LED light mixing system

A light mixing and beam technology, applied in the field of light mixing, can solve the problem of uneven light mixing of LED light sources, and achieve the effects of uniform light mixing, uniform color mixing and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

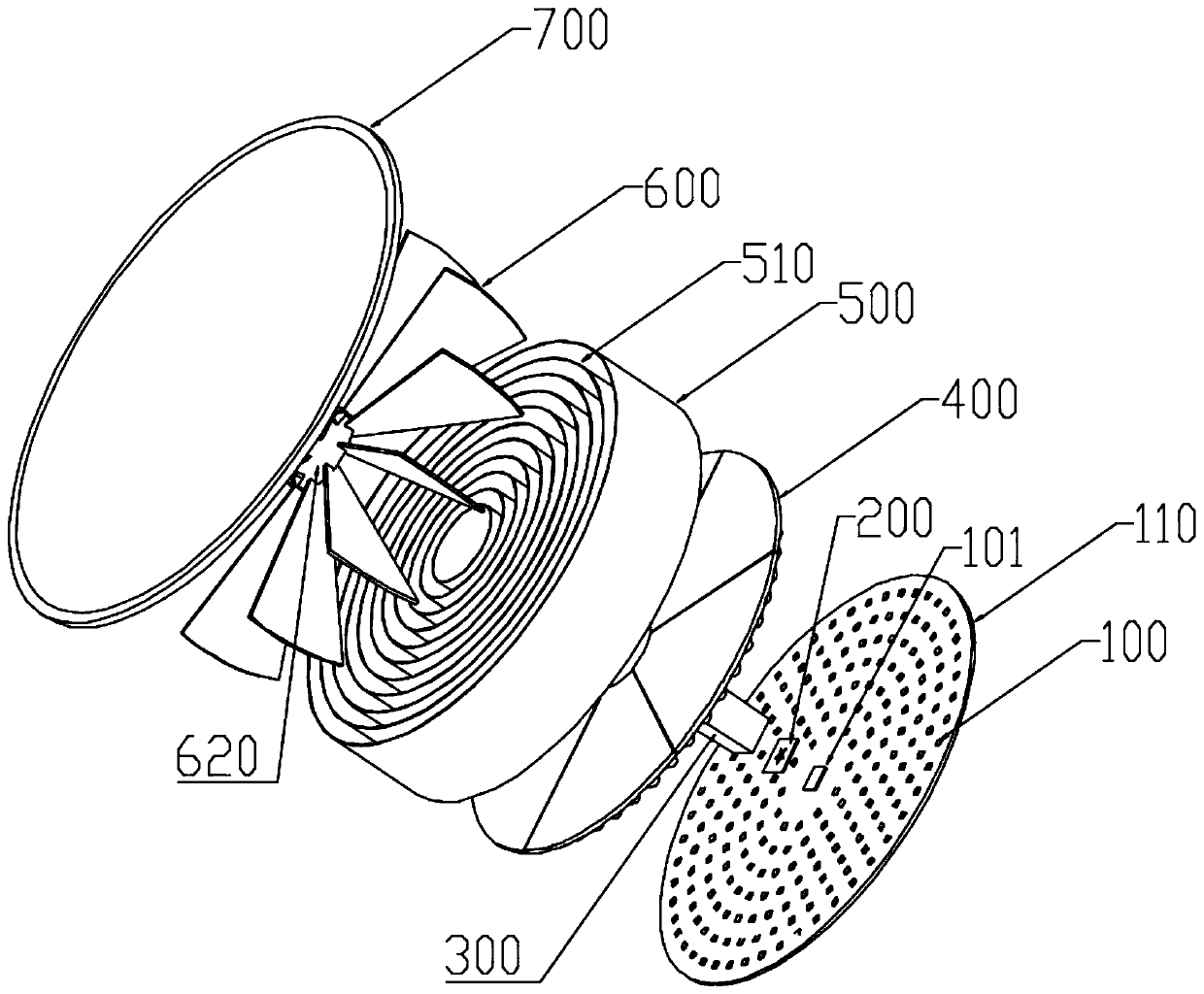

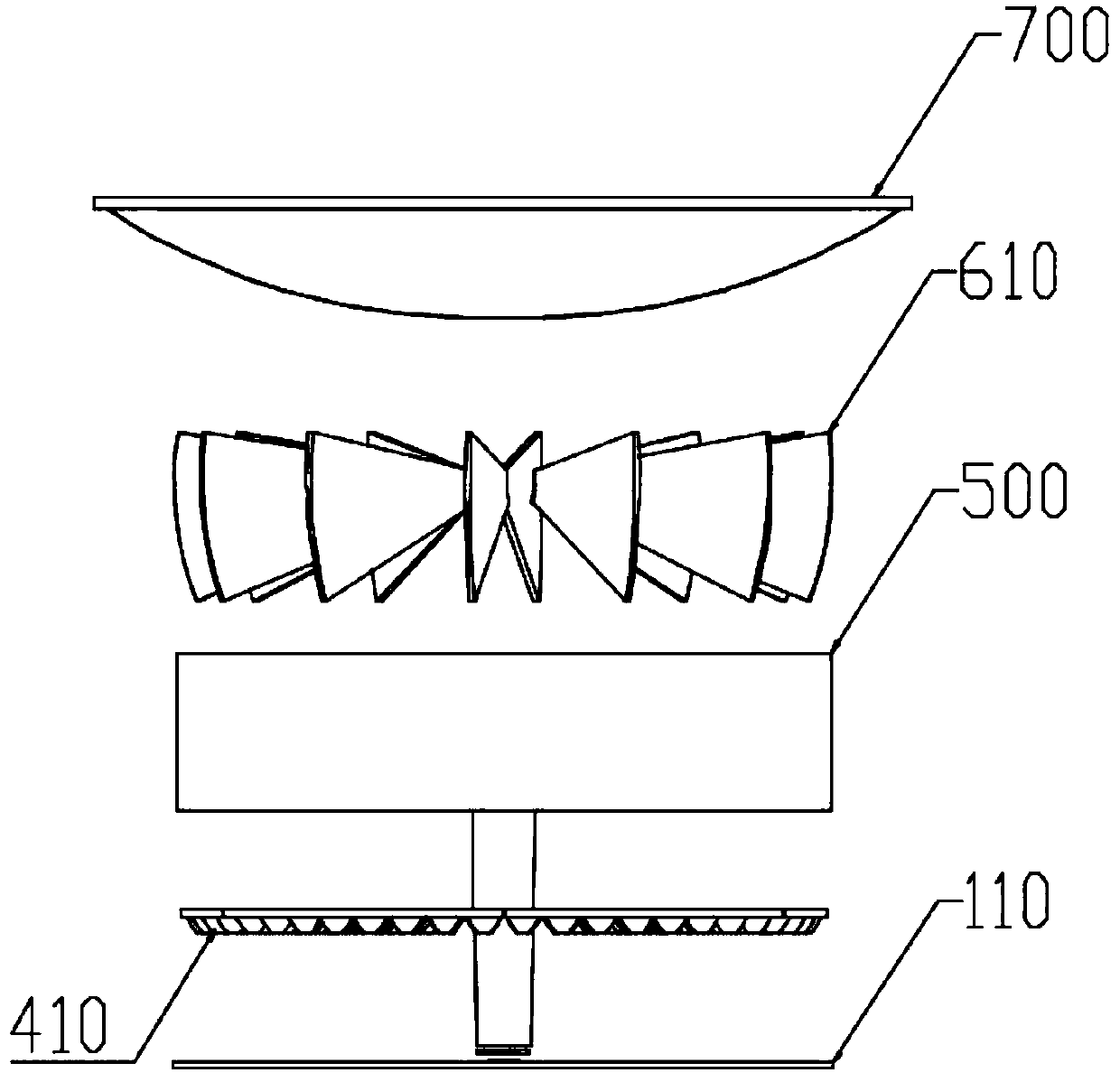

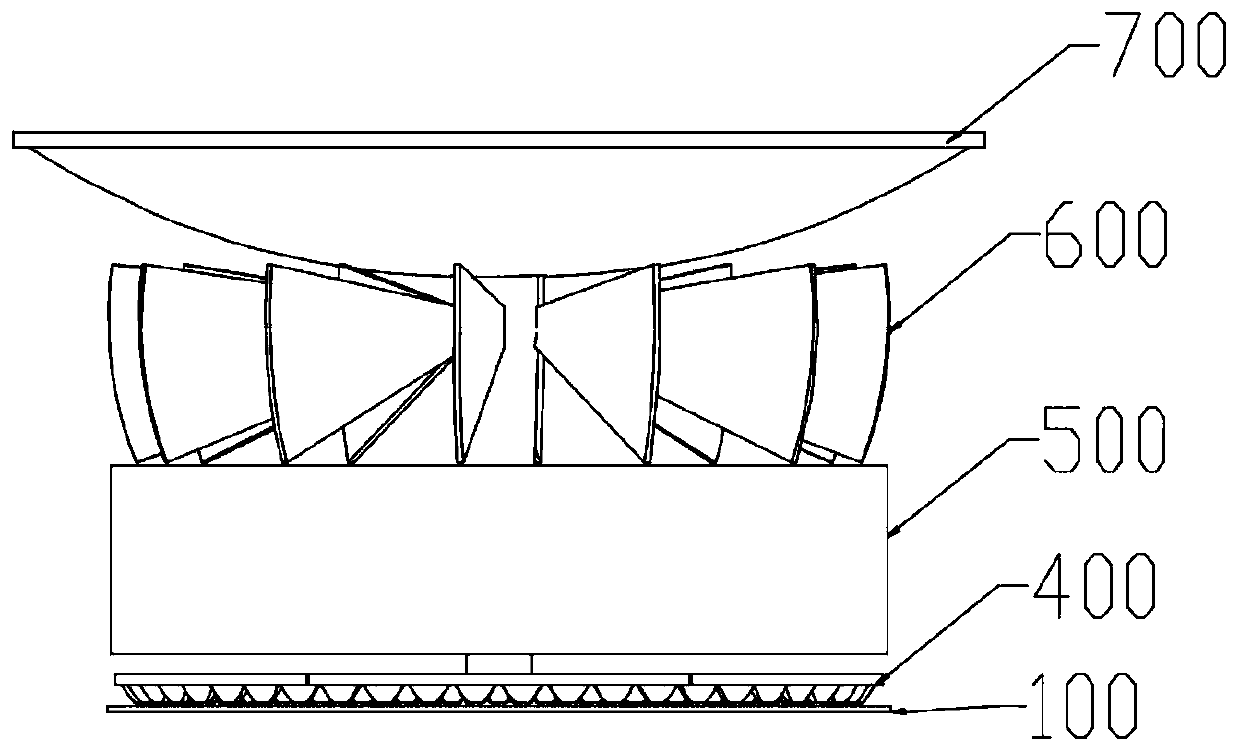

[0032] Such as figure 1 with figure 2 As shown, an LED light mixing system includes a number of LED100 arranged in a certain pattern or shape and a PCB board 110 for installing the LED100. A light mixing module 500 is provided in the light emitting direction of the LED100. The light mixing module The shape of the cross-section of 500 matches the shape formed by the arrangement of LED100, and the light mixing module 500 is provided with a gap for the light emitted by the LED100 to pass through, and the light emitted by the LED100 is at least partially passed through the light mixing module 500. The sidewall of the gap formed by the module 500 reflects and mixes the light and emits it.

[0033] In this technical solution, the light mixing module 500 is arranged in the light output direction of the LED100. When the light beam emitted by the LED100 passes through the light mixing module 500, a small part of the light beam directly passes through the gap of the light mixing modul...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the fixing bar 800 is a comb-shaped fixing member, and the cylinders 510 are connected and fixed by a comb-shaped fixing member, and the comb teeth of the comb-shaped fixing member extend into inside the cylinder 510 .

[0067]The comb-shaped fixing member fixes the light mixing assembly into the light mixing module 500, which is convenient for installation. The comb teeth spacing of the comb-shaped fixing member is slightly smaller than or equal to the thickness of the side wall of the cylinder, so that the comb-shaped structure clamps the light mixing assembly, thereby making the light mixing module 500 more stable. Moreover, the comb-shaped fixing member is located between the installation distances of two adjacent LEDs 100 , so that the light path emitted by the LEDs 100 is not blocked.

[0068] Preferably, the pair of comb-shaped fixing members is located between the installation positions of two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com