Method and device for detecting the end of a yarn on a rotating bobbin in a textile machine

A technology for detecting rotating and textile machines, which is applied in the field of detecting yarn ends and devices on rotating bobbins in textile machines, and can solve problems such as low reliability, damaged packaging, and large suction air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

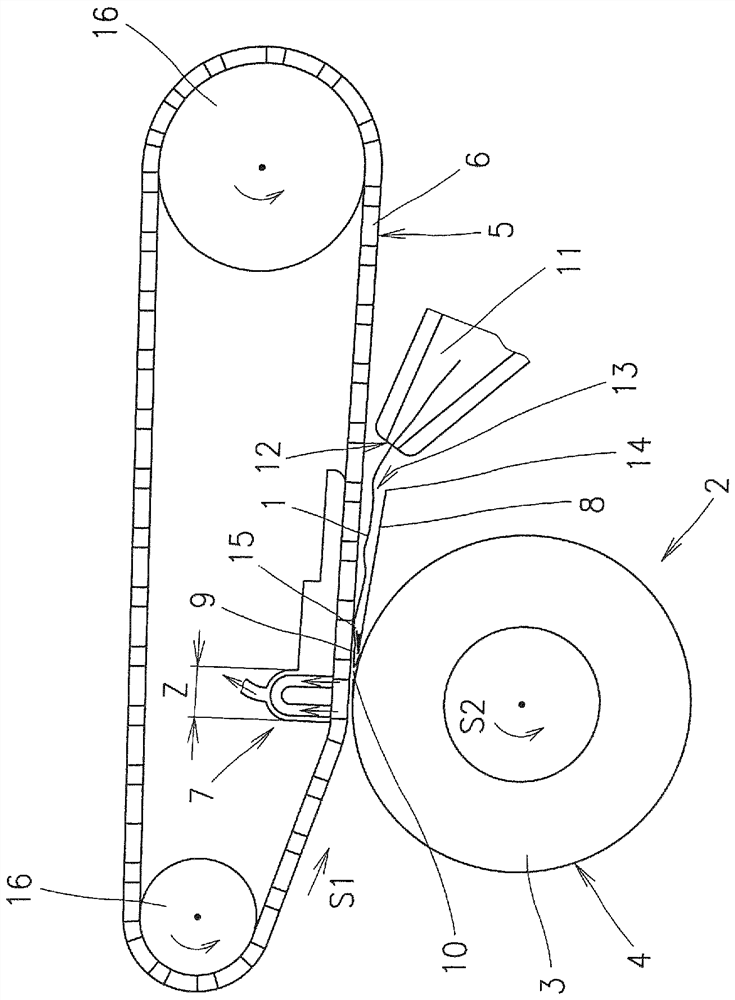

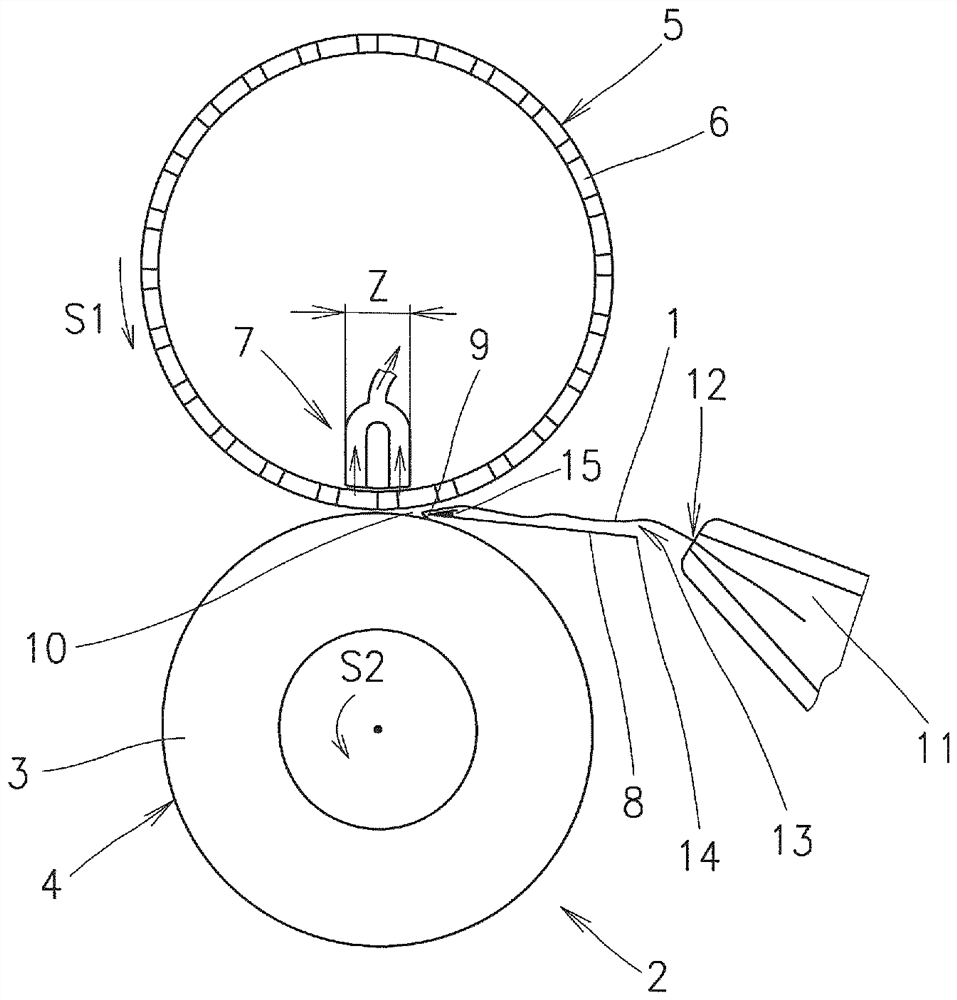

[0026] A method for detecting a yarn end on a bobbin in a textile machine and a device for performing the method will be described with reference to an example of embodiment in a spinning machine for producing yarn 1, said yarn being It is wound onto a rotating bobbin 2 which is rotatably mounted in the machine structure of the textile machine. The wound yarn 1 forms a package 3 with a surface 4 on a bobbin 2 . The method and device can also be used in a textile machine for processing yarn 1 .

[0027] exist figure 1 and figure 2 In the example of embodiment, the movable mechanism 6 is manufactured as an endless movable belt wound around at least two guide pulleys 16, at least one of which is connected to a rotary drive. In a not shown example of embodiment, the system of pulleys 16 is provided with tensioning means to ensure that the required tension is maintained in the movable mechanism 6 .

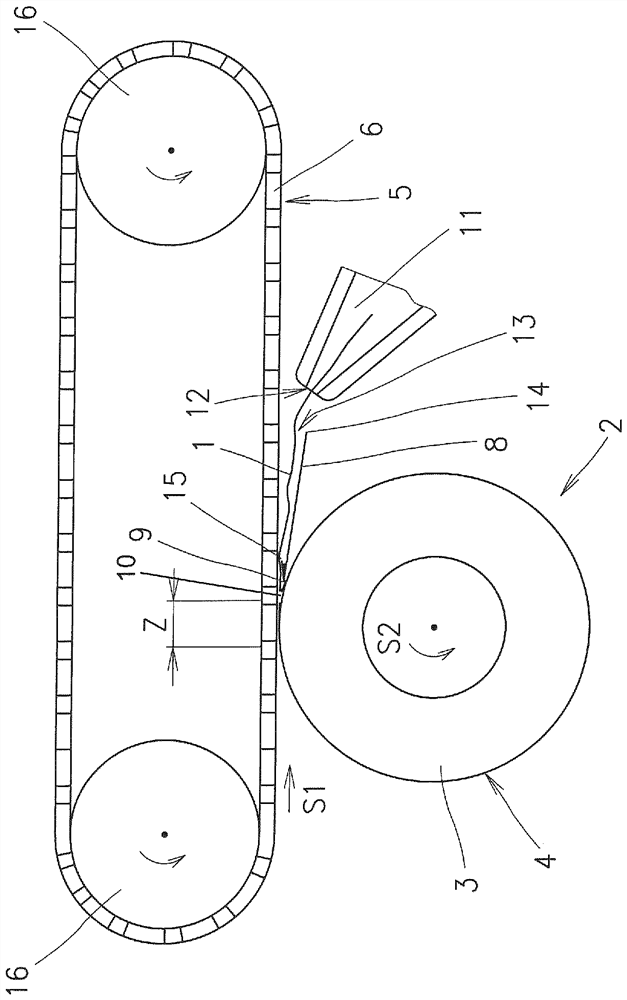

[0028] exist image 3 In the exemplary embodiment of , the movable mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com