Light emitting diode module

A technology of light-emitting diodes and LED modules, which is applied to semiconductor devices of light-emitting elements, light sources, lighting and heating equipment, etc., can solve problems such as inaccurate detection and inaccurate LED output adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

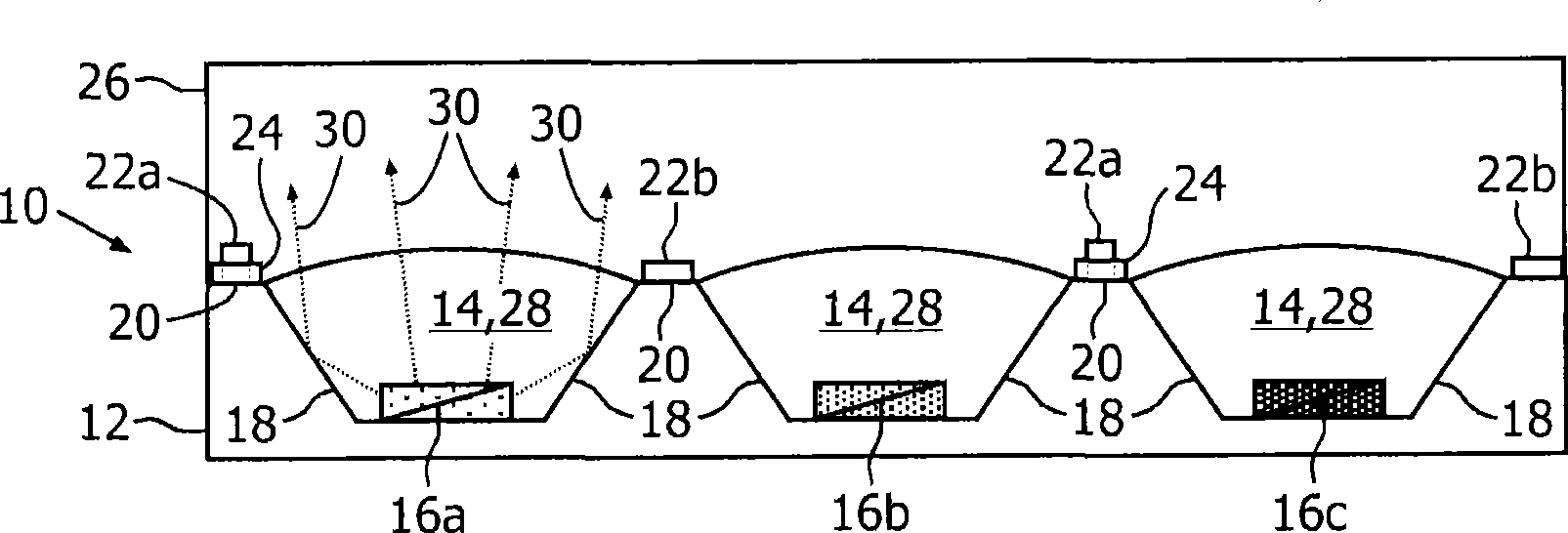

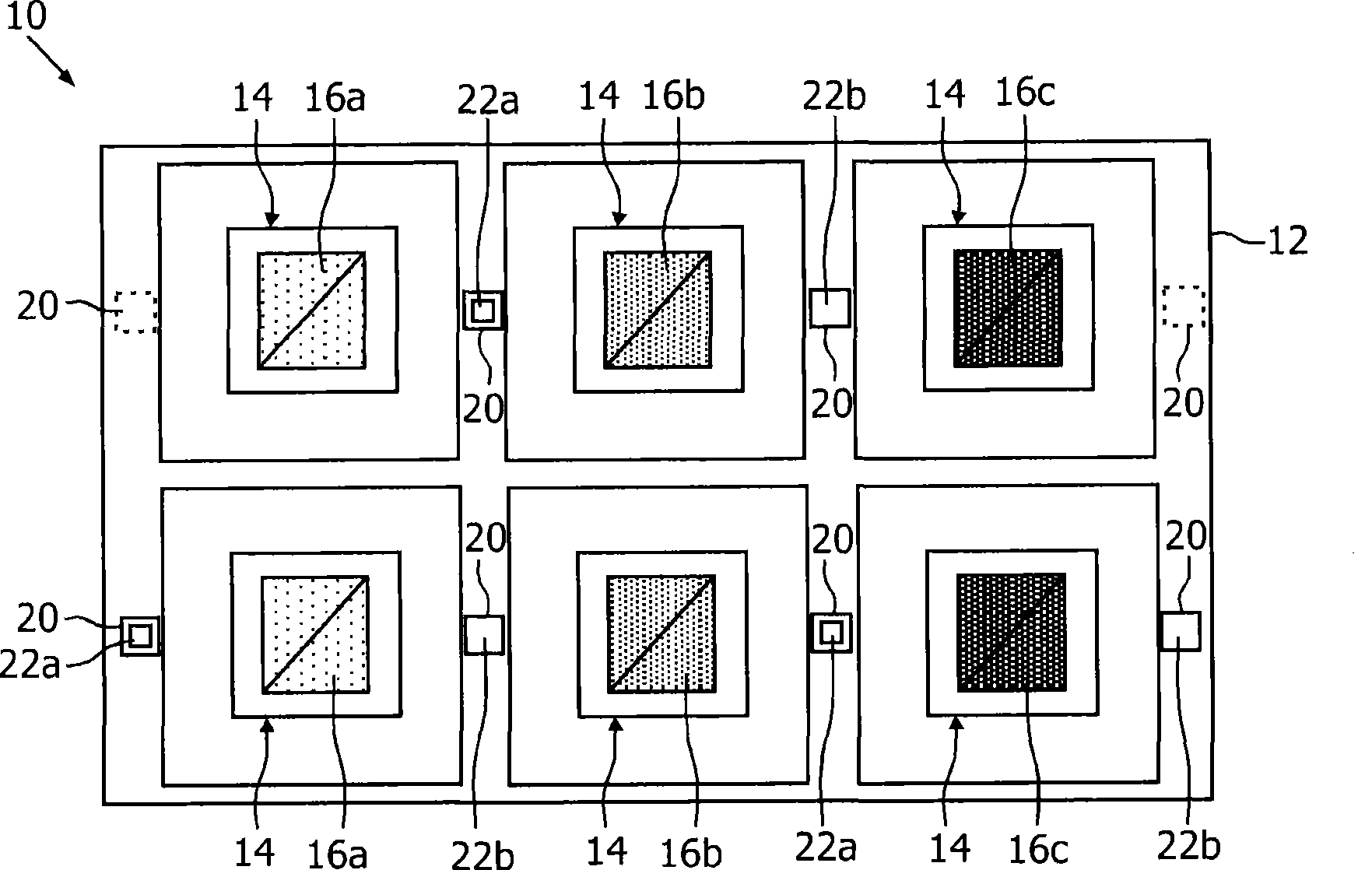

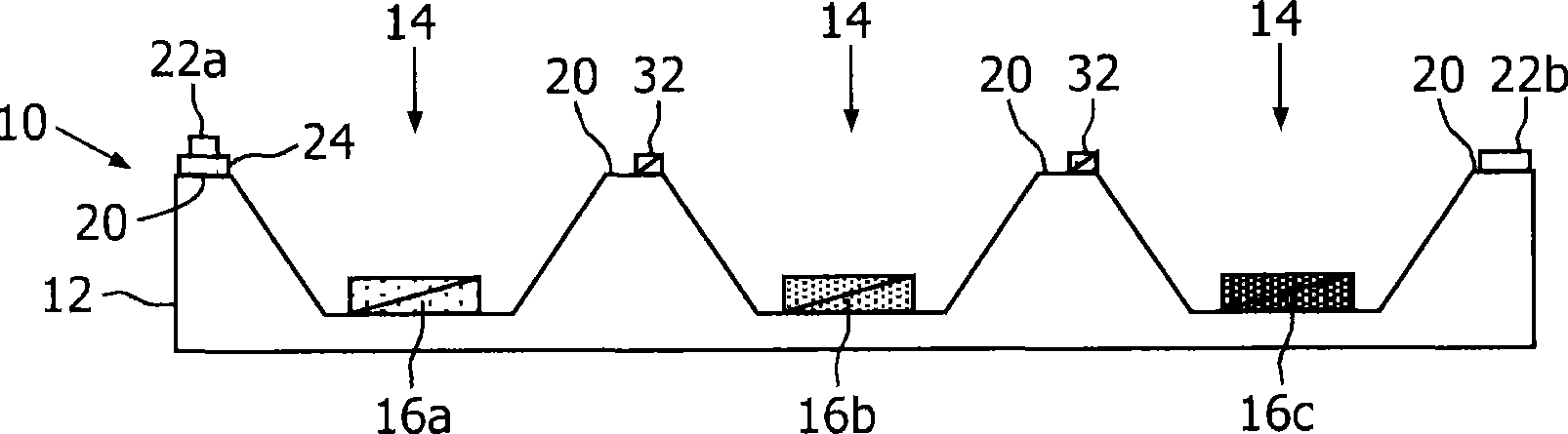

[0017] Figure 1a is a schematic cross-sectional side view of an LED module 10 according to an embodiment of the present invention. The LED module 10 includes a pre-etched substrate 12 with a plurality of recesses 14 . This recess 14 is preferably pre-etched. In each recess 14, LEDs generally indicated at 16 (in this case a red LED 16a, a green LED 16b, and a blue LED 16c) are provided. The LEDs may be intrinsic LEDs or phosphor converted LEDs. Each LED 16 is mounted on the bottom surface of the groove 14 . The groove 14 has inclined side surfaces 18 . Figure 1a The inclined side surfaces 18 in are planar, but alternatively they may be curved. The inclined side surfaces 18 and optionally the bottom surface of the groove 14 are preferably reflective, for example equipped with a reflective coating.

[0018] Between said grooves 14 , close to the outer grooves, substantially flat portions 20 are formed, on which a sensor generally indicated at 22 is mounted. Sensors 22 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com