Axial vibration crawl device

A technology of axial vibration and crawler, which is applied in drilling equipment, drilling equipment and methods, earthwork drilling and production, etc. It can solve the problems of drilling tool assembly retreating and affecting drilling efficiency, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

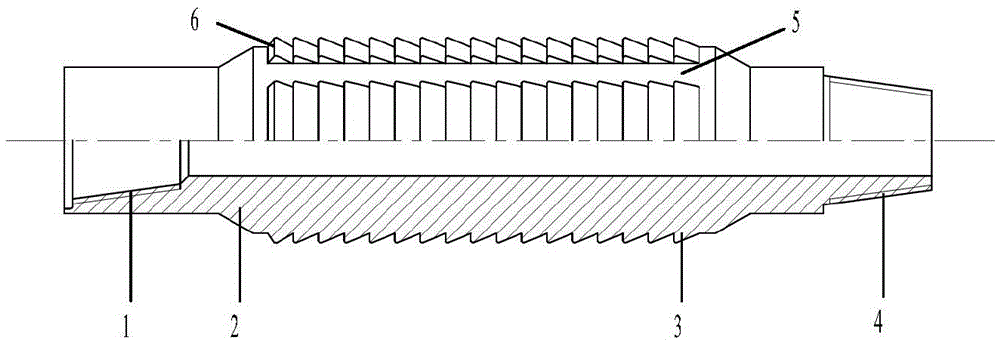

[0013] exist figure 1 In the schematic diagram of the axial vibrating crawler shown, one end of the body 2 is connected to the female buckle 1, the other end of the body is connected to the male buckle 4, and the outer surface of the body is uniformly provided with 6 annular teeth 3 of equal size in the axial direction. Each annular tooth is provided with equal-sized sand dredging grooves 5; the section of each annular tooth is a right-angled triangle, and the right-angled side faces the side of the box, and the section of the first annular tooth 6 on the side of the box is Double bevel.

[0014] This tool is connected to the axial vibration generator through threads, and should be used selectively according to specific working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com