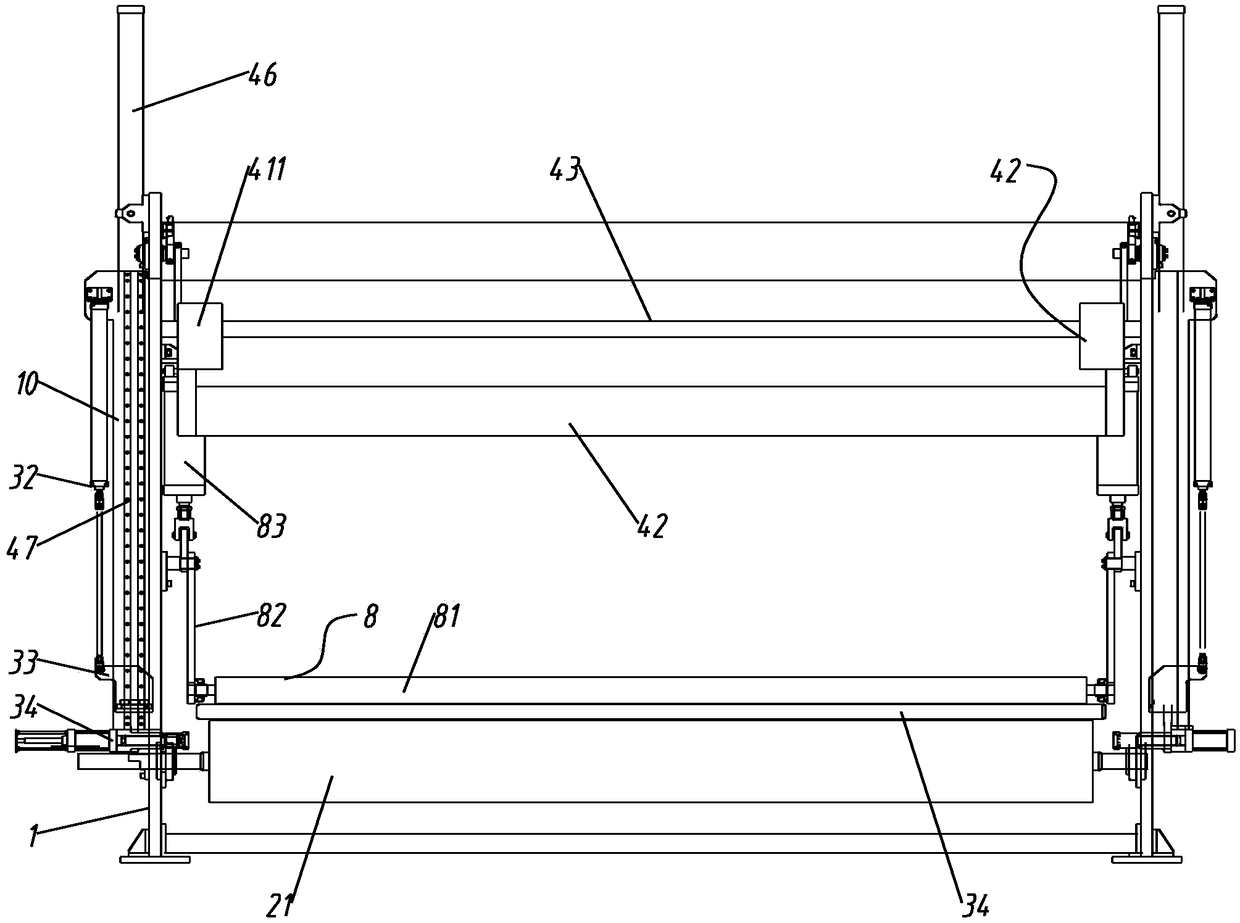

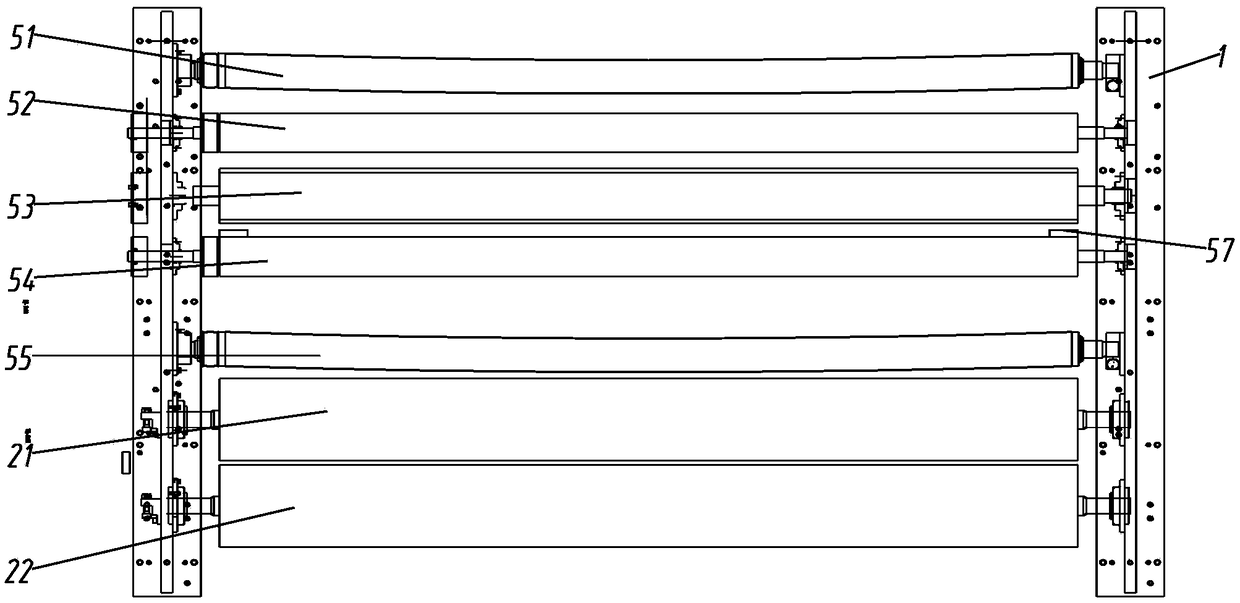

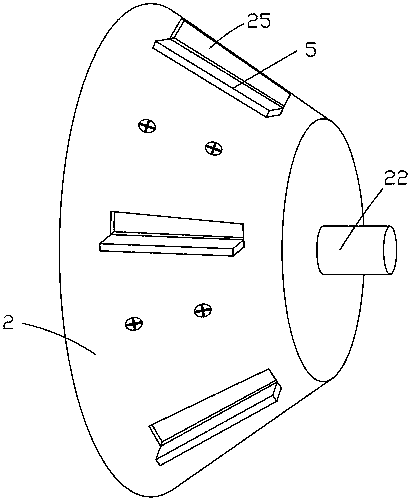

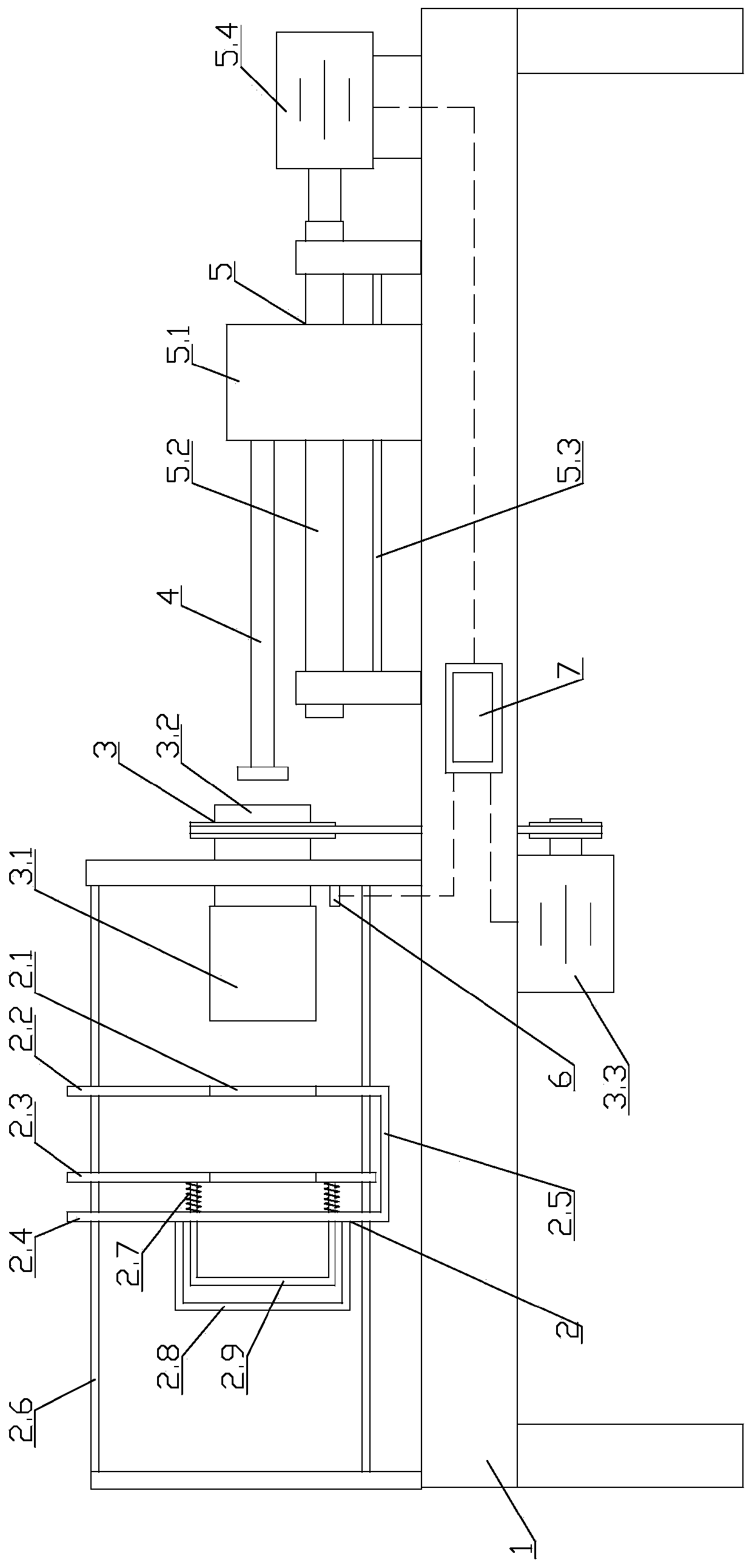

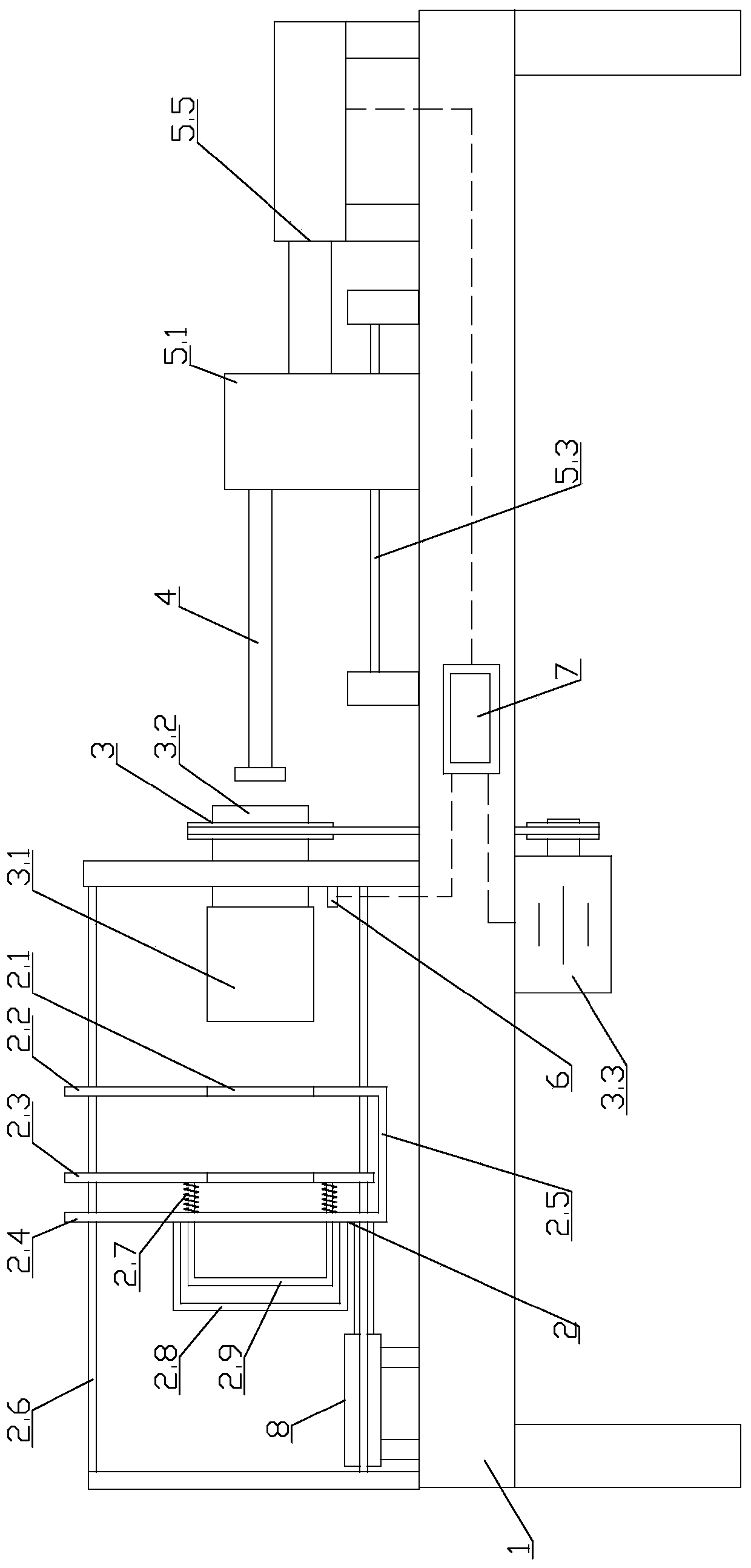

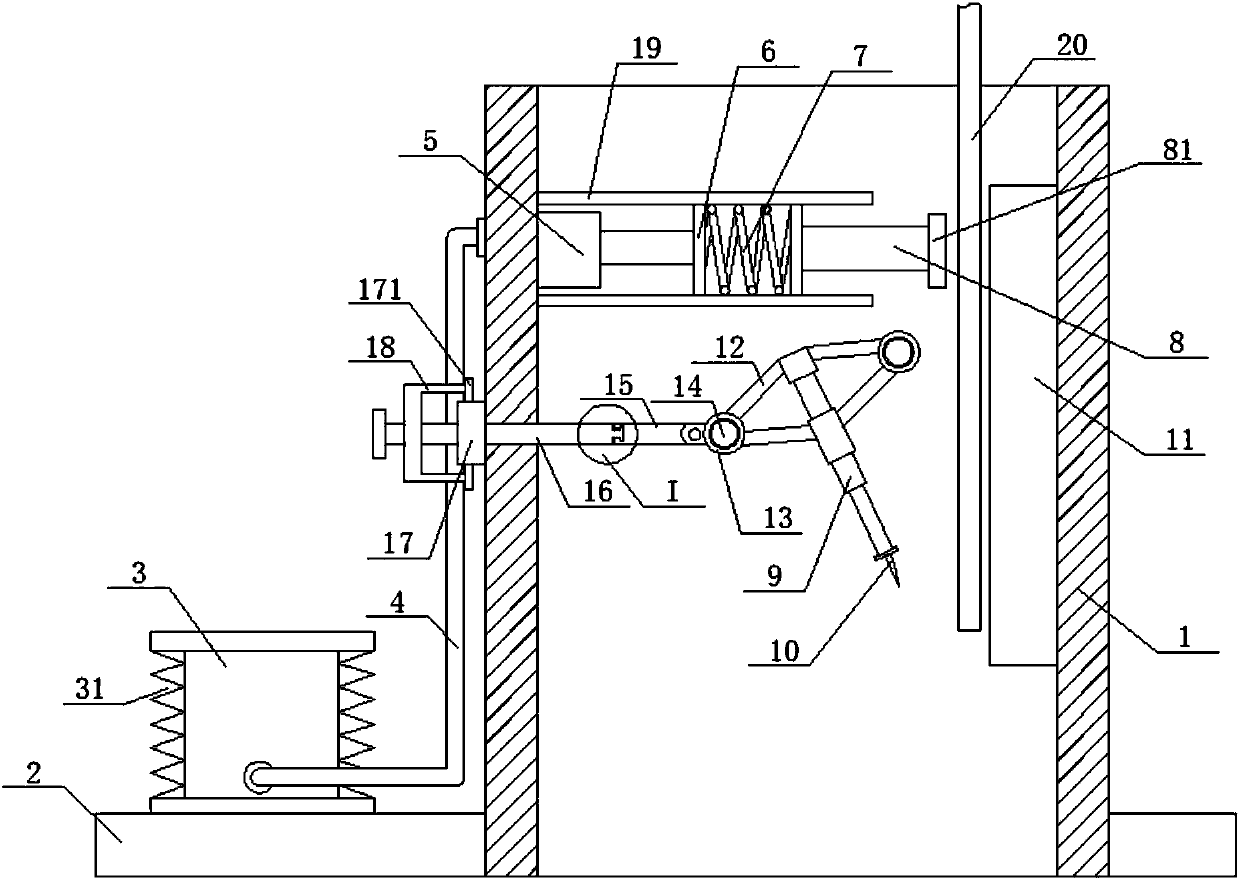

Tree planting machine

ActiveCN108739219AImprove planting efficiencyCompact structurePlantingFurrow making/coveringEngineeringMechanical engineering

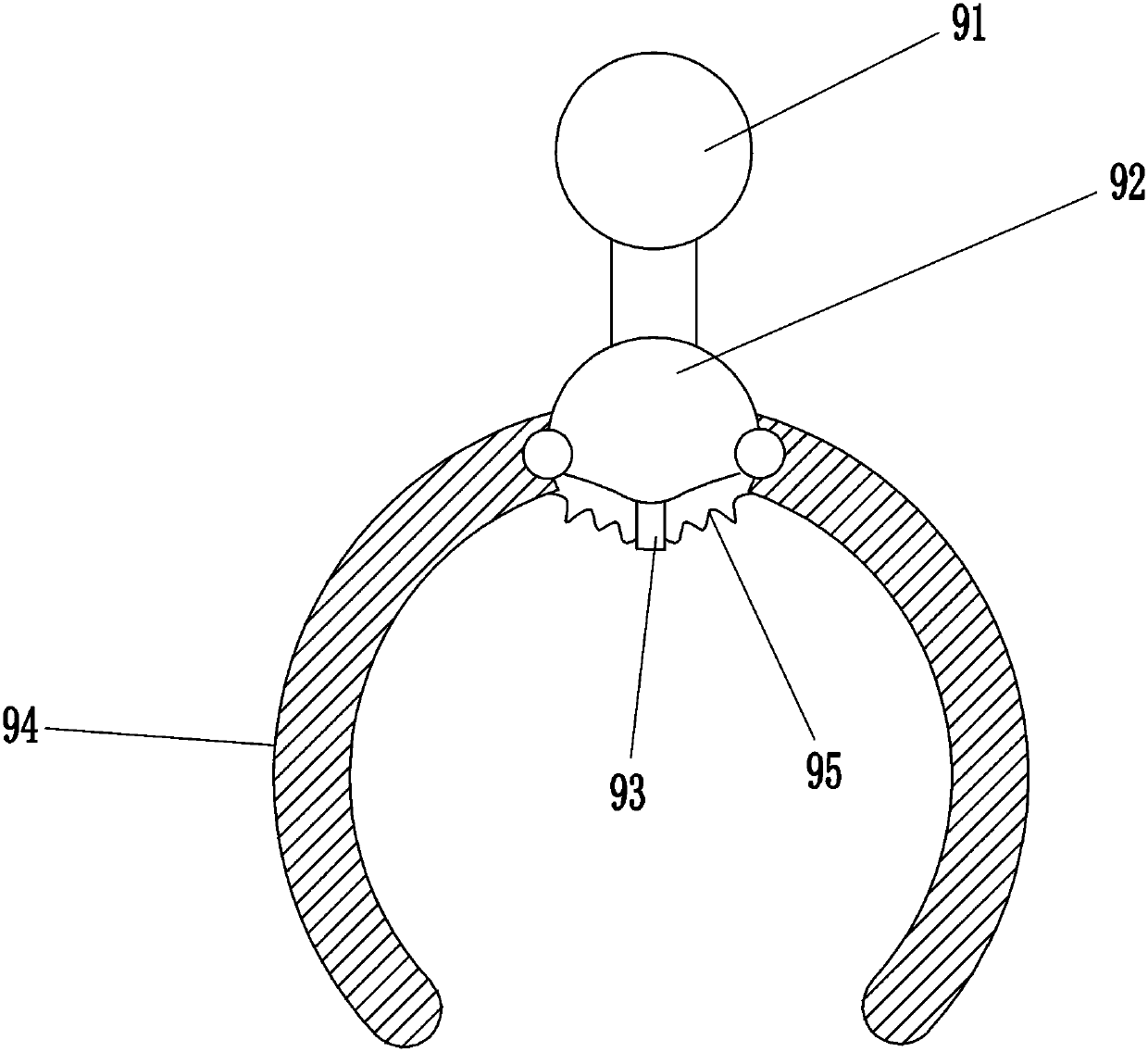

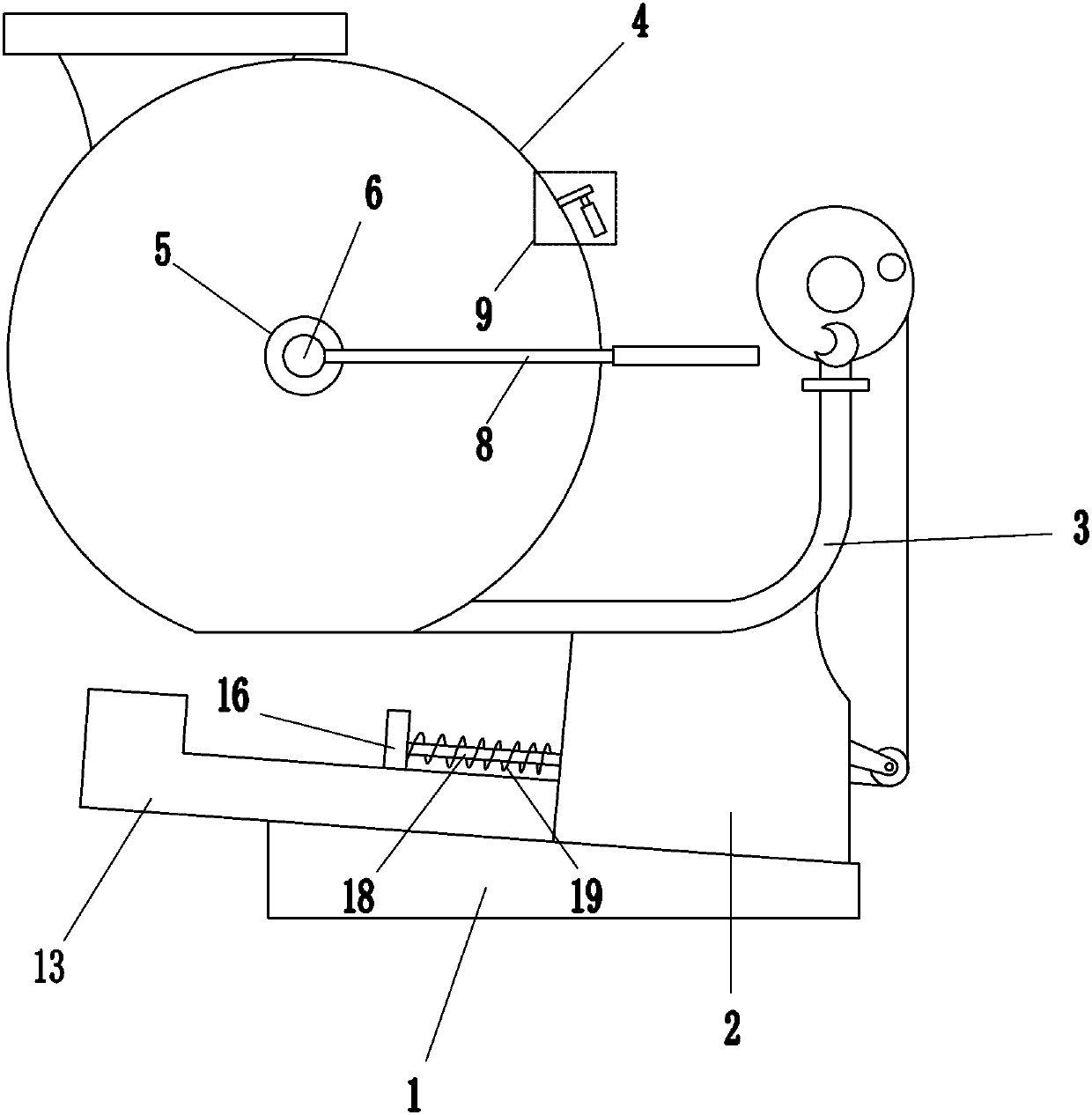

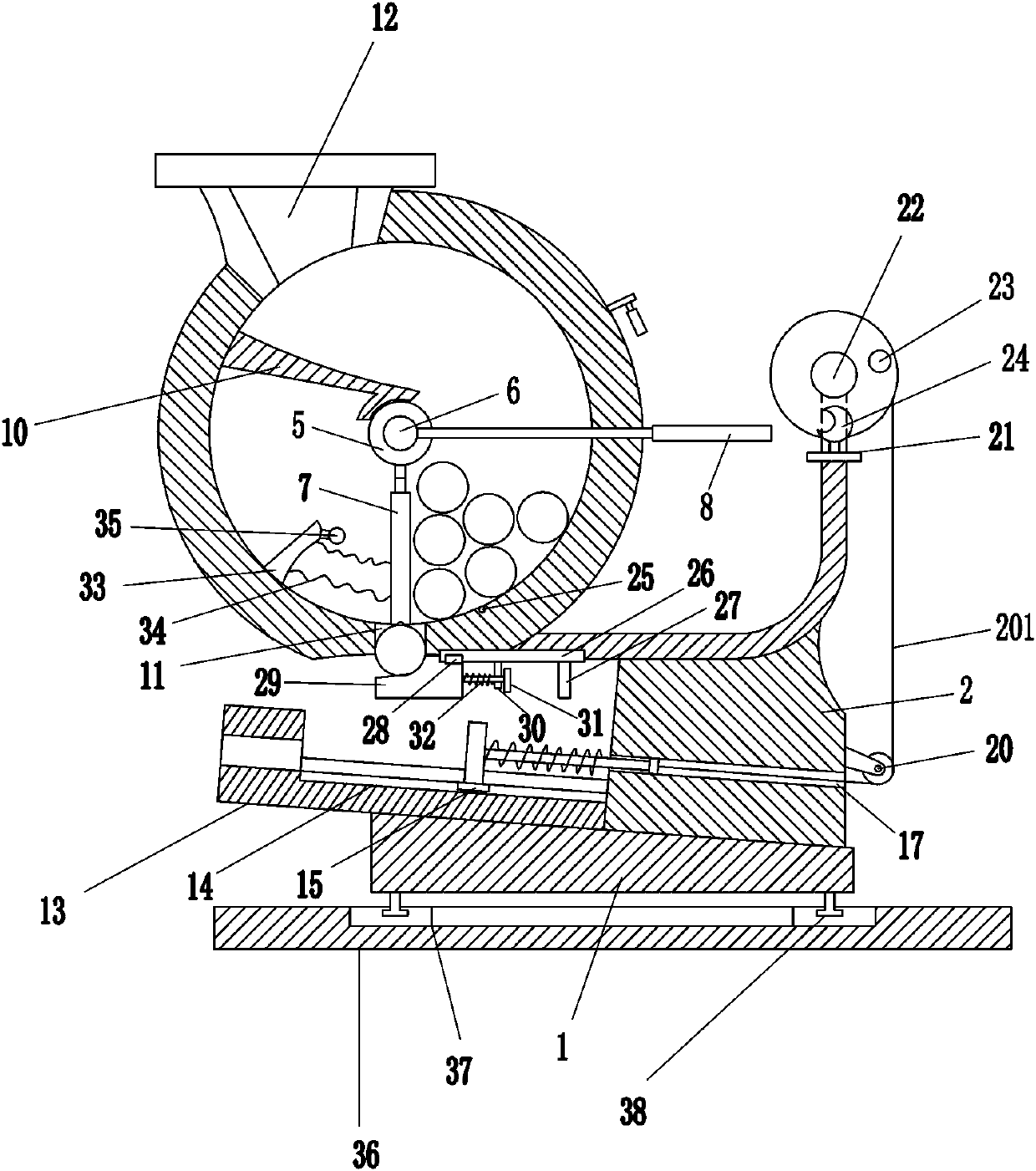

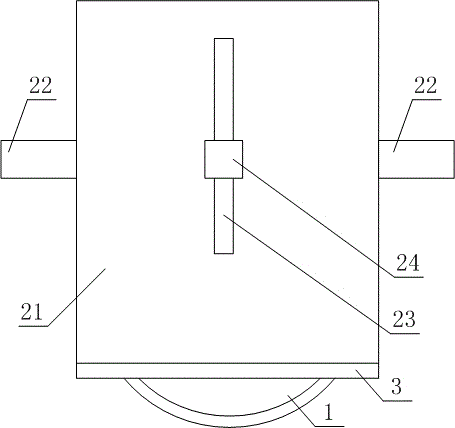

The invention discloses a tree planting machine. The tree planting machine comprises a machine frame, a sapling conveying system and a sapling planting device, wherein the sapling conveying system comprises a conveying belt fixed to the machine frame and used for containing sapling cups, the sapling planting device and the tail end of the conveying belt are adjacently arranged, and the sapling planting device comprises a drilling mechanism, a sapling grabbing mechanism and a sapling cup recycling mechanism which are fixed to the same rotary disc; the drilling mechanism comprises a drill bit driven by a drilling motor, and a sliding rod for driving the drill bit to move up and down; the sapling grabbing mechanism comprises a grabbing claw for grabbing saplings, and a sliding block for driving the grabbing claw to slide up and down; the sapling cup recycling mechanism comprises a mechanical claw for grabbing the sapling cups, and a moving block which drives the mechanical claw to move upand down; the rotating disc is driven by a rotating motor fixed to the machine frame. The tree planting machine is compact in structure and can conveniently complete drilling, sapling transportation,sapling grabbing and planting, soil covering and the like, saplings can be continuously planted in batches, the labor is liberated, the sapling planting efficiency is greatly improved, and time and labor are saved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

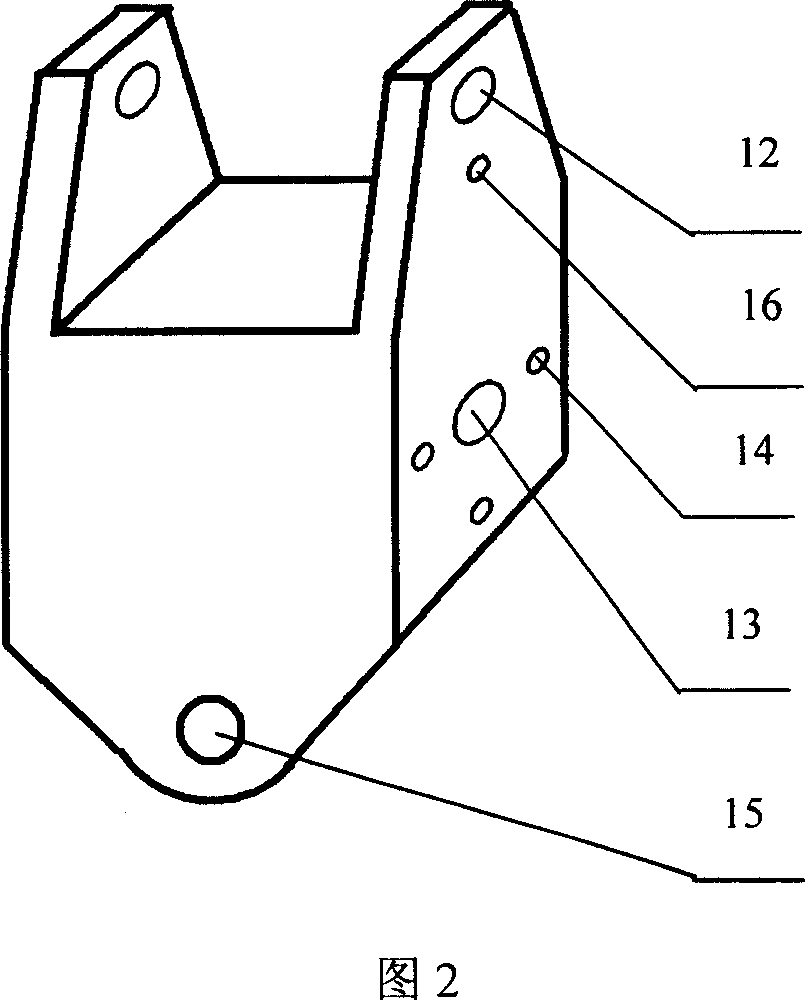

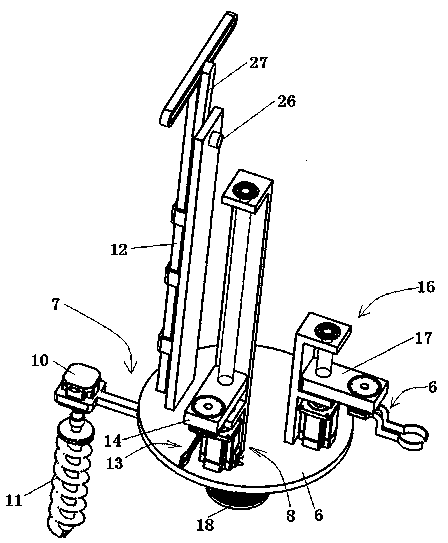

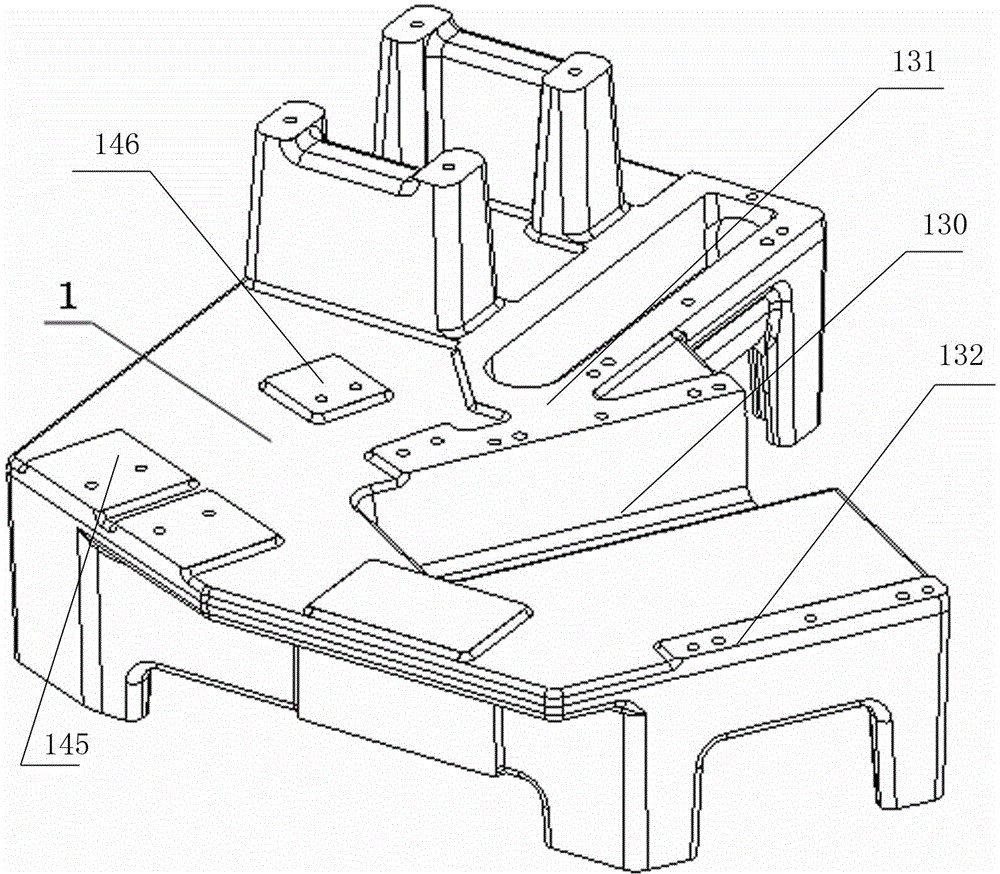

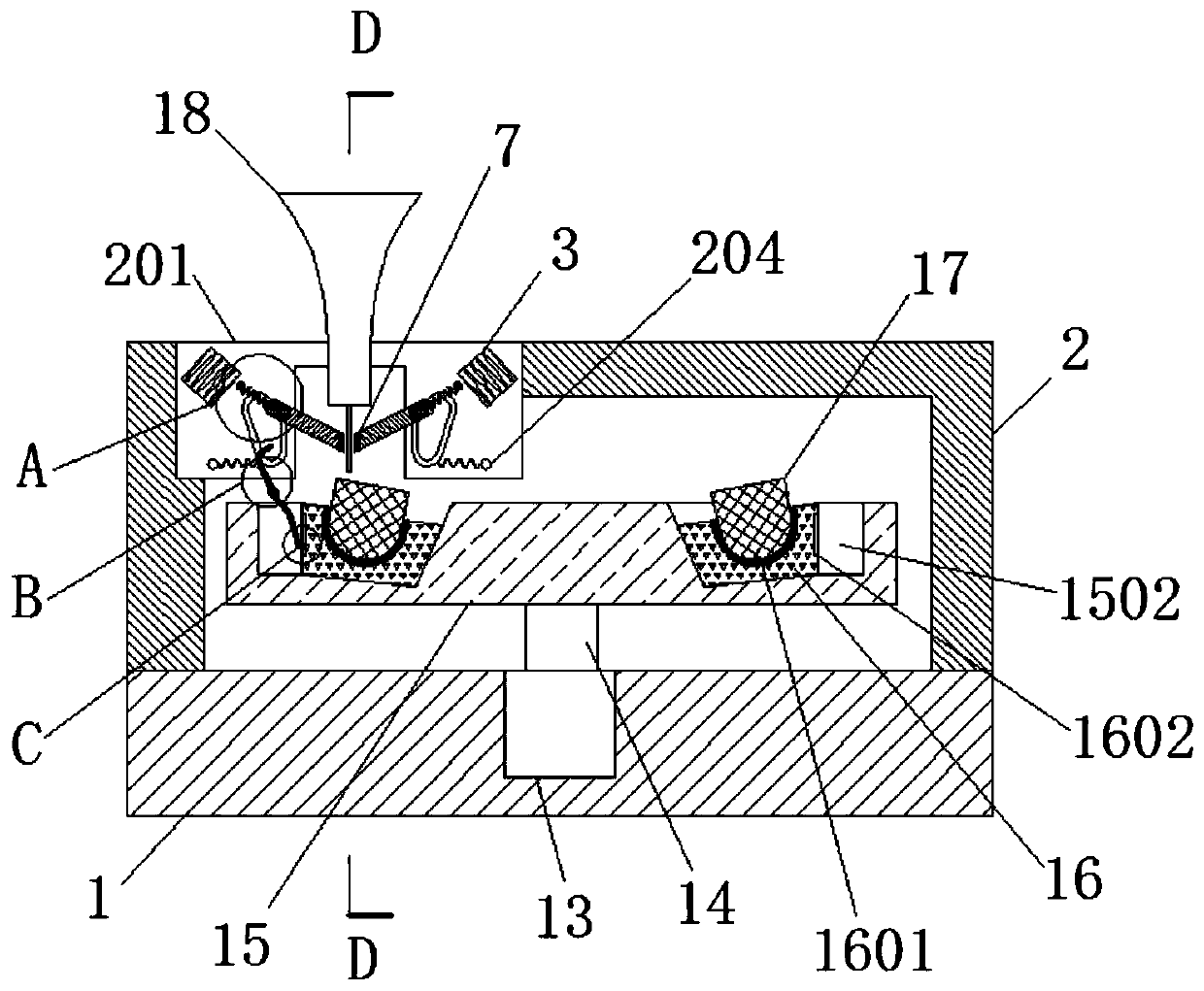

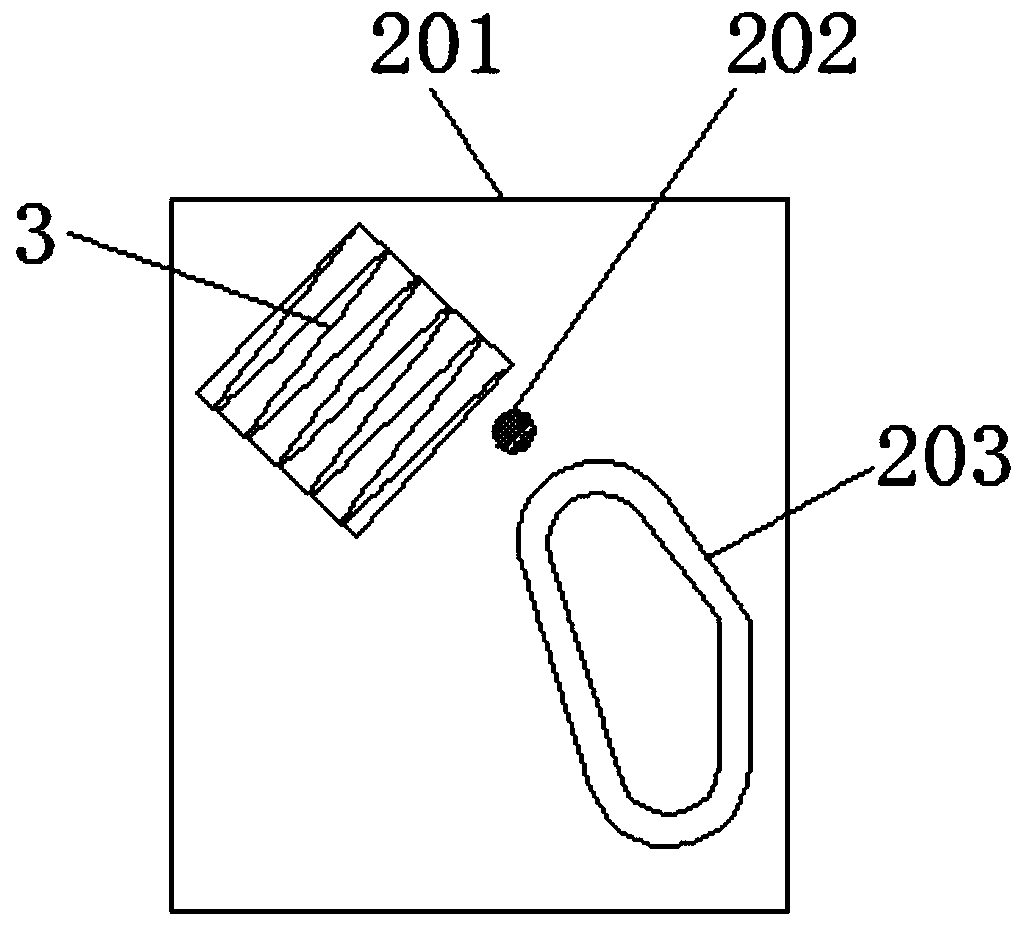

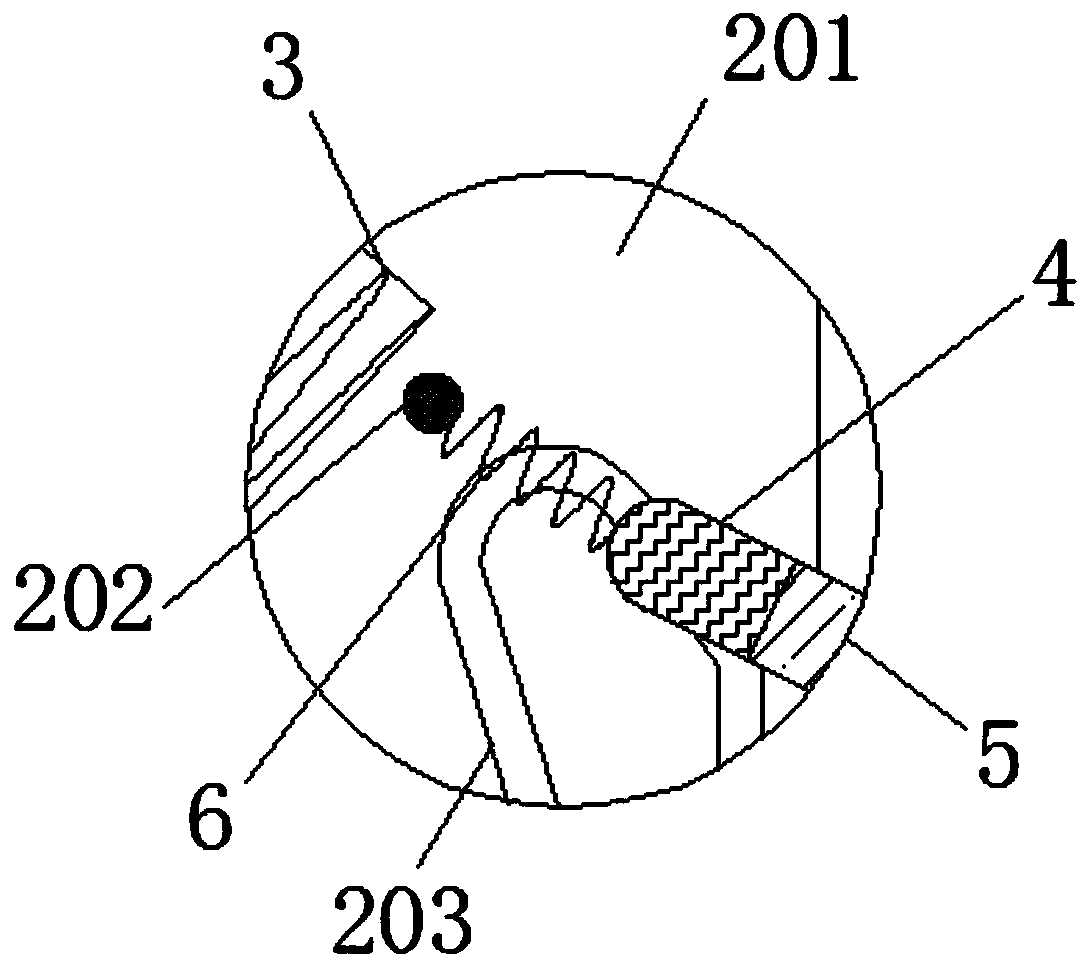

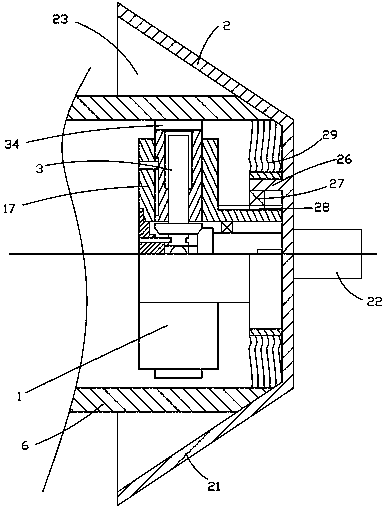

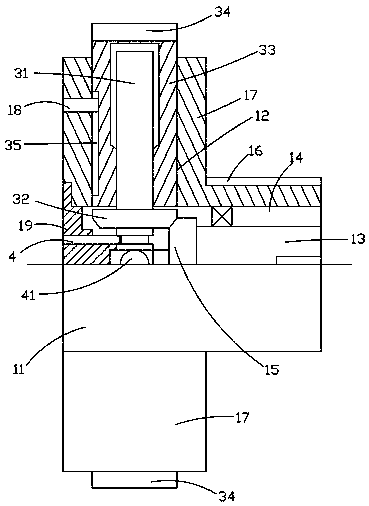

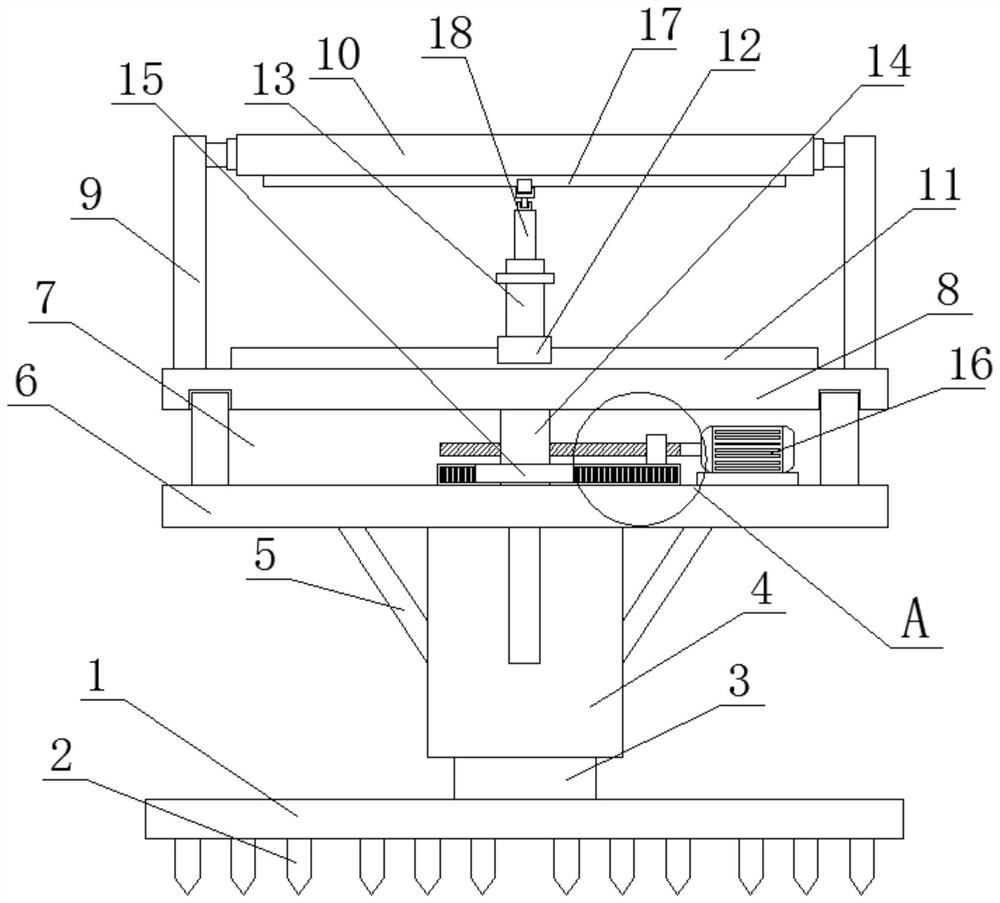

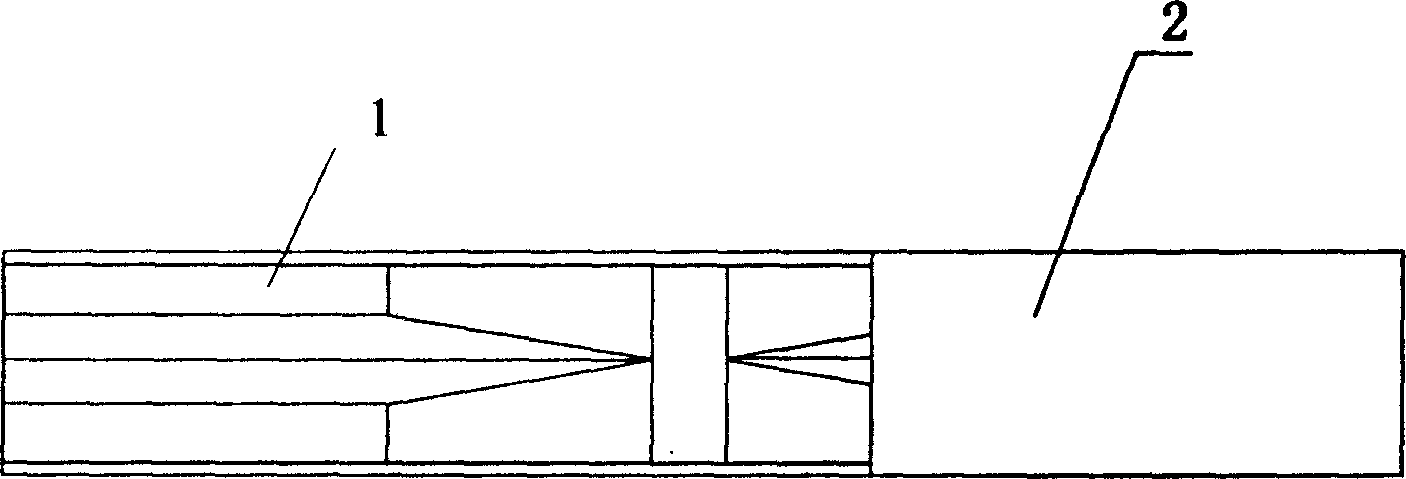

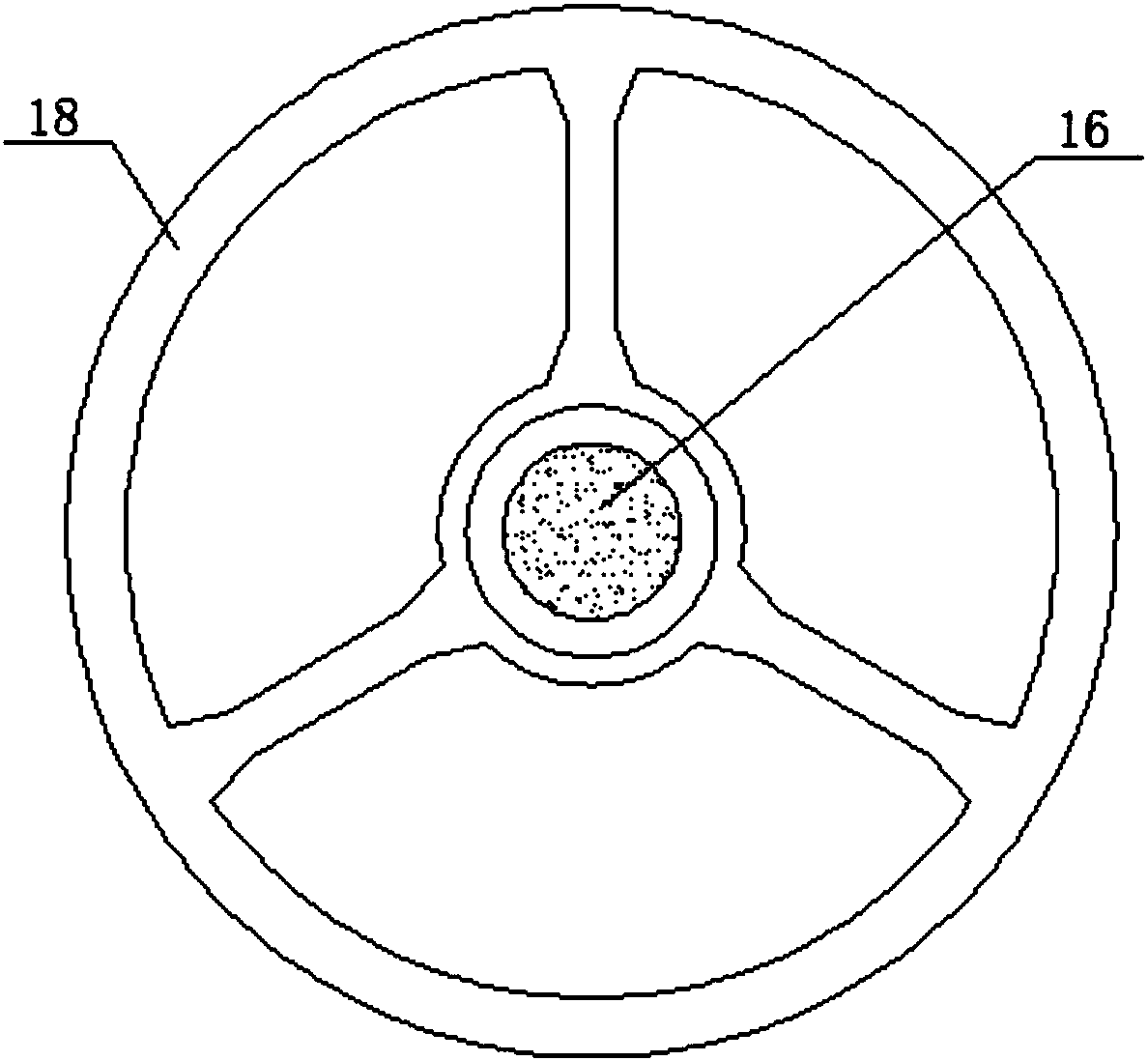

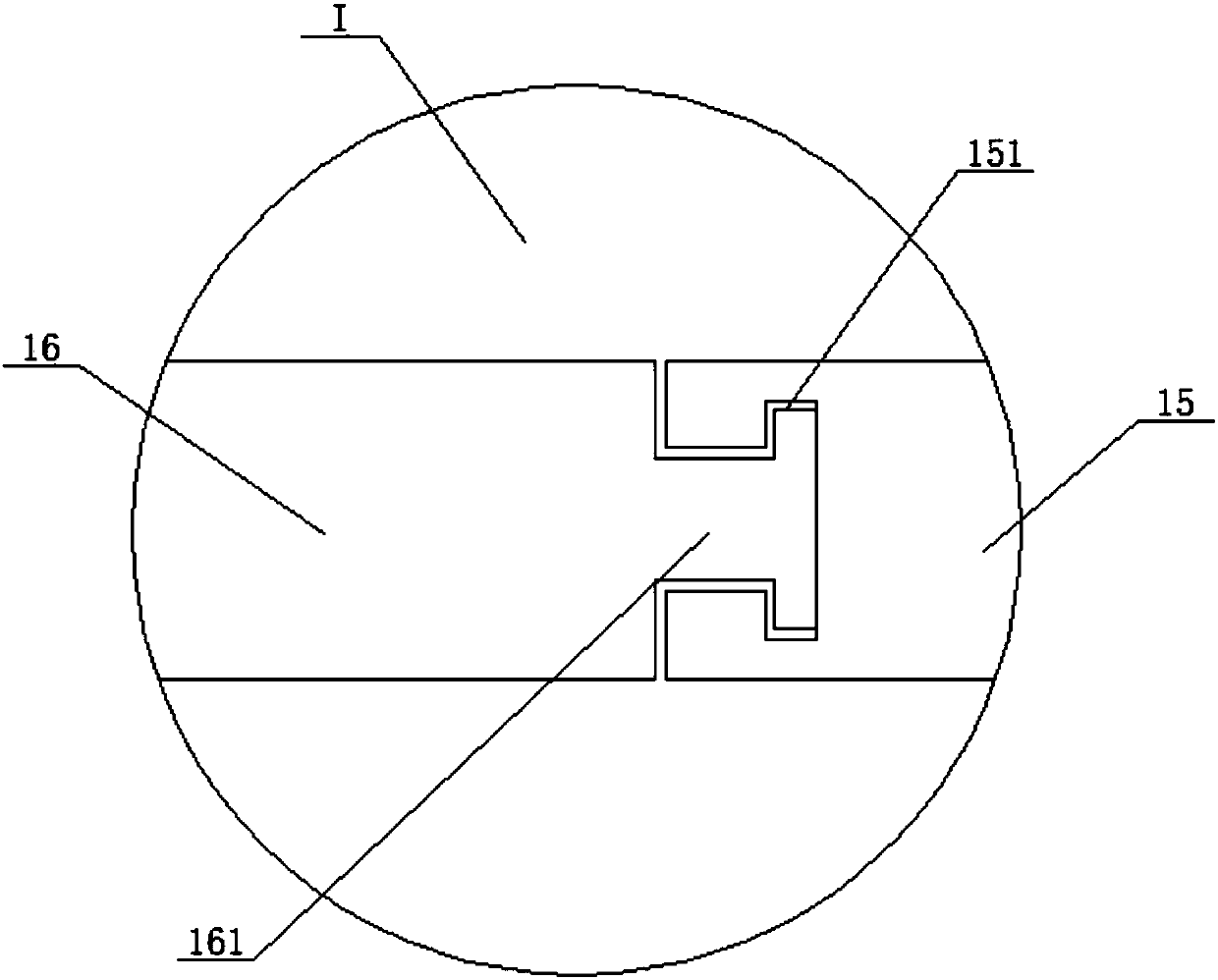

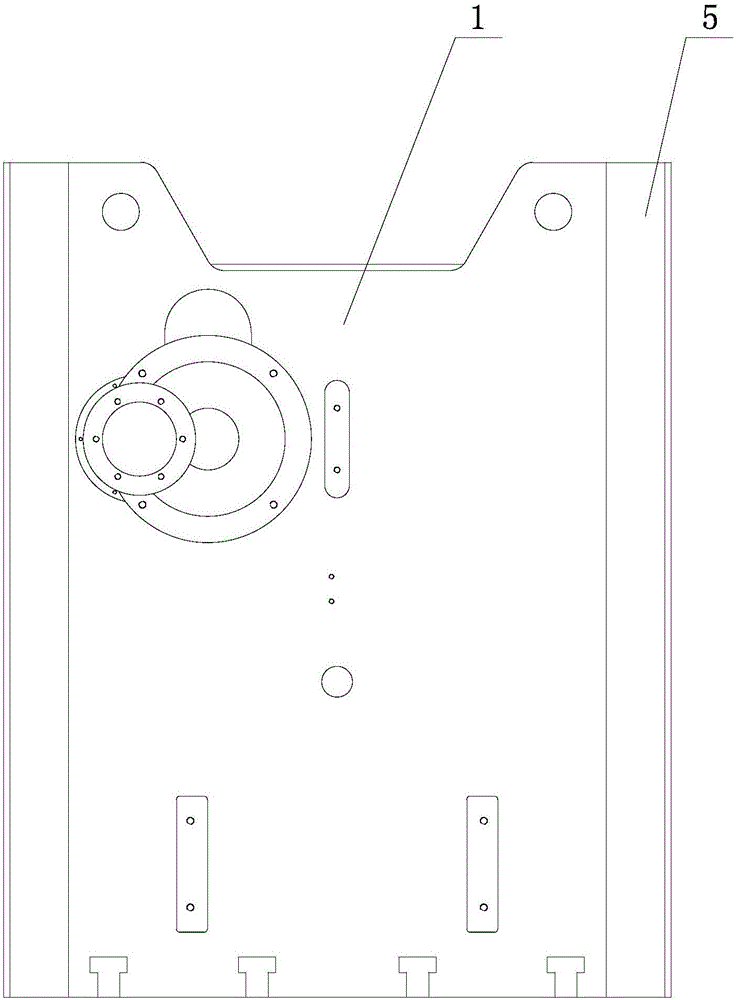

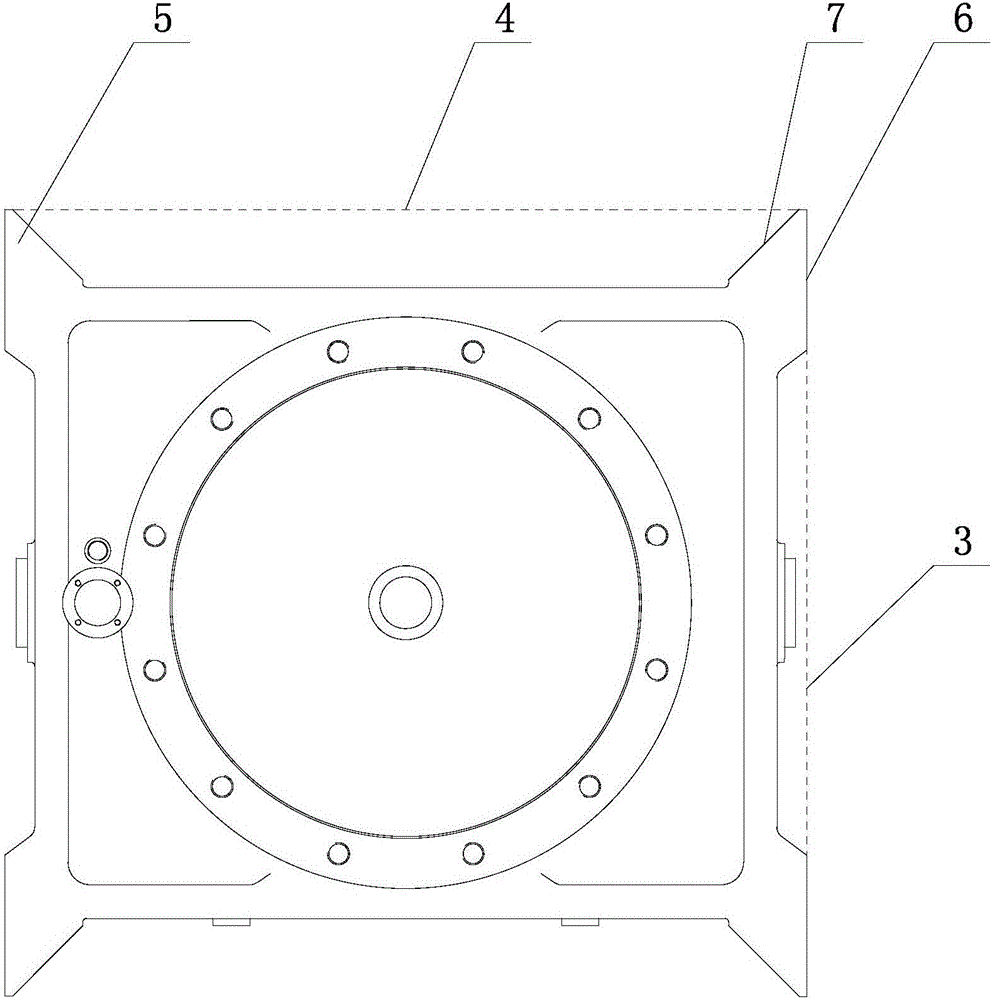

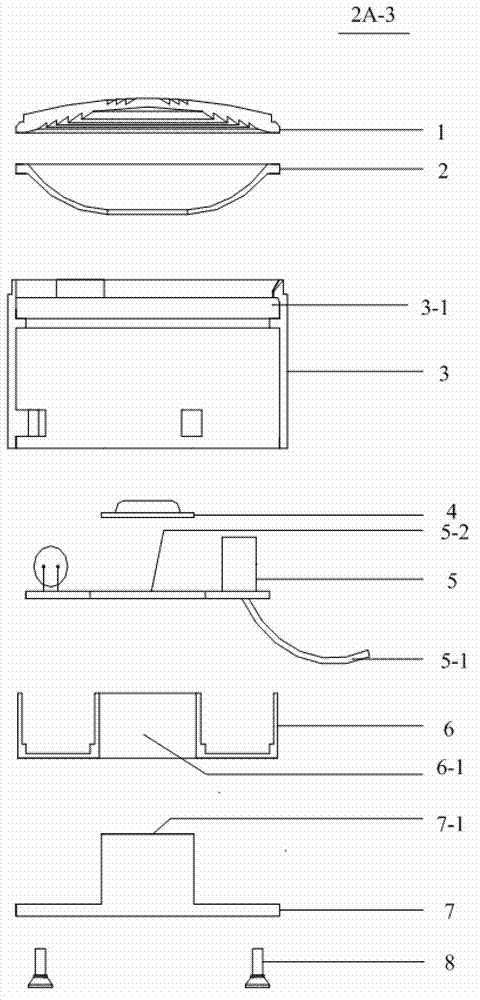

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

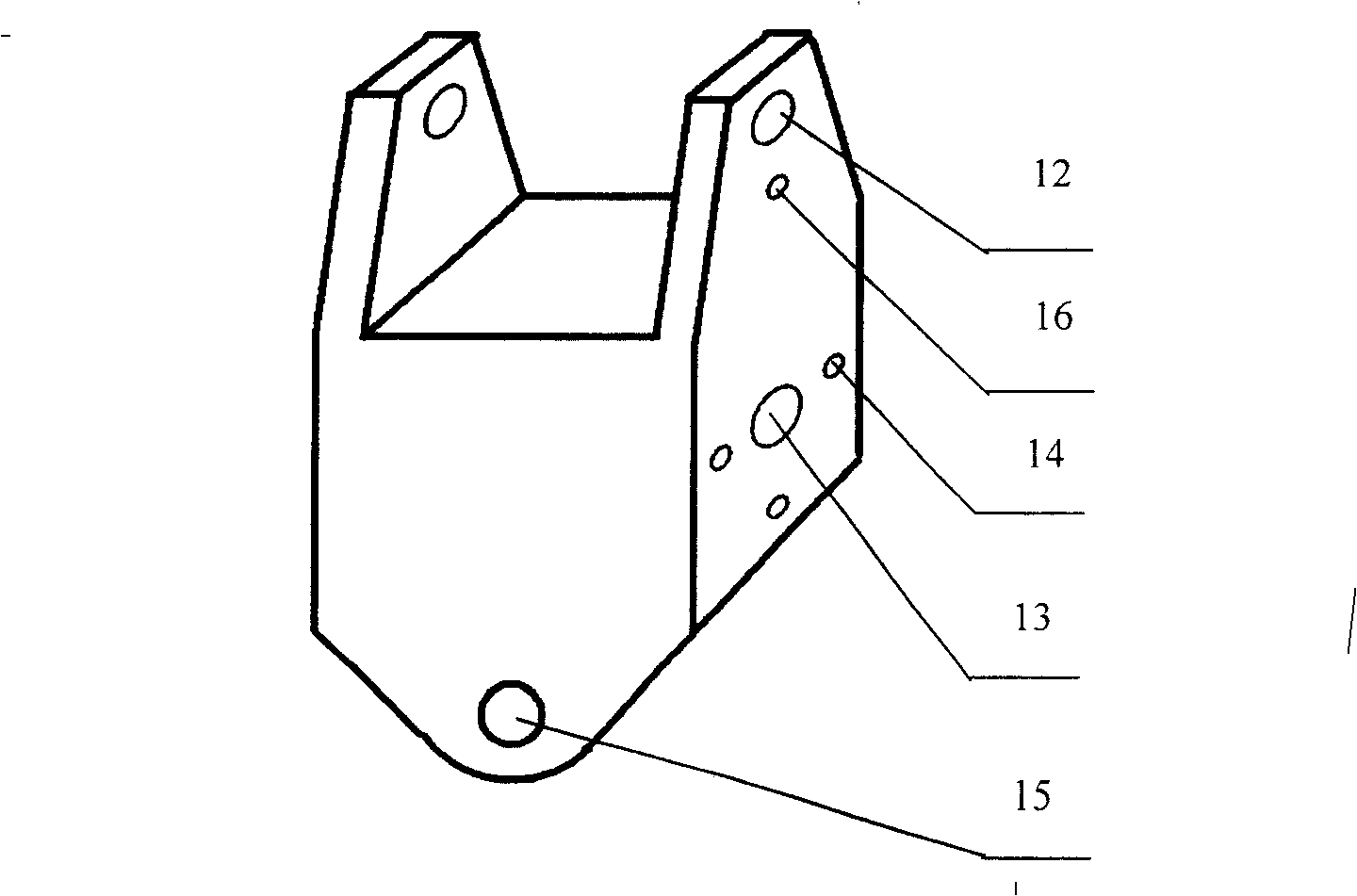

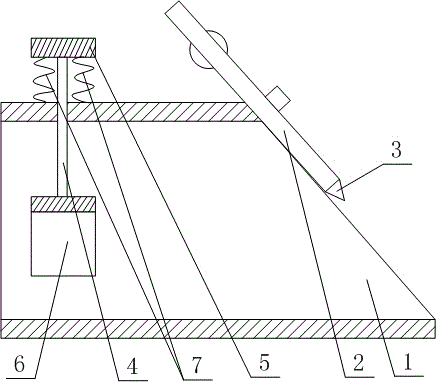

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

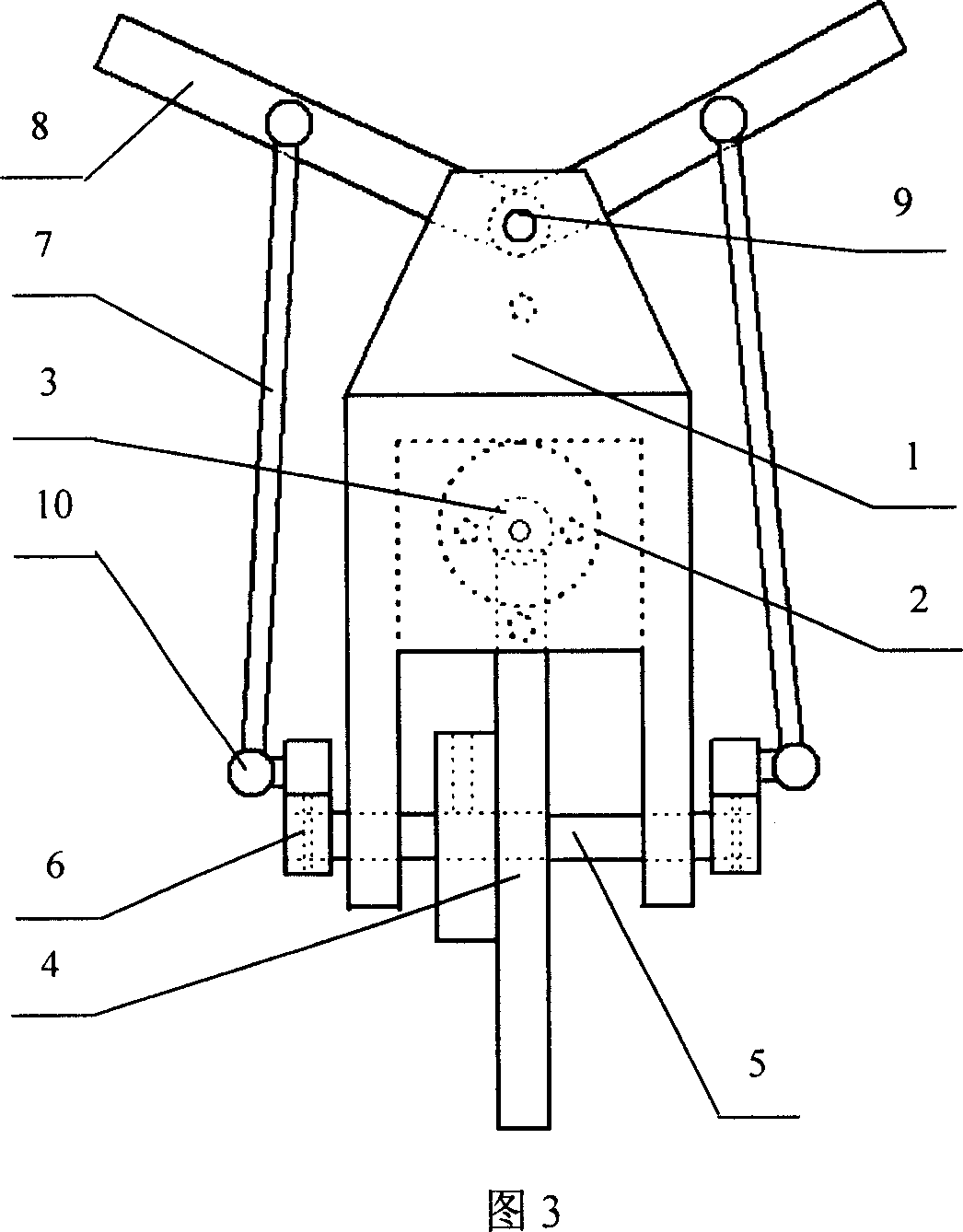

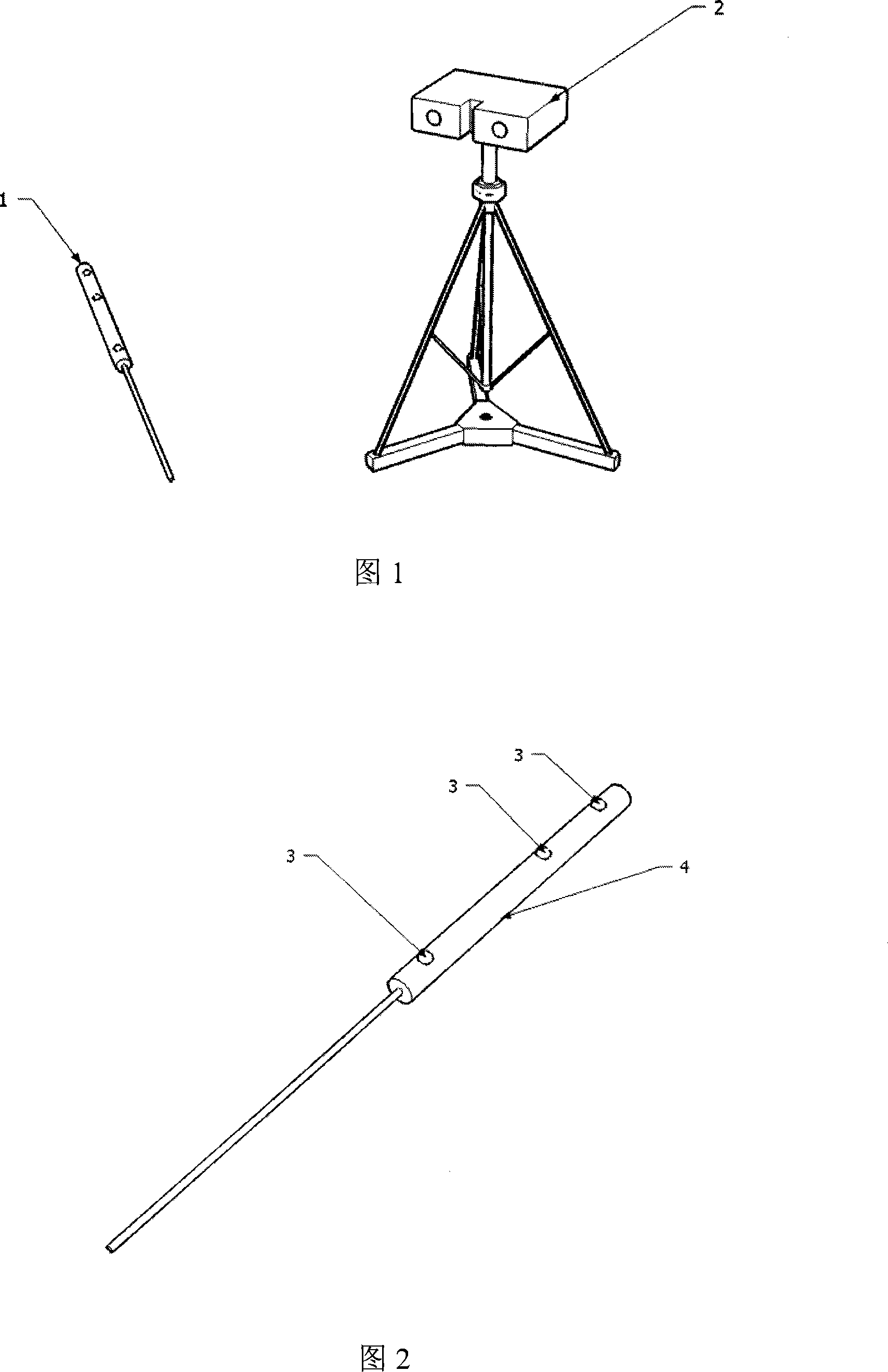

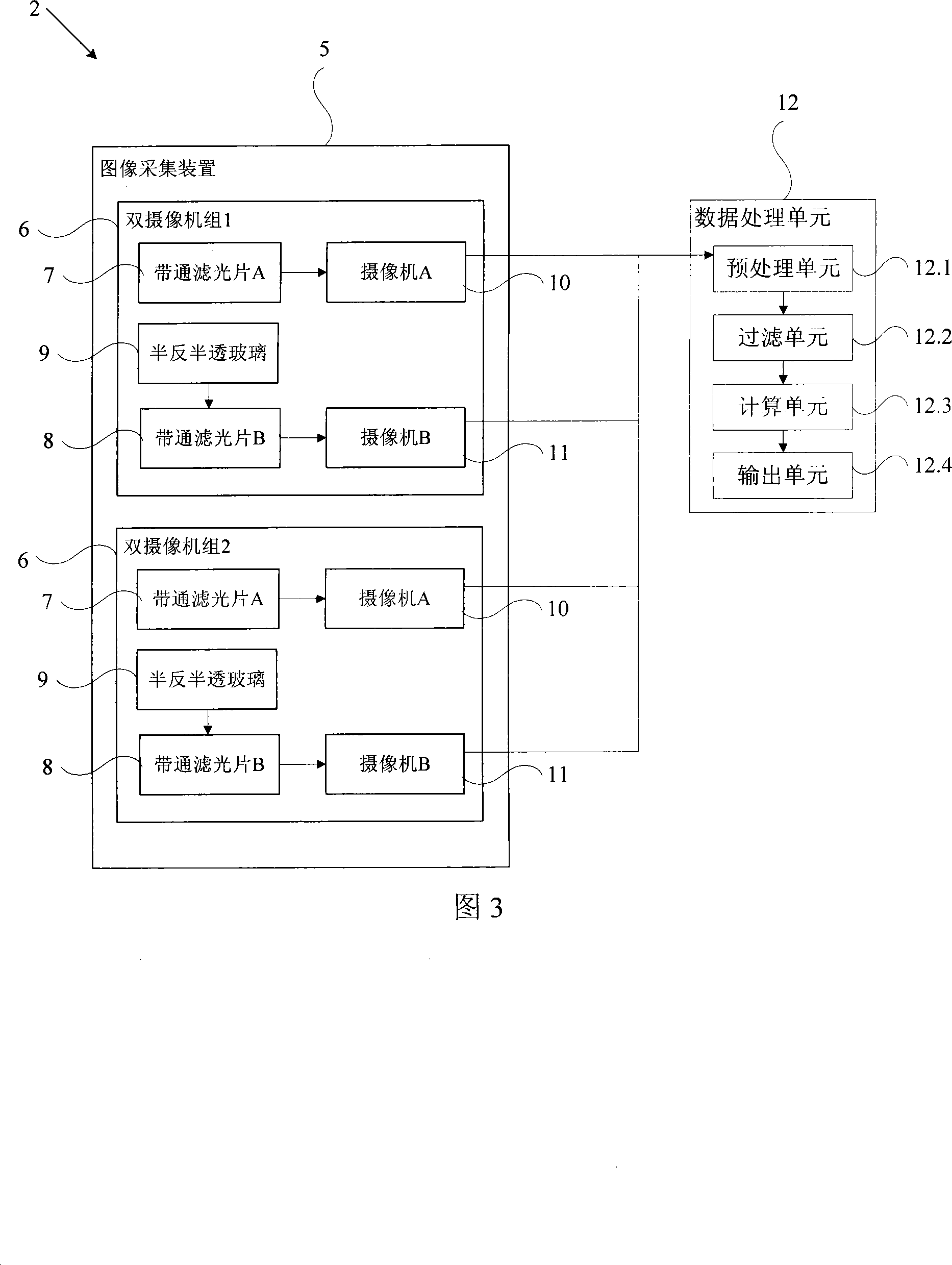

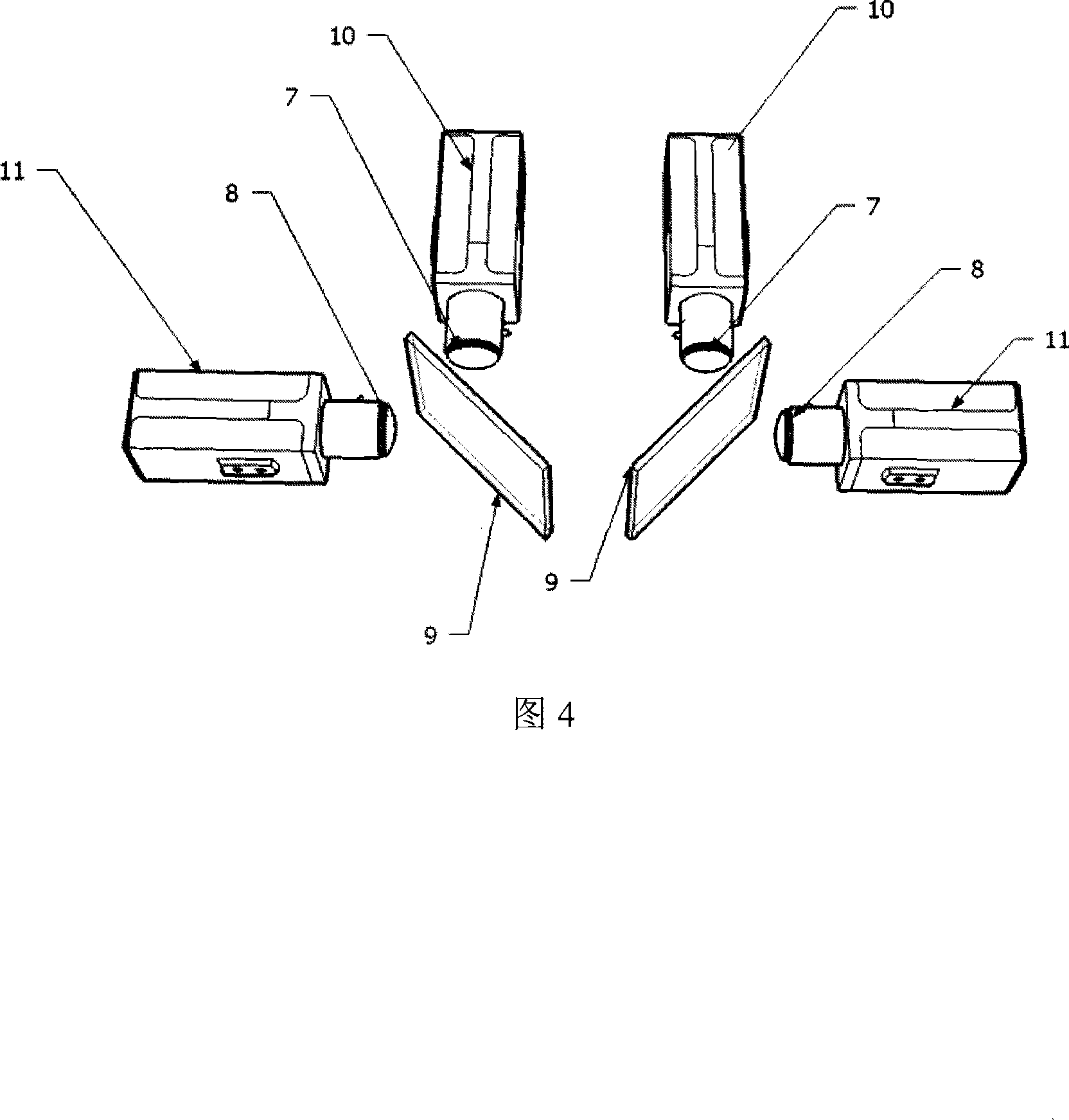

Medicine operation navigation tracking device based on multispectral image

ActiveCN101214142ASame angleTo achieve the purpose of tracking and positioningSurgical navigation systemsDiagnostic recording/measuringBand-pass filterHand held devices

The invention is a medical operation guidance tracker which bases on multi-spectral images. The device includes a tracked handheld device and a tracking device which consists of two camera groups and is fixedly installed. The handheld device includes a device body and a plurality of luminous points used for tracking. The tracking device includes the two camera groups. Every camera group includes two cameras which pass through band pass filters with different band widths and a piece of semi-permeable and semi-reflecting glass. The tracking device also includes a data treatment unit which is coupled with the two camera groups and is used to analyze and treat the acquisitioned images to determine the position and the state of the handheld device. The invention collects images with different spectrums and filters the interferences of a general luminophor on a tracing system to realize the real-time position and state calculation of the handheld device and the tracking requirements on surgical instruments during the operation guidance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

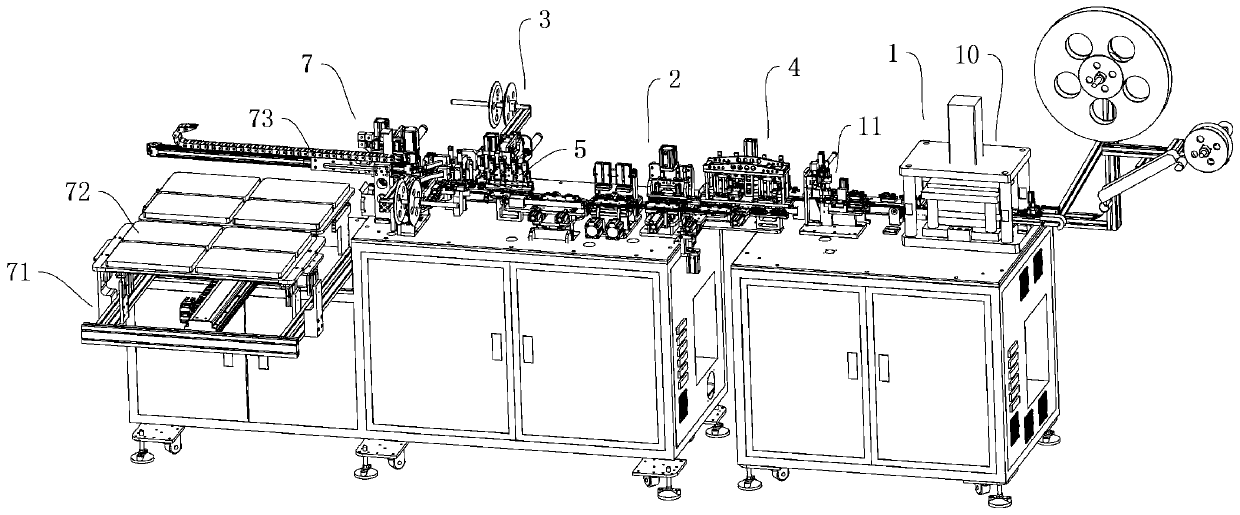

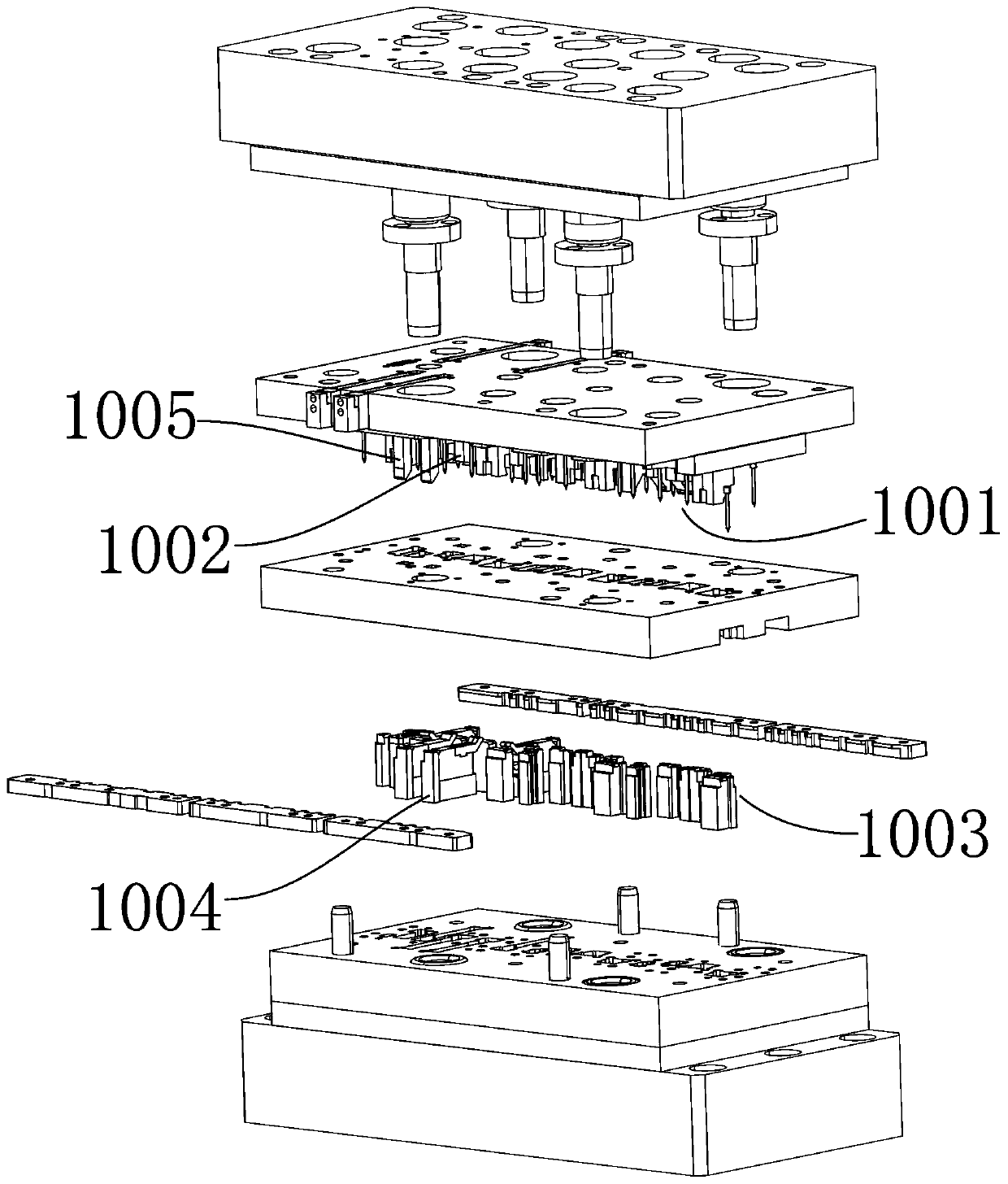

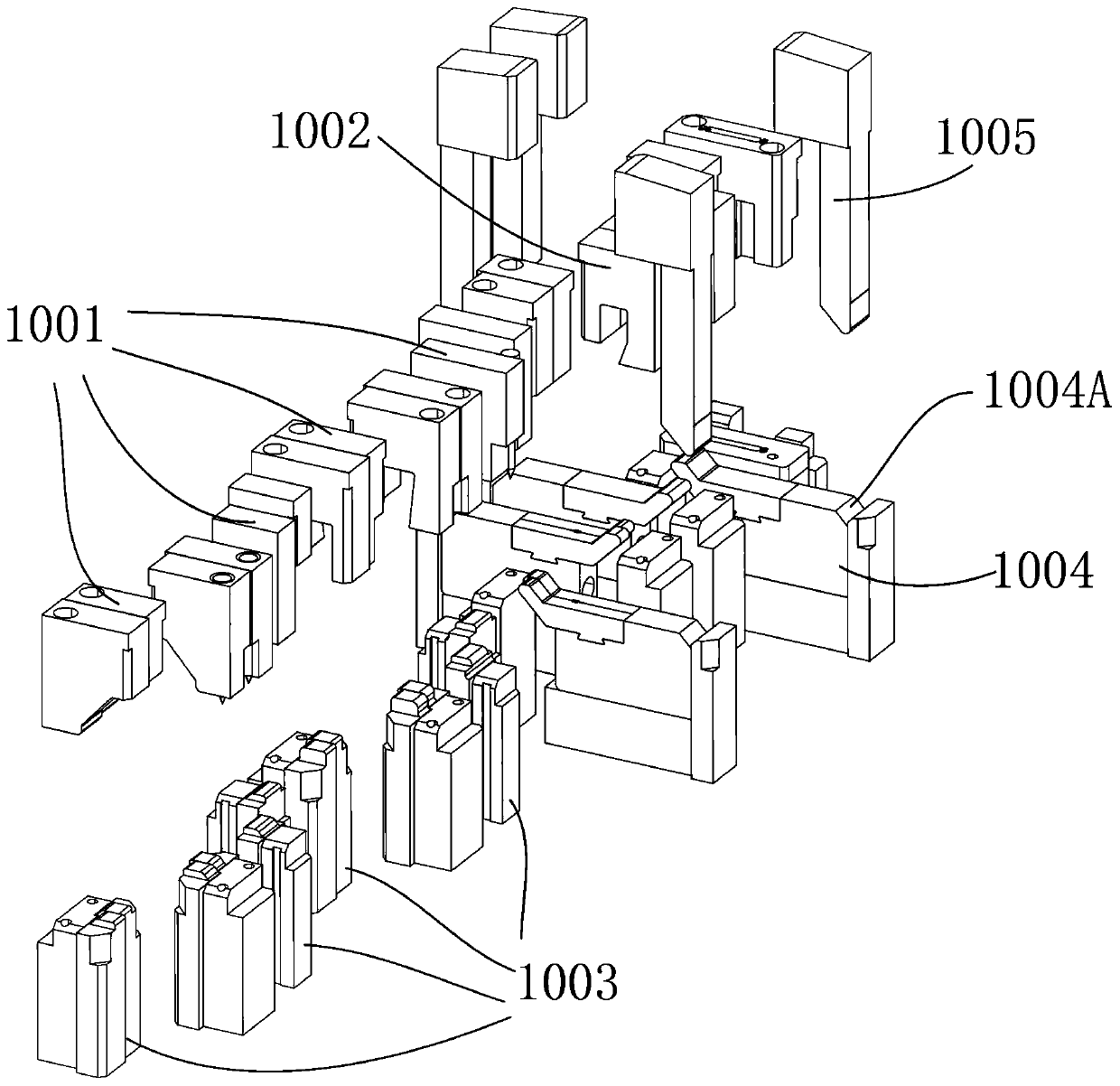

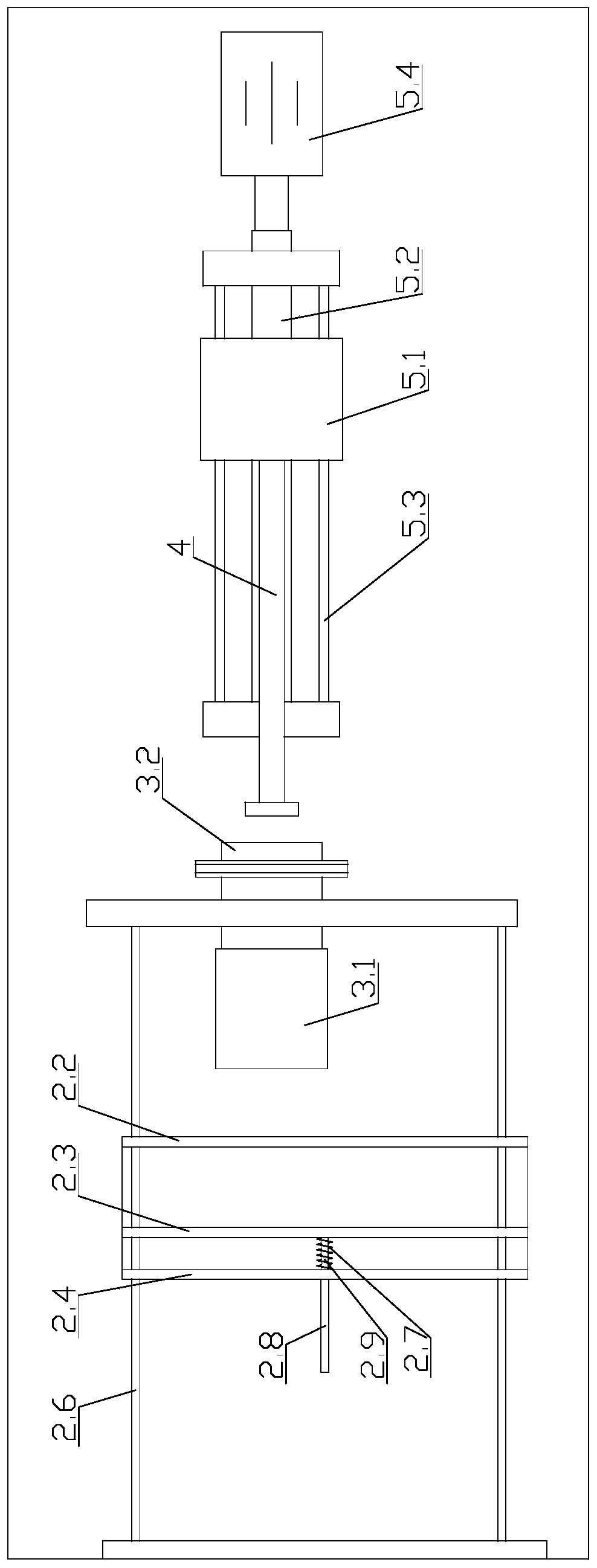

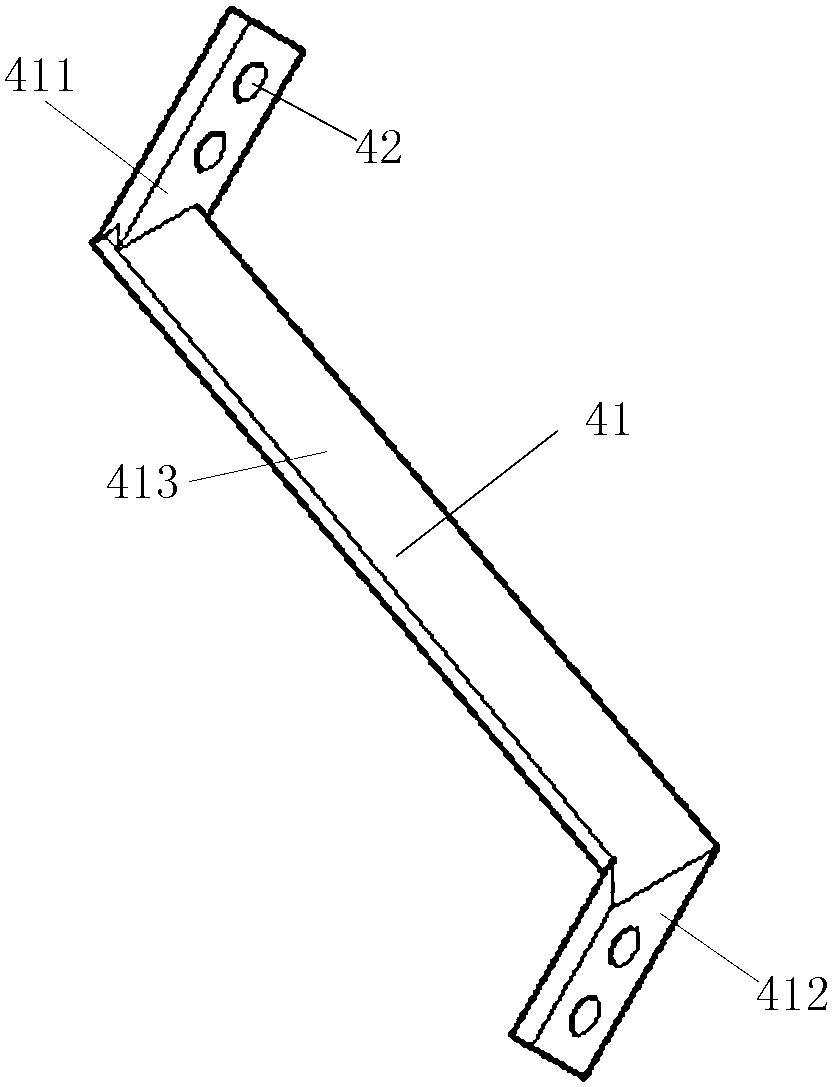

Automatic terminal processing equipment and method

PendingCN110380315ARealize automatic processingImprove yield rateContact member manufacturingContact member assembly/disassemblyManipulatorProduct defect

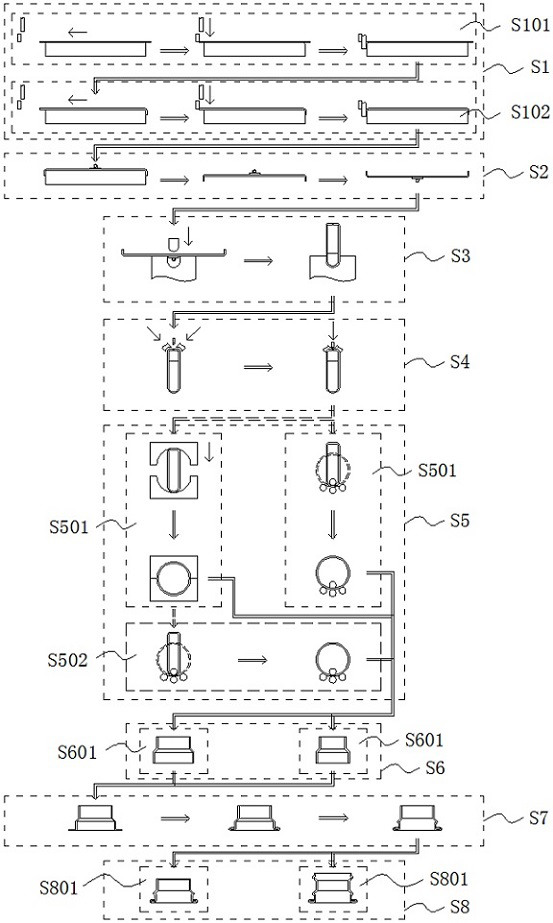

The invention discloses automatic terminal processing equipment. The automatic terminal processing equipment and method includes a terminal bending and cutting device, a terminal tail belt and water gap cutting device and a terminal plugging device according to the terminal processing sequence, wherein correspondingly, the terminal bending and cutting device and the terminal tail belt and water gap cutting device are provided with a conveying robot, correspondingly, the terminal tail belt and water gap cutting device and the terminal plugging device are provided with a conveying mechanism, oneside of an output end of the terminal plugging device is provided with a detection positioning seat for disposing terminals, and the detection positioning seat is correspondingly provided with a metal probe used for detecting terminal plugging. The automatic terminal processing equipment is advantaged in that structural design is reasonable and ingenious, automatic processing of the terminals isachieved, terminal plugging and length of wiring terminals are detected, cost is saved, common bad properties in market can be avoided, the yield of output products is effectively improved, moreover,break of the terminals is avoided through continuous dies for terminal bending, and the product defect rate is reduced.

Owner:东莞诚信电子塑胶有限公司

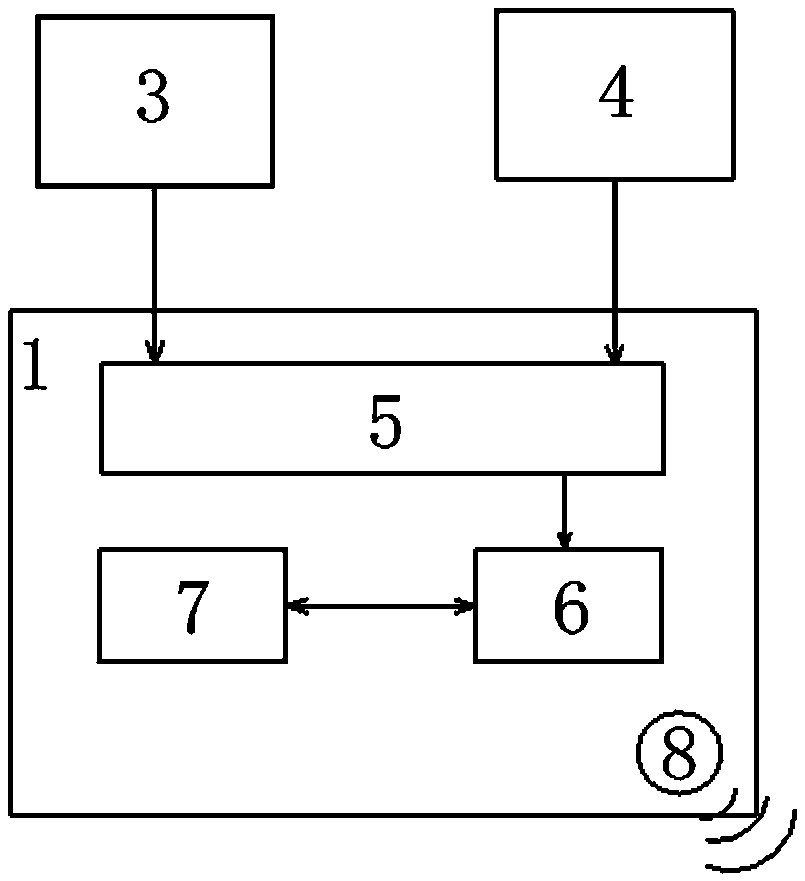

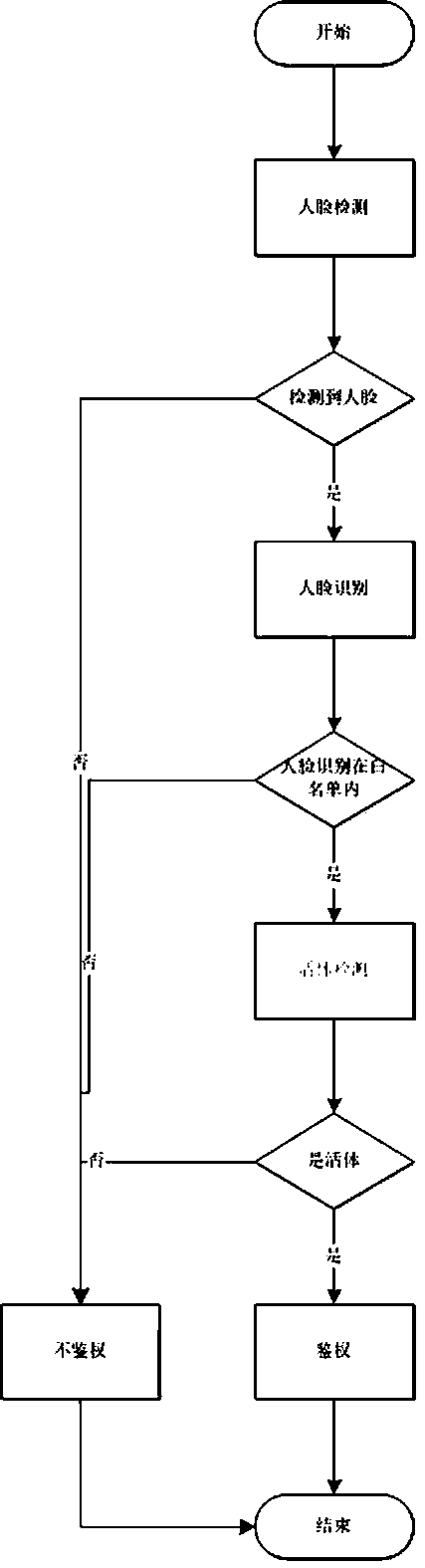

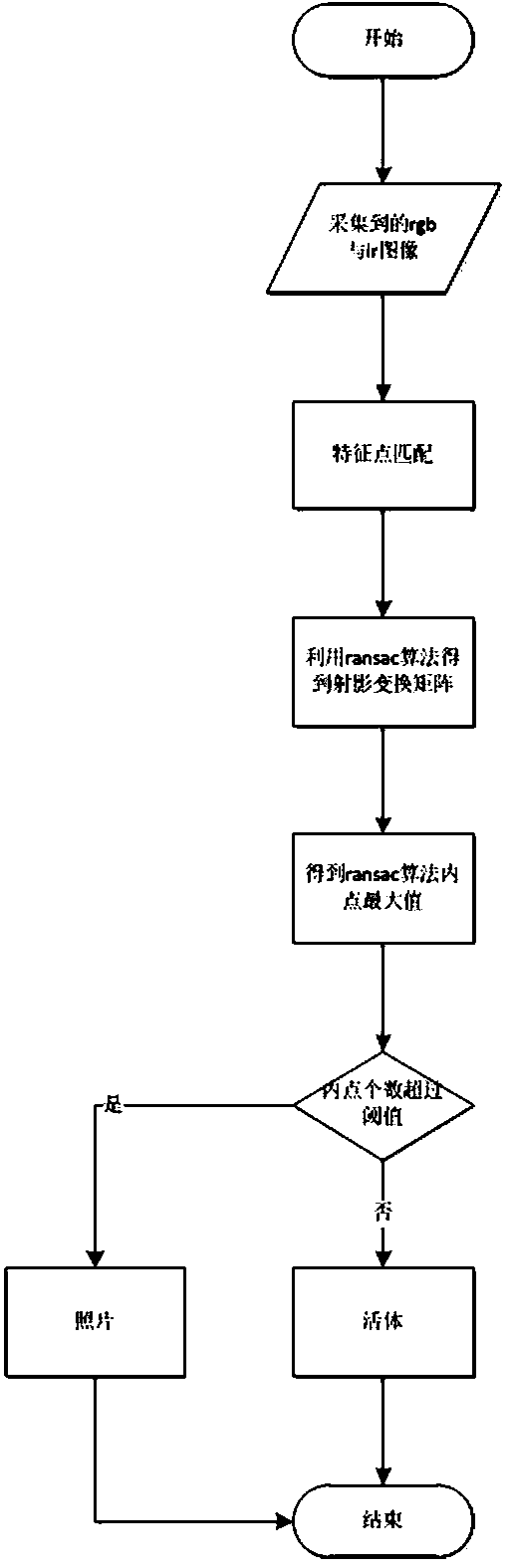

Elevator-scene-based binocular camera face identification and authentication system and method

The invention provides an elevator-scene-based binocular camera face identification and authentication system. The system comprises a binocular image acquisition device, a processor and a comparison data platform, the binocular image acquisition device comprises an RGB camera device and an IR camera device which conduct real-time synchronous acquisition on video images entering the identificationrange, the output ends of the RGB camera device and the IR camera device are connected to the processor, acquisition results are sent to the processor, the processor conducts face identification and data processing on the acquisition results of the RGB camera device and the IR camera device, comparison is conducted with data stored in the comparison data platform, and whether authentication is conducted or not is judged. The invention further provides an elevator-scene-based binocular camera face identification and authentication method. Accordingly, face image acquisition is conducted throughtwo different kinds of image acquisition devices, whether a living face or a photo or video which is used for camouflage exists can be judged, and then the security of elevator control authenticationis guaranteed.

Owner:ZHEJIANG NEW ZAILING TECH CO LTD

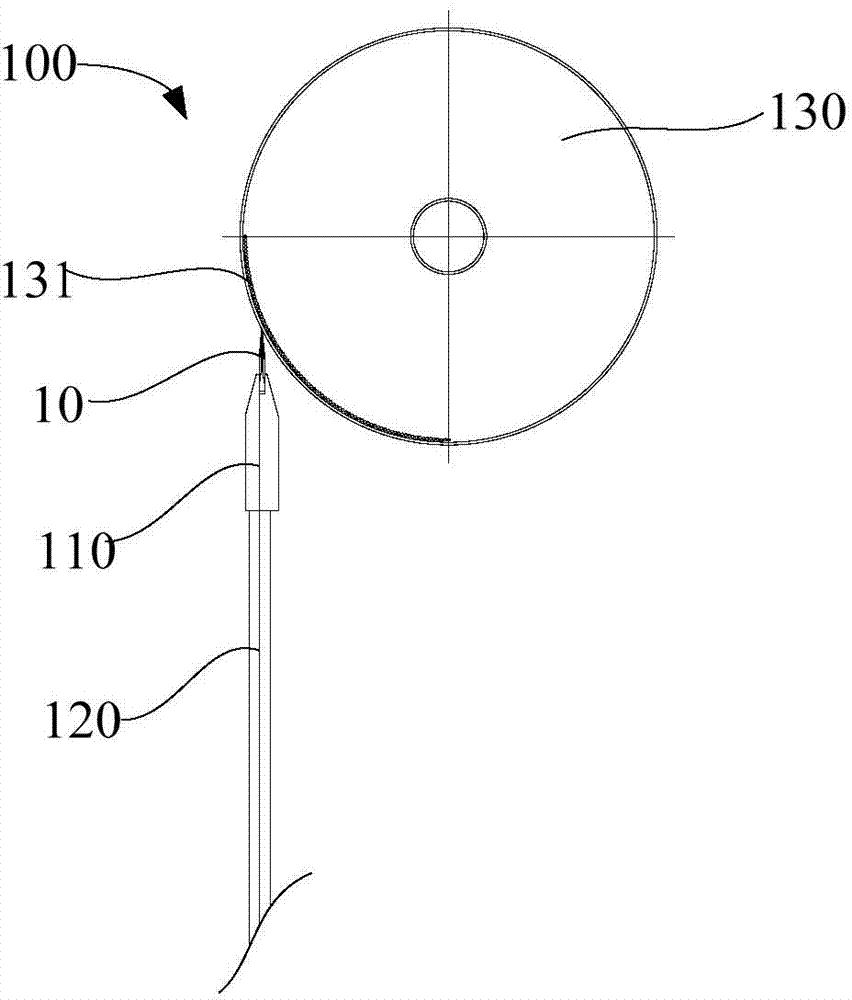

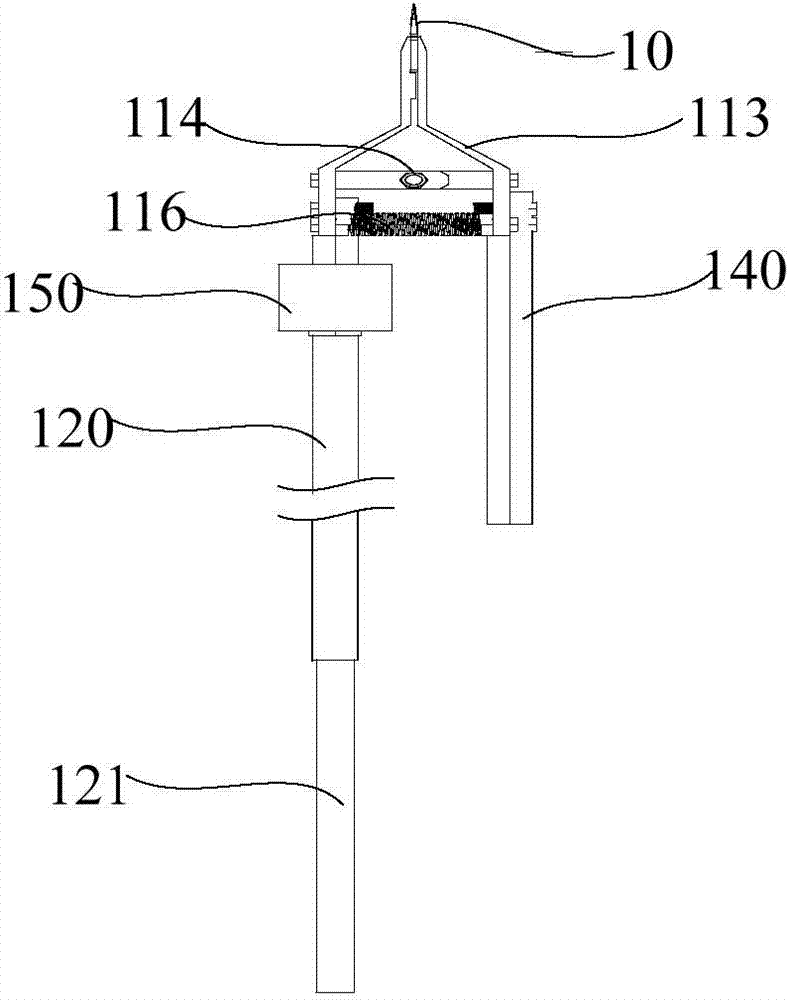

Edge forming device for ceramic tip

ActiveCN104117879ASame angleConsistent sharpnessOther manufacturing equipments/toolsGrinding work supportsMetallurgyGrinding wheel

An edge forming device for a ceramic tip comprises a fixture used for clamping the ceramic tip, a supporting table, a rotating shaft, and a grinding wheel used for grinding the ceramic tip to form a preset small-edge included angle. One end of the rotating shaft is connected with the fixture, the other end of the rotating shaft is connected with the supporting table in a rotating mode, and the rotating shaft swings in a swing plane which is parallel with the plane where the ceramic tip is located. The annular side wall of the grinding wheel is provided with scales uniformly distributed along the periphery of the annular side wall, and the scales indicate the included angles between the radial points of the annular side wall and the swing plane. The relative position of the supporting table and the grinding wheel can be adjusted, so that the ceramic tip makes contact with the different points of the annular side wall of the grinding wheel, and the complement angle of the scale value corresponding to the contact point of the ceramic tip and the grinding wheel is equal to half of the preset small-edge included angle of the ceramic tip. The ceramic tip ground by the edge forming device for the ceramic tip has an edge with angle consistency and sharpness consistency and is attractive in appearance.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

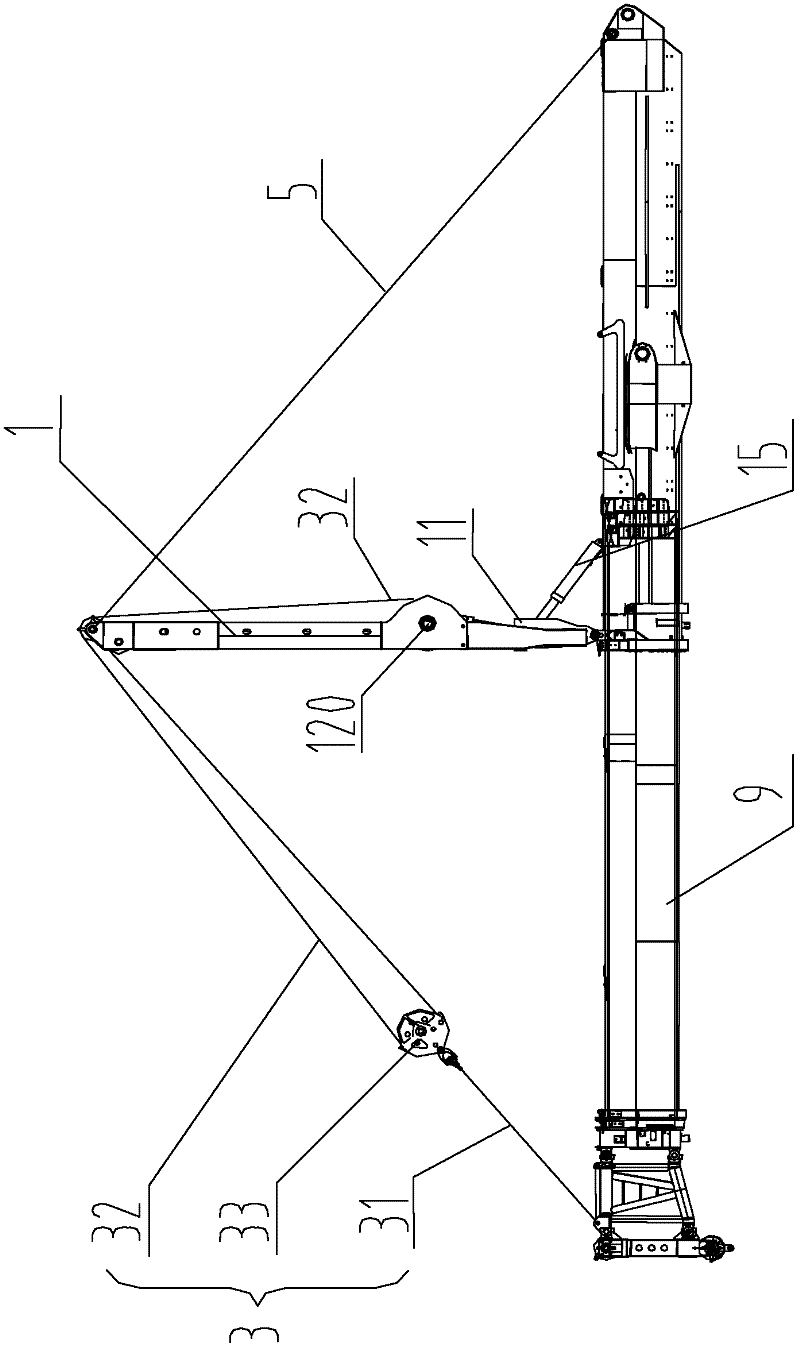

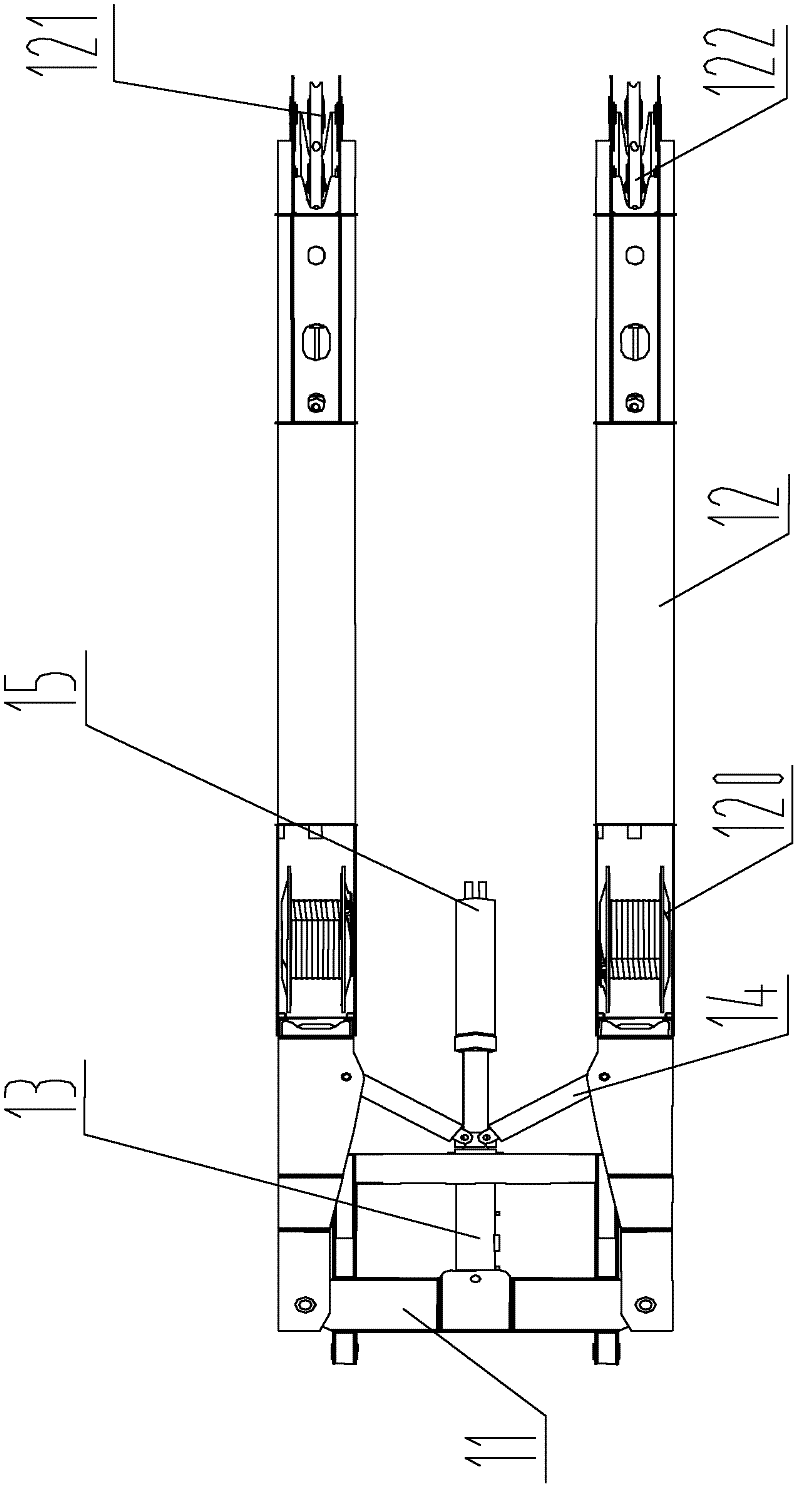

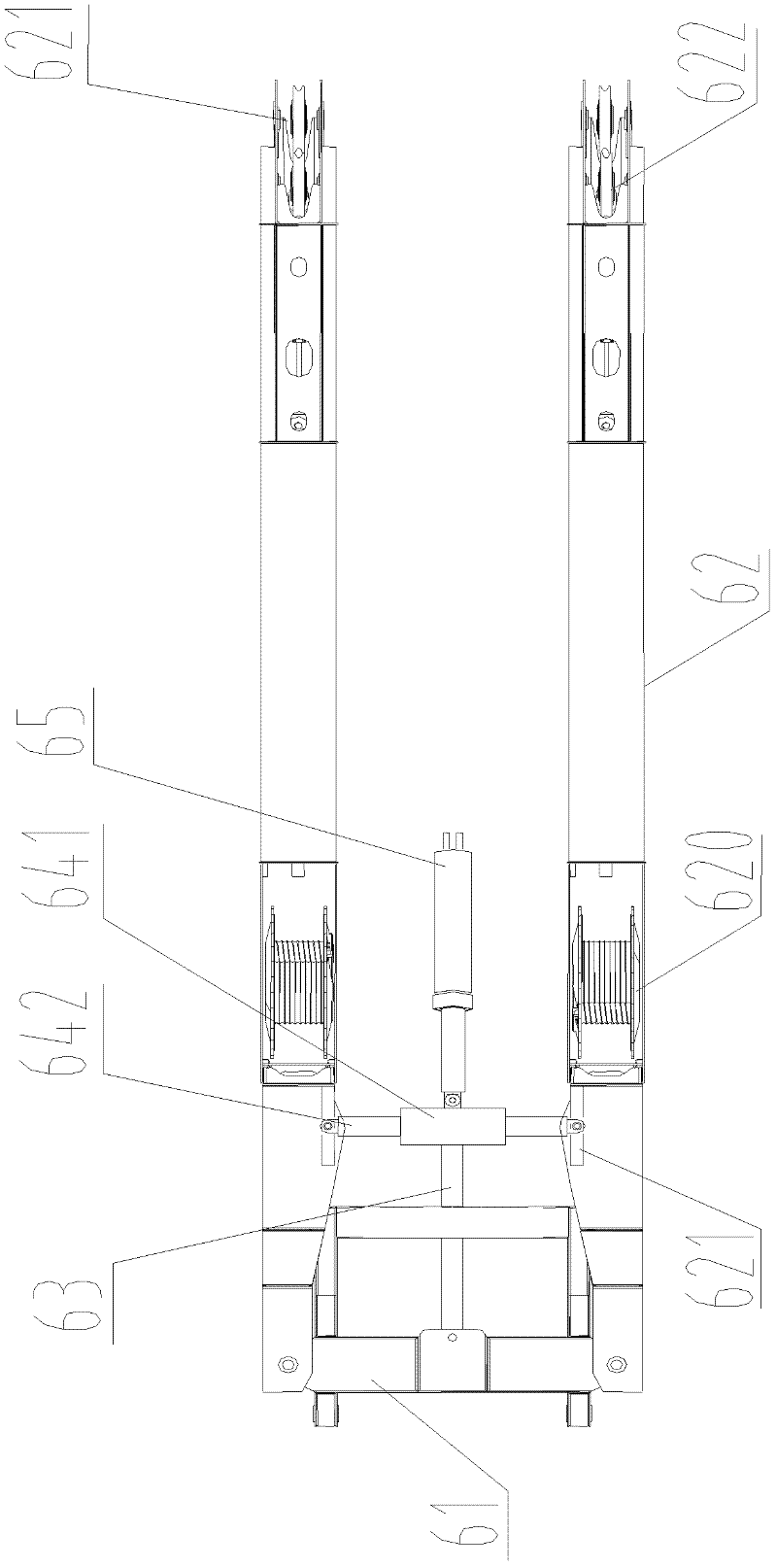

Crane and super-lifting device thereof

The invention provides a crane and a super-lifting device thereof. The super-lifting device comprises a super-lifting mast, a front tensioning mechanism and a rear tensioning mechanism, wherein the super-lifting mast comprises a base, rod parts and only one power mechanism; the base is fixed on a lifting arm of the crane; one end of each rod part is hinged with the base; the power mechanism is fixed on the base, and is hinged with the rod parts; the front tensioning mechanism is connected between the super-lifting mast and the head of the lifting arm; and the rear tensioning mechanism is connected between the super-lifting mast and the tail of the lifting arm. Only one power mechanism is arranged in the super-lifting device, and can be used for driving the two rod parts to unfold simultaneously, so that the two mast rod parts can be unfolded at the same time, and unfolding angles of the two mast rod parts are consistent; therefore, steel wire ropes matched with the two mast rod parts are consistently stressed; and an effect of controlling sidewise bending is achieved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

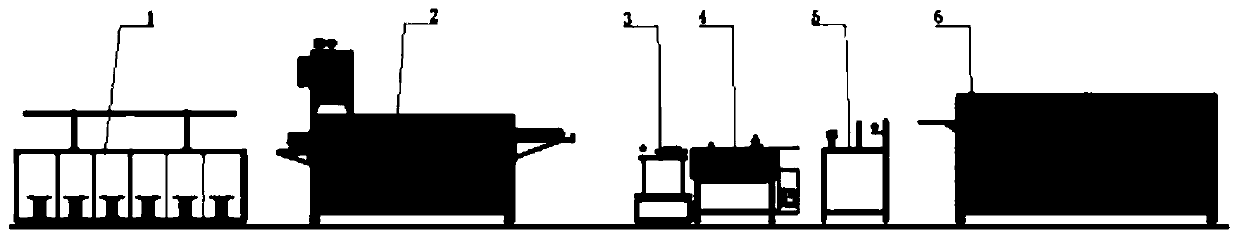

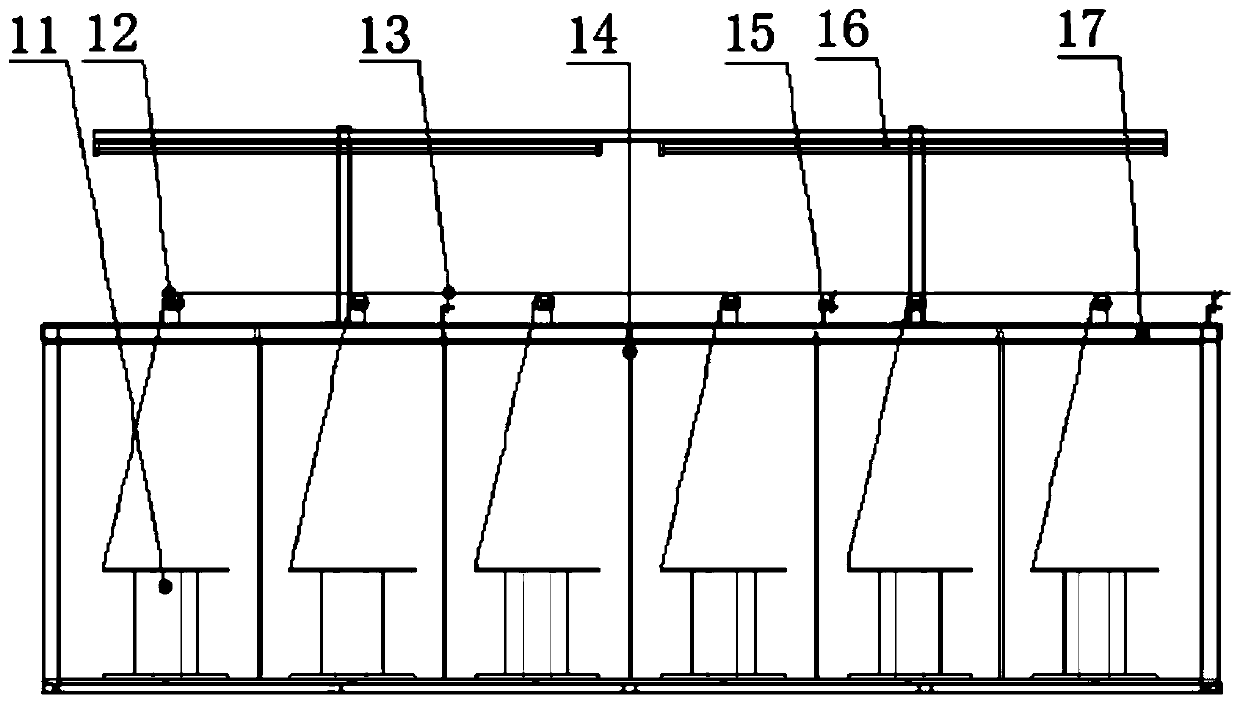

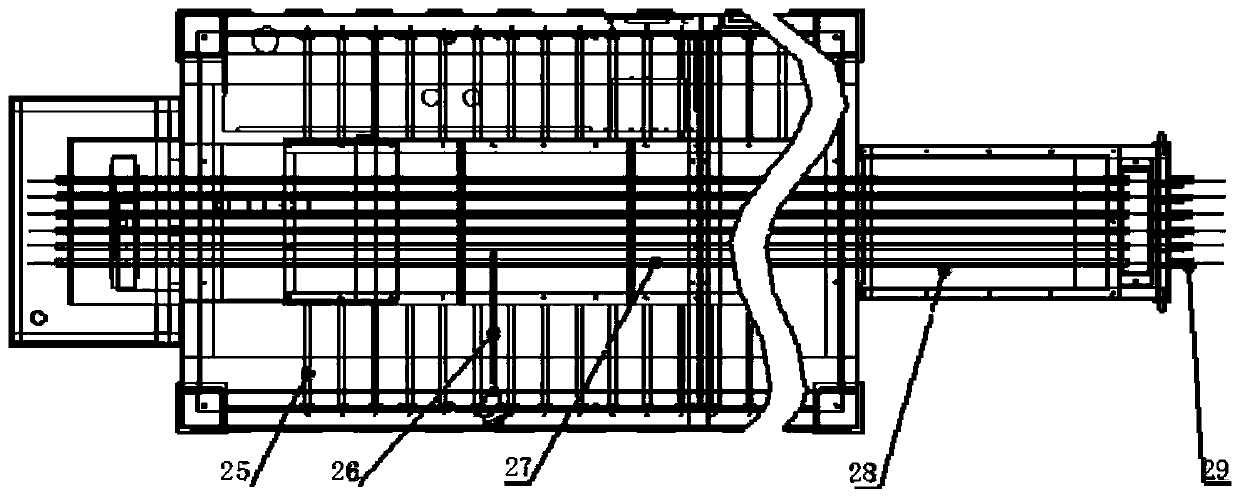

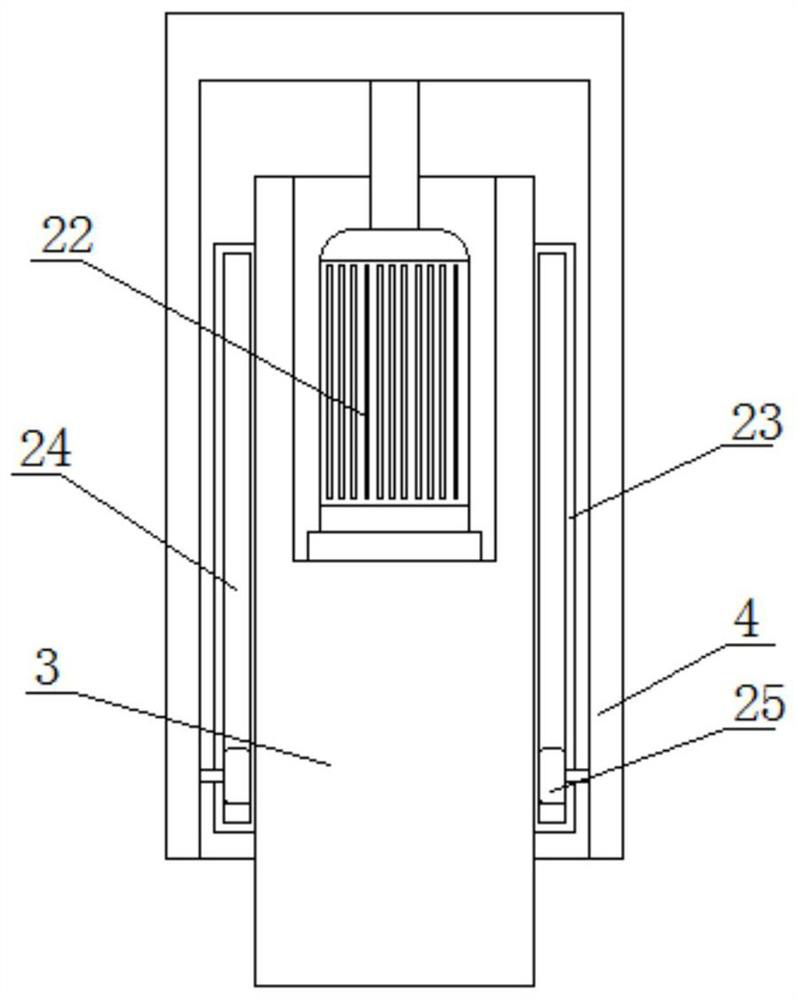

Micro-wire annealing tin plating machine production line

PendingCN109929971AProduction standardizationHigh speed productionHot-dipping/immersion processesFurnace typesFine lineProduction line

The invention discloses a micro-wire annealing tin plating machine production line and belongs to the field of cable machining. The micro-wire annealing tin plating machine production line comprises apay-off frame. A base is arranged at the lower end of the pay-off frame. An annealing furnace, a pickling bath, a tin furnace, a wire passing guide wheel set and a take-up machine. The pay-off frameis provided with a wire shaft. A first wire passing guide wheel is arranged on the surface of the pay-off frame. According to the production line, the special pay-off frame, the annealing furnace, thepickling bath, the tin furnace and the wire passing guide wheel set are arranged to be combined with the take-up machine, thus production of microwires is not troublesome any more, a user only needsto thread wires into the whole production line one by one like that of a traditional machine mode, the equipment can carry out the annealing technology and the tin plated technology automatically, allthe machined wires can be rolled and wound attractively with the standard and at a high speed, the defect that in the current wire industry, the microwires cannot be manufactured in batches is overcome, and the microwires can be produced with the standard and at a high speed.

Owner:鹰潭毅鹏智能科技有限公司

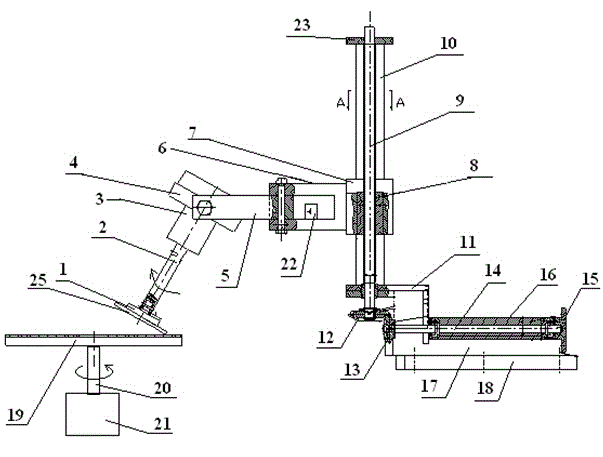

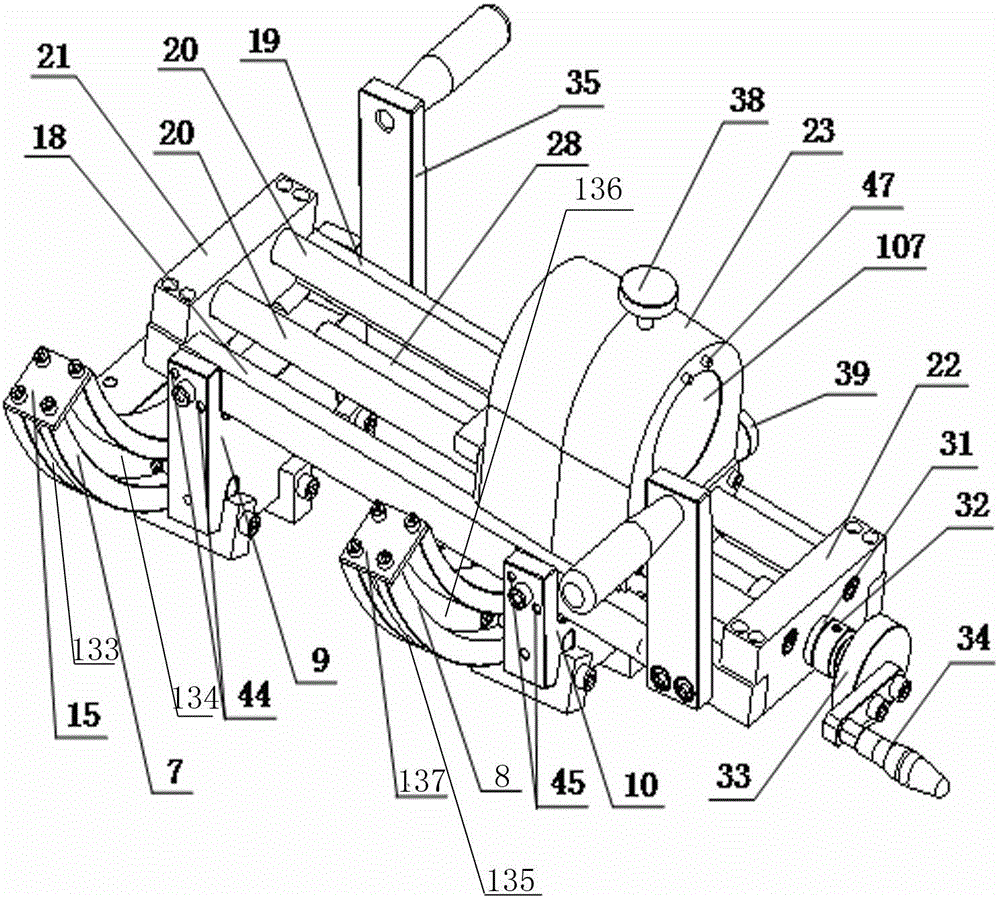

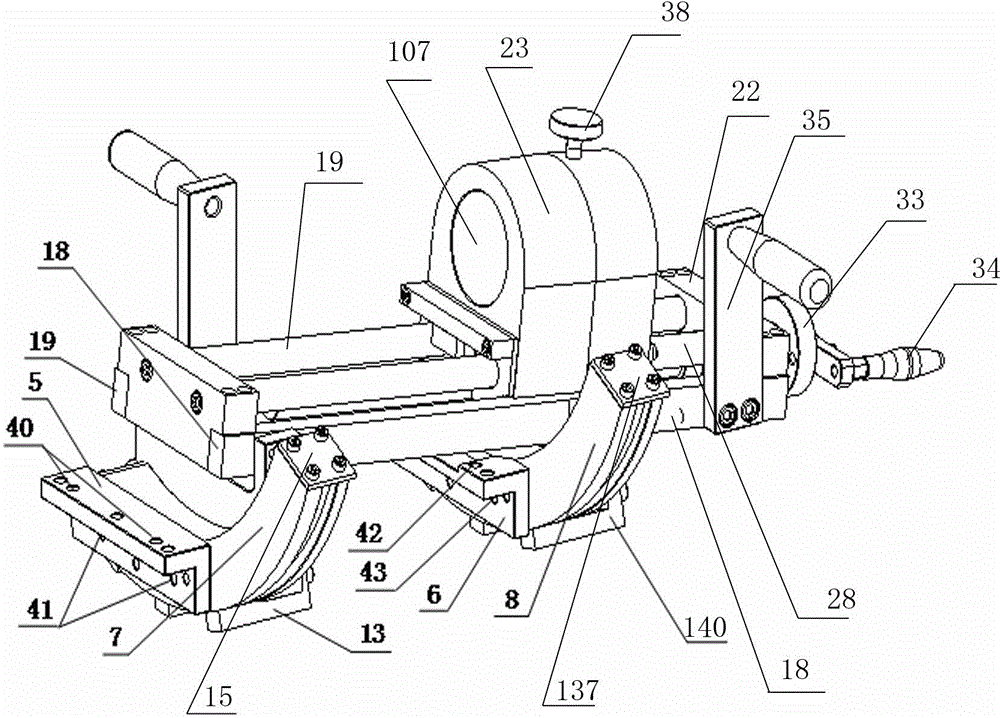

Drilling bit grinder

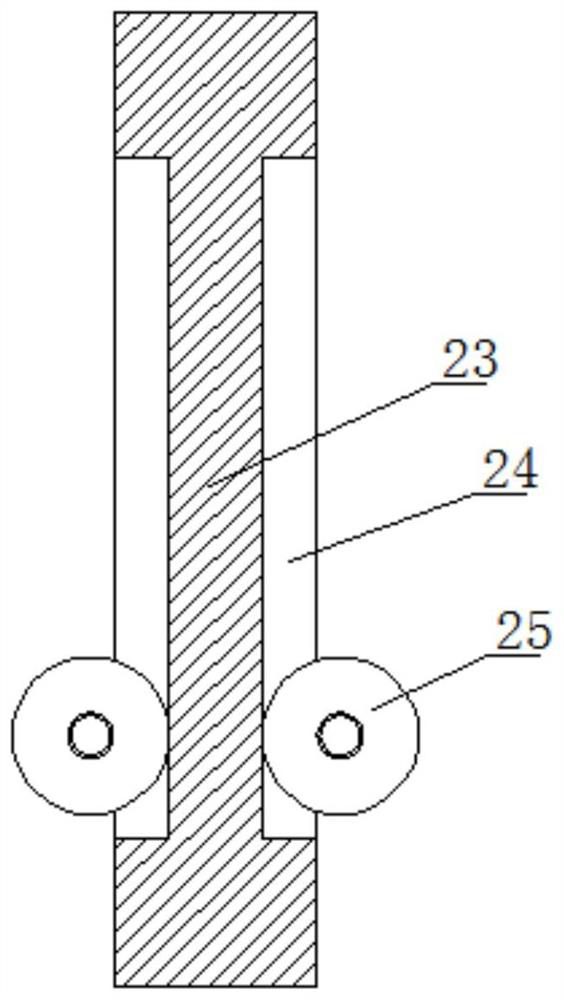

ActiveCN103331656ASolve the inaccurate grasp of the back angleSolve the problem of different high precision and low precisionDrilling toolsGrinding/polishing safety devicesChiselFixed frame

The invention discloses a drilling bit grinder. A drilling bit mounting hole I (107) in a main body of a cutting location seat (23) of a cutting edge grinding seat is opposite to a grinding wheel (3) after inclined; when a drilling bit (90) is inserted into the drilling bit mounting hole I (107) by a fixture set, a central axis of the drilling bit (90) is obliquely opposite to a cutting face I of the grinding wheel (3); the drilling bit (90) is sleeved with the fixture set; after rotating, a guide rail fixing frame I drives the drilling bit (90) to rotate through the cutting location seat (23); a supporting seat (48) of a chisel edge grinding seat is positioned in the middle of a guide rail fixing frame II and rotationally connected with the guide rail fixing frame II; a position adjustment device II is arranged at the bottom of the guide rail fixing frame II; and the position adjustment device II drives the drilling bit to upwarp or descend through a chisel edge locating seat (57). The grinder can be used for grinding a cutting edge and a chisel edge of the drilling bit without an experienced operator when the taper-shank drilling bit is ground, the precision of the ground drilling bit is high, and the diameter range of the grinding drilling bit is wide.

Owner:泰州市利优精密机械有限公司

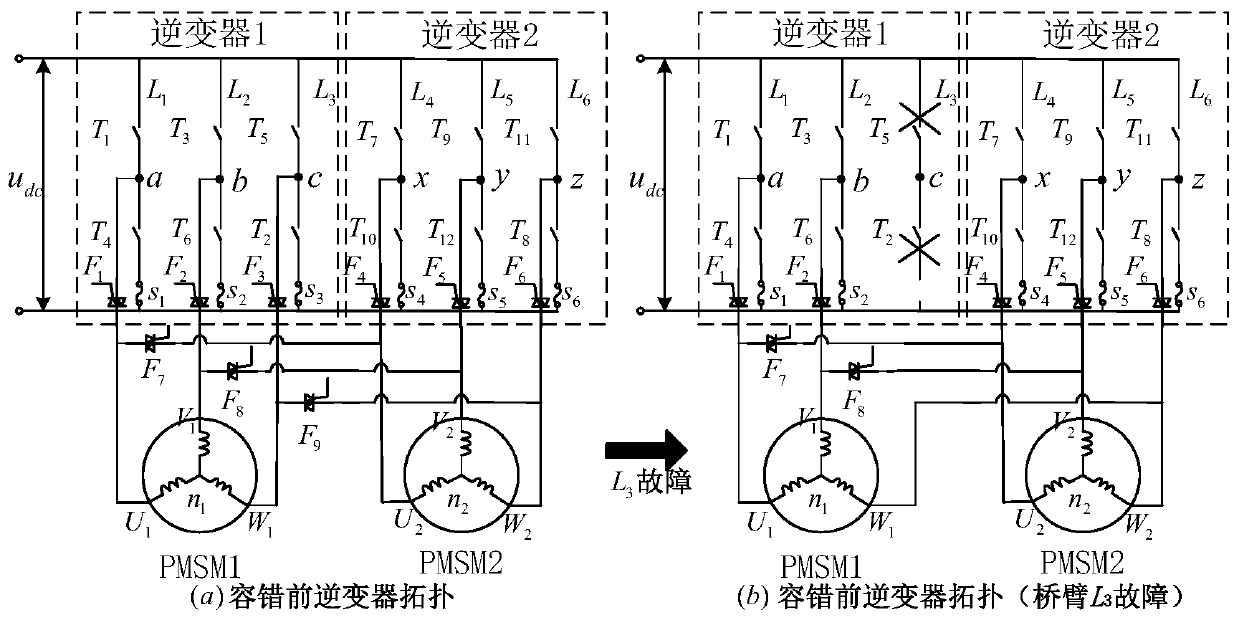

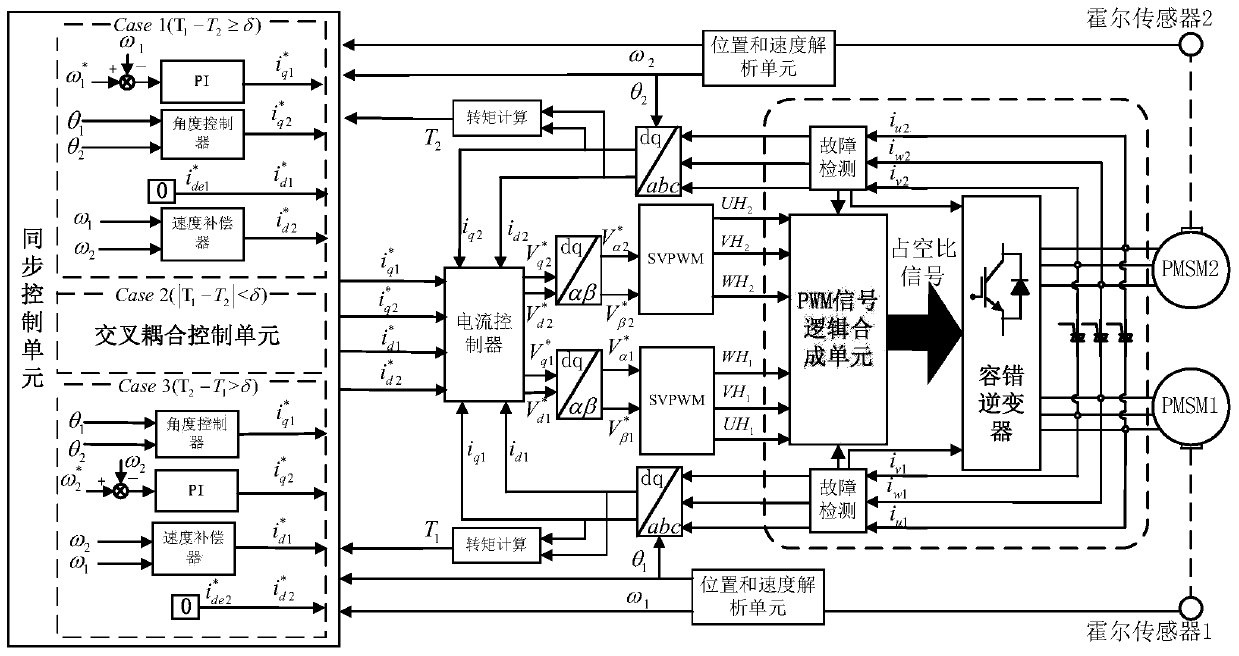

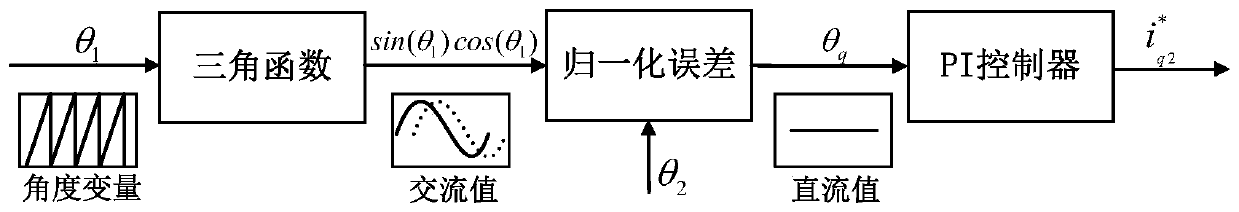

Fault-tolerant control method of dual-motor synchronous control system

ActiveCN111211711AImplement fault toleranceImprove reliabilityElectric motor controlVector control systemsPhase currentsReference current

The invention discloses a fault-tolerant control method of a dual-motor synchronous control system. A feedback rotating speed and a rotor position are input into a synchronous control unit, three-phase currents of double motors are converted through Park and Clark to obtain respective feedback quadrature-direct axis currents, corresponding torques are input into the synchronous control unit to becompared, and a corresponding angle and speed compensation strategies are determined; a quadrature-axis reference current and a direct-axis reference current are compared with the feedback quadrature-direct axis current of the double motors, and respective quadrature-direct axis reference voltages are calculated; Park inverse transformation is performed on the quadrature-direct axis reference voltage of the double motors to obtain two voltage components under a static coordinate system, and three duty ratio signals are obtained; and a fault bridge arm of the inverter is judged by detecting a three-phase current of the double motors, fault signals are sent to a fault-tolerant inverter and a PWM signal logic synthesis unit to complete reconstruction of a fault-tolerant topology and implementation of a fault-tolerant algorithm, and finally fault-tolerant control of the double permanent magnet synchronous motors is achieved. System reliability is high.

Owner:CHECC DATA CO LTD +1

Training pingpong launcher

The invention relates to a launcher and in particular relates to a training pingpong launcher. Therefore, the invention aims to solve the technical problem of providing a training pingpong launcher which is uniform in pingpong launching force and convenient for a player to take training. According to the technical scheme of the invention, the training pingpong launcher comprises an inclined plate,a support rack, an L-shaped rod, a columnar cylinder, bearing seats, a rotating shaft, a shifting plate, and the like, wherein the support rack is mounted on the right side of the top of the inclinedplate; the L-shaped rod with a support function is connected with the top of the support rack; the columnar cylinder for containing pingpongs is mounted at the left end of the L-shaped rod; the bearing seats are mounted into the front side and the rear side of the columnar cylinder in an embedded manner. By adopting a push block, the pingpongs can be launched out, the launching force is uniform,the launching angles are identical, and thus convenience can be brought to players to take training; due to adoption of a clamping device, a rotating rod can be clamped, and thus the shifting plate can be prevented from rotating clockwise; due to adoption of a baffle block, a discharge hole can be baffled, and the consequence that a launching casing is blocked as too many pingpongs fall onto the launching casing can be avoided.

Owner:嘉兴市中意喷织有限公司

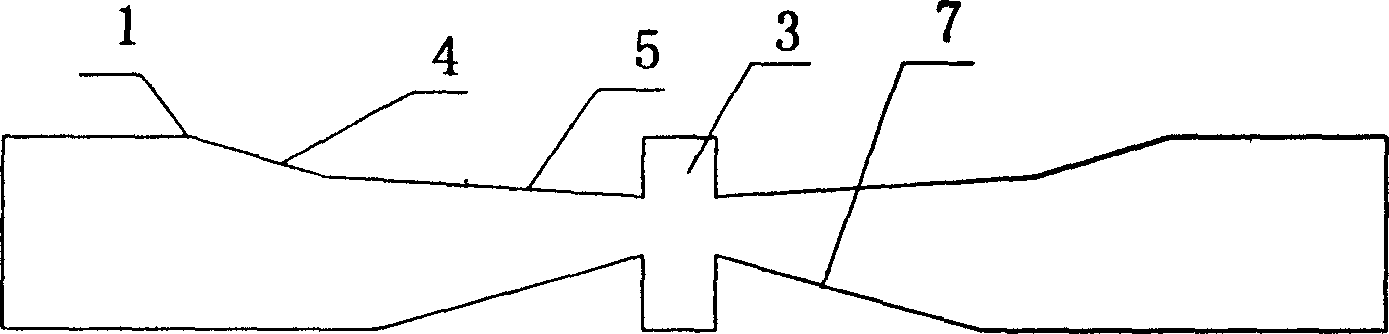

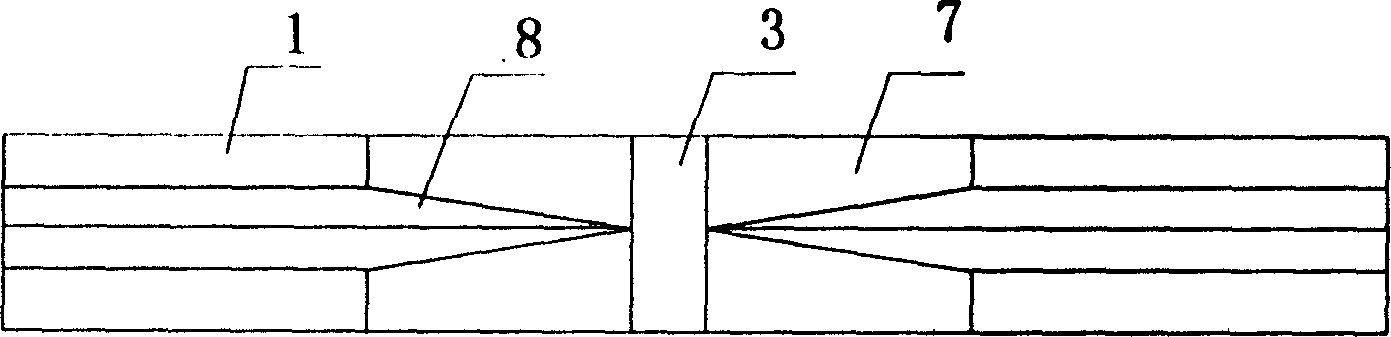

Rim production method facilitating mass material preparation

ActiveCN114102054AGuaranteed welding effectQuality assuranceRimsWheel manufactureCircular sectionManufacturing engineering

The rim production method comprises the following steps that an aluminum plate is cut into rectangular aluminum plate units, and turnups are formed at the ends, in the length direction, of the aluminum plate units; the middles of the aluminum plate units are bent towards the sides where the flanges are located, so that the aluminum plate units form a U-shaped structure; the turned-over edges are pressed to be located in the same plane, the opposite end faces are attached, and the aluminum plate units form a barrel through welding and fixing; machining the barrel into a rim barrel-shaped blank with a circular section; a tire mounting groove and a tire mounting surface are machined in a barrel opening in one end of the rim barrel-shaped blank; carrying out deformity shaping on the rim blank processed with the tire mounting groove and the tire mounting surface; and the shaped rim blank is machined into a rim unit or a rim. According to the rim production method facilitating mass material preparation, rim blanks of the same model can be used for rims of different models and sizes, so that the rim blanks can produce more types of rims, and material preparation and production of the rim blanks are facilitated.

Owner:刘湘平

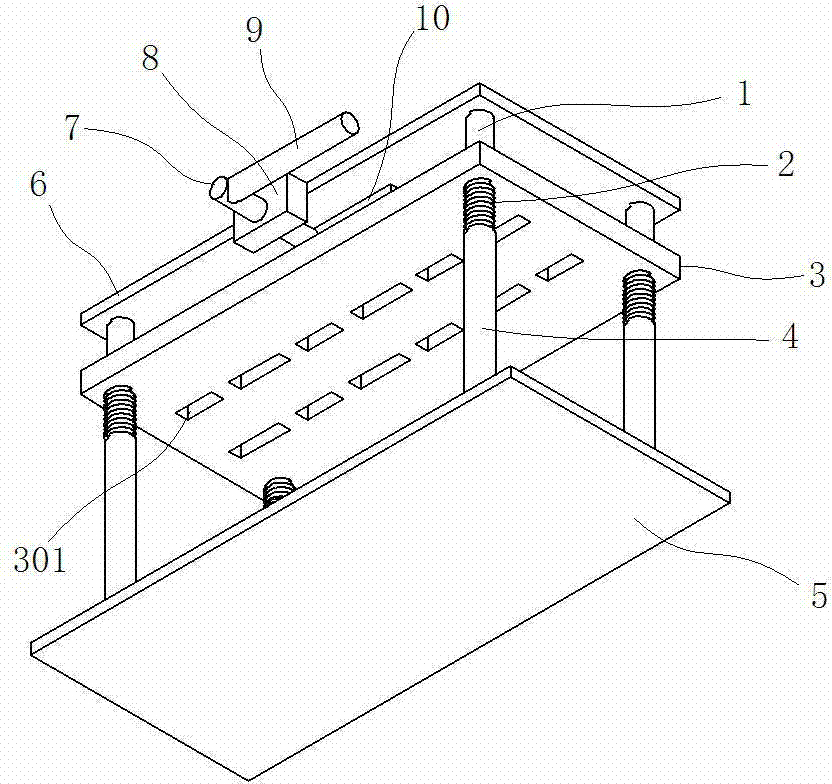

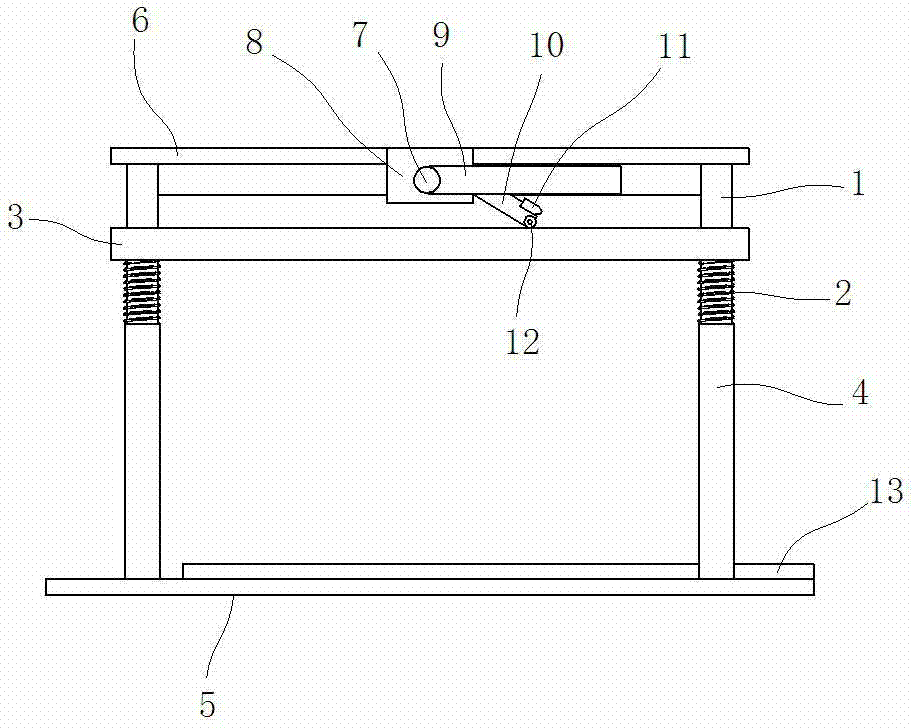

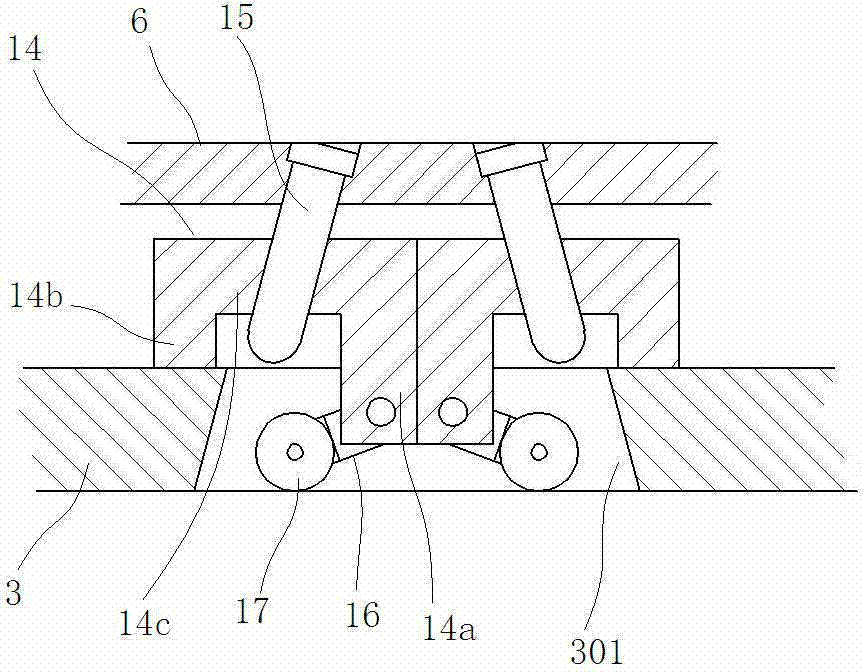

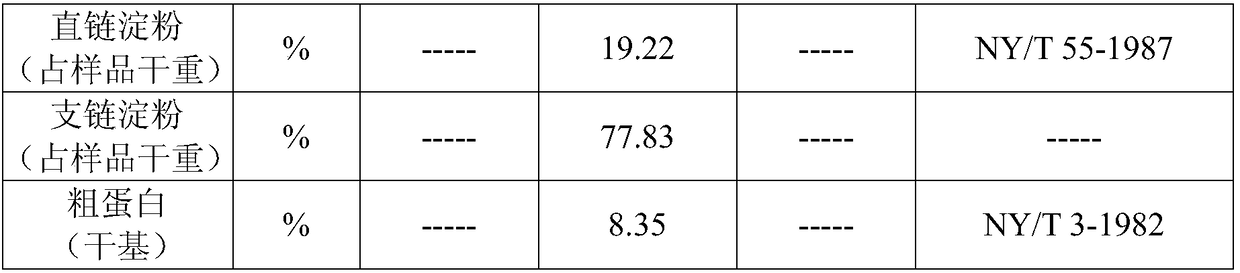

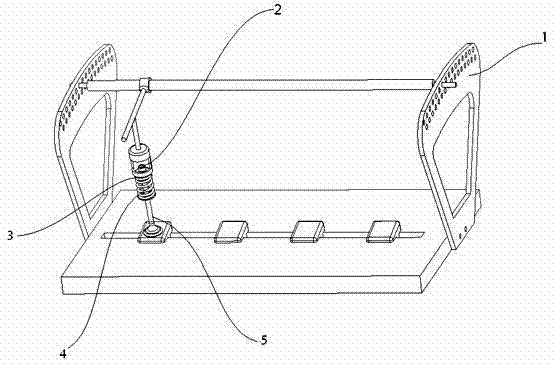

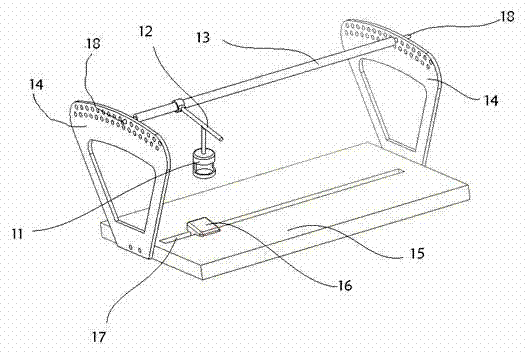

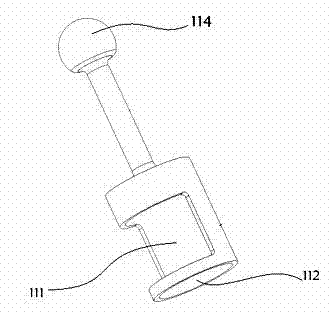

Shaping device for electrode lug of side negative plate

The invention discloses a shaping device for an electrode lug of a side negative plate. The shaping device comprises a bottom plate. The bottom plate is provided with a plurality of locating columns. The locating columns are provided with guide rods and a shaping die plate capable of moving vertically along the guide rods. A panel is fixed to the tops of the guide rods. A starting mechanism capable of enabling the shaping die plate to be pressed is arranged below the panel. The portions, between the shaping die plate and the locating columns, of the guide rods are sleeved with return springs. The shaping die plate is provided with a plurality of rectangular shaping holes. The inner walls of the shaping holes are inclined towards the centers of the shaping holes from bottom to top. Rolling mechanisms acting on the inner side of the electrode lug through pressing wheels are arranged in the shaping holes. According to the shaping device for the electrode lug of the side negative plate, the shaping strength and angle on shaping of the electrode lug of the side negative plate are uniform, and the potential quality hazard of the short circuit due to the fact that the electrode lug is made manually can be effectively avoided.

Owner:ANHUI YONGHENG STORAGE BATTERY

Driving mechanism for wings of minitype ornithopter

A drive mechanism for the wings of miniature ornithopter is composed of a worm-gear speed reducer and two sets of 4-connection-rod unit consisting of crank with one end fixed to the axle of worm gear, connection rod with one end linked to crank, and rocker arm linked between rocker arm and wing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Branch cutting equipment for peony grafting

The invention discloses a branch incision device for peony grafting, which solves the problem that in the prior art, the angle of each cutting chip is manually grasped, which leads to different cutting chip angles and affects the survival efficiency of grafting. The invention comprises a cylindrical rootstock placement chamber, an oblique section arranged at one end of the cylindrical stock placement chamber and at an angle of 30 to 60 degrees to the central axis of the cylindrical stock placement chamber, and a moving plate slidably connected along the oblique section. The cutting knife at the bottom of the moving plate, and the stock pressing device arranged on the cylindrical rootstock placement cavity. The invention has the advantages of simple structure, low cost, consistent cutting angle of stock and the like.

Owner:CHENGDU SENJIE COMML & TRADING CO LTD

Slitting rewinding machine and raw paper processing production line

ActiveCN108975020AQuality improvementKeep the pressure constantWebs handlingProduction linePulp and paper industry

The invention belongs to the technical field of slitting rewinding machines and provides a slitting rewinding machine and a raw paper processing production line. The slitting rewinding machine comprises a rewinding rack, a first bottom roller and a second bottom roller are arranged at the bottom of the rewinding rack, and two mandrel holders are also slidingly disposed on the two sides of the rewinding rack respectively and connected to the rewinding rack through mandrel lifting air cylinders which are arranged in the vertical direction; the mandrel holders are provided with mandrel clamping parts for clamping mandrels, the surfaces of the first bottom roller and second bottom roller are provided with thermal spray coatings, riding roller frames are also slidingly arranged on the rewindingrack, riding rollers are rotatably arranged on the riding roller frames, a synchronous shaft is also rotated on the riding roller frames, synchronous gears are arranged at both ends of the synchronous shaft, synchronous racks meshed with the synchronous gears are arranged on both sides of the rewinding rack, and riding roller lifting air cylinders are connected with the rewinding rack. Through the technical scheme above, the technical problem of low rewinding precision of slitting rewinding machines in the prior art is solved.

Owner:河北入微能源科技有限公司

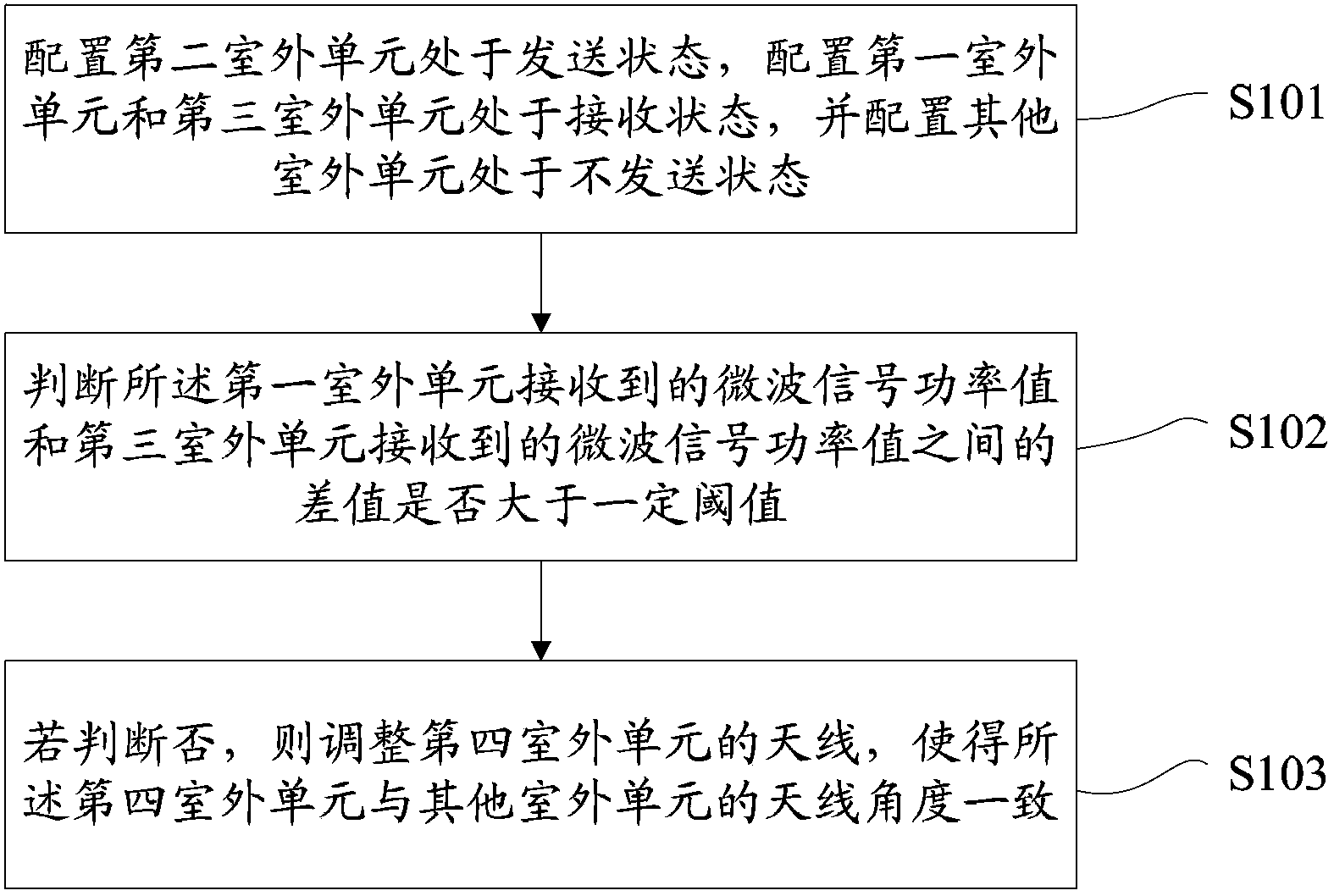

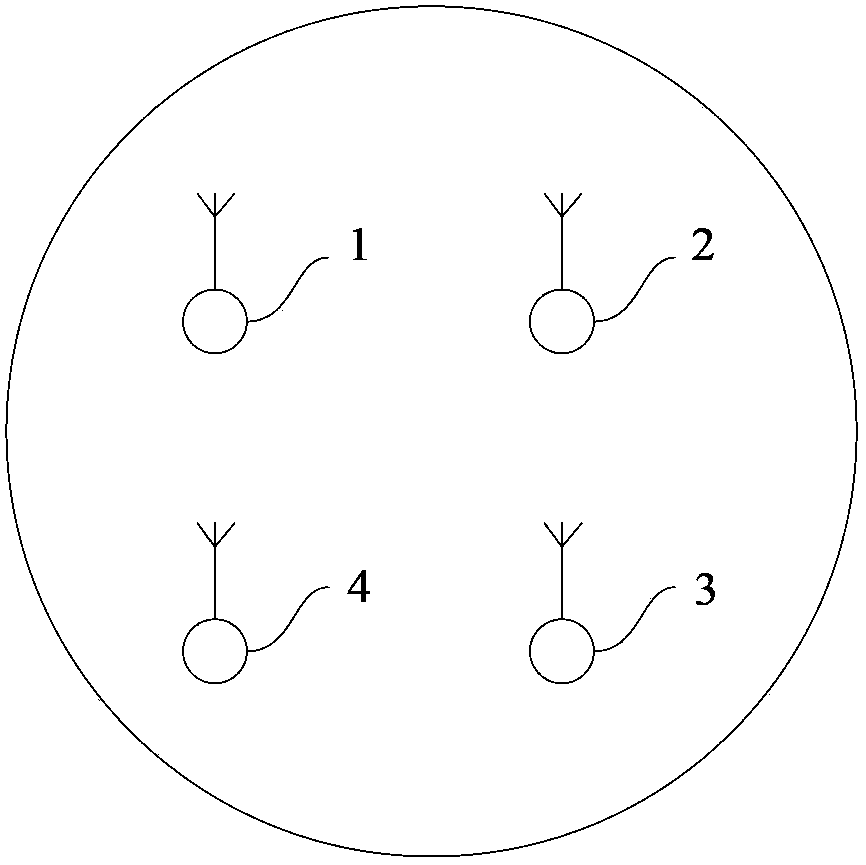

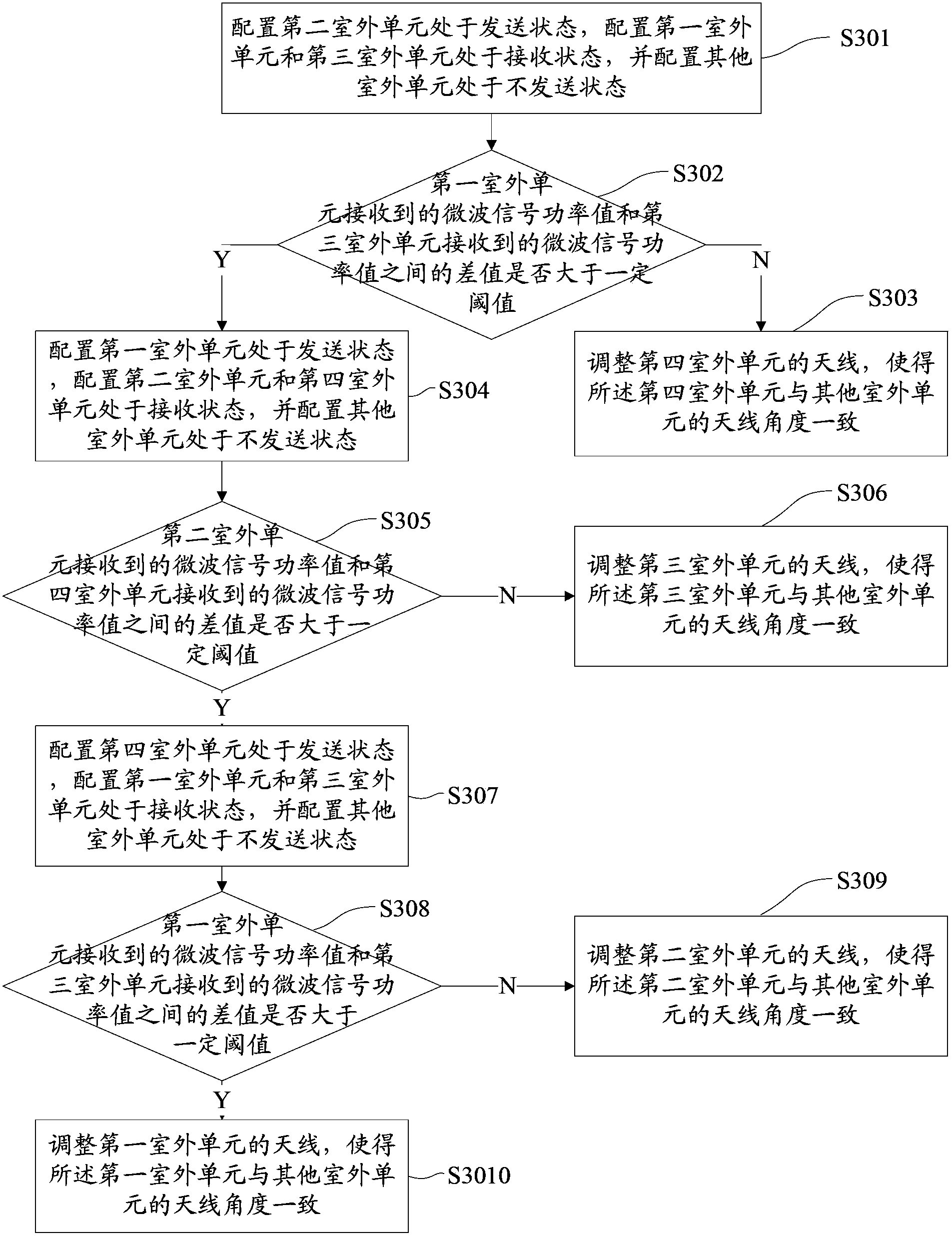

Antenna adjusting method and device for multi-input and multi-output microwave system

ActiveCN103404044AGuaranteed communication performanceSame angleSpatial transmit diversityAntennasMulti inputSide lobe

The invention provides an antenna adjusting method and device for a multi-input and multi-output microwave system, which is suitable for the technical field of microwave antennas. The multi-input and multi-output microwave system comprises four outdoor units, wherein the antenna angle of only one outdoor unit is different from the antenna angles of the other outdoor units. The antenna adjusting method comprises the steps of configuring a second outdoor unit to be in a sending state, and configuring a first outdoor unit and a third outdoor unit to be in a receiving state; determining whether the difference value between the microwave signal power value received by the first outdoor unit and the microwave signal power value received by the third outdoor unit is larger than a certain threshold value; adjusting the antenna of a fourth outdoor unit if the difference value is smaller than the threshold value, so that the antenna angle of the fourth outdoor unit is the same as that of the other outdoor units. The invention is advantageous in that two outdoor units are combined, and the antenna angles can be determined to be consistent or not by determining the received side lobe signal, and thereby the antenna angles in the same site can be consistent.

Owner:HUAWEI TECH CO LTD

Automatic rapid feather inserting device for badminton production and manufacturing

ActiveCN111589083ASolve low work efficiencySame angleSport apparatusStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of sports goods and equipment. The invention discloses an automatic rapid feather inserting device for badminton production and manufacturing. The device comprises a base, coils are arranged on the outer side of the upper part of a fixed plate, a magnet corresponding to the coil is connected to the fixed plate, soft metal rods are connected to the lowerends of sliding rods, an annular groove is formed in the upper portion of a rotary disc, an arc-shaped groove is formed in the outer side of a trapezoidal rotary base, a positioning device is connected into a correcting pipe, and an illuminating lamp and a light resistor corresponding to feathers are arranged on the left side and the right side in the positioning device respectively. Feathers areclamped out from the positioning device, the resistance in the light resistor is rapidly reduced, when the coil is short-circuited, a first spring drives the magnet to slide and reset on the left side of the guide groove, the magnet is driven by the upper portion of the L-shaped swing rod to move, the L-shaped swing rod drives the soft metal rod to move towards the trapezoidal rotary base throughthe sliding rod, the feathers are inserted one by one through the structure, and the working intensity of workers is further reduced.

Owner:HAINING SHIZHENG TRADING CO LTD

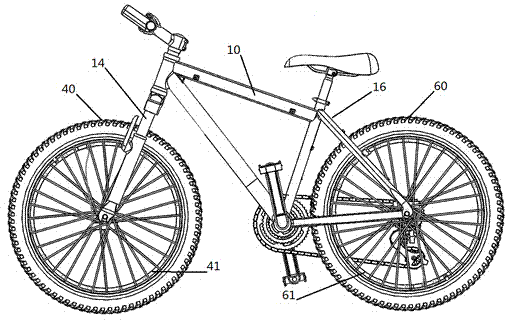

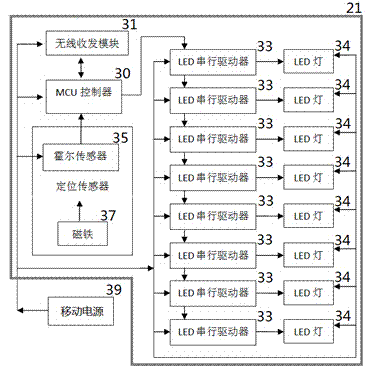

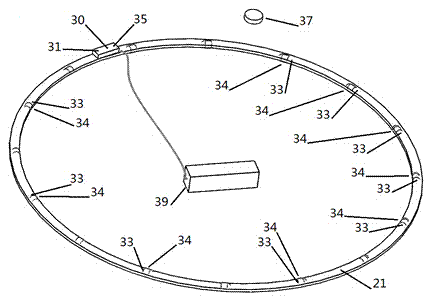

Lighting ring for bicycle wheels, synchronous lighting system and control method

InactiveCN104743007AUse less materialImprove light control effectOptical signalElectricityWireless control

The invention discloses a lighting ring for bicycle wheels, and a synchronous lighting system comprising the lighting ring, and aims at overcoming the problems of a large amount of materials used, complex structure, possible glaring and simple function of the lighting ring mounted on the wheels in the prior art. The lighting ring is characterized by comprising lighting ring bodies and an LED colored marquee wireless control system, wherein the lighting ring bodies are mounted on spokes at the inner sides of rims and connected through wireless communication by using a wireless receiving and sending modules. The lighting ring has the beneficial effects that the materials used are decreed; the light control variation module is improved; the warning light is easily seen and free of glaring to people; the quantity of LED lamps is decreased; the electricity consumption is reduced; the service life of a power bank is prolonged; the rolling of colored rings is slowed down and even stopped, so that the warning effect is clear and obvious, and flickering and fatigue of eyes can be avoided; the front and back colored light rings are consistent and synchronous in color, angle, rotating speed and variation cycle through the wireless communication; the color can be automatically changed to show the performance of a marquee.

Owner:赵明奇

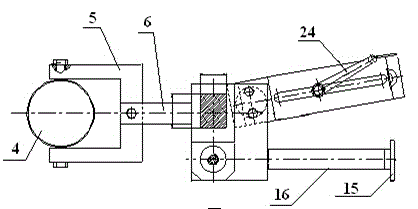

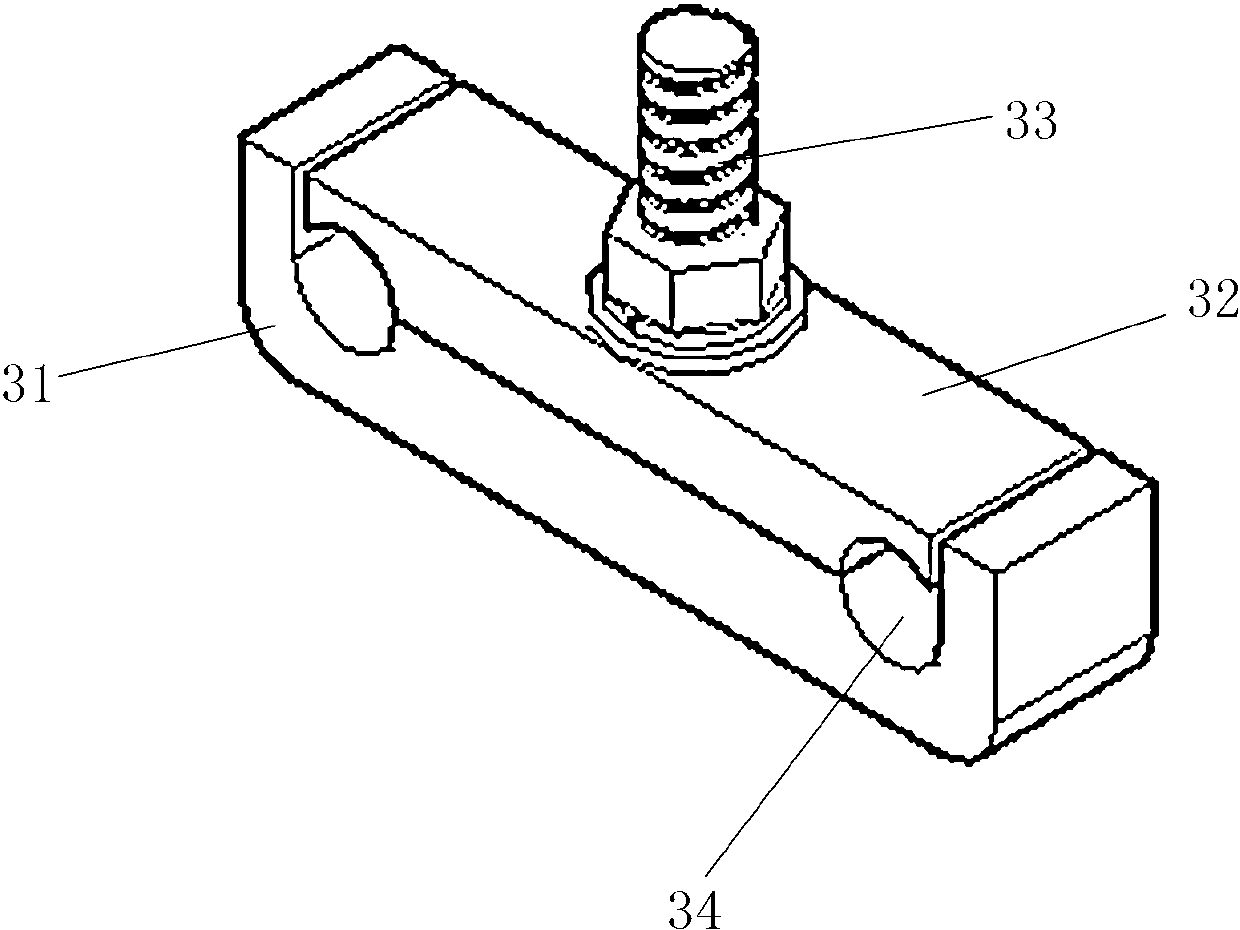

Machining tool for small-diameter pipe welding groove

ActiveCN110202440AGroove angle consistentSame angleEdge grinding machinesGrinding feedersGear wheelDrive shaft

The invention discloses a machining tool for a small-diameter pipe welding groove. The machining tool comprises a positioning mechanism and a grinding mechanism, wherein the grinding mechanism is connected to the rear end of the positioning mechanism and is used for machining the welding groove, the grinding mechanism comprises a horn-shaped grinding head, a connecting rod is arranged at the rearend of the grinding head, and a containing cavity is formed in the side, away from the connecting rod, of the grinding head; the positioning mechanism comprises a pipe body, and fixing assemblies arearranged on the periphery of the front end of the pipe body; each fixing assembly comprises a transmission screw rod, a driven bevel gear, a threaded sliding sleeve and a fixing gasket arranged at theouter end part of the threaded sliding sleeve, the threaded sliding sleeve is arranged in a radial hole of the pipe body, the transmission screw rod is in threaded connection with the threaded sliding sleeve, and the transmission shaft is arranged in an axial hole of the pipe body; and a driving bevel gear is arranged at the front end of the transmission shaft, a driven bevel gear is arranged atthe inner end of the transmission screw rod, the driving bevel gear is in vertical meshing transmission with the driven bevel gear, a plurality of grinding parts are detachably arranged in the containing cavity of the grinding head, and the inclined surface of the groove is smooth and uniform.

Owner:烟台是高装备科技有限公司

Plate sampling machine

InactiveCN111189665AReduce labor intensityPrecise positioningWithdrawing sample devicesControl engineeringElectric machinery

The invention discloses a plate sampling machine which comprises a main rack, a clamping mechanism, a sampling mechanism and a push rod. The clamping mechanism, the sampling mechanism and the push rodare sequentially arranged at the top of the main rack from one end to the other end, the clamping mechanism is slidably arranged at the top of the main rack, the sampling pipe of the sampling mechanism is slidably arranged in the sampling hole of the clamping mechanism, and the push rod is movably arranged in the sampling pipe; a first push-pull structure connected with the push rod is fixed at the top of the main rack and controls the push rod to move along the axial direction of the sampling pipe. The plate sampling machine has the advantages that automatic sampling is achieved through cooperation of the clamping mechanism and the sampling mechanism, manual sampling is replaced, the labor intensity of workers can be effectively reduced and sampling efficiency is improved; the clamping mechanism can play a good role in positioning the plate, and the sampling pipe is driven by the sampling motor so that the consistency of the sampling center and angle can be ensured, the integrity ofthe obtained sample is ensured and the precision and the accuracy of detection are further improved.

Owner:HOHHOT SIFANG ENG QUALITY TESTING CENT

Bridge swivel device capable of rotating stably and construction method thereof

ActiveCN112030778ASame angleMeet the installation requirementsBridge erection/assemblyClassical mechanicsEngineering

The invention belongs to the technical field of bridge rotation, and relates to a bridge rotation device capable of stably rotating and a construction method thereof. A supporting column is fixedly mounted at the top of a bottom plate, and a hydraulic push rod output shaft fixedly mounted at the top end of the supporting column is fixedly connected with the inner wall of the top of a lifting coverslidably connected to the supporting column; a supporting plate is rotationally connected to the top of a supporting disc fixed to the top of the lifting cover, two mounting columns rotationally connected with a containing plate are symmetrically and fixedly mounted at the top of the supporting plate, a mounting pipe is slidably connected to sliding covers symmetrically and fixedly mounted at thetop of the supporting plate, and the tops of two movable covers in threaded connection with the inner wall of the mounting pipe are in transmission connection with the bottom of the containing plate.A supporting shaft is fixedly installed at the bottom of the supporting plate, the bottom end of the supporting shaft is rotationally connected with the top of a supporting disc, and the problems that an existing bridge rotating body device only adjusts plane rotation of a bridge plate and is not provided with a related longitudinal adjusting device, so that the bridge rotating body adjusting range is narrow, and the application range is affected are solved.

Owner:TAIZHOU UNIV

Double-bevel correspondent grafting tool and application thereof

The invention provides a bi-inclined-plane corresponding grafting device, comprising grafting cutting mold and three-flanged grafting cutting knife, a boss is horizontally set in the upper surface of the grafting cutting mold, grafting cutting bi-inclined-plane is horizontally equipped in the two sides of the boss, a grafting locating slot is longitudinally equipped in the upper surface of the grafting cutting mold, which extends to the root of the boss passing through the bi-inclined-plane from the two sides of the grafting cutting mold; a boss is equipped horizontally in the middle of lower surface of the mold, a stock cutting inclined plane is individually equipped in the two sides of the boss, and a stock locating slot extends to the root of the boss passing through the stock cutting inclined plane from the two ends of the lower surface of the grafting cutting mold longitudinally; when applying the device, putting the grafting or stock in the grafting locating slot or stock locating slot, cutting out the needed standard relevant grafting inclined plane along the grafting bi-inclined-plane or stock cutting plane with three-flanged grafting cutting knife. Comparing with the current technique, the bi-inclined-plane relevant grafting method in this method is characterized by the rational design, multifunction, uniform cutting angle standard, easy-to-operate, fast speed and high survival rate, for which it possesses good spread practical value.

Owner:薛军 +3

Film mulching and soil covering dry farming method for rice in cold region

InactiveCN108142232ASave seedlingsOmit transplantingPlant protective coveringsRice cultivationWater savingPlant disease

The invention provides a film mulching and soil covering dry farming method for rice in a cold region. The method comprises the following steps: (1) soil preparation stage before seed sowing: carryingout autumn soil preparation on the to-be-sowed ground and carrying out one-turning-two-rotating or deep-loosening-two-rotating so that the to-be-sowed ground is flat, soil blocks are fine and brokenand the ground is in a to-be-sowed state; (2) film mulching: adhering rice seeds to fertilizers by using environmentally friendly glue on a biodegradable film and then storing the film for mulching; (3) film mulching and soil covering: applying a seed fertilizer and a base fertilizer into soil of the to-be-sowed ground, laying the biodegradable film adhered with the rice seeds in step (2) on the ground, covering the film with soil and then pressing to ensure soil moisture content of the soil and early emergence; and (4) after management: carrying out leaf fertilizer application management, disease management, insect management and water replenishing management after sowing the seeds and before harvesting, and then harvesting the rice. The method is water-saving, labor-saving, environmentally friendly, economical and simple, meanwhile, complicated and difficult links of seedling culture, rice transplanting, weeding and the like are omitted, and a planting procedure is simplified reasonably.

Owner:佳木斯高坤农业科技发展有限公司

Engine valve locking piece assembling and disassembling tool

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Grafting auxiliary equipment used for fruit tree planting

The invention discloses grafting auxiliary equipment used for fruit tree planting. The equipment includes a shell, a base plate, an inflation shell, pre-folding grooves, a gas pipe, a supporting rod,spring fixing disks, a spring, push rods, a fixing plate, an electric push rod, a cutting knife, a cutting board, support rods, a shaft sleeve, a fixing shaft, a connecting rod, a clamping groove, a screw rod, a clamping convex, a nut, a disc, a rotating disc, a casing pipe and a scion. The equipment is reasonable in structural design; workers can adopt sitting postures to complete operation in awhole course during the whole cutting, so that convenience can be brought for the workers, and work intensity can be reduced; through mechanized structural scion cutting means, all scion cutting angles can be guaranteed to be the same, a large batch of grafting work can be conveniently performed, and the success rates of grafting can be effectively enhanced; and through the adjusting of the anglesof tail end cutting of the scion, cutting can be conveniently performed on the scions with different diameters and kinds.

Owner:闽清县盛旺佳食用菌农业专业合作社

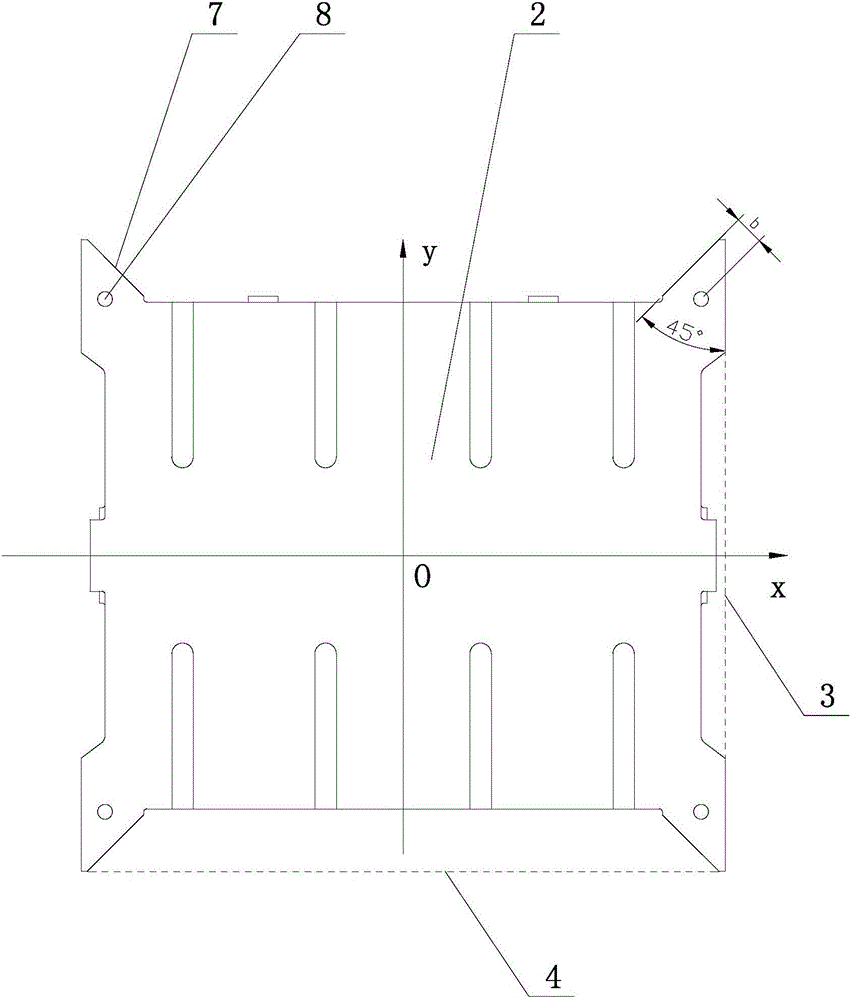

Machining method for X-shaped sliding block guide rails

ActiveCN107175359APrecise processingPrecise control angleMilling equipment detailsEngineeringAngle gauge

The invention relates to a machining method for X-shaped sliding block guide rails. According to the method, firstly, rough machining and finish machining are performed on an X-shaped sliding block; then the bottom plane of the X-shaped sliding block is set as a reference surface, and two adjacent side surfaces of the X-shaped sliding block are set as process reference surfaces; secondarily, finish milling is performed on two guide rail surfaces opposite to the process reference surface A; the center of the bottom plane of the X-shaped sliding block is used as the reference, and four process holes with equal diameters are machined in the positions, corresponding to the four X-shaped sliding block guide rails, of the bottom plane of the X-shaped sliding block and are used as auxiliary process references; the process reference surface A and the process reference surface B are used as references, and angles of 45-degree guide rail surfaces are controlled by the aid of an angle template and an angle gauge; process hinge pins are mounted in the four process holes, the size and position symmetry degrees of the four 45-degree guide rail surfaces are guaranteed, and finally, the X-shaped sliding block is rotated, and finish milling machining is performed on the 45-degree guide rail surfaces of the four X-shaped sliding block guide rails. The method has the advantages of being simple, convenient, accurate in positioning, simple to operate, high in machining precision and the like.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

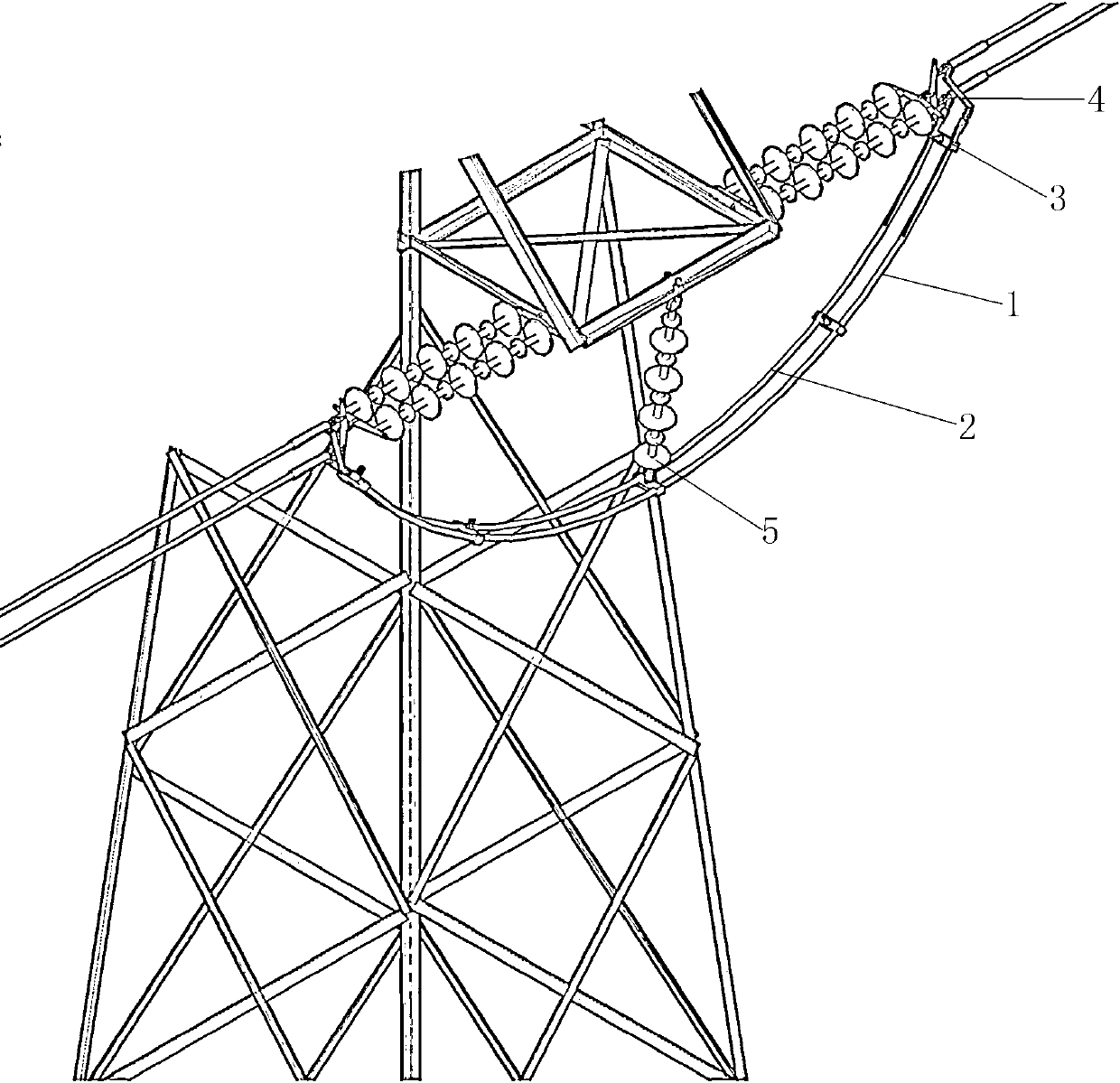

By-pass method of combined guide line of electric transmission line

ActiveCN103346517ASame angleBeautiful appearanceOverhead installationTransmission lineStructural engineering

The invention relates to a by-pass method of a combined guide line of an electric transmission line. The method comprises the following steps that (1) connecting plates are pressed on the two ends of the by-pass jumper of a number one line and the two ends of the by-pass jumper of a number two line respectively; (2) the two by-pass jumpers are arranged in parallel and the two sides of the two by-pass jumpers are maintained to be even, spacer bars are mounted on the center parts of the two by-pass jumpers, after the spacer bars are firmly mounted, the spacer bars are mounted on the root parts of the connecting plates on the two sides of the two by-pass jumpers respectively, and then spacer bars are mounted among the connecting plates and the centers of the by-pass jumpers respectively; (3) the by-pass jumper of the number one line is connected with corner-shaped connecting plates through the connecting plates; (4) tower mounting is carried out after the by-pass jumpers of the combined guide line assembling is finished; (5) the by-pass jumper of the number one line is in butt joint with the number one line through the corner-shaped connecting plates. According to the by-pass method of the combined guide line of the electric transmission line, due to the fact that the two by-pass jumpers are placed in parallel and the two sides of the two by-pass jumpers are maintained to be even, the spacer bars are mounted on the center parts of the by-pass jumpers, the two by-pass jumpers are made to pass through a thick screw, the thick screw is equivalently an axis support, mutual complementation of twisting force and mutual absorption are obtained by the two by-pass jumpers , and therefore the two by-pass jumpers can be parallel on a same line without a crooked phenomenon.

Owner:STATE GRID CORP OF CHINA +1

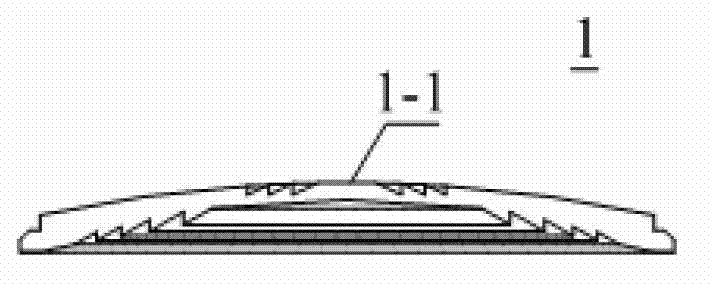

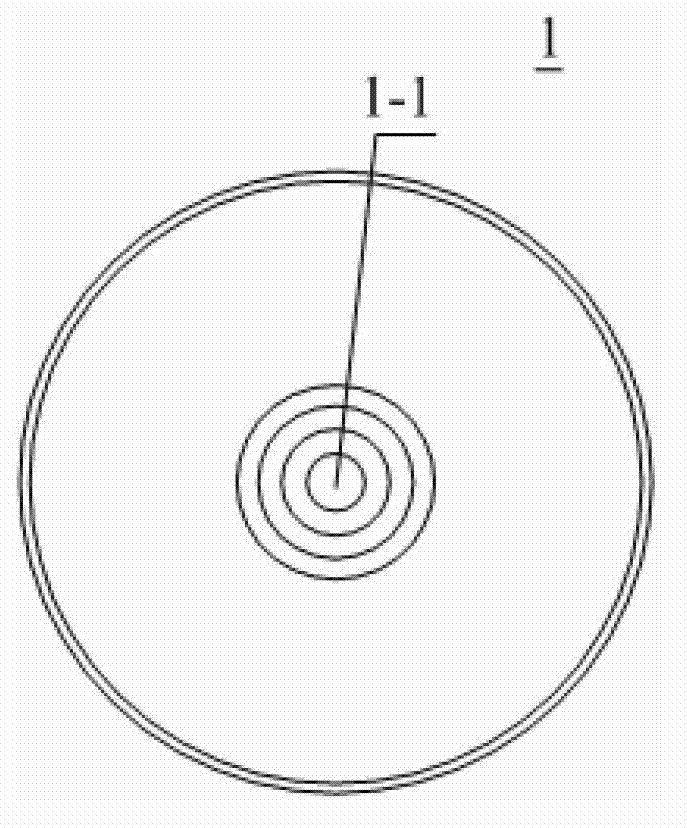

Light-emitting diode (LED) light source module

InactiveCN102865487ASimplify the design processSimplify the installation processPoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention provides an LED light source module. The module comprises a casing, a heat conduction member, an LED light source and an LED driving power supply, wherein a clamping ring is arranged on the inner side of the casing; an optical reflector and an optical lens are arranged on the clamping ring from bottom to top; a power supply insulating cavity is arranged inside the casing below the clamping ring; a power supply cavity and a light source cavity are arranged in the power supply insulating cavity; the heat conduction member is inserted inside the casing through the light source cavity, and an installation platform is arranged at the top of the heat conduction member; an LED light source is installed on the installation platform; the LED driving power supply is inserted into the inner portion of the casing through the power supply cavity, and an input end and an output end of the LED driving power supply are respectively connected with a mains supply and an LED light source. The problems that in a current LED lamp, interconvertibility and generality of all parts are poor and light quality of the LED lamp is poor are solved, the installation and maintenance difficulties of the LED lamp are reduced, and production and maintenance costs of the LED lamp are reduced.

Owner:HANGZHOU YOUWANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com