Rapid forming full-color 3D printer device and printing method thereof

A 3D printer, fast technology, applied in the coating device, 3D object support structure, additive manufacturing, etc., can solve the problems of low printing efficiency, complex structure, uneven color mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

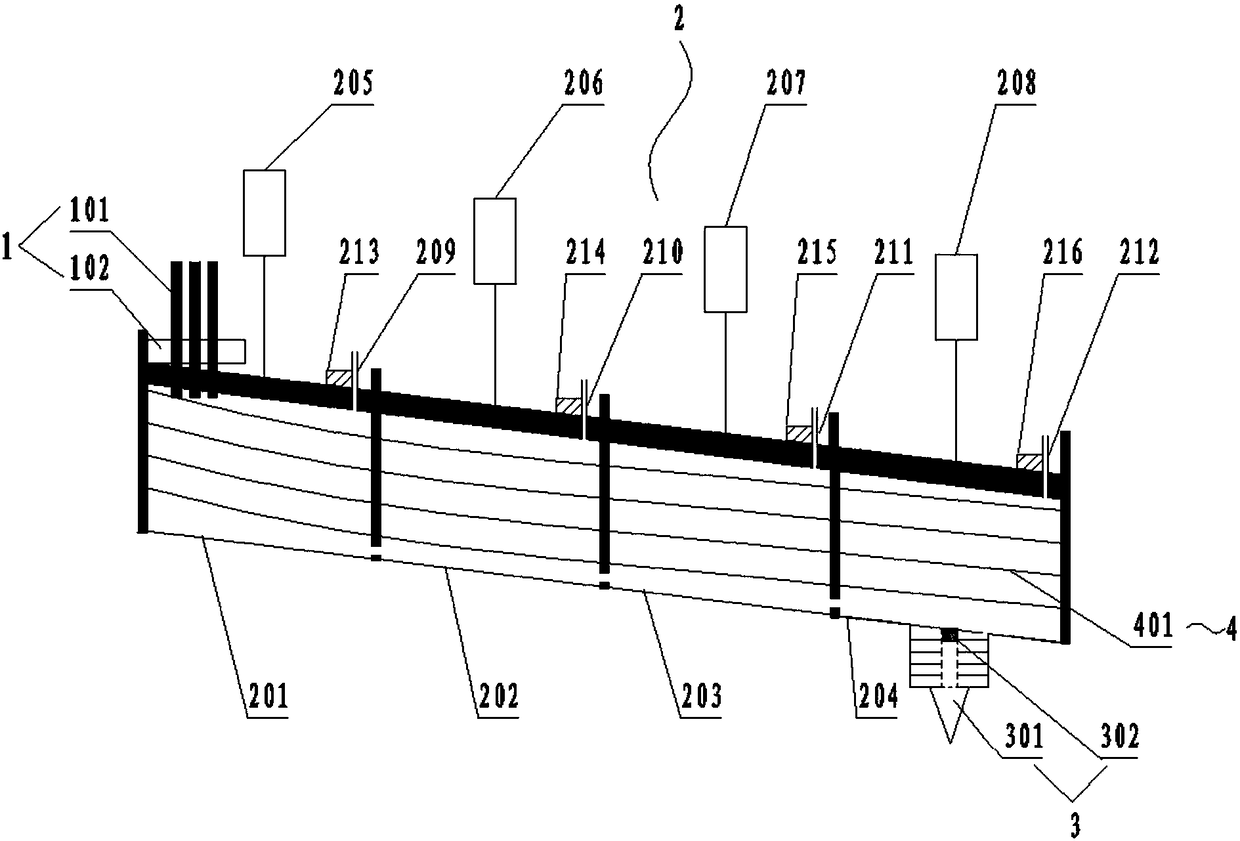

[0078] A rapid prototyping full-color 3D printer device, comprising a feeding system 1, a melting pool system 2, a nozzle system 3, a heating system 4, and a control system; the feeding system 1 is connected to the input end of the melting pool system 2, and the melting The output end of the pool system 2 is connected to the nozzle system 3, the heating system 4 is connected to the molten pool system 2, and the control system is connected to the feeding system 1, the molten pool system 2, the nozzle system 3, and the heating system 4 respectively.

[0079] Described feed system 1 comprises feed pipe 101, feed motor 102, and this feed pipe 101 links to each other with feed motor 102, and feed motor 102 is connected with control system; Described feed pipe 101 includes three feeding Feed pipe, the three feed pipes are equipped with red, green, blue, yellow, cyan and other wires respectively.

[0080]The molten pool system 2 includes a plurality of molten pools, a molten pool sol...

Embodiment 2

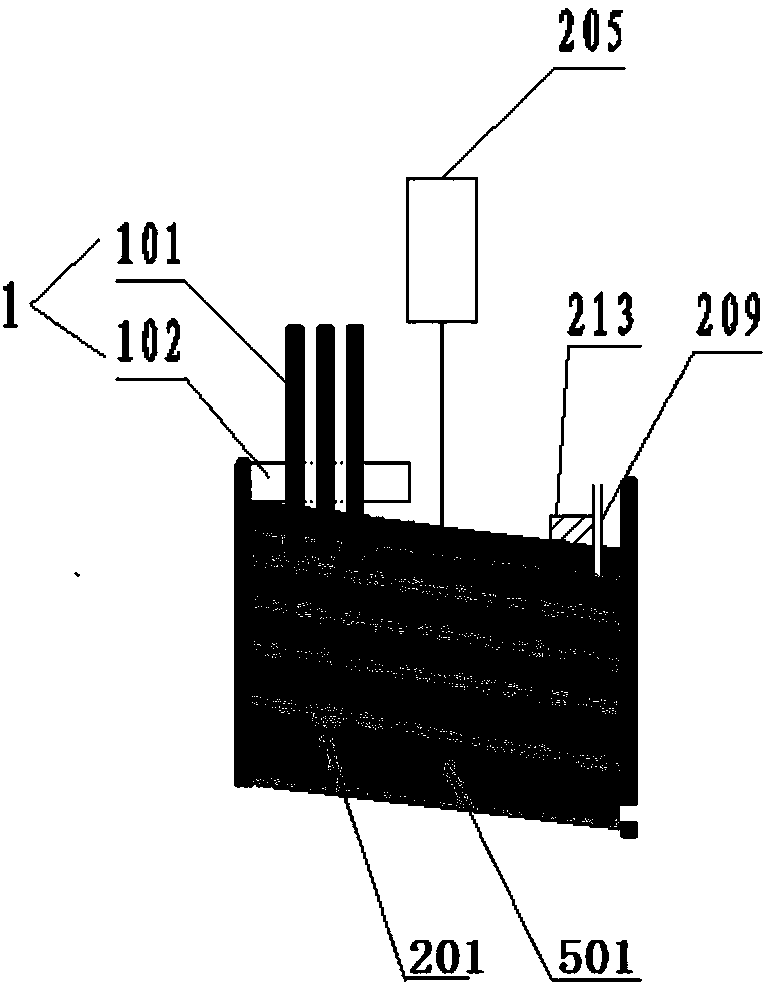

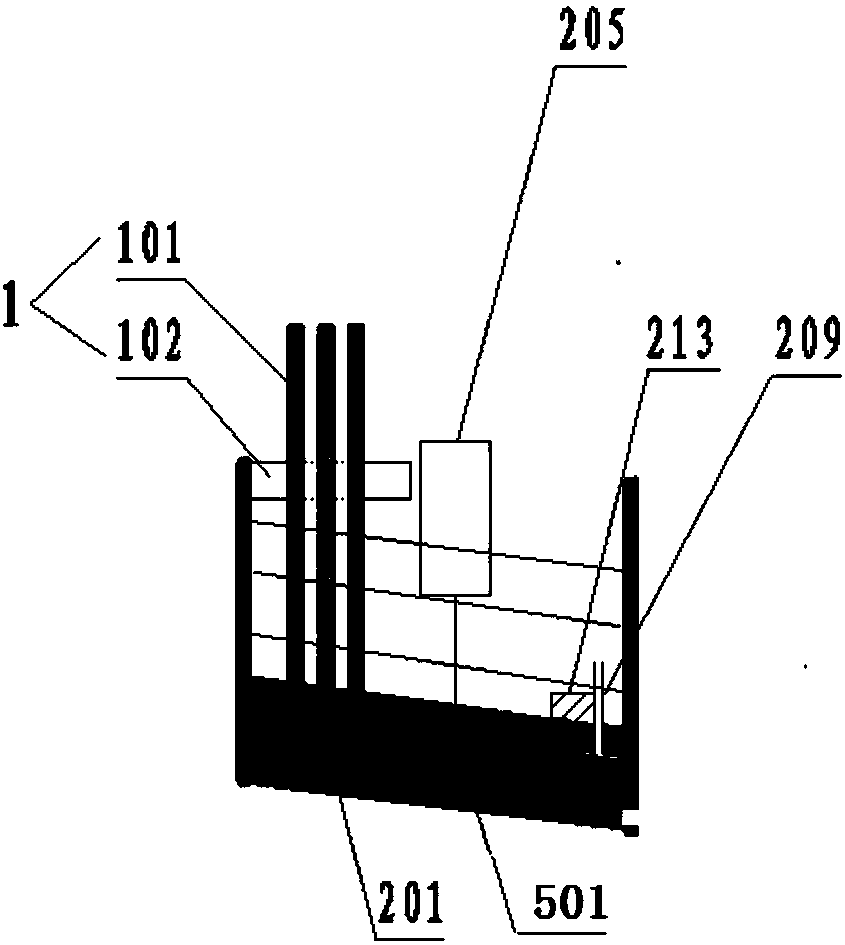

[0088] A printing method for a rapid prototyping full-color 3D printer device, the method is a printing method when a single molten pool works, figure 2 Shown is a single melt pool of a rapid prototyping full-color 3D printer setup, image 3 Shown in is a schematic diagram of the working process of a single molten pool of a rapid prototyping full-color 3D printer device. Combine now figure 2 , image 3 The printing method when the rapid prototyping full-color 3D printer device works in a single molten pool is described as follows:

[0089] A printing method of a rapid prototyping full-color 3D printer device, the printing method comprising the following steps:

[0090] A. Calculate the various colors and wire materials needed to print the model through the software;

[0091] B. The feeding motor 102 of the feeding system is controlled by the control system to precisely control the amount of red, green, blue, yellow, and cyan wires, and any color raw materials can be mixe...

Embodiment 3

[0102] A printing method of a rapid prototyping full-color 3D printer device, the method is a printing method when working with multiple molten pools, Figure 4 It is a schematic diagram of the structure of the first molten pool of the rapid prototyping full-color 3D printer device full of molten material, Figure 5 It is a schematic diagram of the structure of the second molten pool full of molten material in the rapid prototyping full-color 3D printer device, Figure 6 It is a schematic diagram of the structure of the first and third melting pools full of molten material in the rapid prototyping full-color 3D printer device, Figure 7 Schematic diagram of the structure of the second and fourth melting pools full of molten material for the rapid prototyping full-color 3D printer device, now combined Figure 4 , 5 , 6, 7 illustrate the printing method of the rapid prototyping full-color 3D printer device when it works in multiple molten pools.

[0103] A printing method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com