Multi-shaft drilling machine

A multi-axis drilling machine and rotating shaft technology, which is applied to the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve unreliable clamping, low processing efficiency, inaccurate shaft tube positioning, etc. problems, to avoid excessive damage, reduce intermediate processes, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

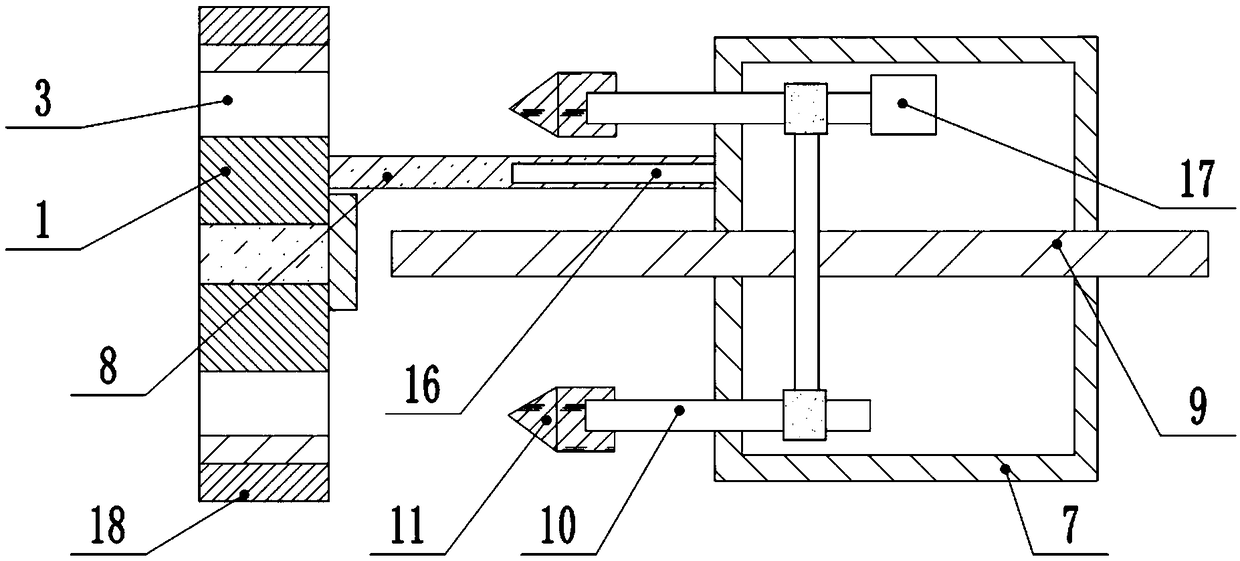

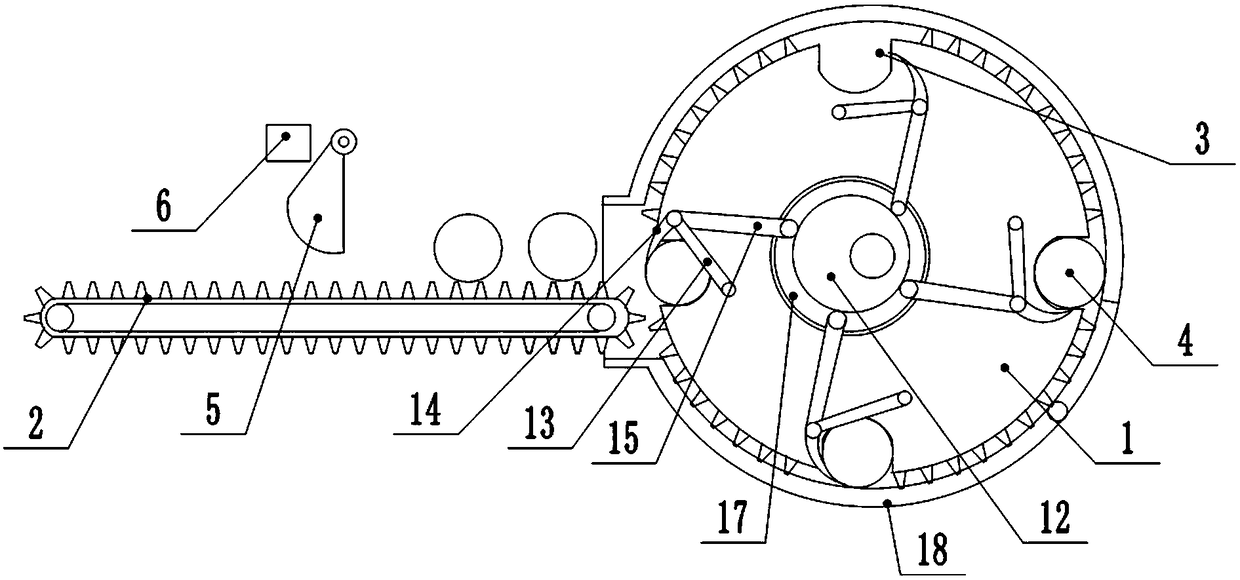

[0019] The reference signs in the drawings of the description include: positioning gear 1, conveyor belt 2, gap 3, parts 4, limit plate 5, fixed block 6, placement box 7, connecting rod 8, threaded rod 9, rotating shaft 10, drill bit 11, Eccentric wheel 12, guide rod 13, ratchet 14, pull bar 15, chute 16, second motor 17, baffle plate 18.

[0020] Examples are attached figure 1 Shown: a multi-axis drilling machine, including a frame, a positioning mechanism and a drilling mechanism are arranged on the frame, and the positioning mechanism is located on the left side of the drilling mechanism.

[0021] Such as figure 2 As shown, the positioning mechanism includes a conveyor belt 2 , a positioning gear 1 and an eccentric wheel 12 located on the right side of the conveyor belt 2 .

[0022] The conveyor belt 2 rotates circularly around two runners, and the runners are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com