Drilling bit grinder

A technology of grinding machine and drill bit, which is used in drilling tool accessories, drilling/drilling equipment, grinding/polishing equipment, etc., which can solve the problems of complicated operation, poor grinding of taper shank bits, and different cutting edge heights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

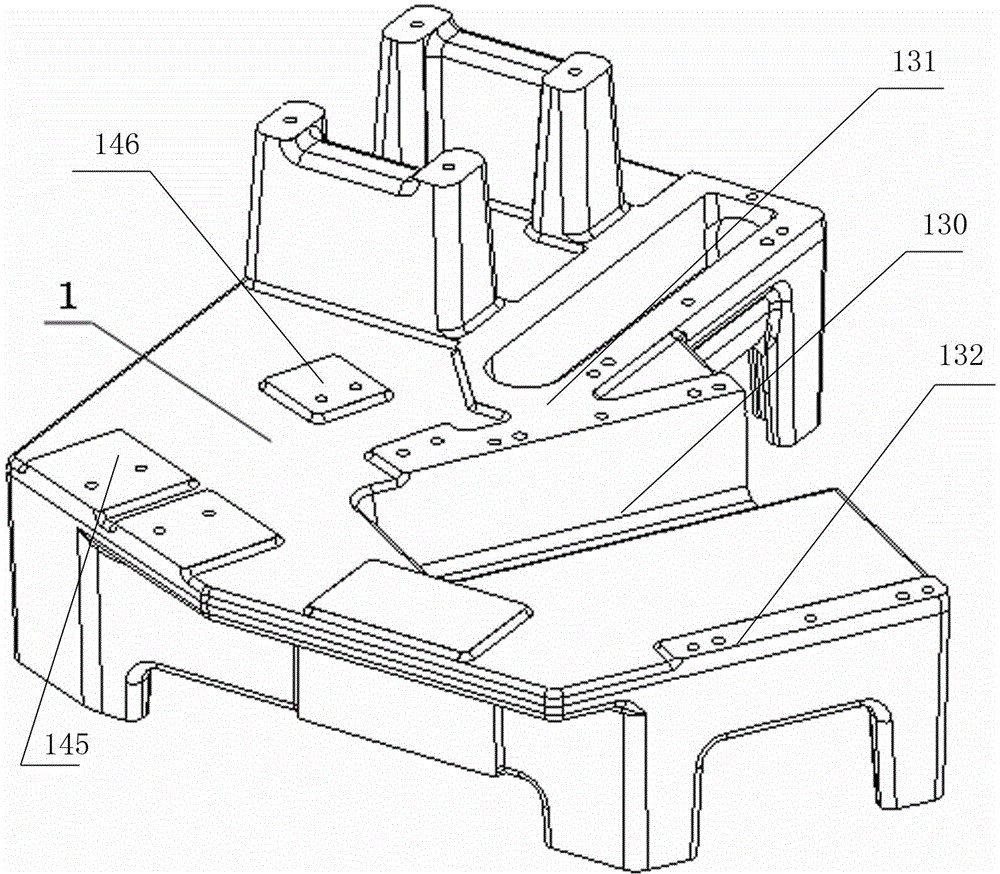

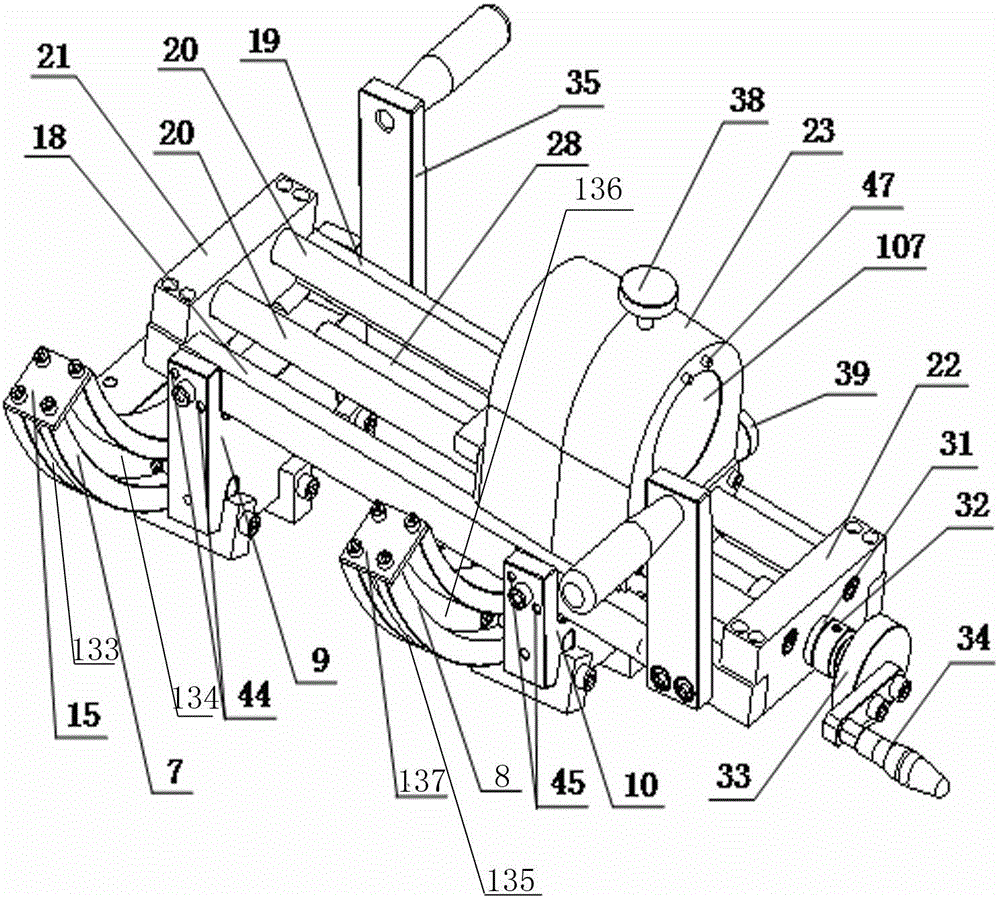

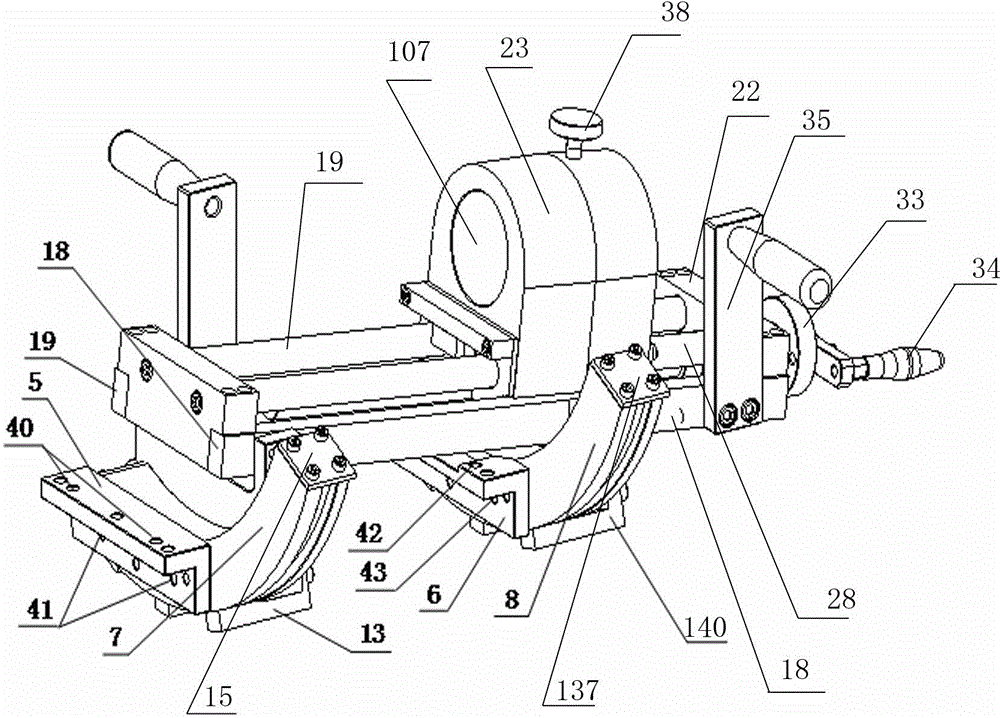

[0030] exist figure 1 , figure 2 with image 3Among them, the present invention discloses a drill grinding machine, which mainly includes a plate-shaped base 1, a motor 2, a cutting edge grinding seat and a chisel edge grinding seat. The plate-shaped base 1 is set as a plate-shaped casting, and under the plate-shaped base 1 There are five foot bosses, two feet bosses are provided on both sides of the base, and a foot boss is provided in the middle of the base. The output shaft of the motor 1 is connected to the grinding wheel 3, and the grinding wheel 3 is covered with a grinding wheel mask. 4. The motor 2, the cutting edge grinding seat and the chisel edge grinding seat are located on the plate base 1. The cutting edge grinding seat mainly includes the cutting positioning seat 23, the guide rail fixing frame I, the slide rail group I and the position adjustment device I, The main body of the cutting positioning seat 23 is provided with a drill bit mounting hole I107, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com