Quick connecting method for metal hose

A technology of quick connection and metal hose, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that cannot be disassembled and restored, and cannot be reused, so as to simplify the structure and withstand high pressure , High reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

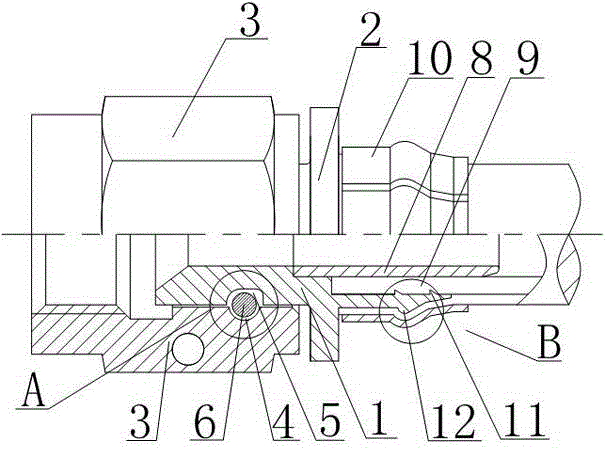

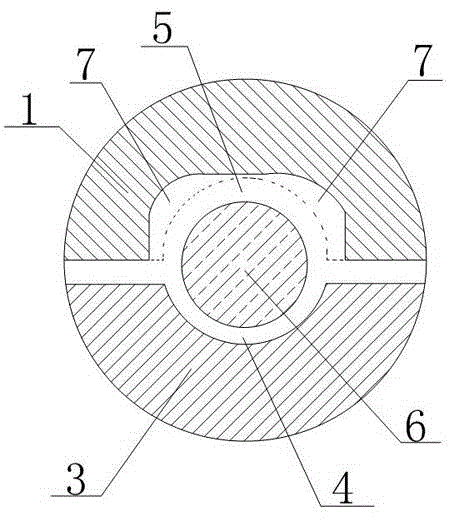

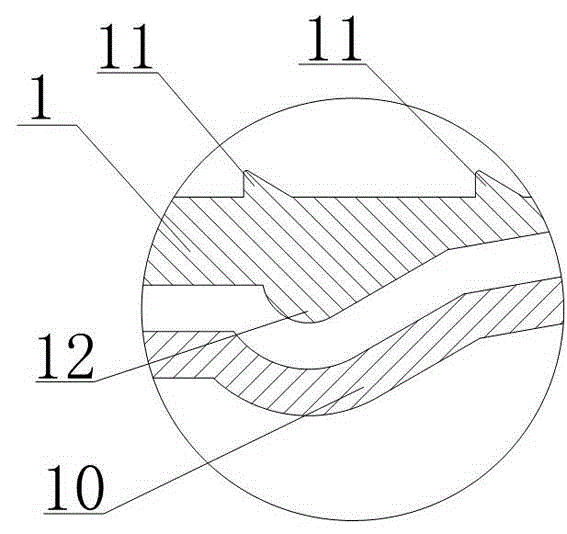

[0023] Such as Figures 1 to 3 As shown, a quick connection method for a metal hose in the present invention includes a cylindrical nozzle 1, and the nozzle 1 is provided with a stopper 2 protruding from the surface of the nozzle 1 and surrounding the nozzle 1. The nozzle 1 on one side of the head 2 is fitted with an outer nut 3, and the other side is provided with a hose connection. The inner wall of the outer nut 3 is recessed downward to form a groove 4 with a semicircular cross section. On the two adjacent sides of the outer nut 3, the through hole 13 communicates. The axis of the through hole 13 is tangent to the circle where the groove 4 is located. The nozzle 1 is provided with a matching groove 5 corresponding to the groove 4. Connect end to end to form a closed ring, and a steel wire 6 is installed in the space formed by the groove 4 and the matching groove 5; the cross section of the matching groove 5 is based on the radius of the cross section of the groove 4, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com