Color mixing 3D printing nozzle device based on FDM technology and discharging method thereof

A 3D printing and color mixing technology, which is applied to coating devices, 3D object support structures, additive manufacturing, etc., can solve the problems of post-processing coloring, etc., and achieve the effects of uniform color mixing, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

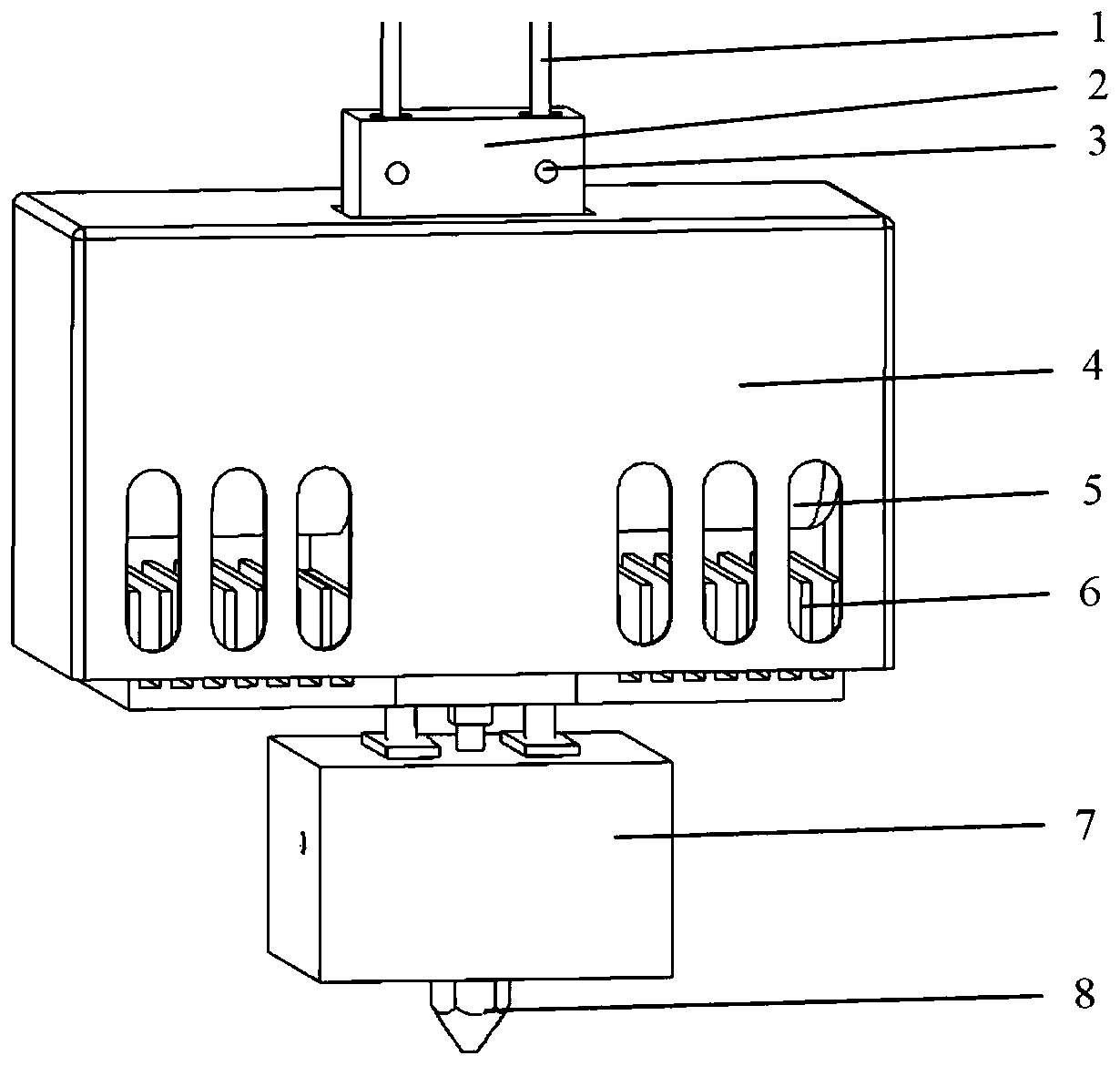

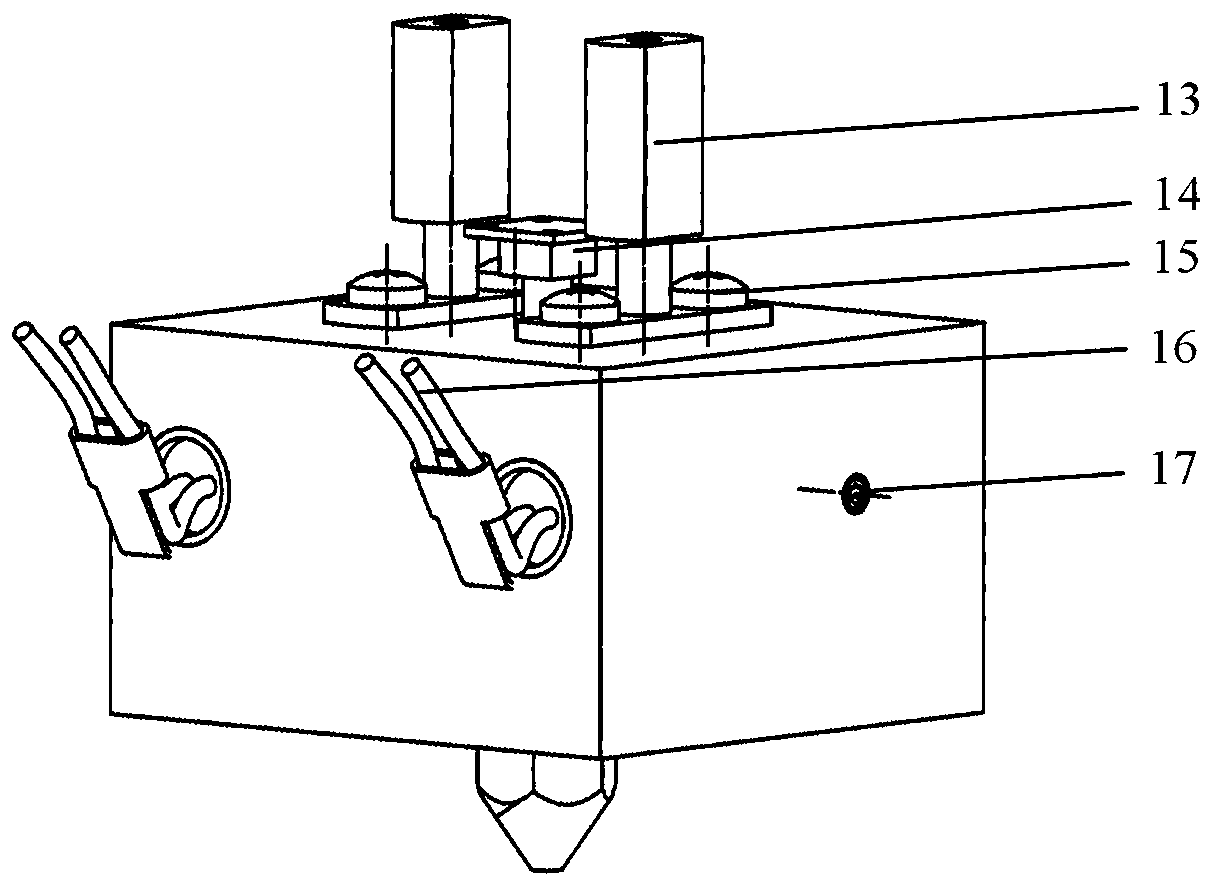

[0038] Such as figure 1 As shown, the color mixing 3D printing nozzle device based on FDM technology includes a feeding mechanism and a mixing heating mechanism. The feeding mechanism includes a feeding shell 4, a feeding guide block 2, a feeding conduit 1 and a feeding drive assembly. The feed shell 4 is provided with a plurality of vents. The feed guide block 2 is fixed on the top of the feed shell 4 inner cavity. Two feeding passages are opened on the feeding guide block 2 . The inner ends of the two feed conduits 1 extend into the two feed passages on the feed guide block 2 respectively, and are respectively fixed by conduit set screws 3 .

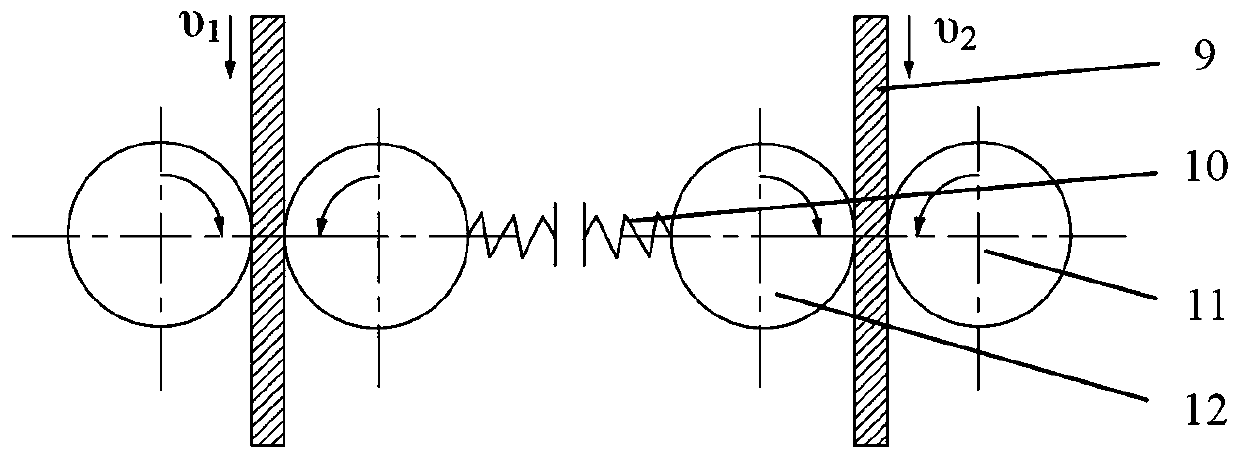

[0039] Such as figure 1 and 2As shown, the feeding drive assembly includes a feeding motor 5 , a driving conveying wheel 11 , an extruding conveying wheel 12 , an extruding slider and an extruding spring 10 . The drive conveyor wheel 11 is supported in the feed housing 4 . The feeding motor 5 is fixed in the feeding shell 4, and...

Embodiment 2

[0052] On the basis of Embodiment 1, the color-mixing 3D printing nozzle device based on FDM technology also includes two independent heating blocks 20 . The tops of the two independent heating blocks 20 are provided with threaded holes corresponding to the bolts 15 on the two heating guide pipes 13 . The independent heating block 20 is provided with a vertically arranged heating channel. The independent heating block 20 is provided with a heating hole 7-3 and a temperature detection hole 7-4. The heating hole 7-3 is provided with a heating wire. A temperature sensor is arranged in the temperature detection hole 7-4. Nozzles are provided at the bottoms of the heating channels in the two independent heating blocks 20 .

[0053] By removing the heating mixing block 7 and installing independent heating blocks 20 on the bottoms of the two heating guide tubes 13, independent printing of two colors of 3D printing filaments can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com