Compound color polyester chopped fiber and production device and method thereof

A polyester staple fiber and production device technology, which is applied in fiber processing, fiber cutting, fiber mixing and other directions, can solve the problems of uneven mixing of raw materials, increased cotton mixing costs, long process, etc., and is suitable for market economy, less chromatic aberration, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

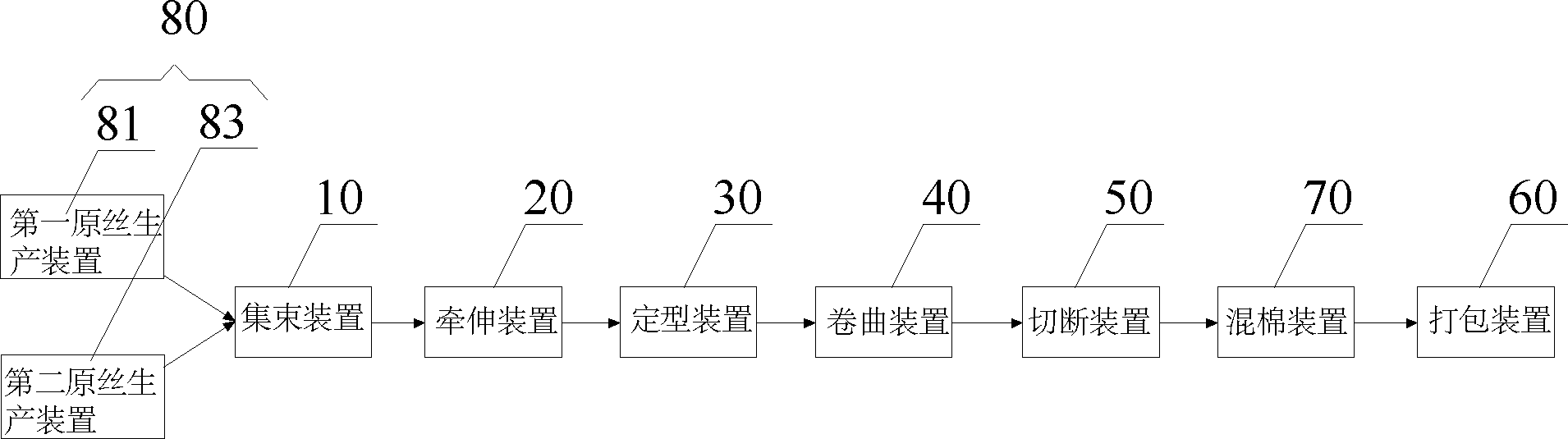

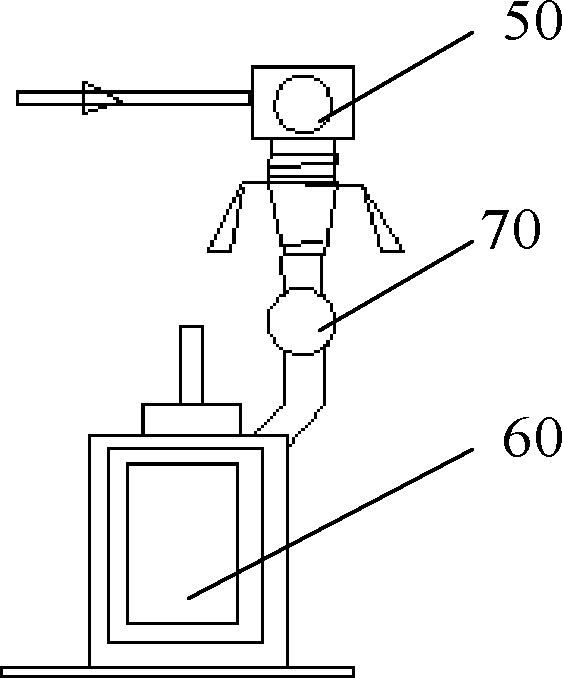

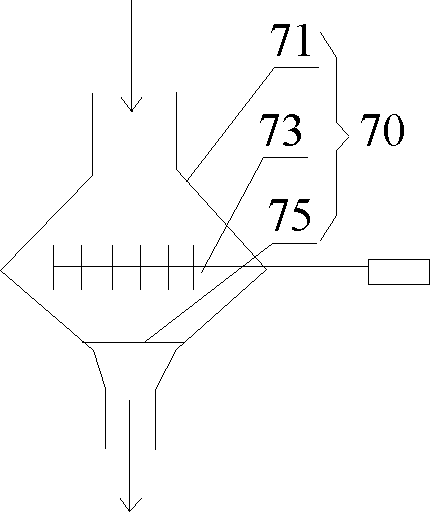

[0045] Equipment: includes a raw silk production device 80, a bundling device 10, a drafting device 20, a sizing device 30, a crimping device 40, a cutting device 50, a cotton blending device 70, and a baling device 60 connected in sequence. The raw silk production device 80 includes at least: a first raw silk production device 81 and a second raw silk production device 83. The first raw silk production device 81 in the raw silk production device 80 includes a first pressurizing part 811, an in-line adding part 813, a static mixer 815, a second pressurizing part 817, and a filter 819 that are connected in sequence. The cotton mixing device includes a cotton mixing box 71, a stirring rod 79 and a baffle part. The cotton mixing box 71 is arranged on the noil channel between the cutting device 50 and the baling device 60, and communicates with the noil channel; the stirring rod 73 is provided Inside the mixing box, one end is connected with the inner wall of the mixing box 71, and...

Embodiment 2

[0048] Equipment: Same as Example 1.

[0049] Process parameters: The diameter of the cutting blade in the cutting device is 500mm; the speed of the cutting blade is 180m / min; the residence time of the cut multicolor polyester fiber in the mixing box is 50 seconds, and the speed of the stirring rod is 800r / min.

Embodiment 3

[0051] Equipment: Same as Example 1.

[0052] Process parameters: The diameter of the cutting cutter in the cutting device is 550mm; the rotating speed of the cutting cutter is 165m / min; the residence time of the cut multicolor polyester fiber in the mixing box is 40 seconds, and the rotating speed of the stirring rod is 1650r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com