Rapid shaping type full-color 3D (Three Dimensional) printer material conveying system and control method thereof

A 3D printer and feeding system technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of low heating temperature, uneven color mixing, incomplete melting of materials, etc., to achieve the feeding system accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

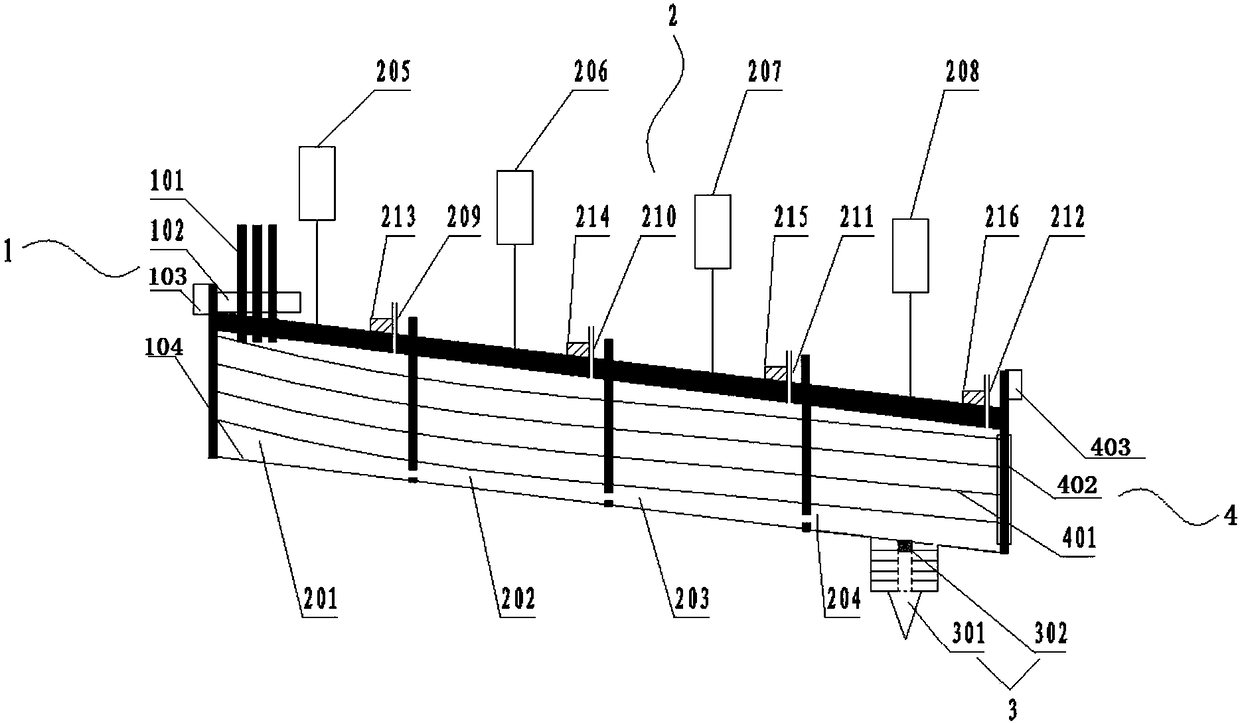

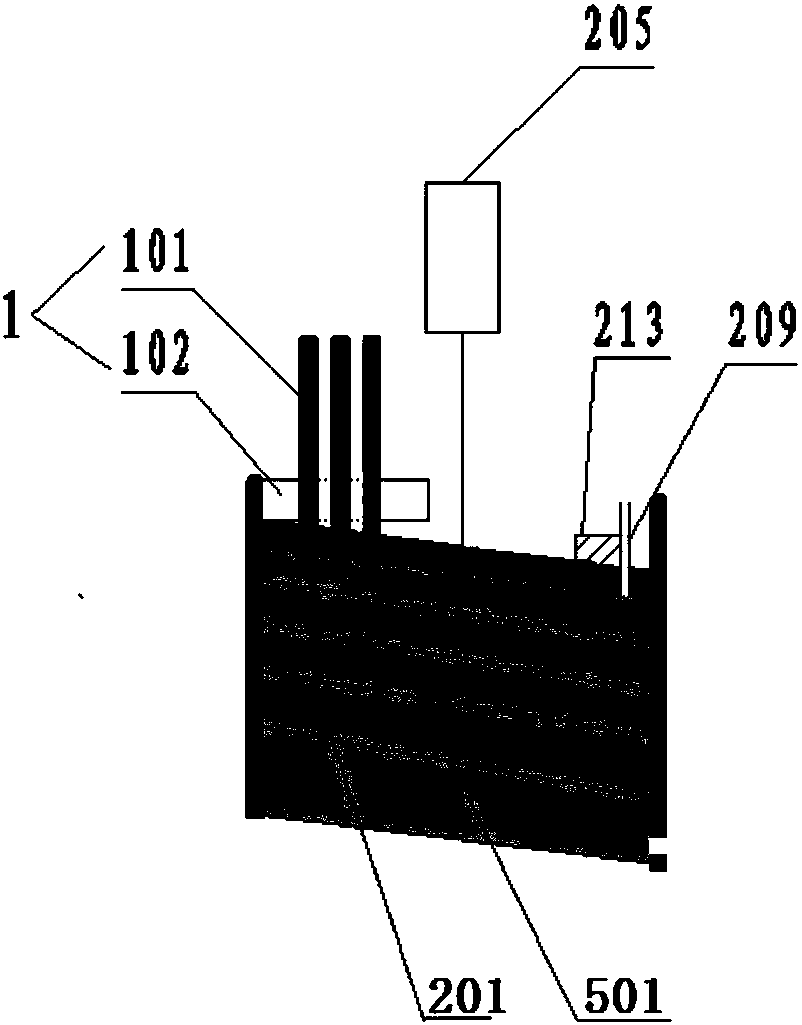

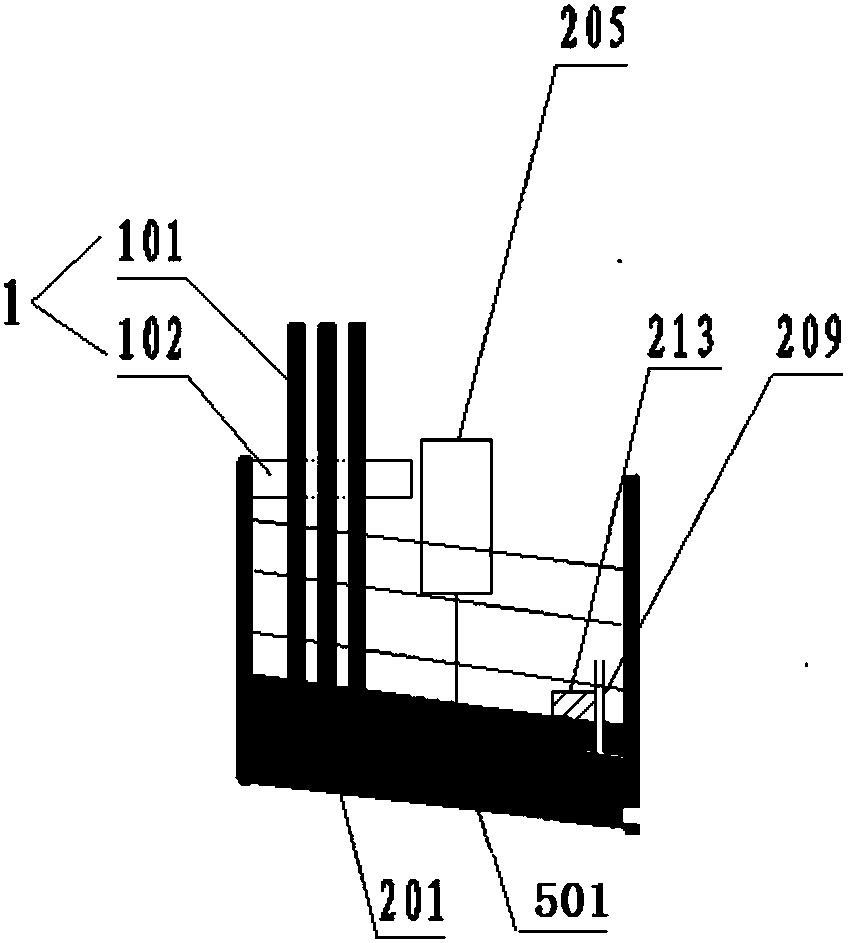

[0135] A feeding system for a rapid prototyping full-color 3D printer, comprising a feeding system 1, a molten pool system 2, a nozzle system 3, and a heating system 4, the feeding system 1 is connected to the input end of the molten pool system 2, and the molten pool The output end of the system 2 is connected with the nozzle system 3 , and the heating system 4 is connected with the molten pool system 2 .

[0136] Described feed system 1 comprises feed pipe 101, feed motor 102, motor controller 103, material quantity sensor 104, and this feed pipe 101 links to each other with feed motor 102, and material quantity sensor 104, feed motor 102 respectively Connected to the motor controller 103, the material sensor 104 is installed at the bottom of the molten pool system; the feed pipe 101 is at least three feed pipes, respectively equipped with red, green, blue, yellow, cyan and other wires .

[0137] The molten pool system 2 includes a plurality of molten pools, a molten pool s...

Embodiment 2

[0145] A control method for the feeding system of a rapid prototyping full-color 3D printer. The method is to first calculate the amount of wire materials of various colors required for printing the model; then control the feeding motor of the feeding system to precisely control the amount of wire materials of various colors , and finally by controlling the temperature of each molten pool in the molten pool system to mix the molten materials one by one and send them to the print nozzle.

[0146] The above-mentioned "controlling the feeding motor of the feeding system to precisely control the amount of wires of various colors" is to monitor the amount of molten material in the molten pool in real time through the material sensor installed at the bottom of the molten pool system, and the detected molten pool is melted. The feed amount is fed back to the motor controller, so that the motor controller can quickly and accurately adjust the feed motor of the feed system to achieve re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com