Branch cutting equipment for peony grafting

A branch and incision technology, which is applied in the field of branch incision equipment for peony grafting, can solve the problems of different chip angles, affecting the grafting survival efficiency, etc., and achieves the effects of low cost, simple structure and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

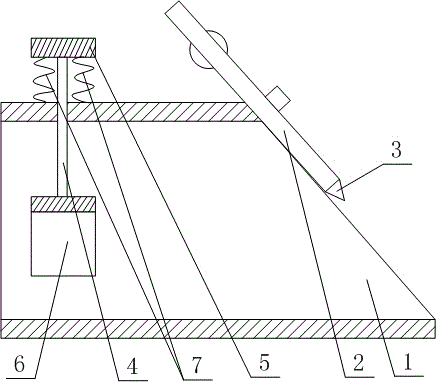

[0027] A branch cutting device for peony grafting, such as figure 1 and figure 2 As shown, it includes a cylindrical rootstock placement cavity 1, a beveled surface arranged at one end of the cylindrical rootstock placement cavity 1 and set at an angle of 30 to 60 degrees to the central axis of the cylindrical rootstock placement cavity 1, and slidingly connected along the beveled surface. The moving plate 2, the cutting knife 3 arranged at the bottom of the moving plate 2, and the stock pressing device arranged on the cylindrical rootstock placement cavity 1.

[0028] Described stock pressing device comprises that one end extends into the moving rod 4 in cylindrical root stock placement cavity 1 from above, is arranged on the handle piece 5 of moving rod 4 tops, is arranged on the arc pressing part 6 of moving rod 4 bottoms, And the back-moving spring 7 that is arranged between the holding block 5 and the cylindrical stock placement cavity 1 outer casing.

[0029] The movi...

Embodiment 2

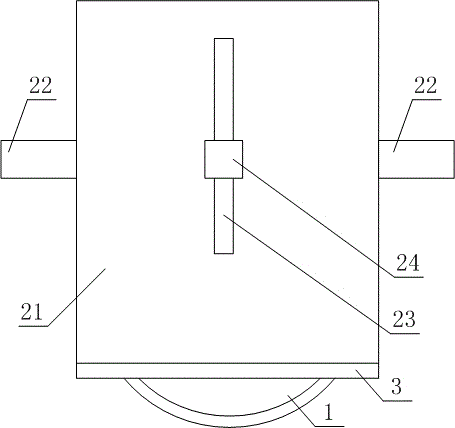

[0032] The difference between this embodiment and Embodiment 1 is that this embodiment also optimizes the specific structure of the operating rod 22, and the specific settings are as follows:

[0033] The operating rod 22 is in the shape of a "Y", and the top two ends of the operating rod 22 are respectively fixed on the plate body 21 at the two ends of the through hole 23 . The bottom end of the operating rod 22 is used for hand-held operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com