Combined color blending machine

A color mixing machine and unit technology, which is applied in fiber mixing, textile and paper making, fiber processing, etc., can solve problems such as uneven mixing and color difference, and achieve high production efficiency and uniform color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

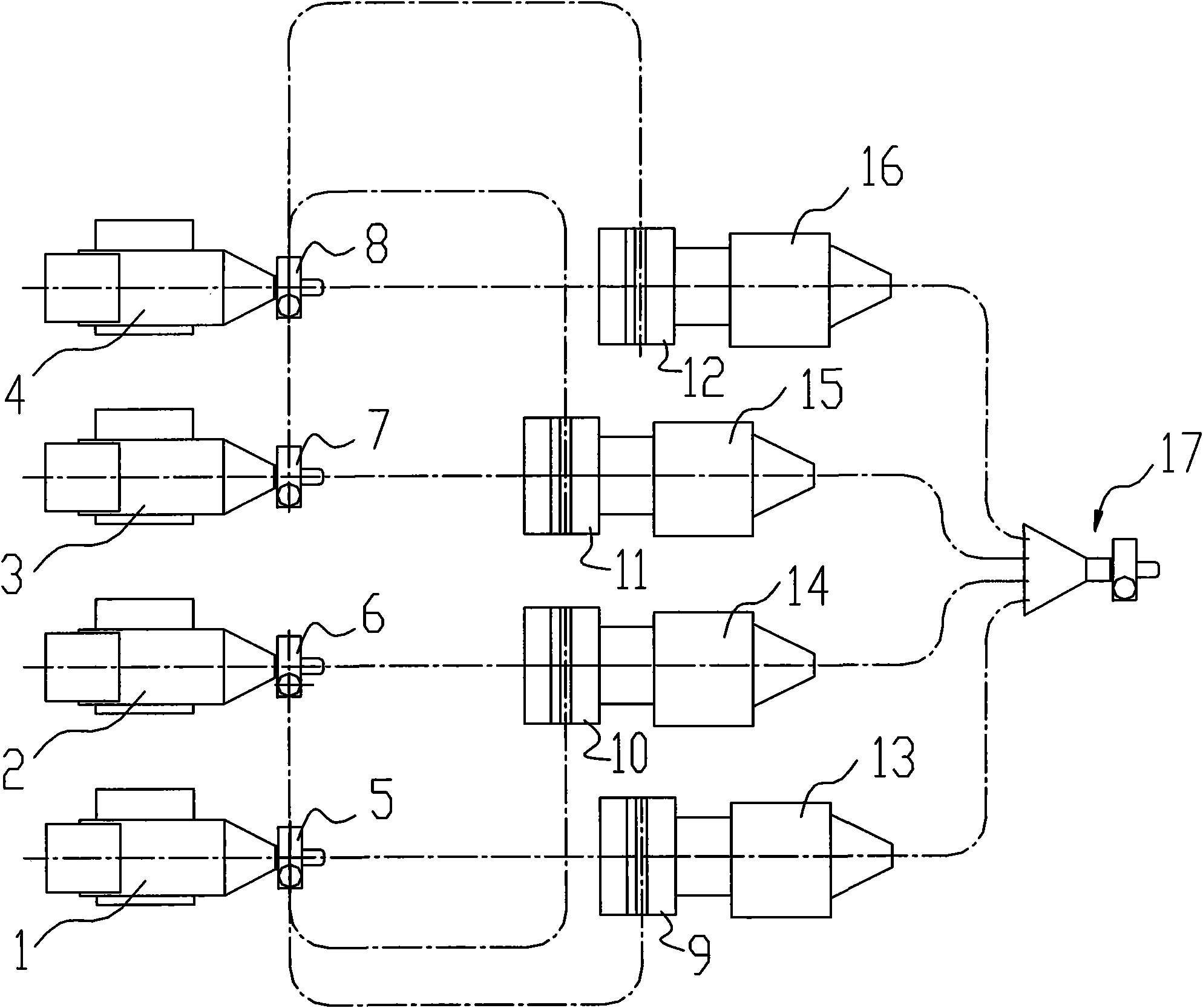

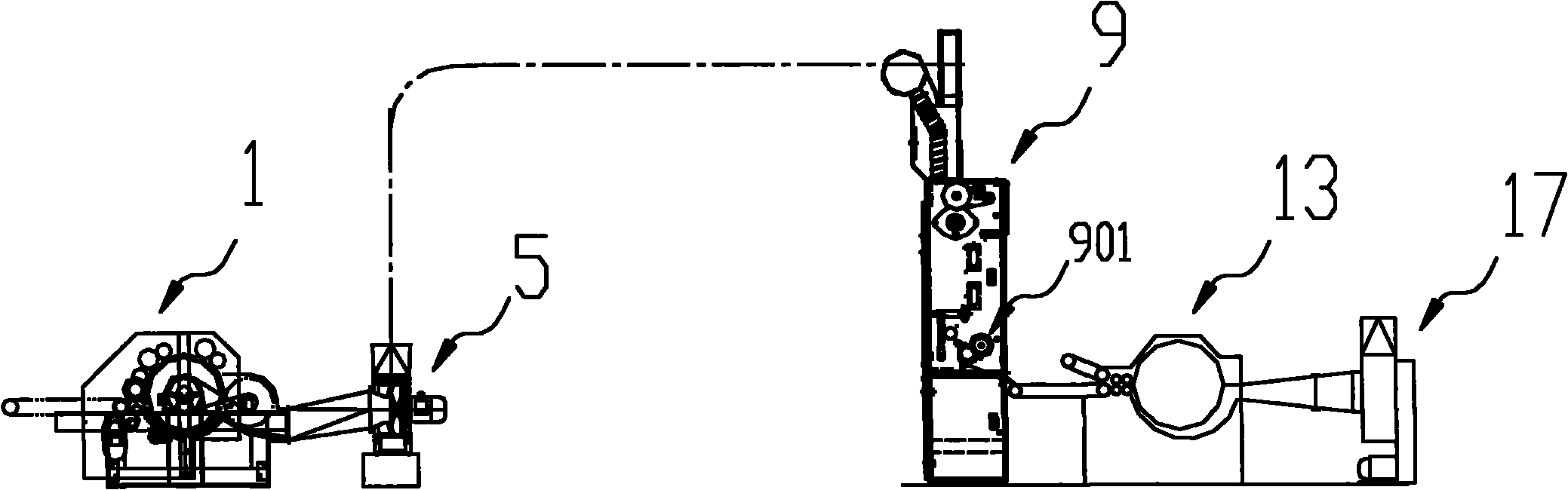

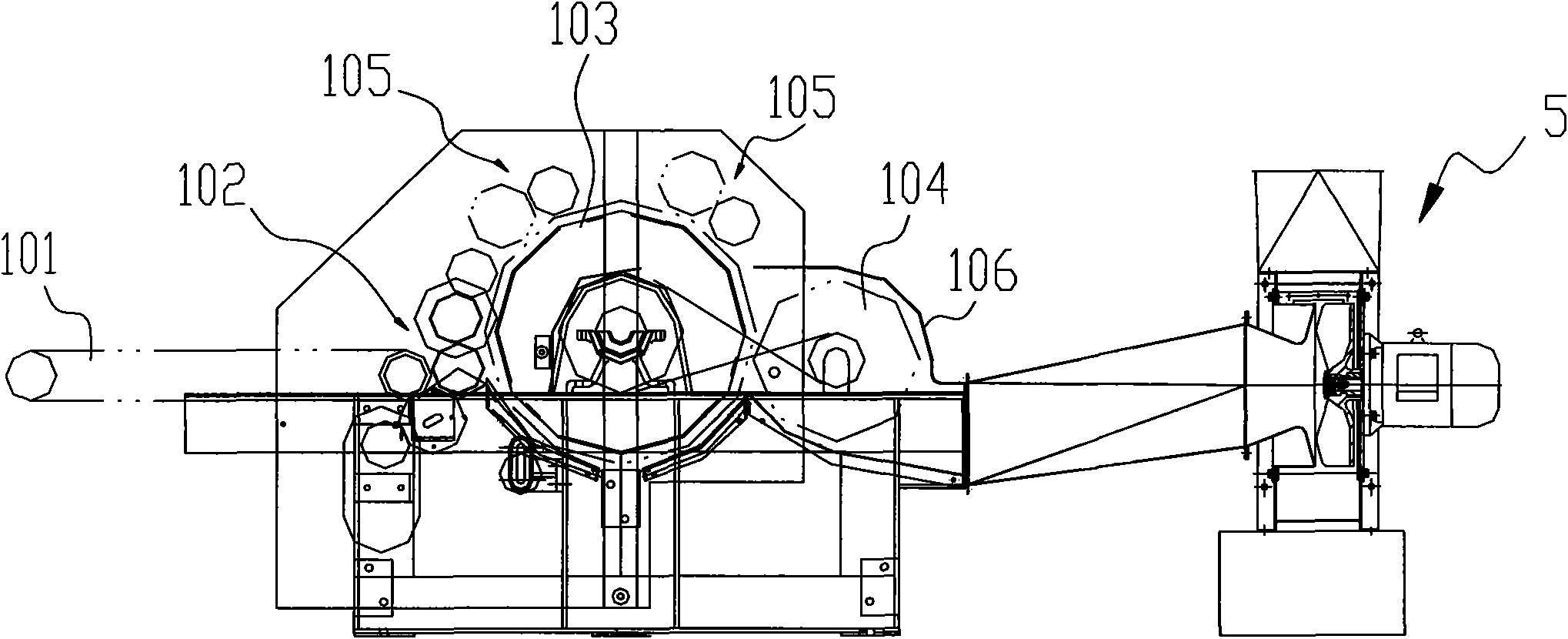

[0019] to combine figure 1 , figure 2 , image 3 and Figure 4 , a combined color mixing machine, including a mixing opening unit, a conveying fan unit, an air pressure control cotton box group, an opening unit and a mixing device. The above-mentioned mixing unit has four mixing units 1, 2, 3, and 4, and the four mixing units are arranged side by side in sequence. The conveying fan unit has four first-stage fans 5, 6, 7, and 8, and the air pressure control cotton box The air pressure control cotton boxes 9, 10, 11, 12, four air pressure control cotton boxes are also correspondingly distributed side by side successively, and the opening unit has four openers 13, 14, 15, 16. The above-mentioned mixed start-up corresponds to the first-stage fan, the first-stage fan and the air pressure control cotton box, and the air pressure control cotton box and the opener correspond one by one. As far as any mixing machine is concerned, such as the mixing machine 1, the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com