Damping door lock and washing machine

A washing machine and door lock technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., to achieve the effect of compact structure and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

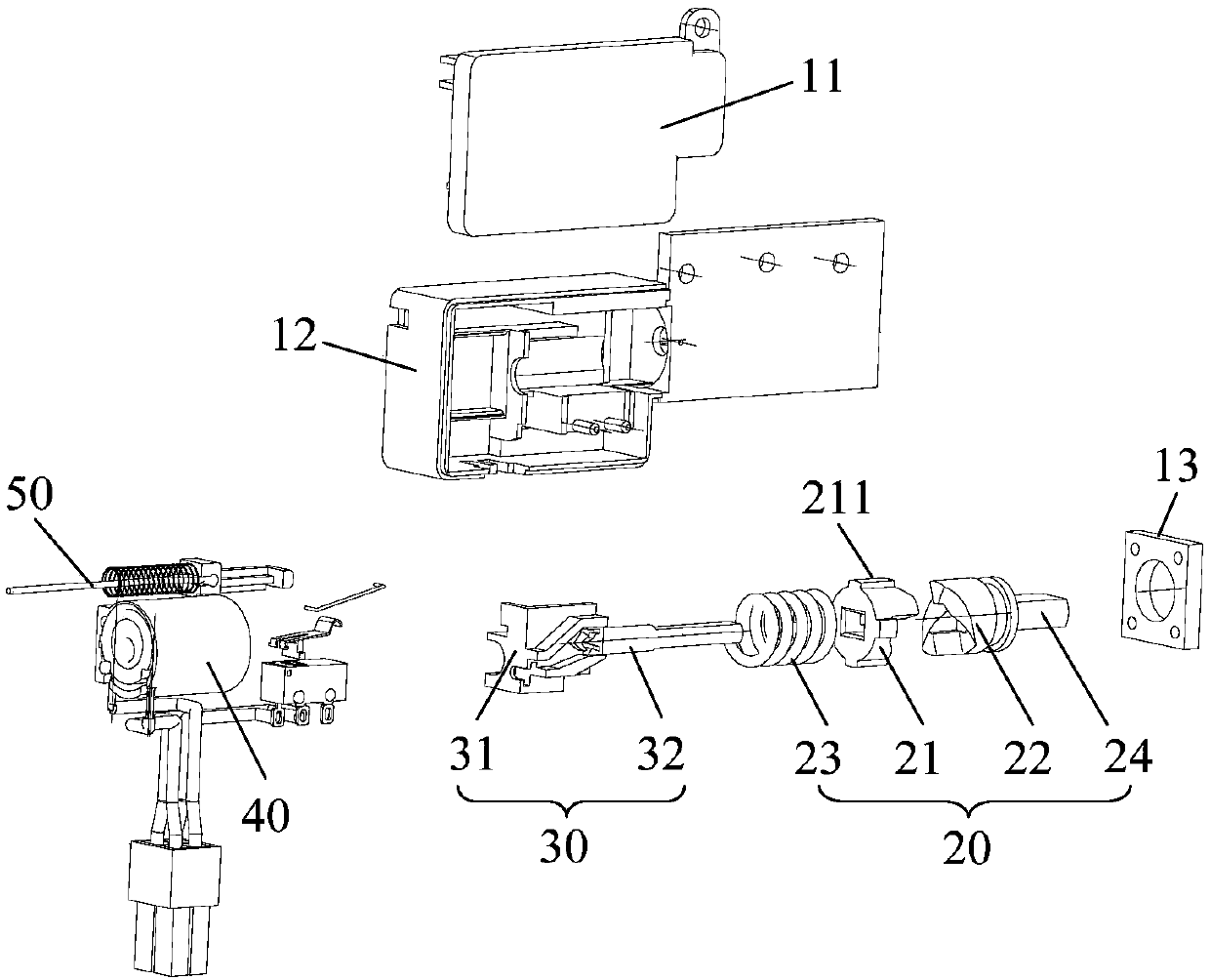

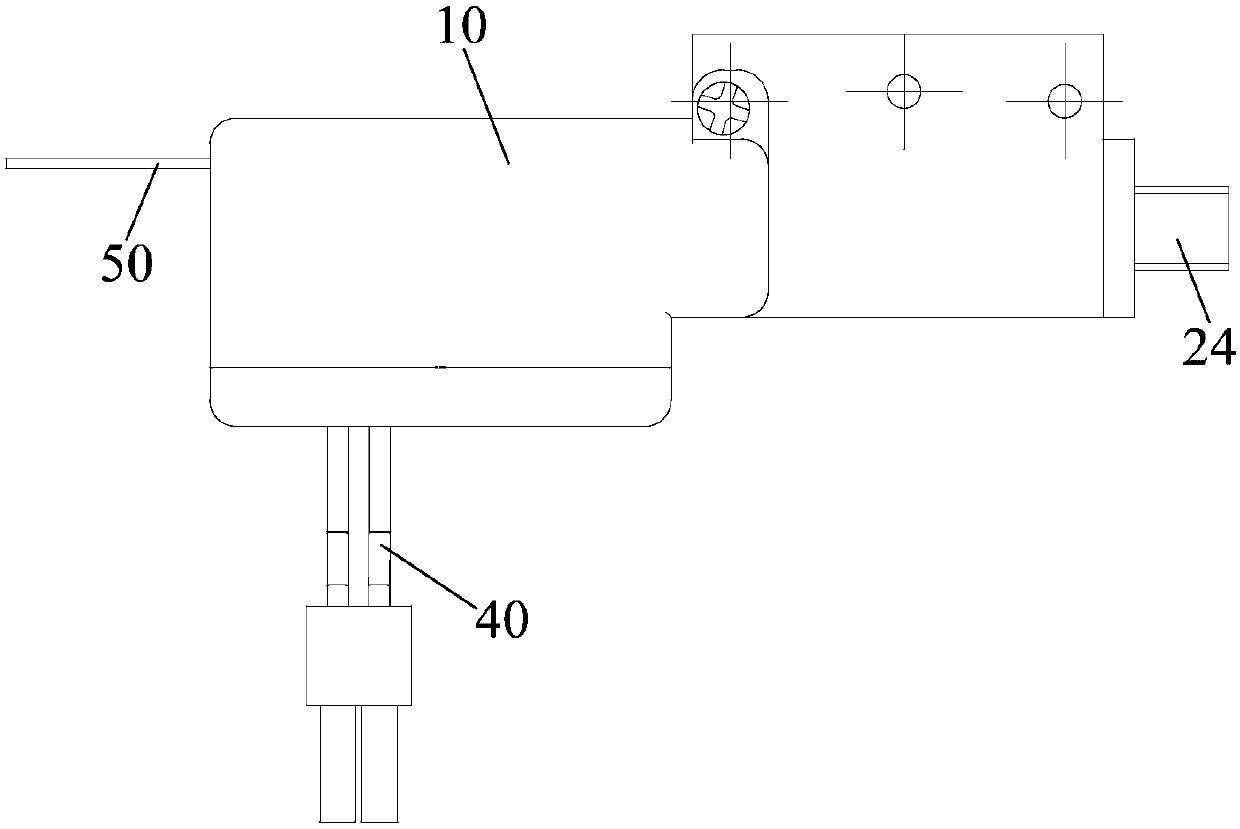

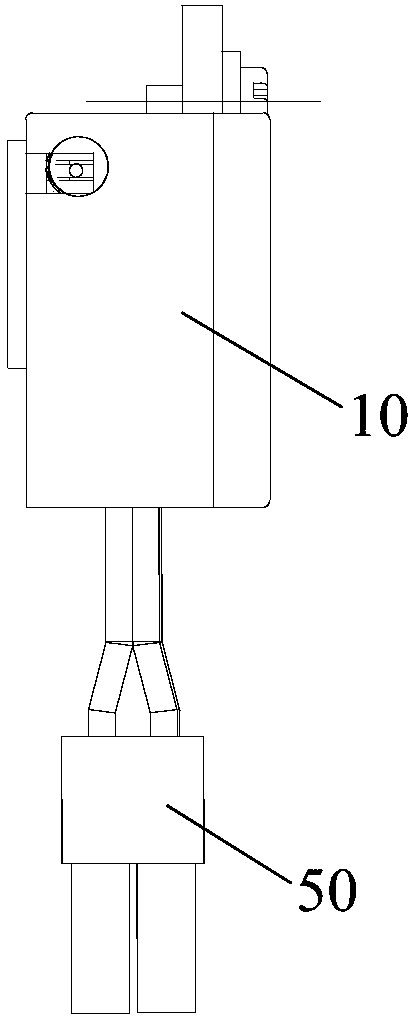

[0079] Embodiment one (as Figure 1 to Figure 6 shown)

[0080] The fixing part 21 is located between the limiting part 31 and the rotating part 22, and the fixing part 21 is provided with an escape hole, and the limiting shaft 32 is inserted into the shaft hole 221 through the avoiding hole, as Figure 1 to Figure 6 shown.

[0081] Furthermore, the damping door lock 1 is installed in the rotating shaft 202 of the door cover 2, and is fixedly connected with the door cover 2 through the first connection part, and fixedly connected with the body workbench 3 through the second connection part.

[0082] The fixed part 21 is located between the limiting part 31 and the rotating part 22, and the limiting shaft 32 needs to pass through the fixing part 21 to be inserted into the shaft hole 221 on the rotating part 22, so a corresponding avoidance hole is opened in the middle of the fixing part 21 , to avoid the limit shaft 32; at this time, the rotating part 22 is relatively close t...

Embodiment 2

[0084] Embodiment 2 (not shown in the figure)

[0085] The difference from Embodiment 1 is that the rotating part 22 is located between the limiting part 31 and the fixing part 21, the fixing part 21 is sleeved on the second connecting part, and can rotate relative to the second connecting part, and the second connecting part passes through The fixing part 21 is fixedly connected with the workbench of the machine body.

[0086] The rotating part 22 is located between the limiting part 31 and the fixing part 21, and the fixing part 21 is relatively close to the connecting part of the body and the door cover 2, so the second connecting part needs to pass through the fixing part 21 to be fixedly connected with the workbench of the body. Corresponding holes also need to be opened in the middle of the fixing part 21 to avoid the second connecting part, and at the same time, it is necessary to ensure that the relative rotation between the second connecting part and the fixing part 2...

Embodiment 3

[0087] Embodiment three (not shown in the figure)

[0088] The difference from the first embodiment is that the damping door lock 1 is installed in the workbench 3 of the machine body, and is fixedly connected with the workbench 3 through the first connection part, and is fixedly connected with the door cover 2 through the second connection part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com