Fastener punching machine

A technology for fasteners and driving machines, which is applied in the directions of staple staple tools, nailing tools, manufacturing tools, etc. The effect of moving in the reverse direction and reducing the cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

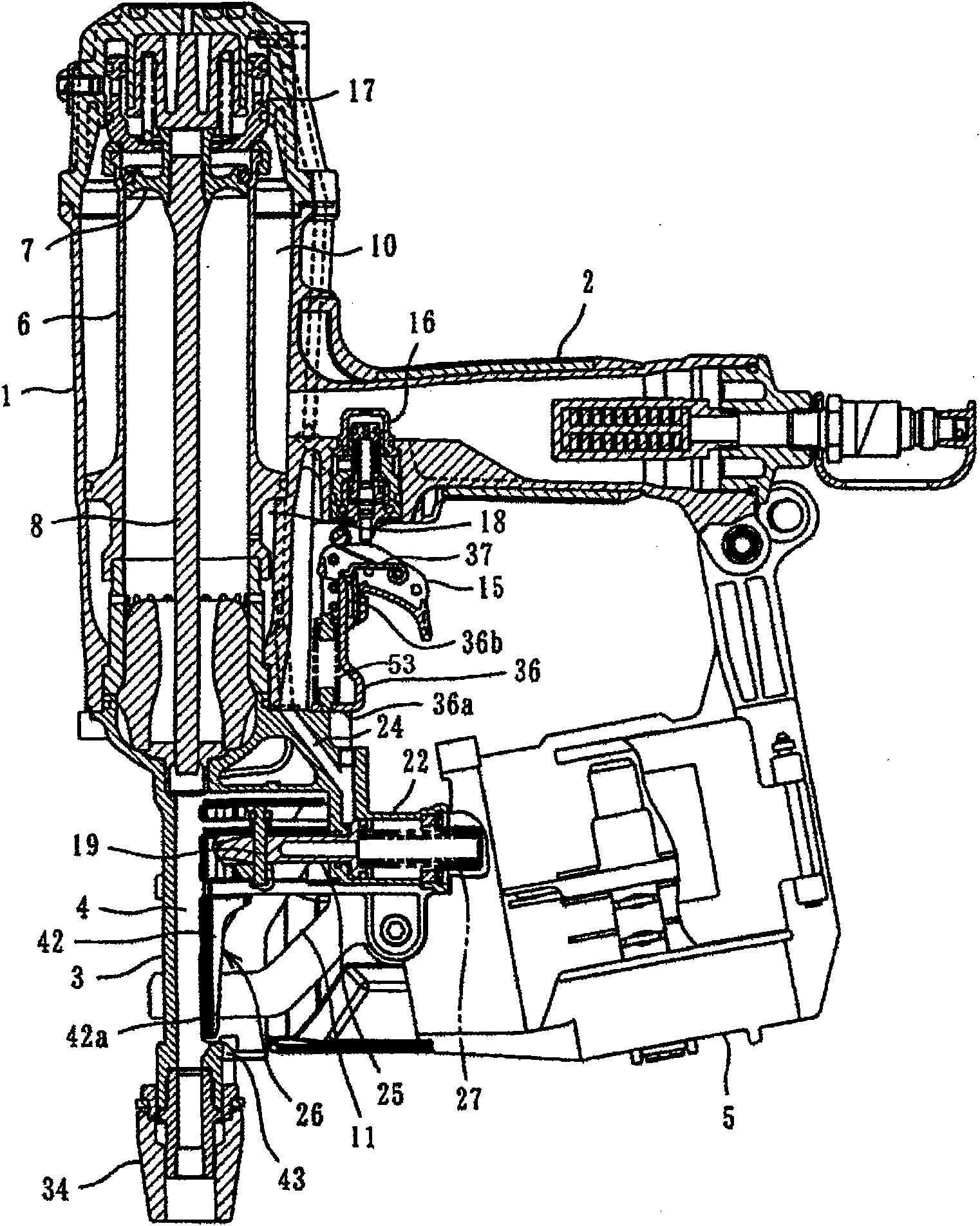

[0077] (Nailer)

[0078] figure 1 A nailing machine as one embodiment of the fastener driving machine of the present invention is shown. The nailing machine is integrally provided with a handle 2 at the rear of the nailing machine main body 1, and a machine head 3 with an injection port 4 is integrally provided at the lower part of the nailing machine main body 1, and is connected to the rear of the machine head 3. A magazine 5 of nails is supplied to the injection port 4 , and a striking mechanism is provided in the nailer main body 1 . That is, the striking piston 7 is housed in the striking cylinder 6 and allowed to slide freely. A driving tool 8 is integrally fixed to the lower portion of the striking piston 7 , and the driving tool 8 is configured to slide in the injection port 4 of the hand piece 3 . In addition, an air chamber 10 for storing compressed air supplied from a compressed air supply source (not shown) such as an air compressor or the like is formed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com