Rim production method facilitating mass material preparation

A production method and rim technology, which is applied in the manufacture of rims, wheels, wheels, etc., can solve the problems of fixed time period, high production cost, and high inventory cost of wheel hubs, and achieve the effects of guaranteed welding effect, short processing time, and simple hemming operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

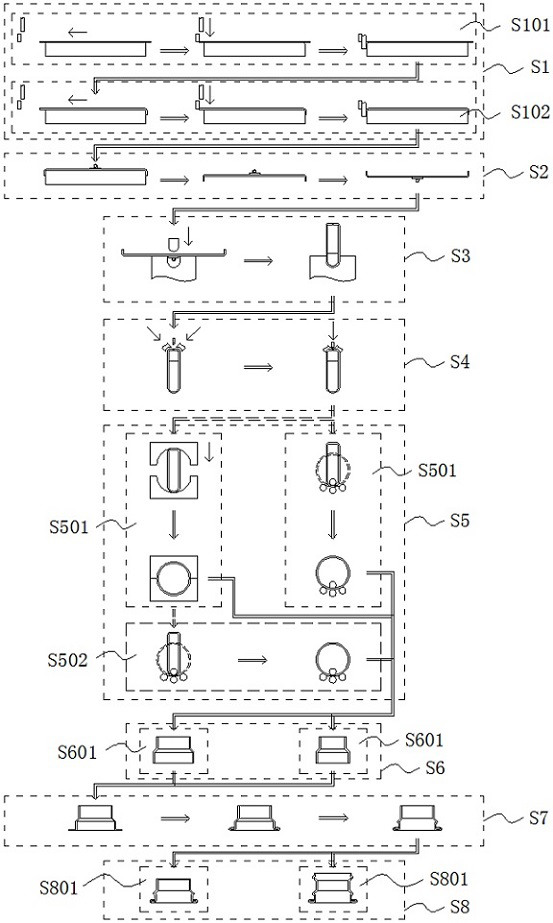

[0076] A method for producing a wheel rim that facilitates mass material preparation, comprising the following steps:

[0077] S0. According to the circumferential length and axial length of the rim tubular blank, the aluminum plate is cut into rectangular aluminum plate units, and the length of the aluminum plate unit is equal to the circumferential length of the rim tubular blank, and the width of the aluminum plate unit is equal to that of the rim tubular blank. The axial length is equal;

[0078] S101. Move the aluminum plate unit along the length direction of the aluminum plate unit until one end of the aluminum plate unit in the length direction is in contact with the positioning device, and then bend the end of the positioned aluminum plate unit downward;

[0079] S102. Move the aluminum plate unit along the length direction of the aluminum plate unit until the other end of the aluminum plate unit in the length direction contacts the positioning device, and then bend th...

Embodiment 2

[0088] A method for producing a wheel rim that facilitates mass material preparation, comprising the following steps:

[0089] S0. According to the circumferential length and axial length of the rim tubular blank, the aluminum plate is cut into rectangular aluminum plate units, and the length of the aluminum plate unit is equal to the circumferential length of the rim tubular blank, and the width of the aluminum plate unit is equal to that of the rim tubular blank. The axial length is equal;

[0090] S101. Move the aluminum plate unit along the length direction of the aluminum plate unit until one end of the aluminum plate unit in the length direction is in contact with the positioning device, and then bend the end of the positioned aluminum plate unit downward;

[0091] S102. Move the aluminum plate unit along the length direction of the aluminum plate unit until the other end of the aluminum plate unit in the length direction contacts the positioning device, and then bend th...

Embodiment 3

[0100] A method for producing a wheel rim that facilitates mass material preparation, comprising the following steps:

[0101] S0. According to the circumferential length and axial length of the rim tubular blank, the aluminum plate is cut into rectangular aluminum plate units, and the length of the aluminum plate unit is equal to the circumferential length of the rim tubular blank, and the width of the aluminum plate unit is equal to that of the rim tubular blank. The axial length is equal;

[0102] S101. Move the aluminum plate unit along the length direction of the aluminum plate unit until one end of the aluminum plate unit in the length direction is in contact with the positioning device, and then bend the end of the positioned aluminum plate unit downward;

[0103] S102. Move the aluminum plate unit along the length direction of the aluminum plate unit until the other end of the aluminum plate unit in the length direction contacts the positioning device, and then bend th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com