Hoisting method of obliquely-pulling type insulator string ultra-long tubular bus

An ultra-long tube type and insulator string technology, which is applied in the installation of busbars, portable lifting devices, hoisting devices, etc., can solve problems such as high safety risks, safety accidents, and inability to connect, and achieve high safety factor and construction efficiency. The effect of lifting, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

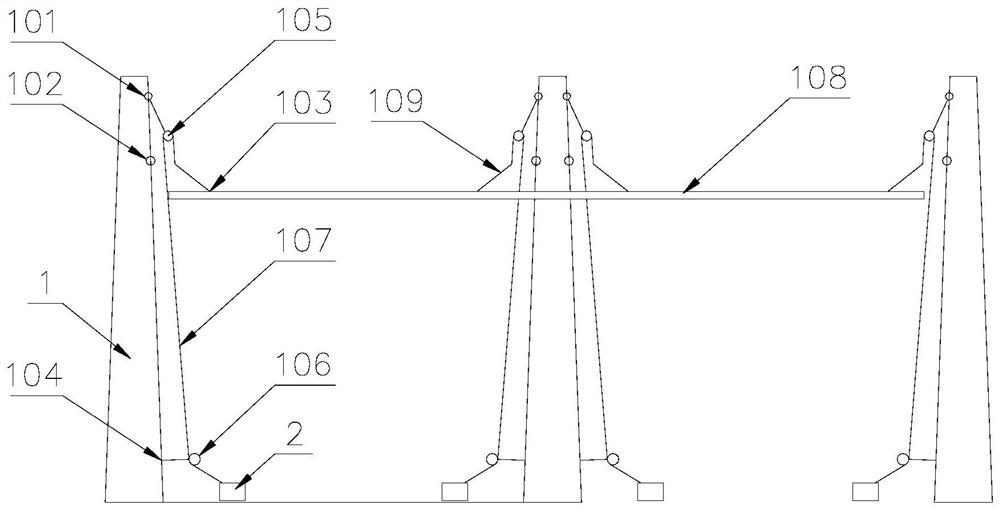

[0046] A cable-stayed insulator string hoisting method for an ultra-long tubular busbar, comprising the following steps:

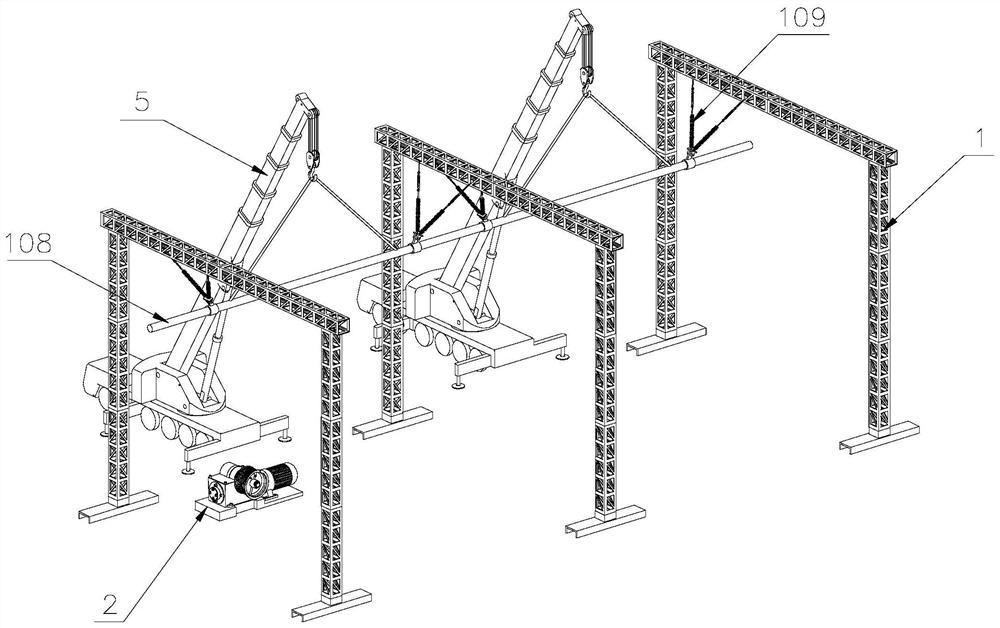

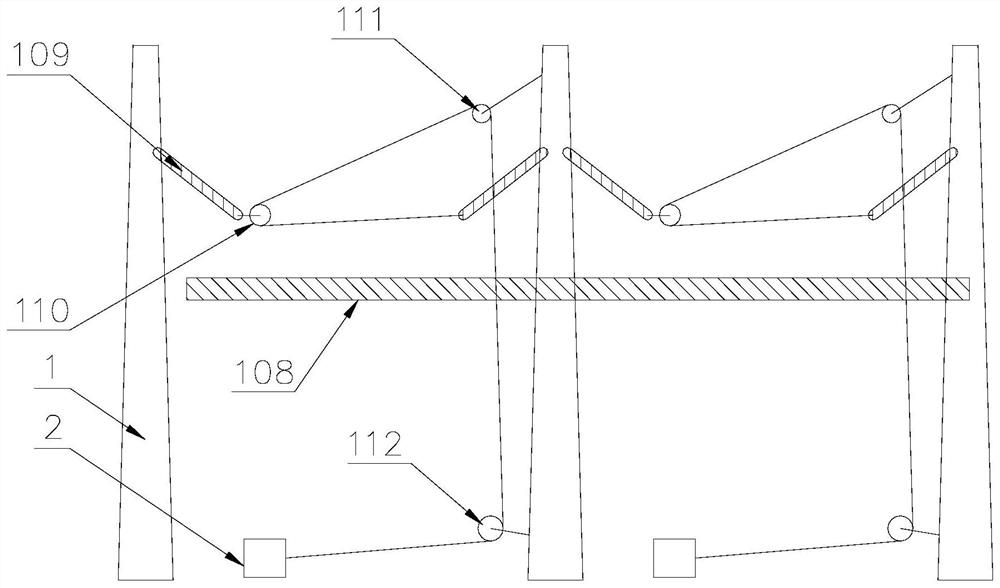

[0047] S1: Hoisting of V-shaped insulator strings, check that the assembly of V-shaped insulator strings 109 meets the design and specification requirements, measure the length of the insulator strings, and make the insulator strings of the same type of each tubular busbar 108 equal in length; before hoisting the tubular busbars 108, first Assemble the insulator strings, first use the crane 5 to hang the insulator strings on both sides on the lower part of the portal frame 1, and connect the pairs of insulator strings into a V shape by the aerial workers in the bucket arm truck;

[0048] S2: Install the pulley block, install the first set of pulleys 110 at the lower end of the outer V-shaped insulator string 109, install the second set of pulleys 111 on the portal frame 1 above the inner V-shaped insulator string 109, and install the second set of pulleys 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com