Tree planting machine

A technology for planting trees and saplings, applied in planting methods, conveyor objects, excavation/covering trenches, etc., can solve the problems of low forest coverage, low equipment integration, low automation, etc., and achieve a compact structure , the structure is reasonable, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

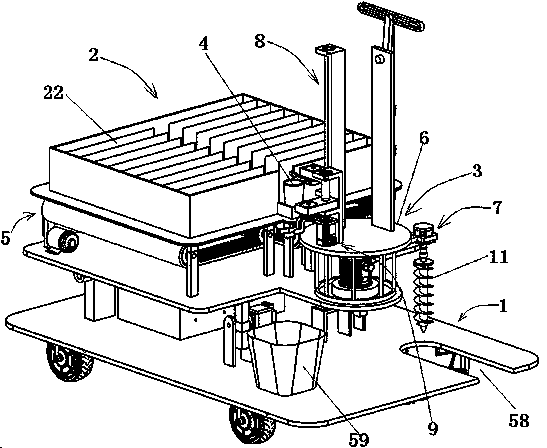

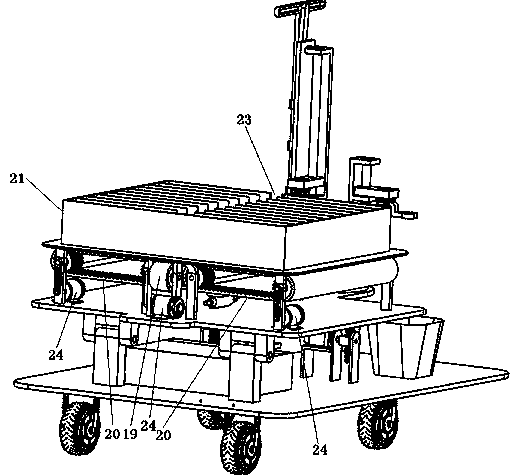

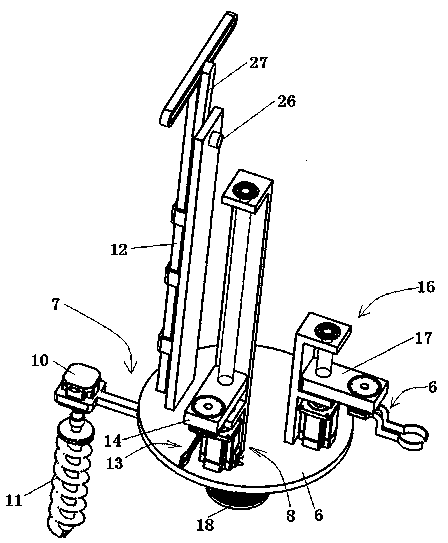

[0030] Such as Figures 1 to 9 The tree planting machine shown comprises frame 1, sapling transmission system 2, sapling planting device 3, and described sapling transmission system 2 comprises the conveyer belt 5 that is fixed on frame 1 for placing sapling cup 4, and sapling planting device 3 and all The ends of the conveyor belt 5 are arranged adjacently, and the sapling planting device 3 includes a drilling mechanism 7 fixed on the same rotating disk 6, a sapling grasping mechanism 8 and a sapling cup recovery mechanism 9, and the drilling mechanism 7 includes a drilling mechanism 7. The drill bit 11 driven by the motor 10, and the slide bar 12 that drives the drill bit 11 to move up and down, the sapling grabbing mechanism 8 includes grabbing claws 13 for grabbing saplings, and a slide block 14 that drives the grabbing claws 13 to slide up and down. The cup recovery mechanism 9 includes the mechanical claw 16 of grabbing the sapling cup 4, and the moving block 17 that dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com