Machining method for X-shaped sliding block guide rails

A technology of rail processing and sliding block, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of cumbersome processes and difficult to guarantee processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

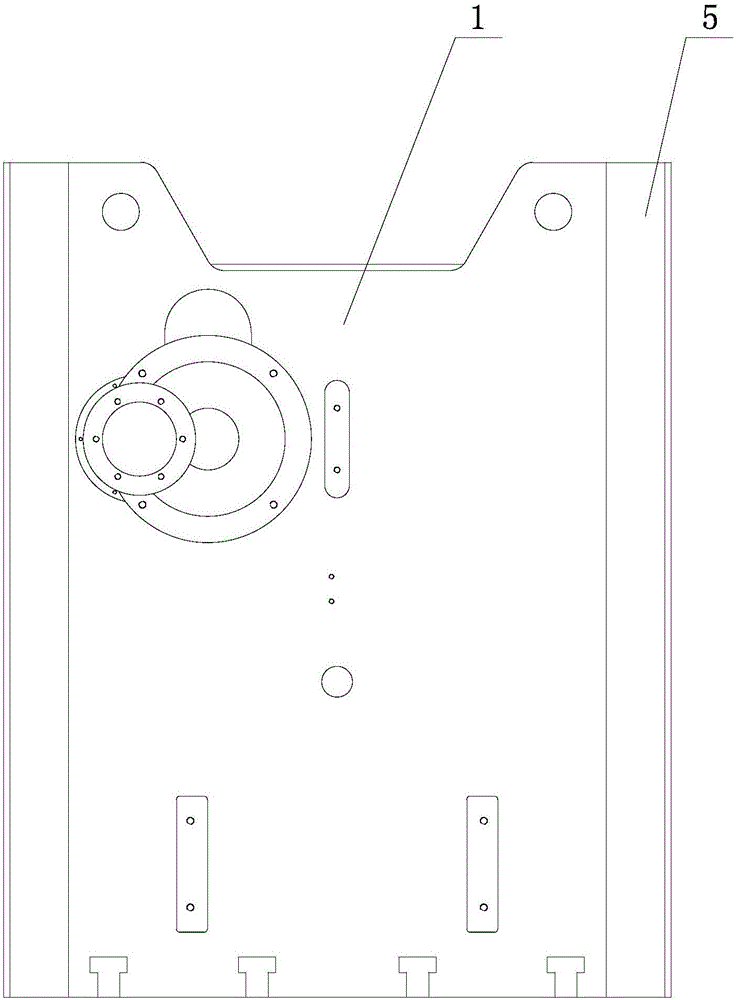

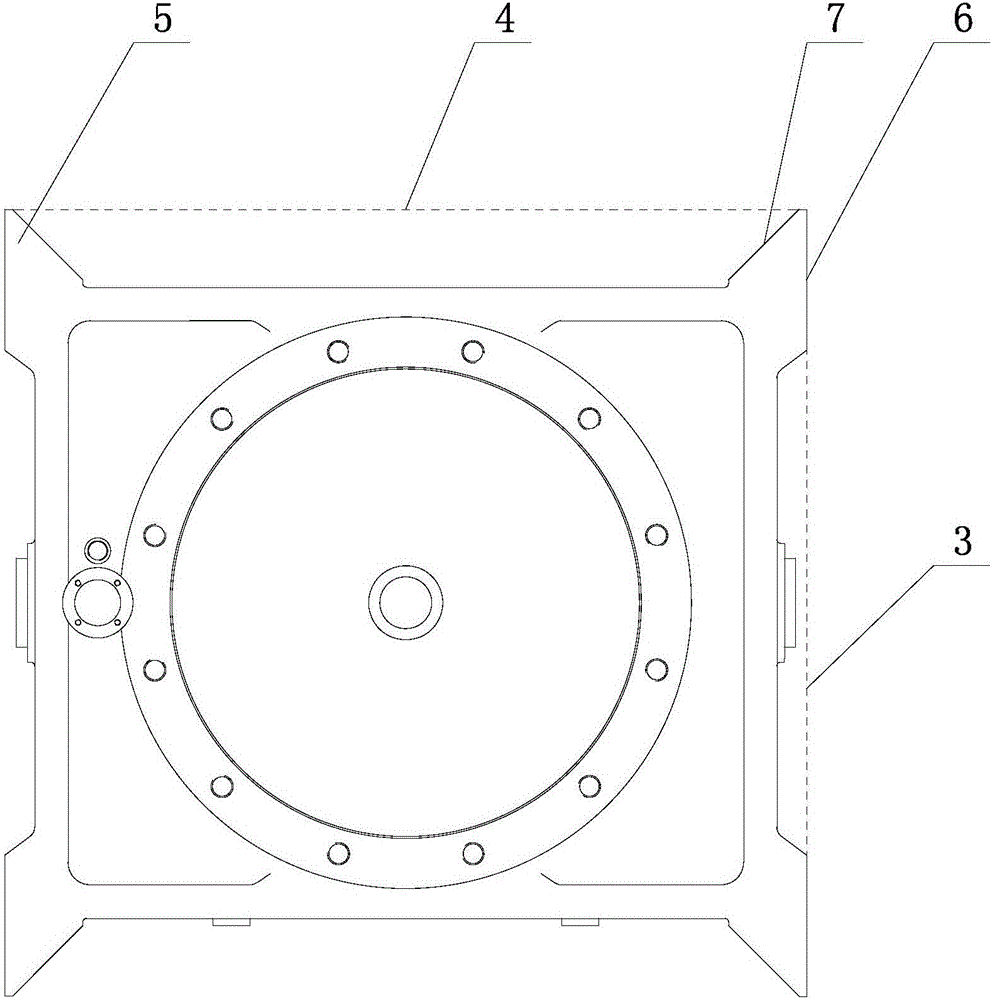

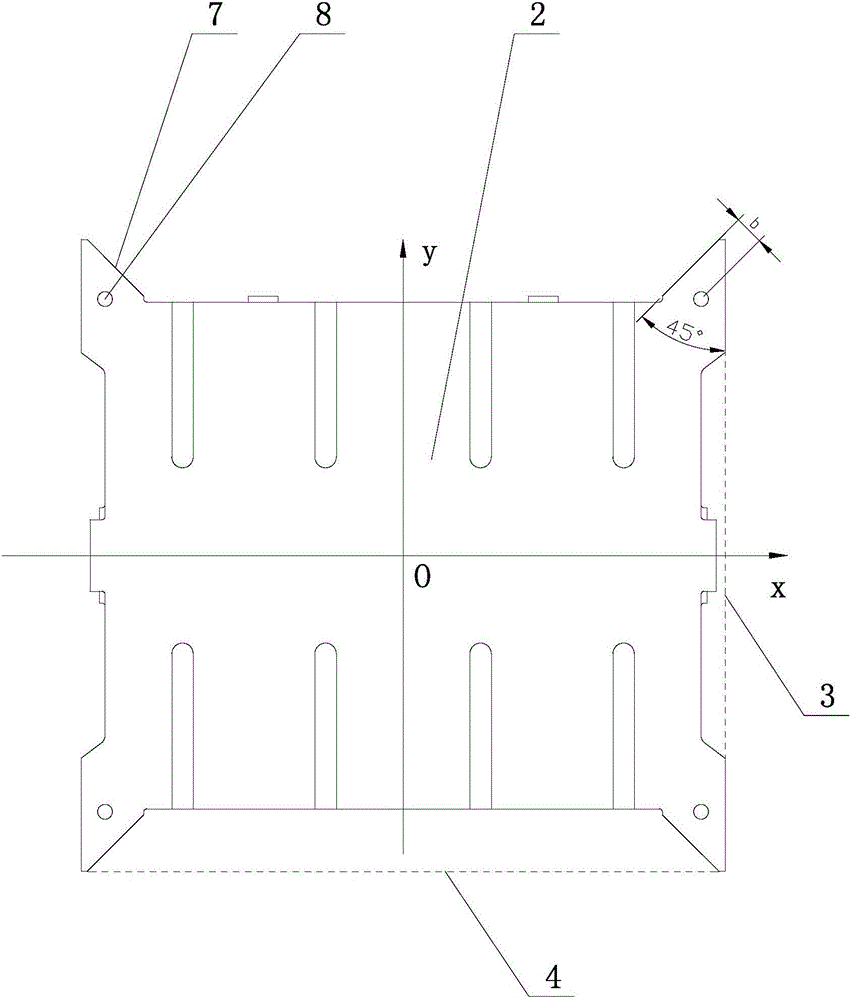

[0024] Such as Figure 1-4 As shown, the X-shaped slider guide rail processing method includes the following steps:

[0025] (1) Carry out rough machining and finishing machining on the X-shaped slider 1, leaving a reasonable machining allowance to ensure subsequent machining;

[0026] (2) Set the bottom plane of the X-shaped slider 1 as the reference plane 2, the two adjacent sides of the X-shaped slider 1 as the process reference plane, and the one with two rail surfaces 6 in the process reference plane as the process reference plane A3, without The guide rail surface 6 is the process reference plane B4. In one clamping, the reference plane 2, the process reference plane A3 and the process reference plane B4 set by finish milling, so that the two guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com