Tin bar granulator

A technology of granulator and tin bar, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of unconnected pins and incomplete welding, etc., and achieve the effect of preventing reverse movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

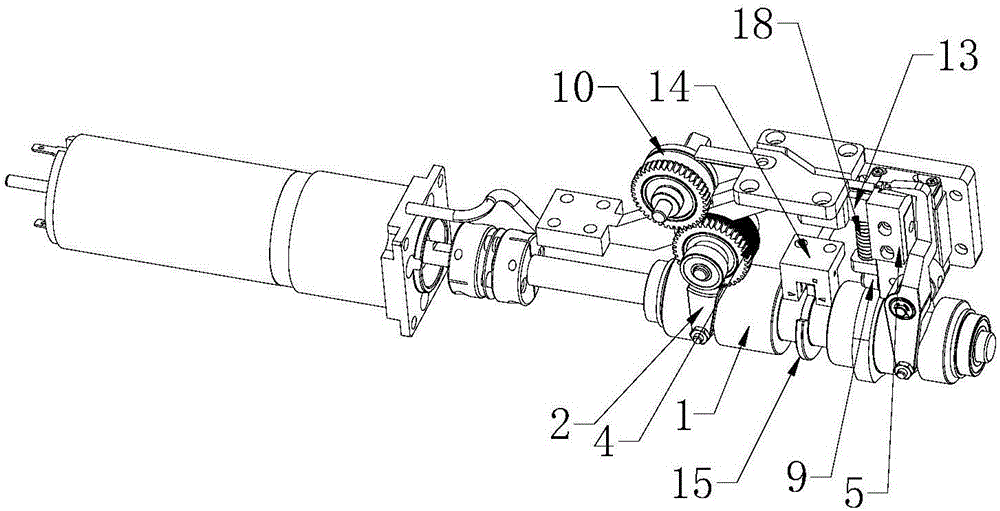

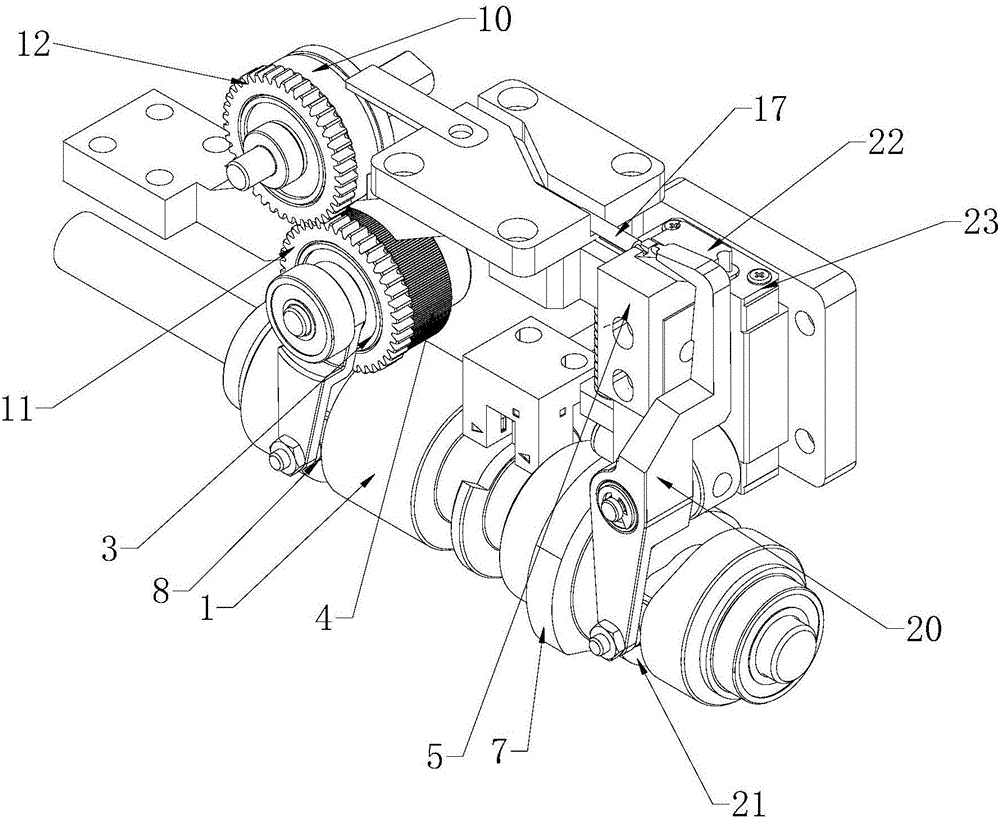

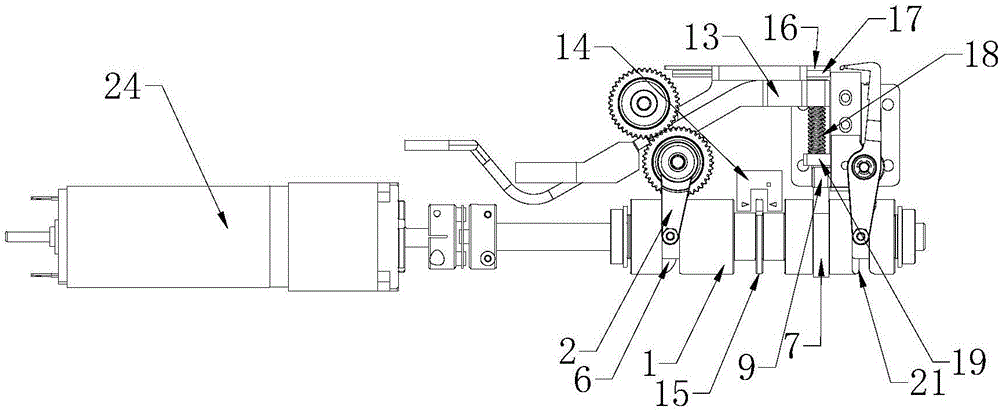

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Such as Figure 1~4 As shown, in this embodiment, a tin bar granulator includes a rotating shaft 1, a swing rod 2, a one-way bearing 3, a conveying wheel 4, a cutting knife block 5, a first cylindrical cam groove 6 and a disc-shaped Cam 7, the first cylindrical cam groove 6 surrounds the outer surface of the rotating shaft 1, one end of the swing rod 2 is connected to the first cylindrical cam groove 6, and the swing rod 2 is far away from the first cylindrical cam groove One end of a cylindrical cam groove 6 is connected with the one-way bearing 3, the delivery wheel 4 is sleeved on the outer surface of the one-way bearing 3, the rotating shaft 1 passes through the disc cam 7 and is connected with the one-way bearing 3. The disk-shaped cam 7 is relatively fixed, and the cutting knife block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com