Plate sampling machine

A sampling machine and plate technology, which is applied in sampling, sampling devices, analyzing materials, etc., can solve the problems of high labor intensity of manual sampling, affecting the accuracy of detection, poor sample integrity, etc., so as to reduce labor intensity of workers and improve sampling efficiency. , the effect of good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

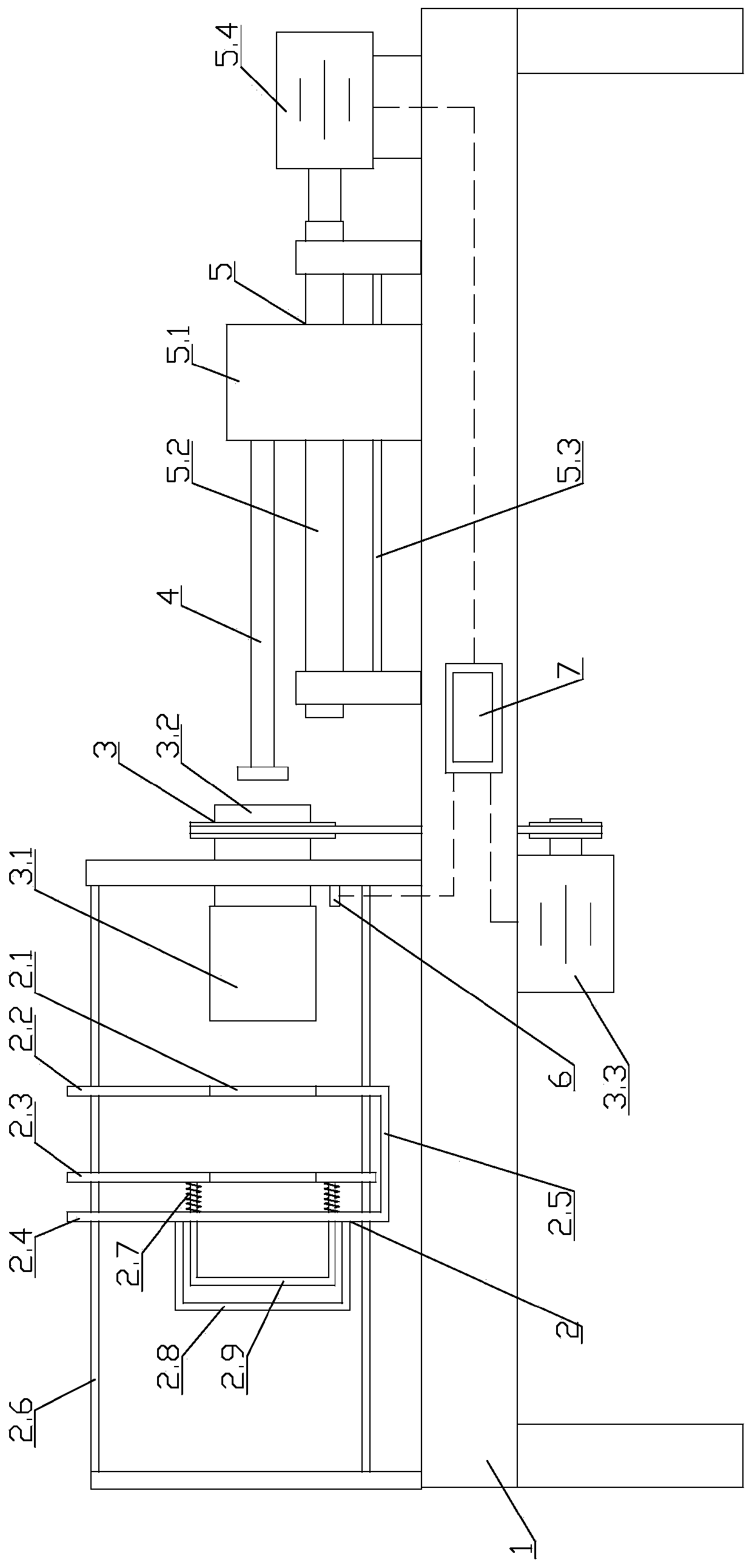

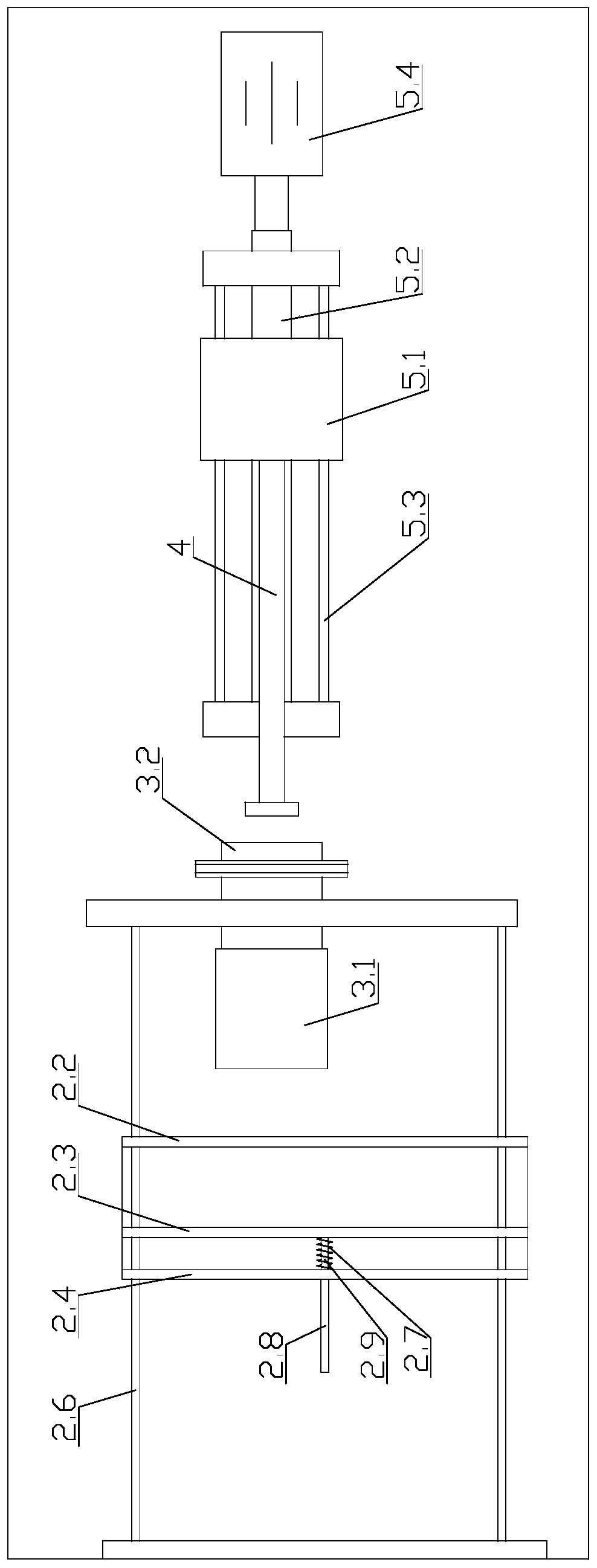

[0022] Embodiment 1: as figure 1 and figure 2 As shown, a plate sampling machine includes a main frame 1, a clamping mechanism 2, a sampling mechanism 3 and a push rod 4. On the top of the main frame 1, a clamping mechanism 2, a sampling mechanism 3 and a putter 4,

[0023] The clamping mechanism 2 is slidably arranged on the top of the main frame 1, and the sampling tube 3.1 of the sampling mechanism 3 is slidably arranged inside the sampling hole 2.1 of the clamping mechanism 2,

[0024] The sampling mechanism 3 includes at least one casing 3.2 that rotates vertically on the top of the main frame 1. Multiple casings 3.2 and matching sampling tubes 3.1 can be arranged side by side. The sampling tubes 3.1 and push rods 4 are in one-to-one correspondence with the sampling holes 2.1. , can realize intercepting multiple samples at the same time; the casing 3.2 is arranged along the sliding direction of the clamping mechanism 2, and the sampling motor 3.3 connected with the cas...

Embodiment 2

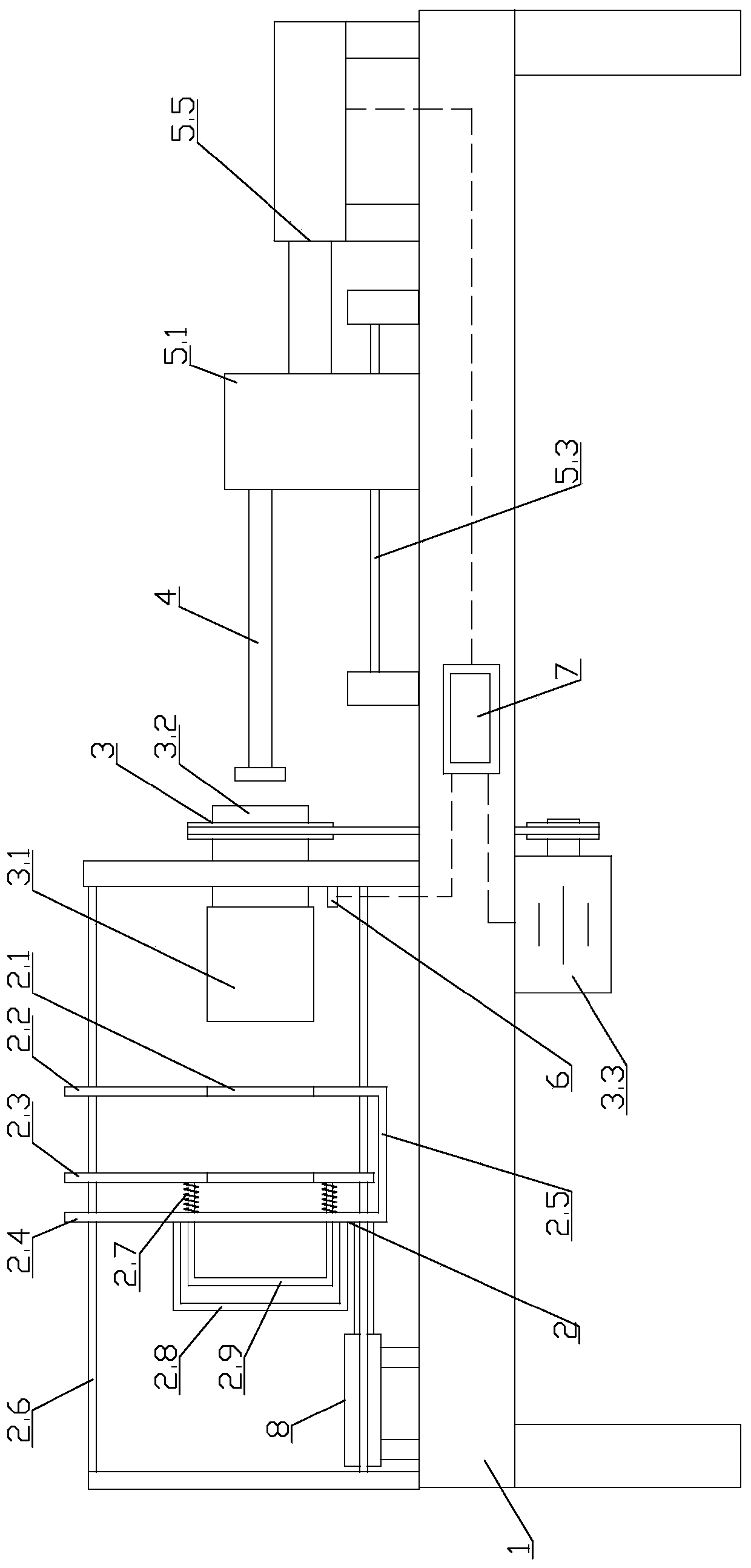

[0029] Embodiment 2: as image 3 As shown, its overall structure is the same as that of Embodiment 1, the difference is that the first push-pull structure 5 includes a telescopic rod 5.5, and the telescopic rod 5.5 is any one of a hydraulic cylinder, an air cylinder or an electric push rod. In this embodiment, the telescopic The rod 5.5 is preferably a cylinder, one end of the telescopic rod 5.5 is fixed with the main frame 1, and the other end of the telescopic rod 5.5 is fixed with a push rod 4, and the telescopic control push rod 4 of the telescopic rod 5.5 stretches into or withdraws from the sampling pipe 3.1; the controller 7 The output end of the telescopic rod is electrically connected to the telescopic rod 5.5, and the expansion and contraction of the telescopic rod 5.5 is controlled by the controller 7;

[0030] A second push-pull structure 8 connected to the clamping mechanism 2 is fixed on the top of the main frame 1. The second push-pull structure 8 controls the c...

Embodiment 3

[0031] Embodiment 3: as Figure 4 and Figure 5 As shown, its overall structure is the same as that of Embodiment 2, except that it also includes a stepping structure 9, and the stepping structure 9 includes a stepping motor 9.1, a driving sprocket 9.2, a driven sprocket 9.3, a chain 9.4 and a push plate 9.5; at the bottom of the connecting frame 2.5 between the first splint 2.2 and the second splint 2.3, a driving sprocket 9.2 and a driven sprocket 9.3 are rotated side by side, and the stepping motor 9.1 is connected to the driving sprocket 9.2. The outside of sprocket 9.2 and driven sprocket 9.3 is provided with chain 9.4, and the transmission direction of chain 9.4 is vertically set relative to second track 2.6, and driving sprocket 9.2, driven sprocket 9.3 and chain 9.4 constitute sprocket chain mechanism, Drive driving sprocket 9.2 to rotate by stepping motor 9.1, and then drive chain 9.4 to rotate; The controller 7 controls the opening and closing of the stepping motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com