Driving mechanism for wings of minitype ornithopter

A technology of flapping-wing aircraft and driving mechanism, which is applied in the field of driving mechanism, and can solve the problems of inability to realize symmetrical flapping of the left and right wings, lack of self-locking property, and many deceleration stages, so as to overcome the asymmetrical flapping of the left and right wings , light weight and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

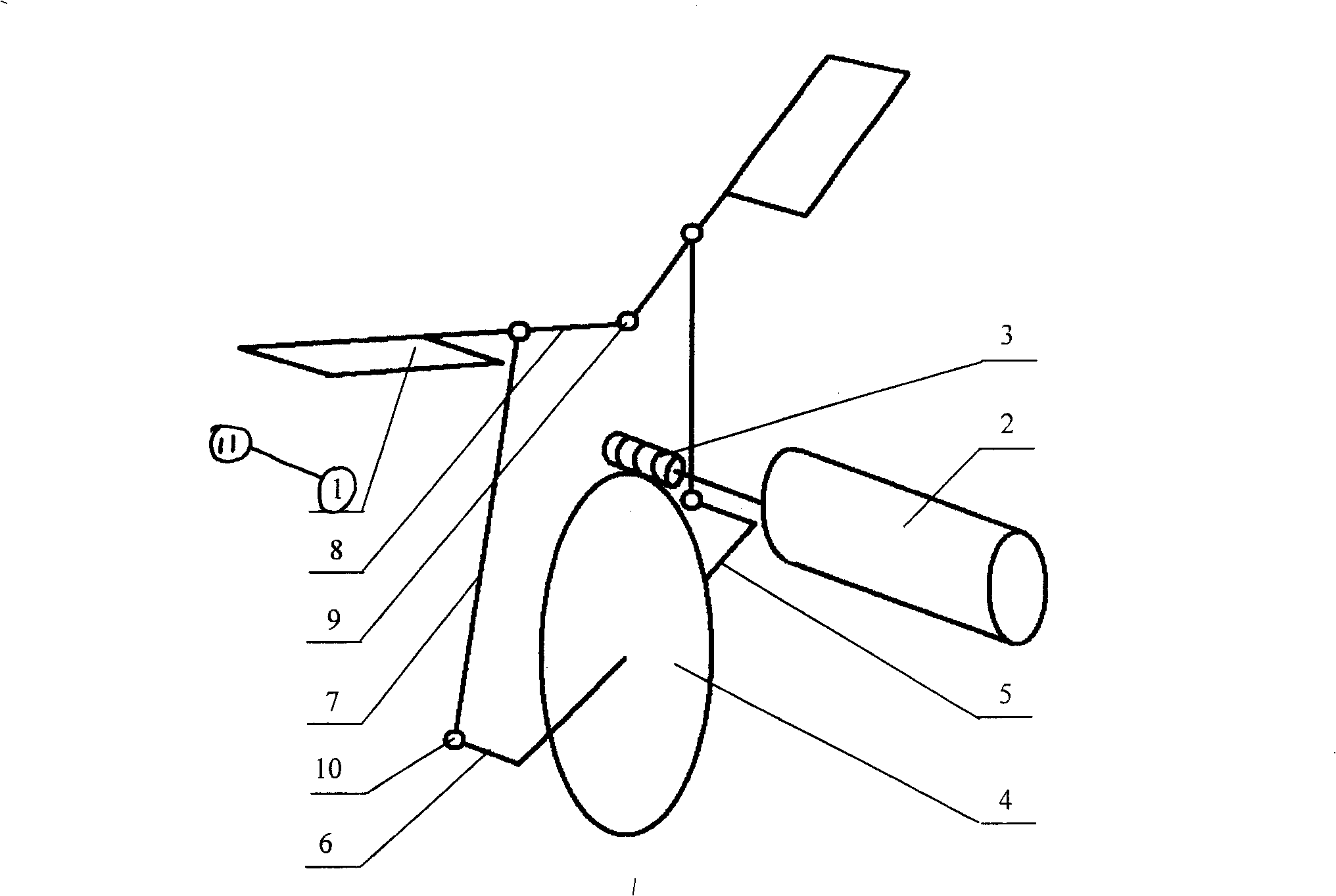

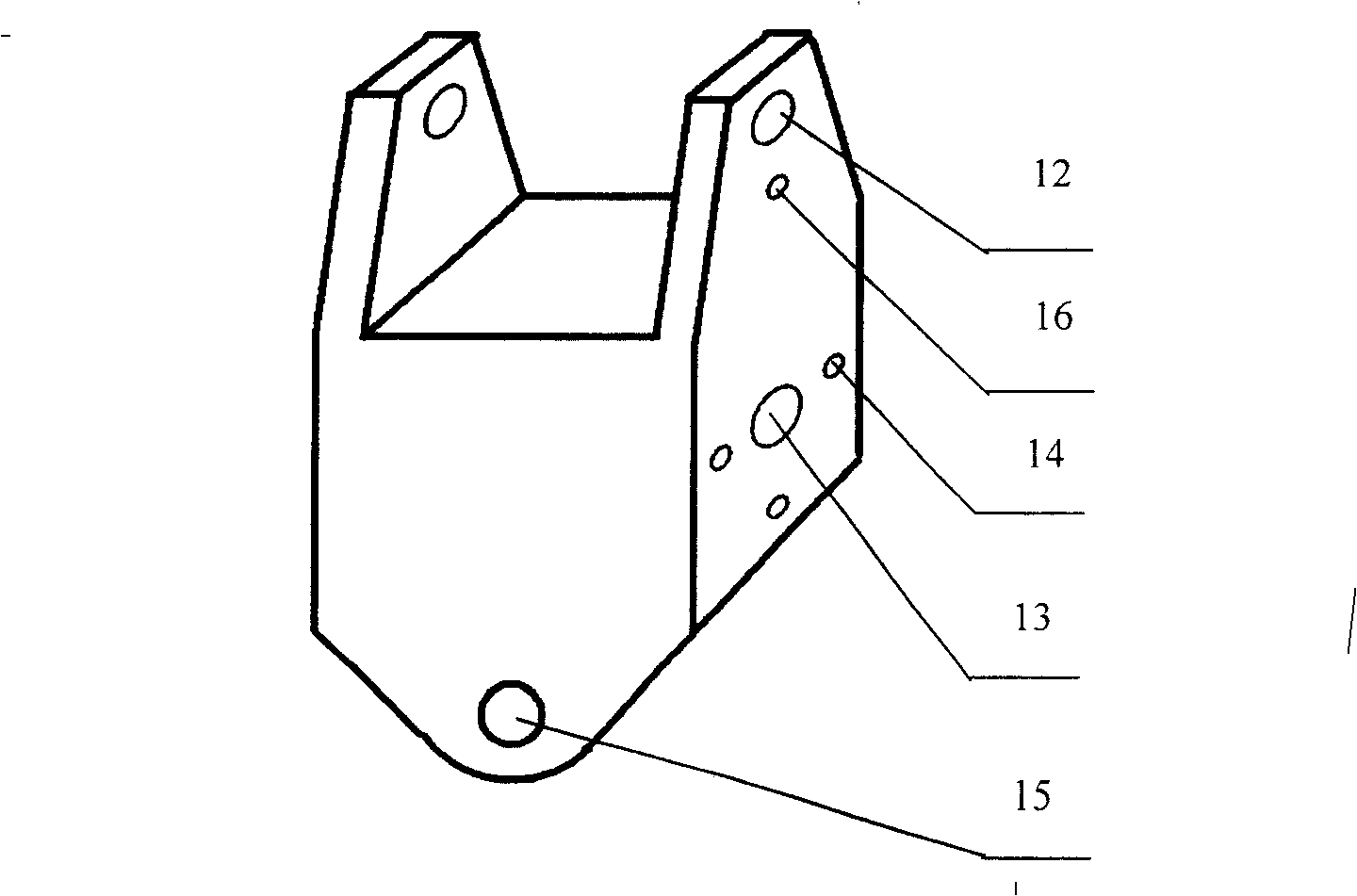

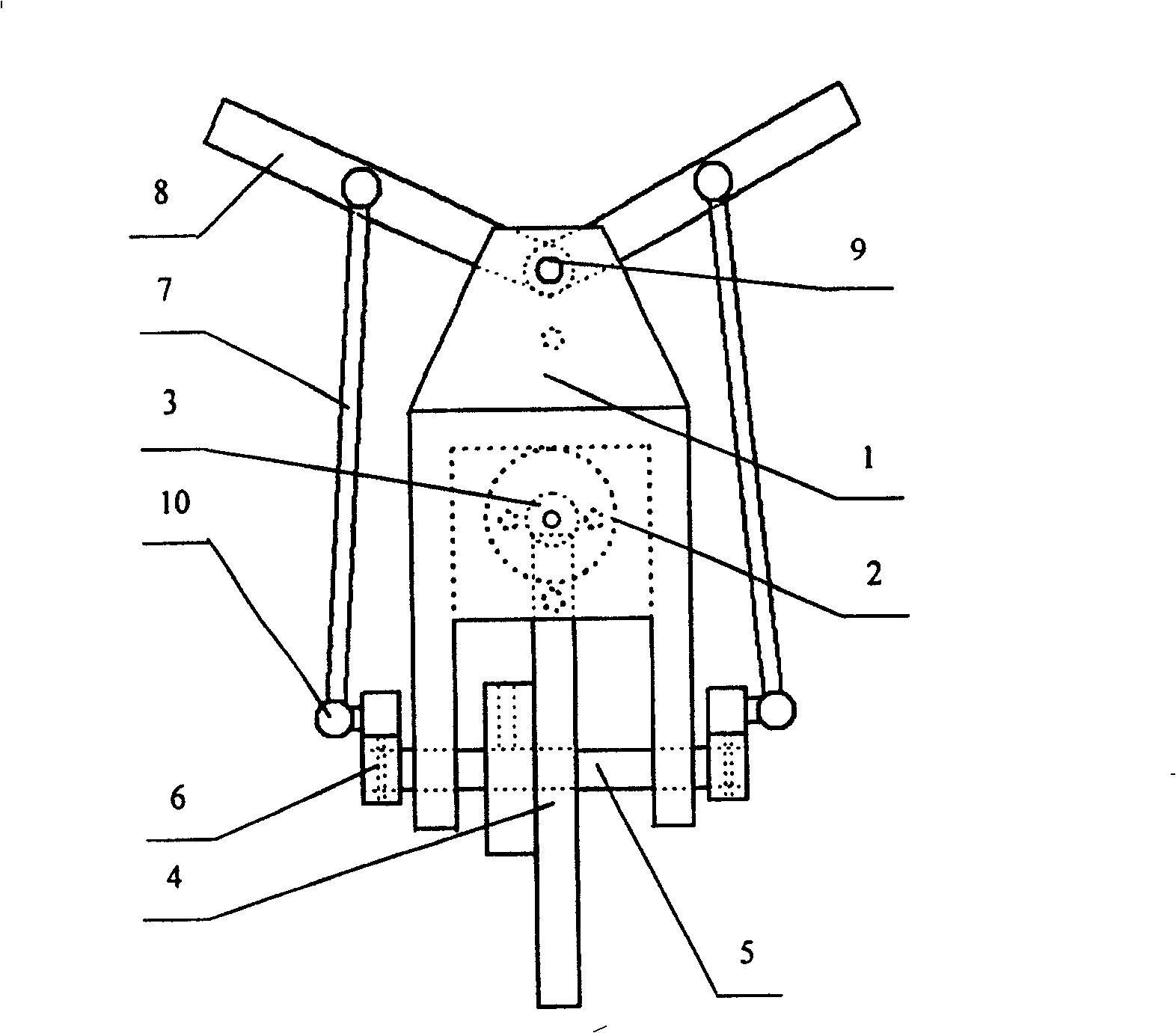

[0022] This embodiment is a set of miniature flapping wing aircraft wing drive mechanism, which adopts a worm gear mechanism to convert the high speed of the motor into the required low speed of the wing drive mechanism. This embodiment includes a shaft frame 1, a micro motor 2, a worm screw 3, a worm gear 4, a worm gear shaft 5 and a crank 6, a spherical hinge 10, a connecting rod 7 and a rocker arm 8, and the worm gear reduction mechanism and the motor are symmetrical axes, through Pedestal 1, crank 6, connecting rod 7, and rocker 8 form a set of spatial four-bar linkages on both sides of the worm gear mechanism and the micromotor 2. When the worm gear 4 rotates, the crank 6 is driven by the worm gear shaft 5 to rotate together. Crank 6 drives rocking arm 8 to swing up and down through connecting rod 7 again, and then drives wing 11 to flutter up and down. The specific implementation process is:

[0023] The fuselage 17 of the present embodiment is a plate type, and its fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com