Patents

Literature

51results about How to "Unloading safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

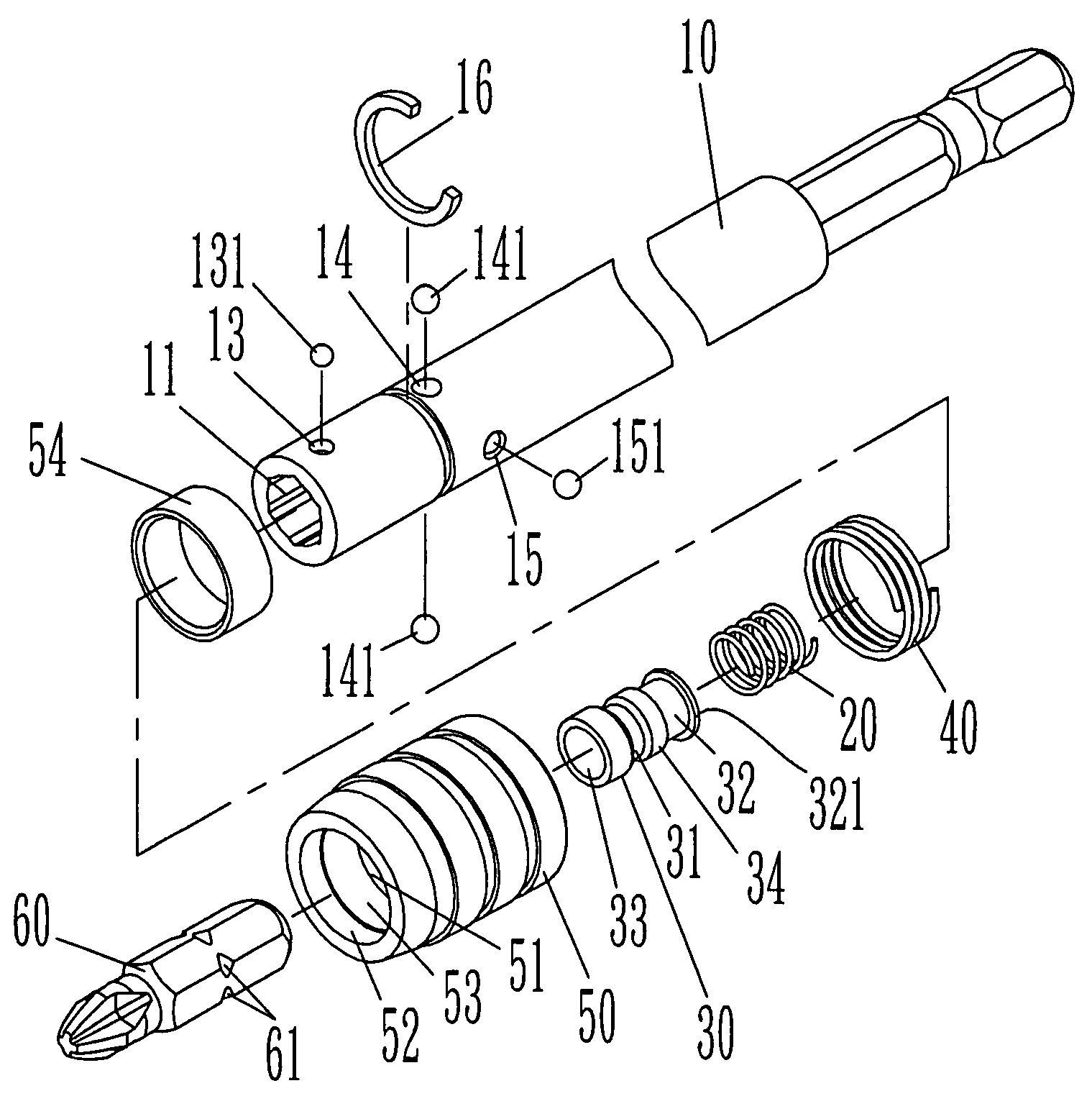

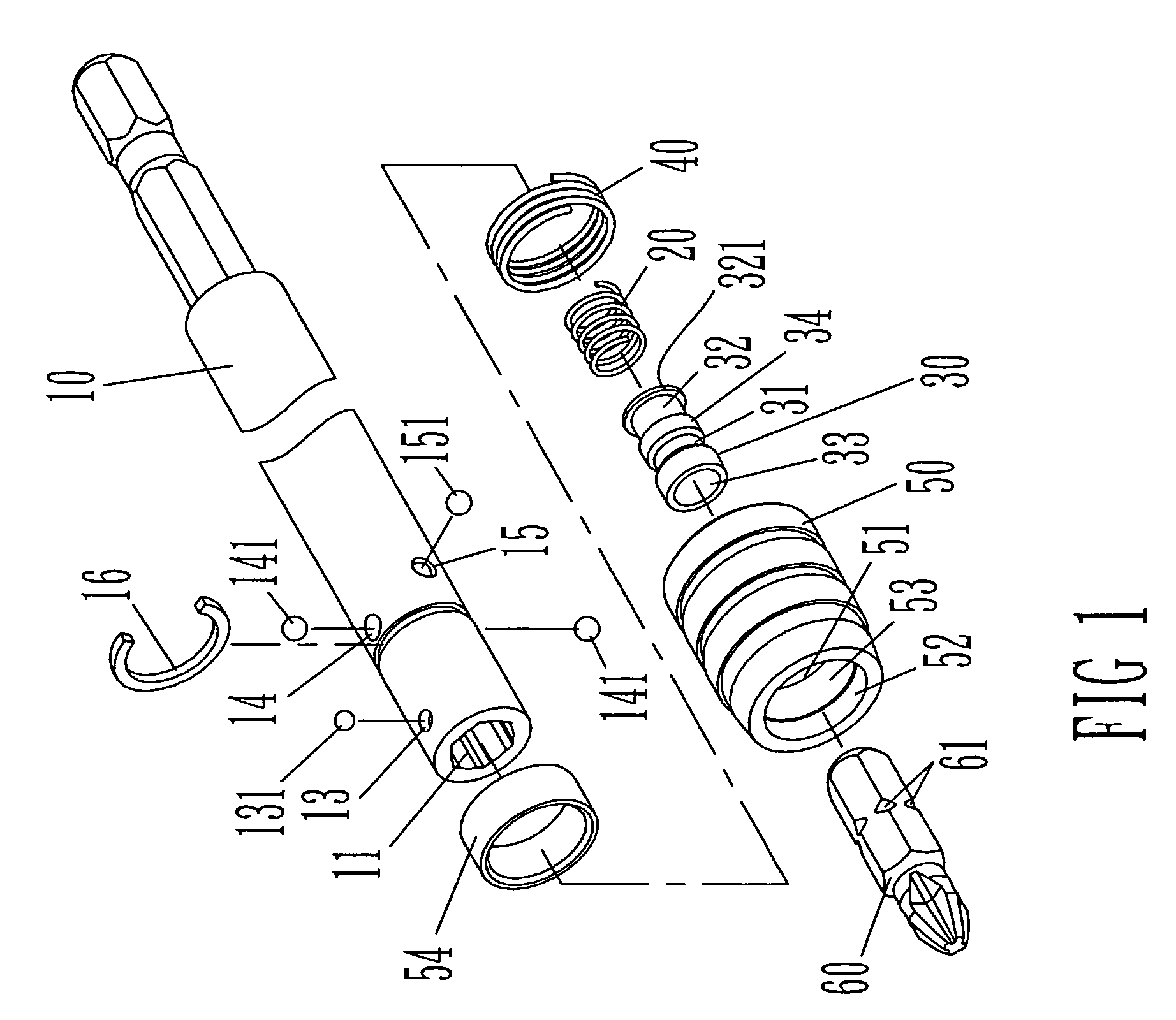

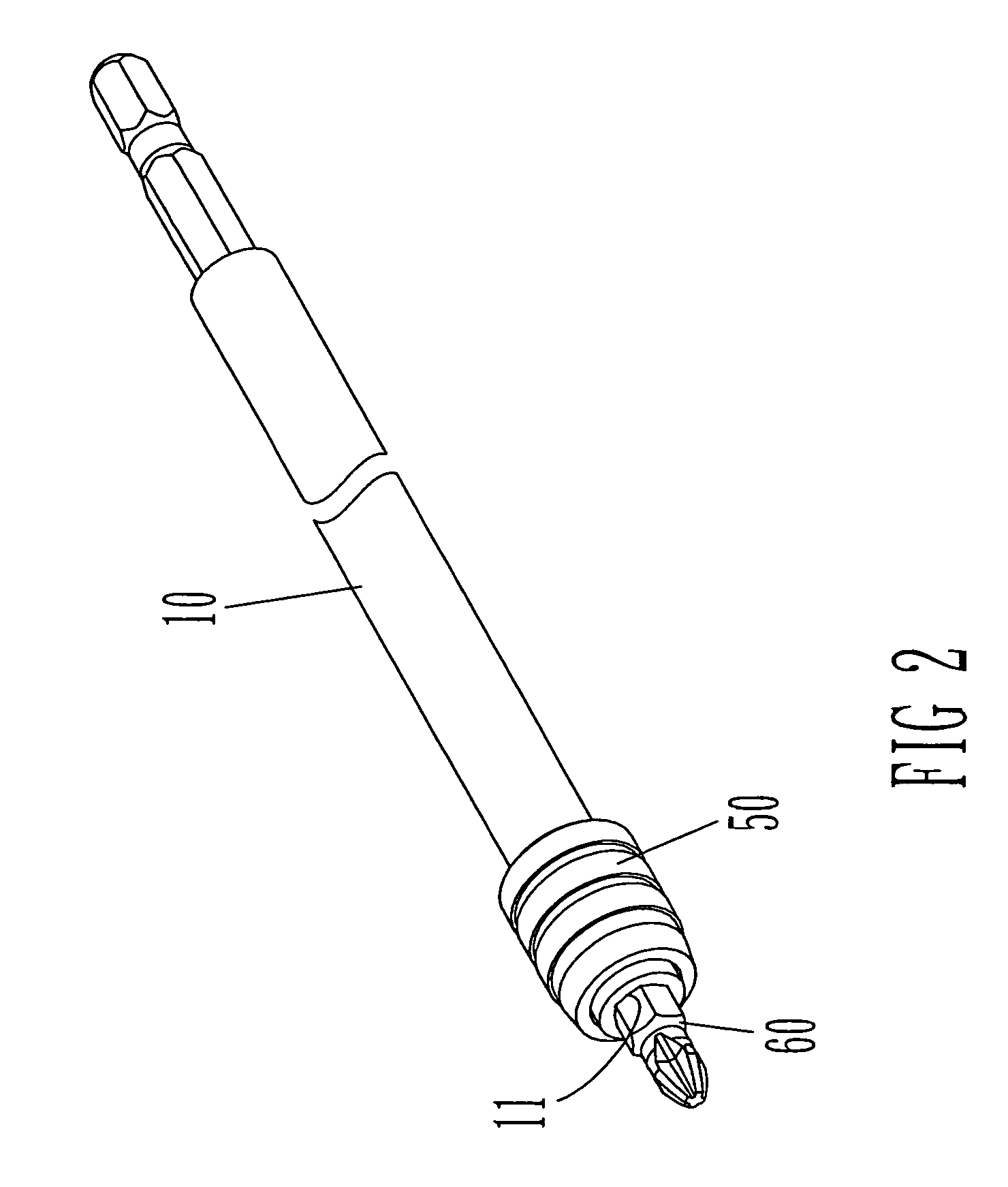

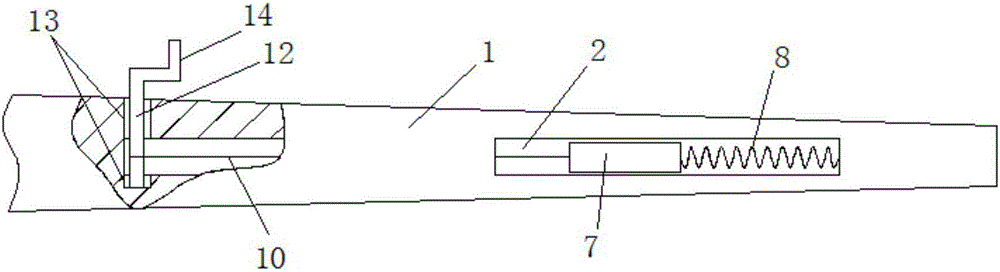

Device for locking and releasing a screw bit

InactiveUS7922180B2Easy to installUnloading safetySleeve/socket jointsSpannersEngineeringMechanical engineering

Owner:MENG CHI FEN

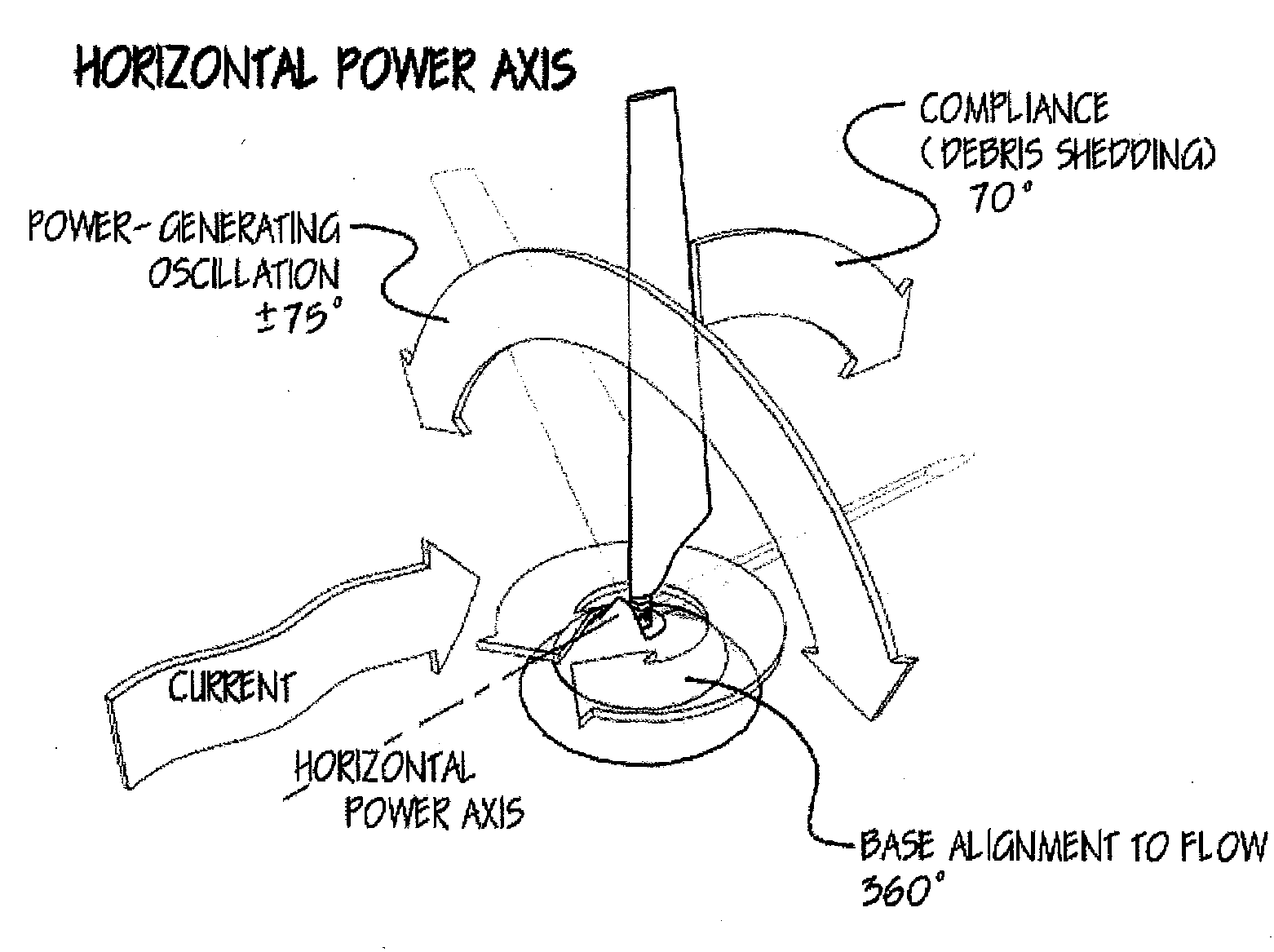

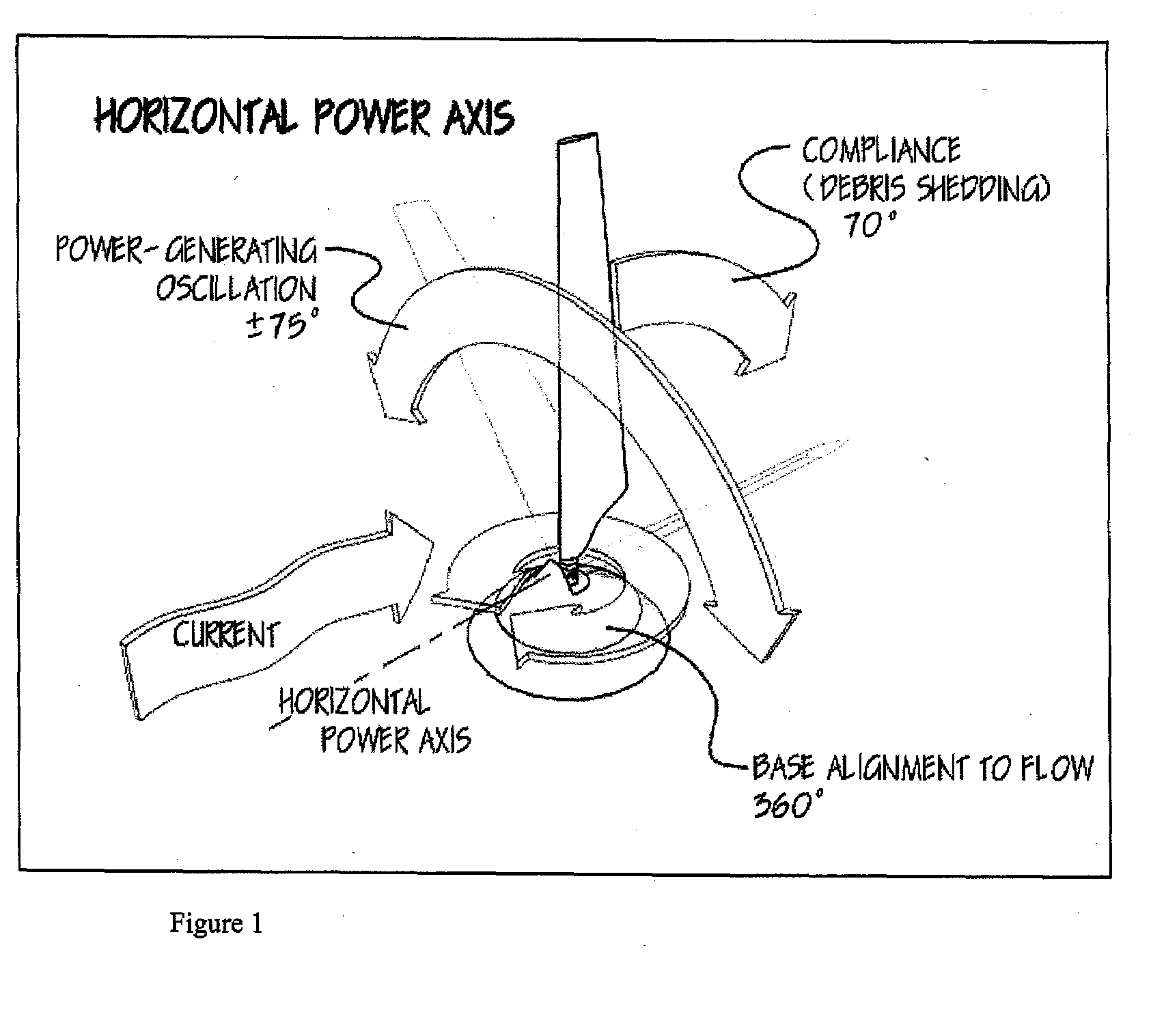

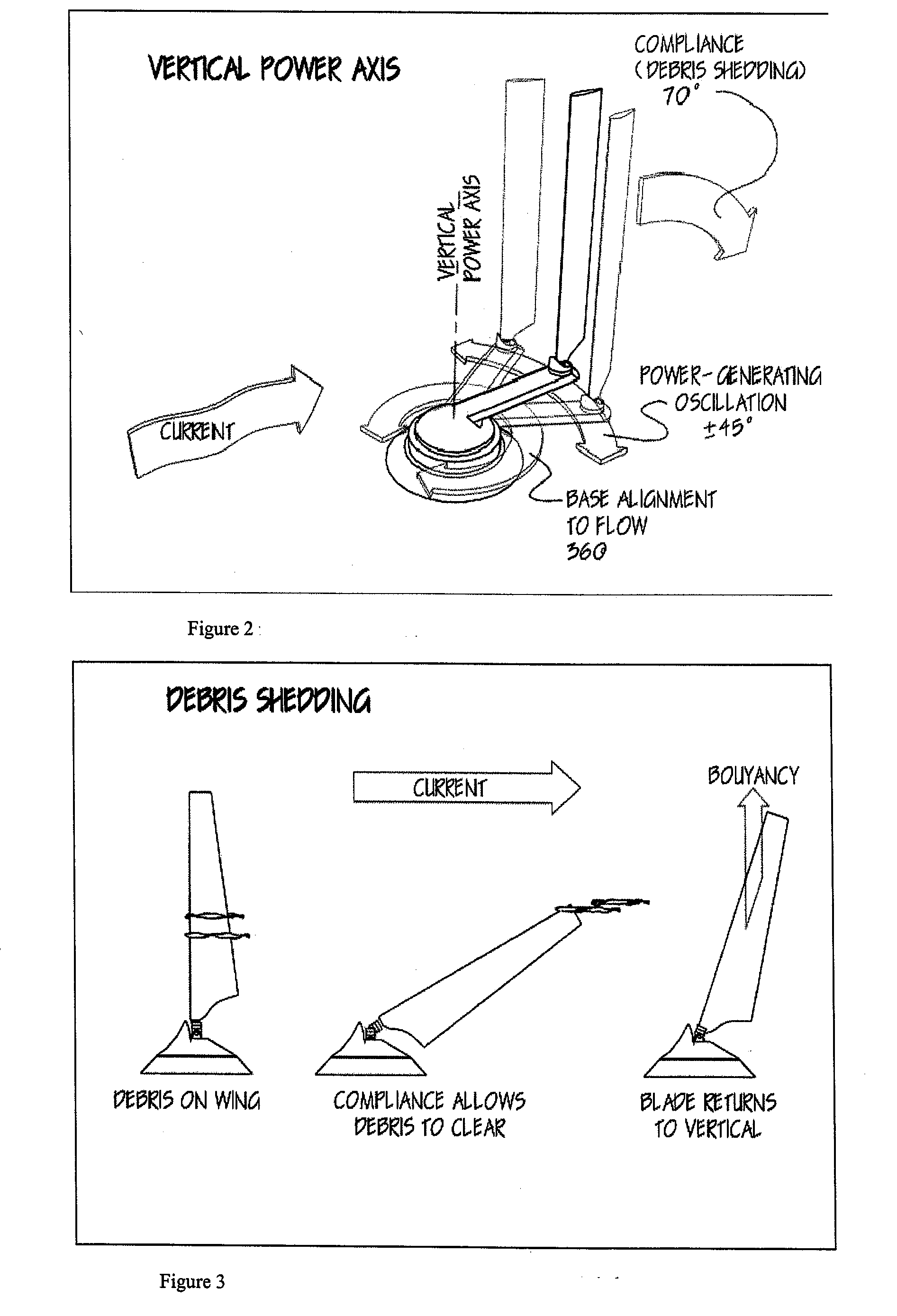

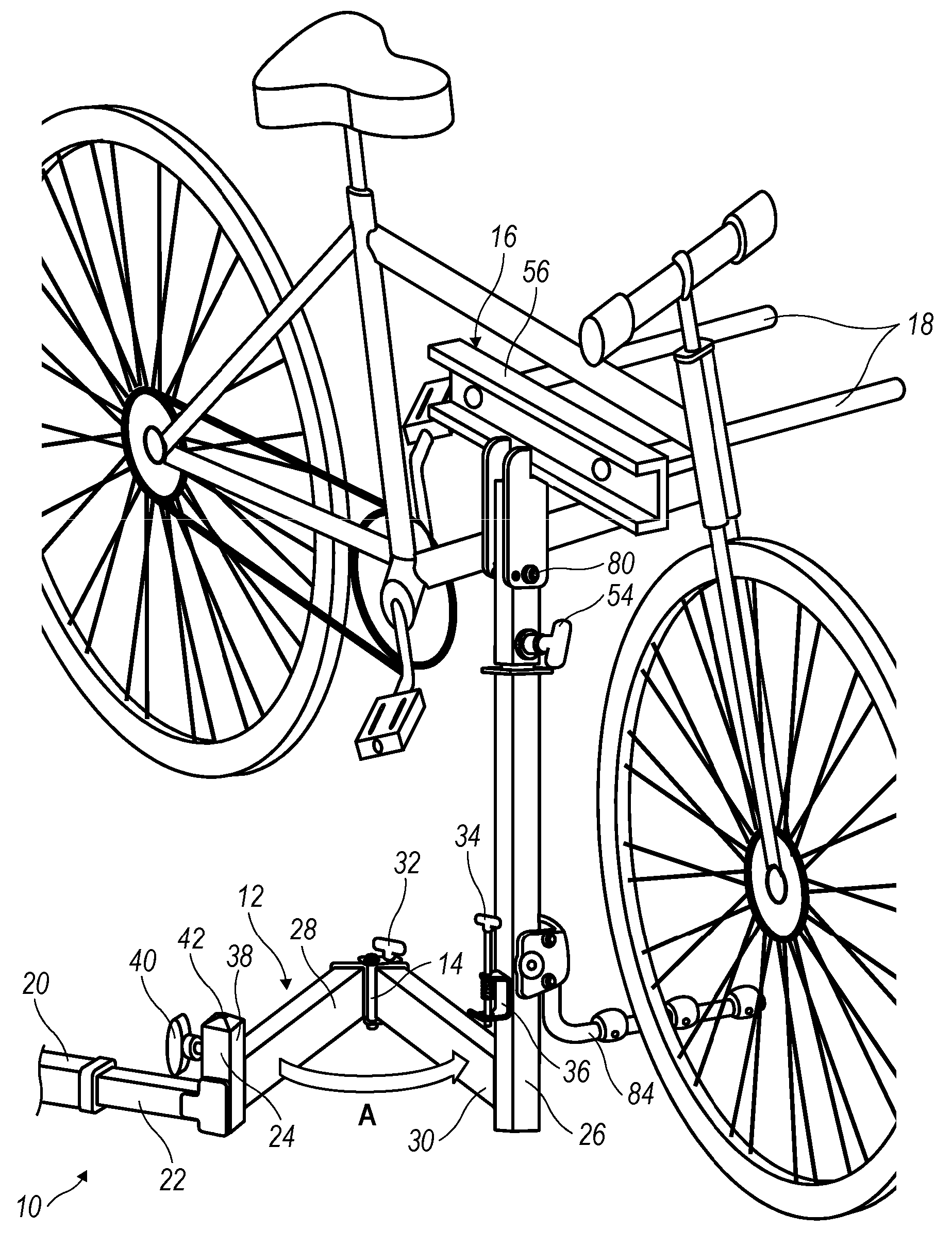

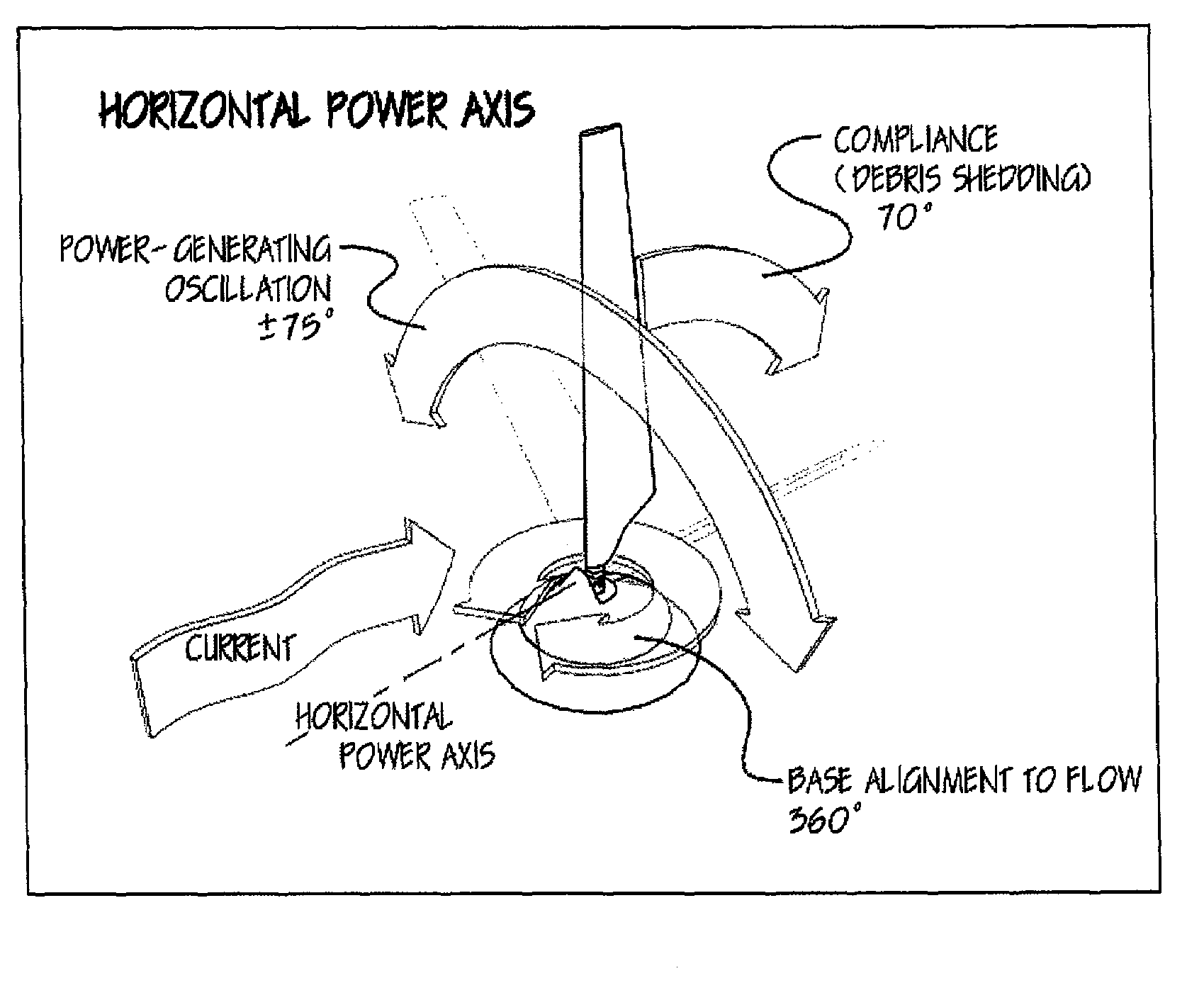

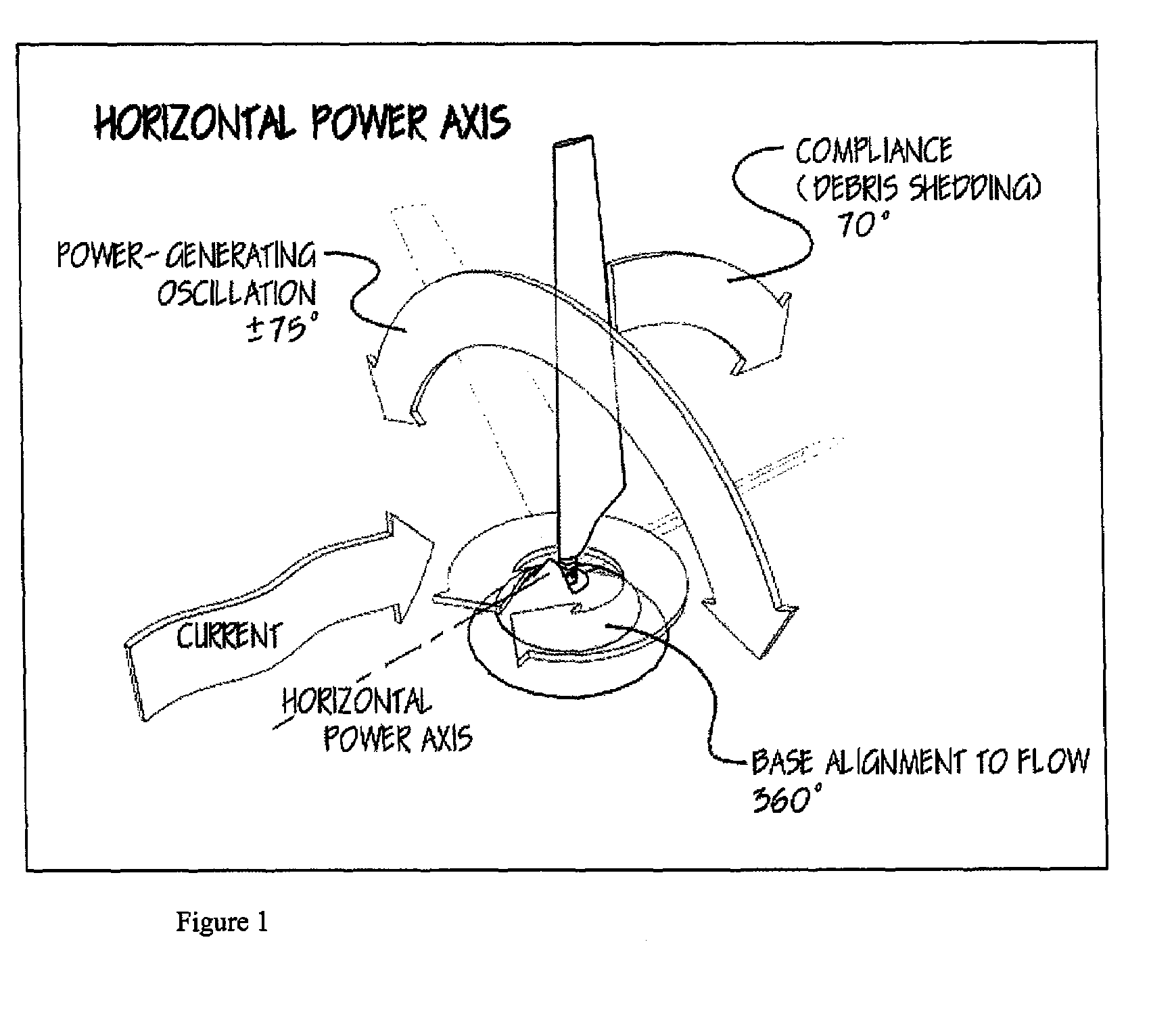

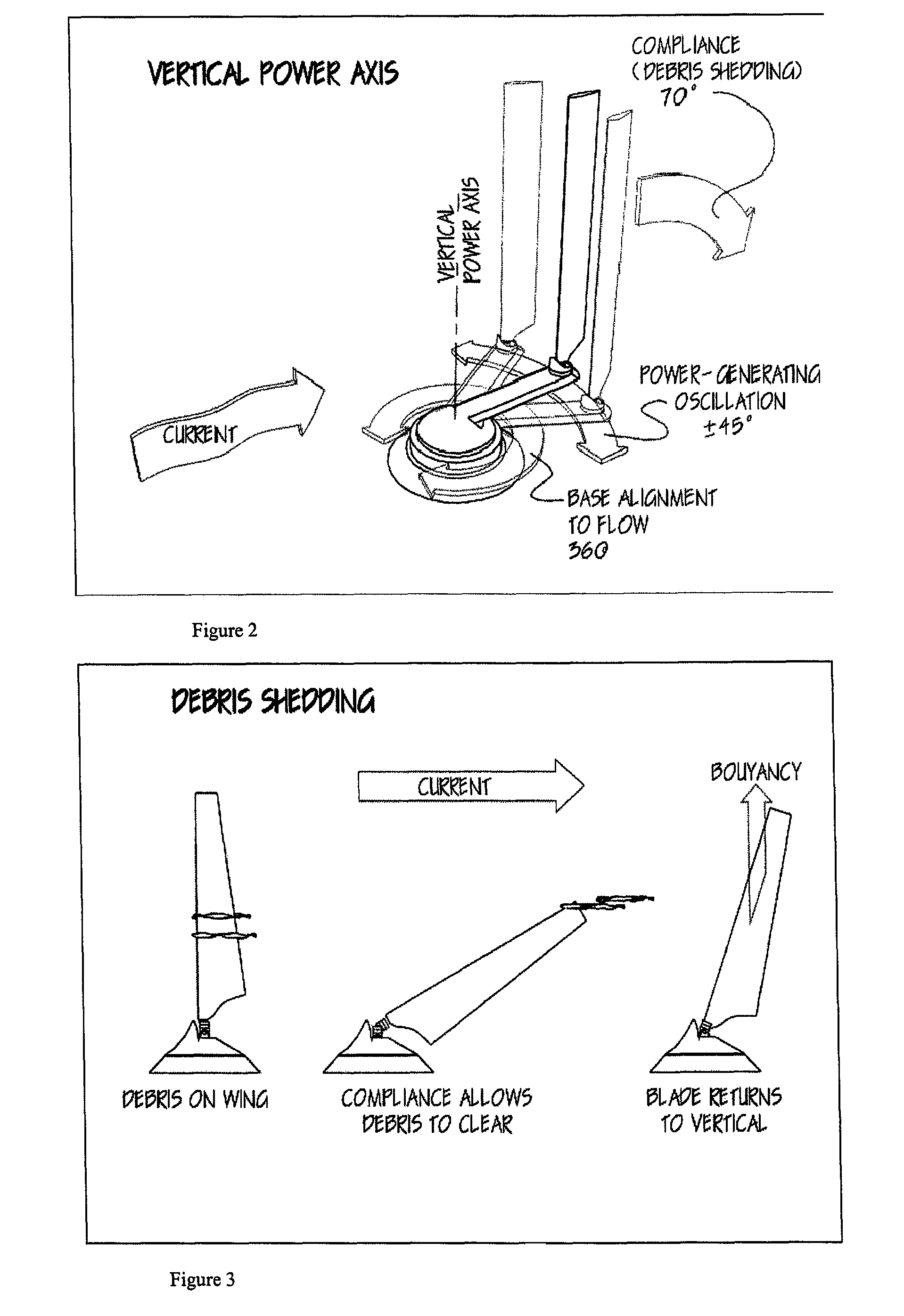

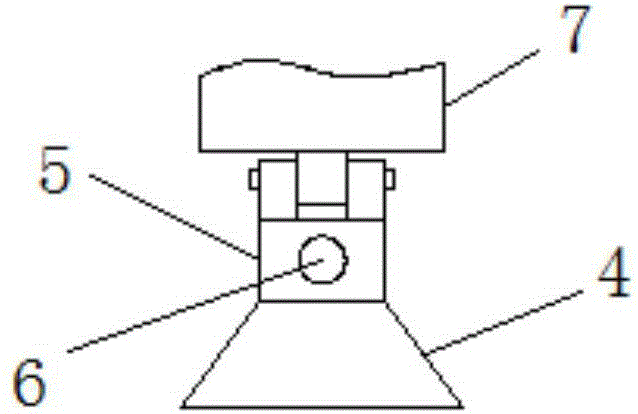

Buoyant blade free stream tidal power device

InactiveUS20090218822A1Unloading safetyEliminate requirementsFluid couplingsMachines/enginesKnife bladesBuoyancy

Accordingly, the system for extracting power from tidal or other water action in a water region having a bottom surface, comprises: a base assembly positionable on the bottom surface of the water region; a buoyant blade assembly mounted on the base assembly, the blade assembly including at least one buoyant blade member, wherein the blade assembly or the blade member is capable of oscillating through an angle, wherein the buoyant blade member is mounted such that when the base assembly is positioned properly in the water region relative to the direction of the tide or other water action, torque is generated by the oscillating movement of the buoyant blade assembly or the buoyant blade member, and wherein the base assembly includes a power-extracting mechanism responsive to the torque generated by the tide or other action of water or the buoyant blade assembly; and a system for coupling the torque to the power-extracting mechanism.

Owner:RINK PHILIP A

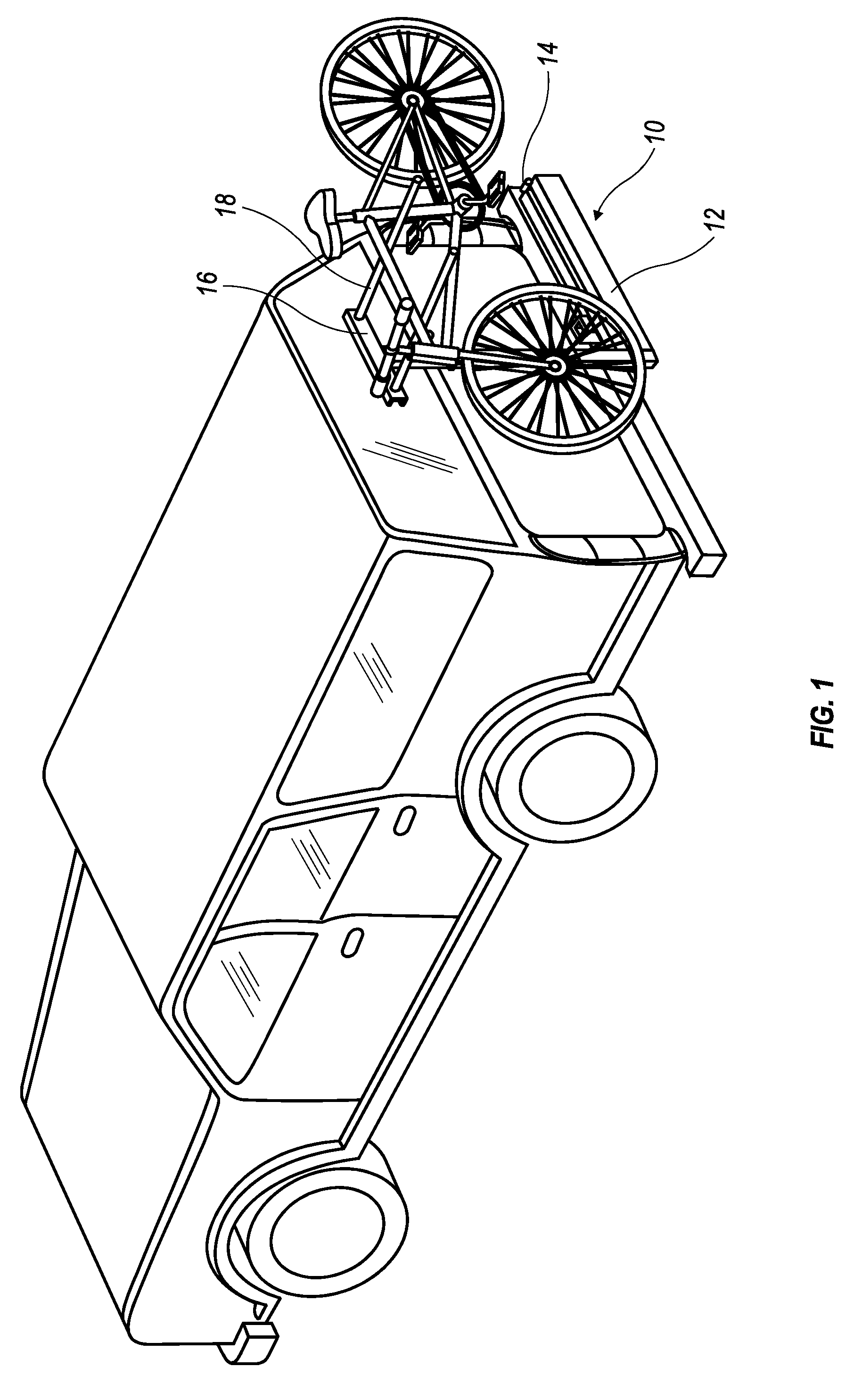

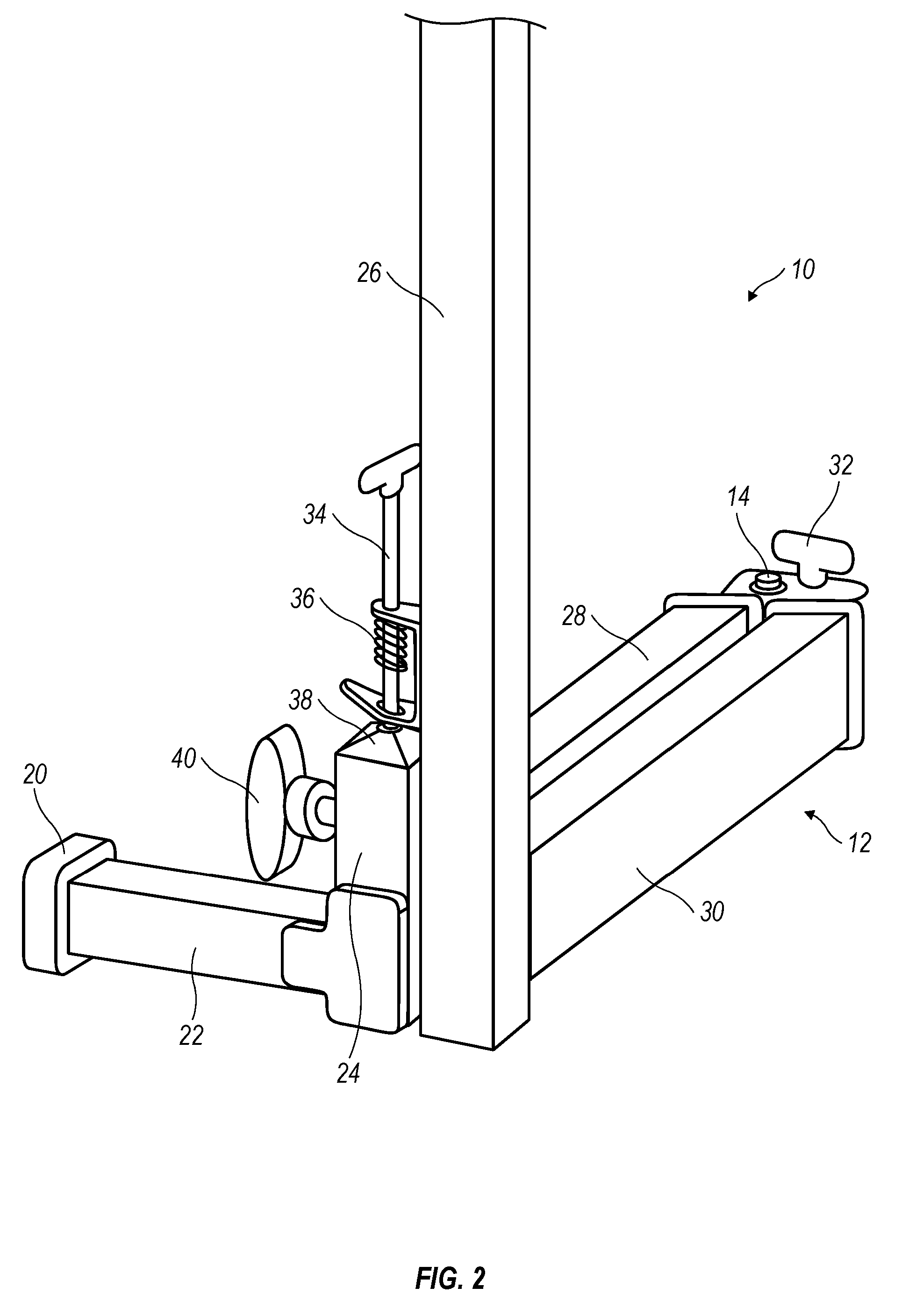

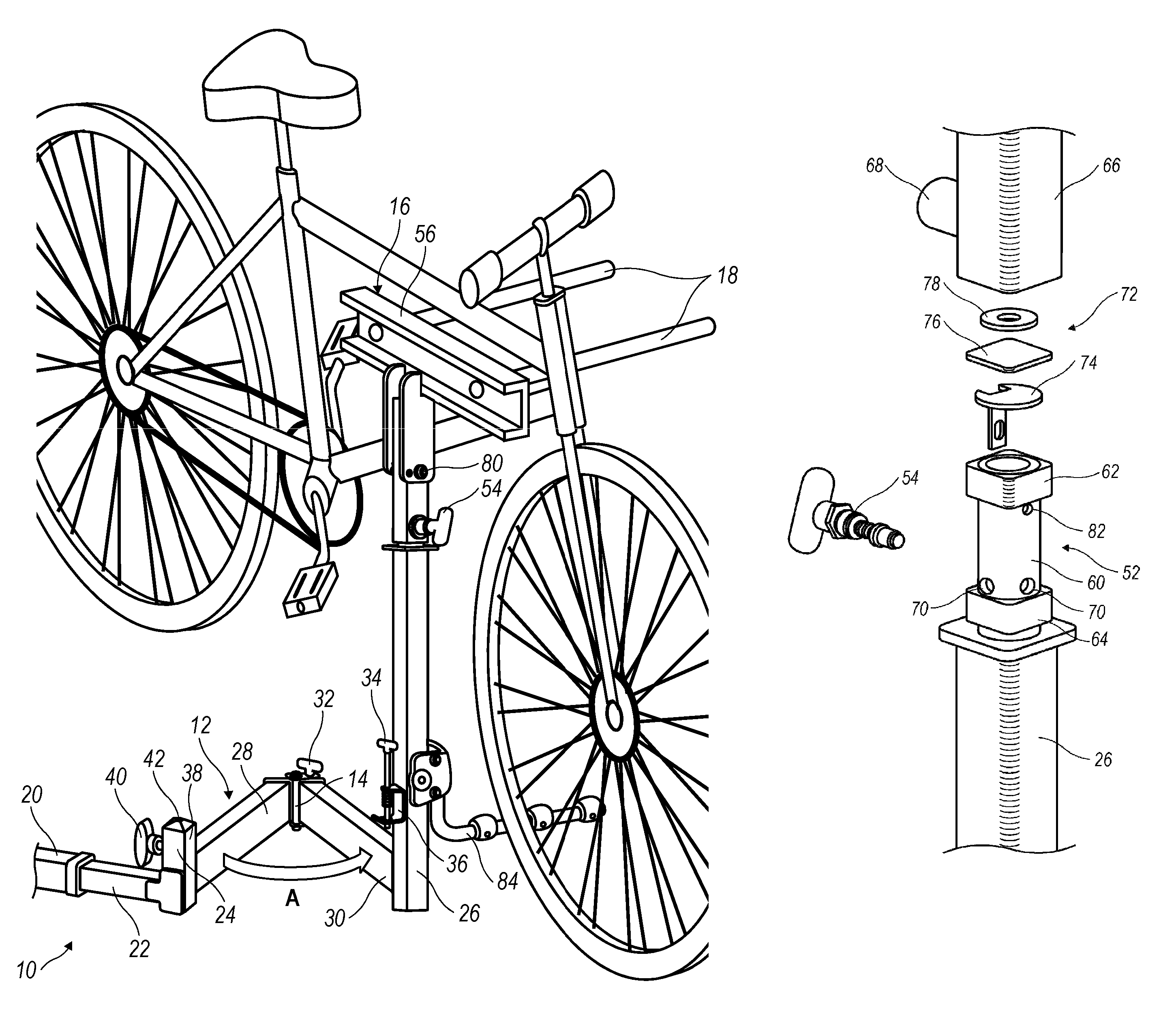

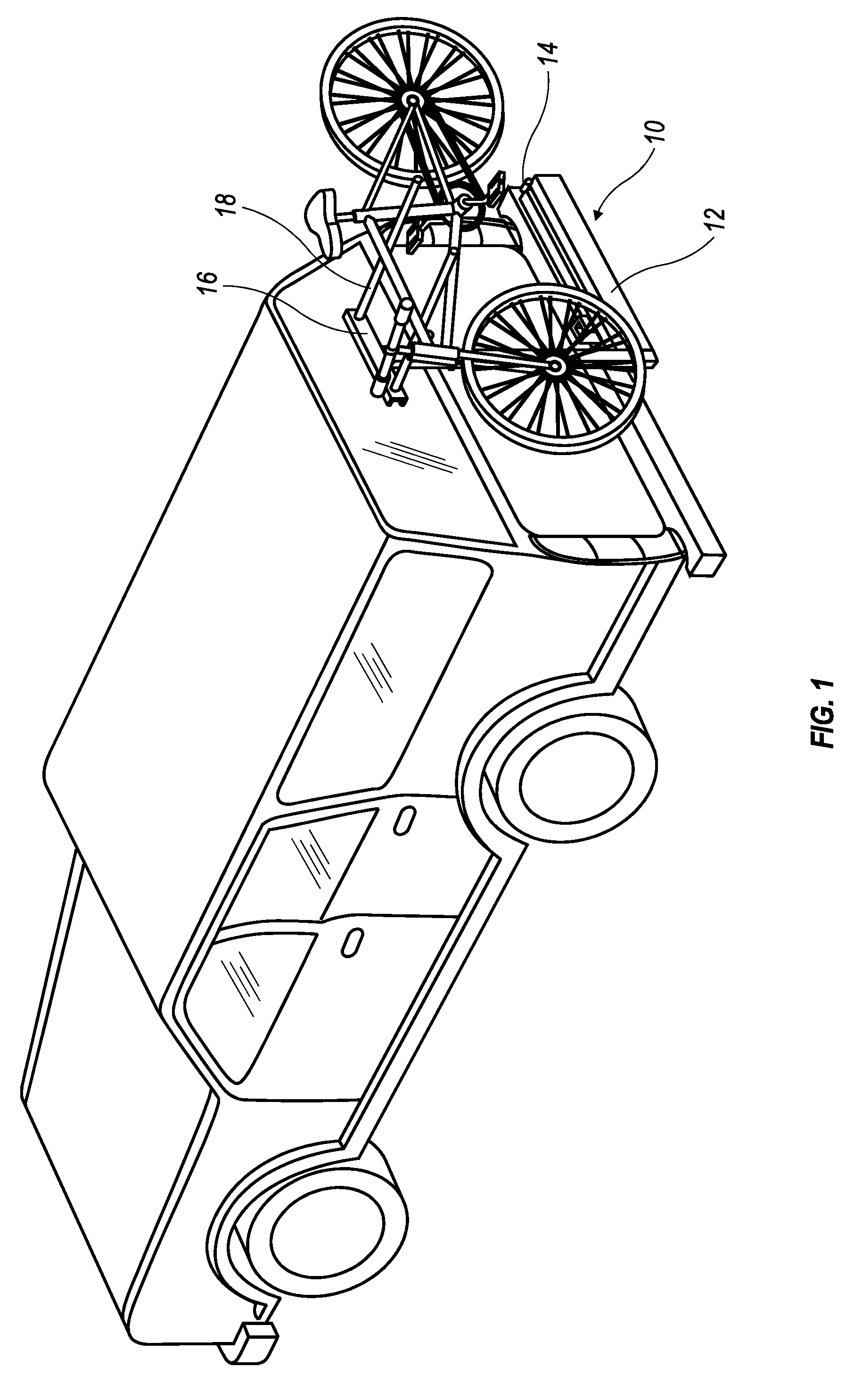

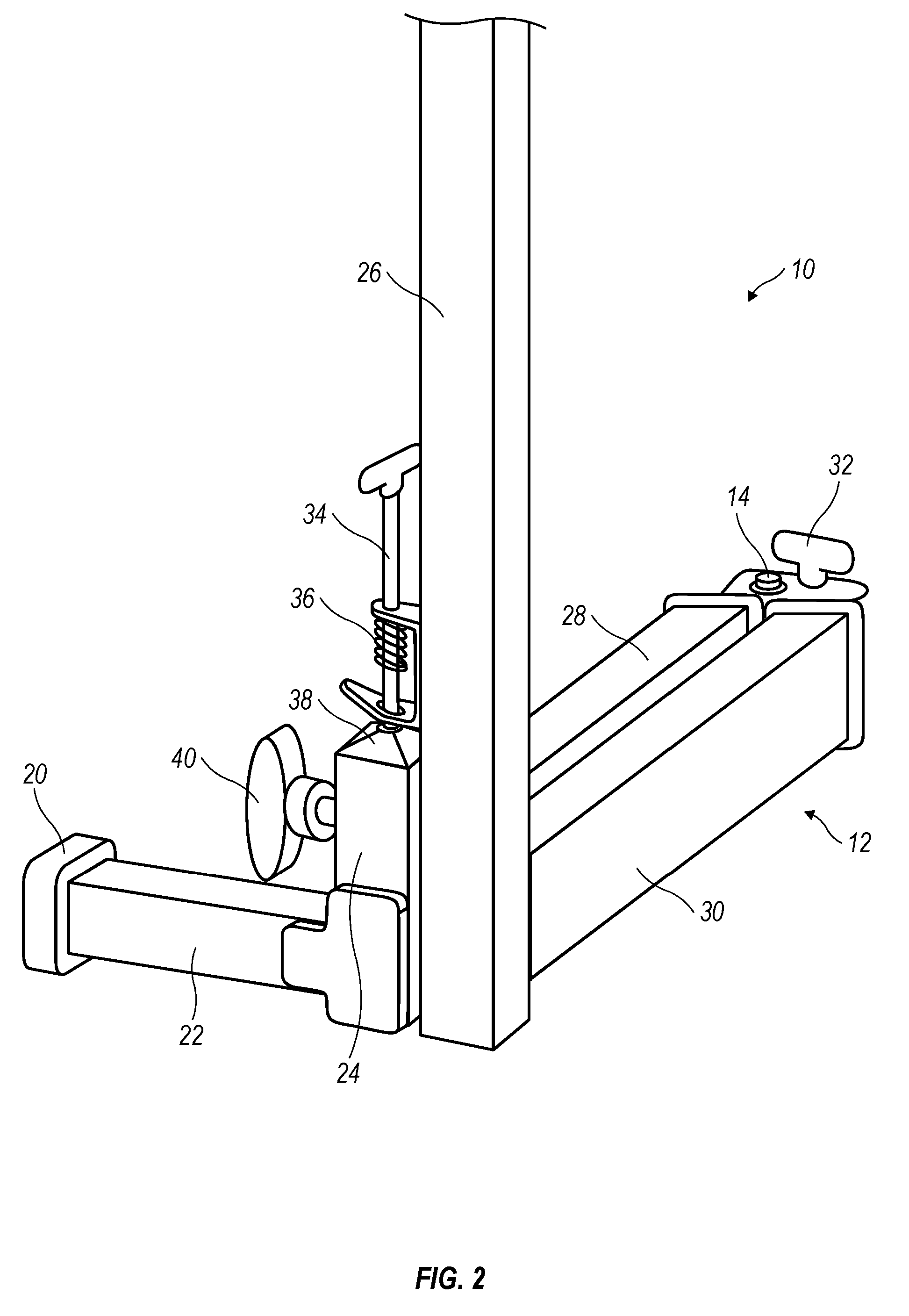

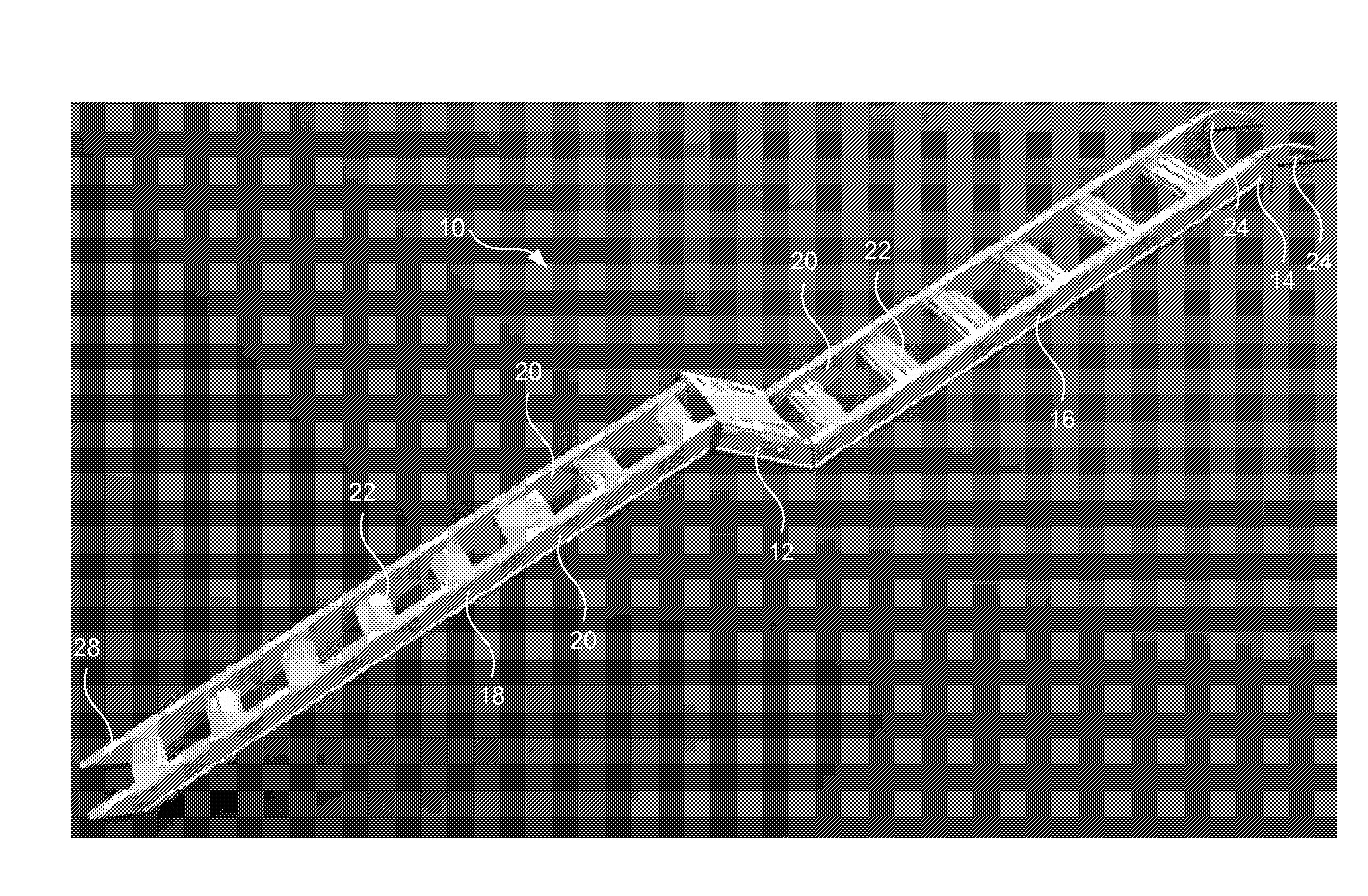

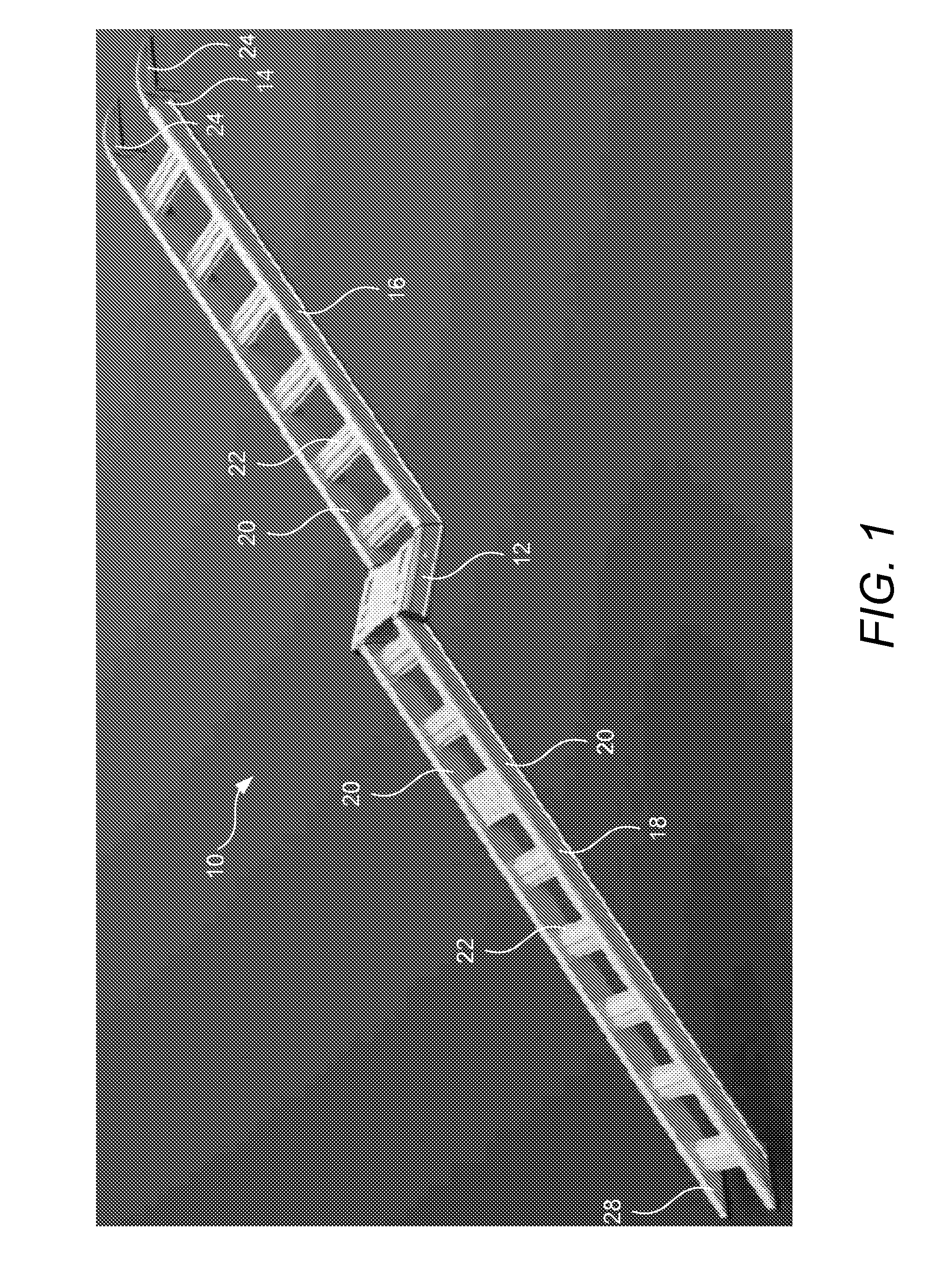

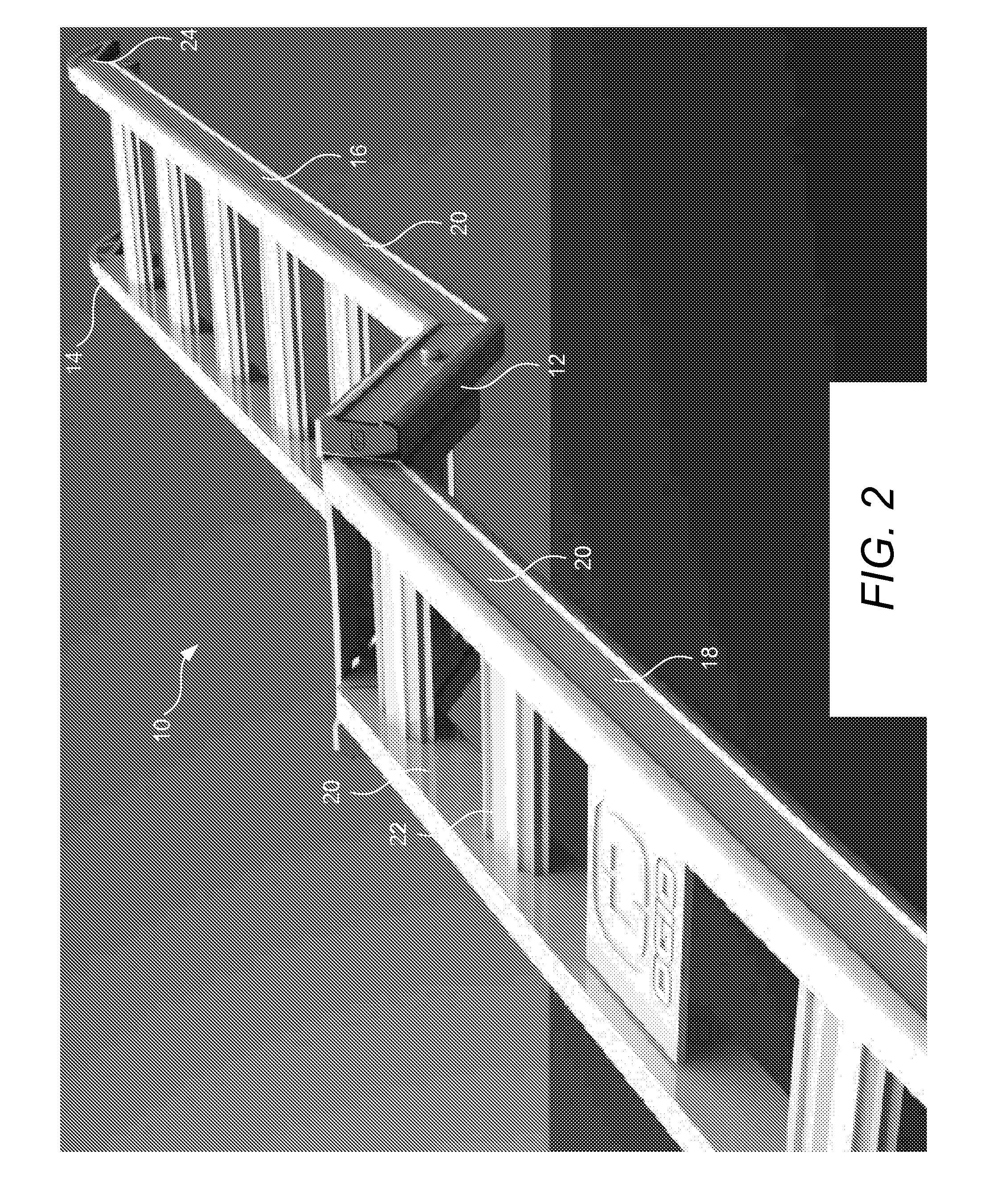

Rotatable hitch mountable load carrier

ActiveUS20060273125A1Improve safetyPrevent inadvertent rotationSupplementary fittingsEngineeringCoupling

A vehicle mountable load carrier generally includes a connecting member for insertion into a hitch mount receiver of a vehicle, an upright post connected to the connecting member and an upright load supporting member coupled to the upright post by an extendable support arm having an open and closed positions. The extendable support arm includes at least a first section and a second section and has a pivoting coupling therebetween such that at least the second section can be moved between a closed position and an open position. The pivoting coupling includes a releasable lock to retain the extendable support arm in a locked-open position.

Owner:THULE SWEDEN AB

Buoyant blade free stream tidal power device

InactiveUS7839009B2Unloading safetyEliminate requirementsFluid couplingsWind motor combinationsEngineeringKnife blades

Accordingly, the system for extracting power from tidal or other water action in a water region having a bottom surface, comprises: a base assembly positionable on the bottom surface of the water region; a buoyant blade assembly mounted on the base assembly, the blade assembly including at least one buoyant blade member, wherein the blade assembly or the blade member is capable of oscillating through an angle, wherein the buoyant blade member is mounted such that when the base assembly is positioned properly in the water region relative to the direction of the tide or other water action, torque is generated by the oscillating movement of the buoyant blade assembly or the buoyant blade member, and wherein the base assembly includes a power-extracting mechanism responsive to the torque generated by the tide or other action of water or the buoyant blade assembly; and a system for coupling the torque to the power-extracting mechanism.

Owner:RINK PHILIP A

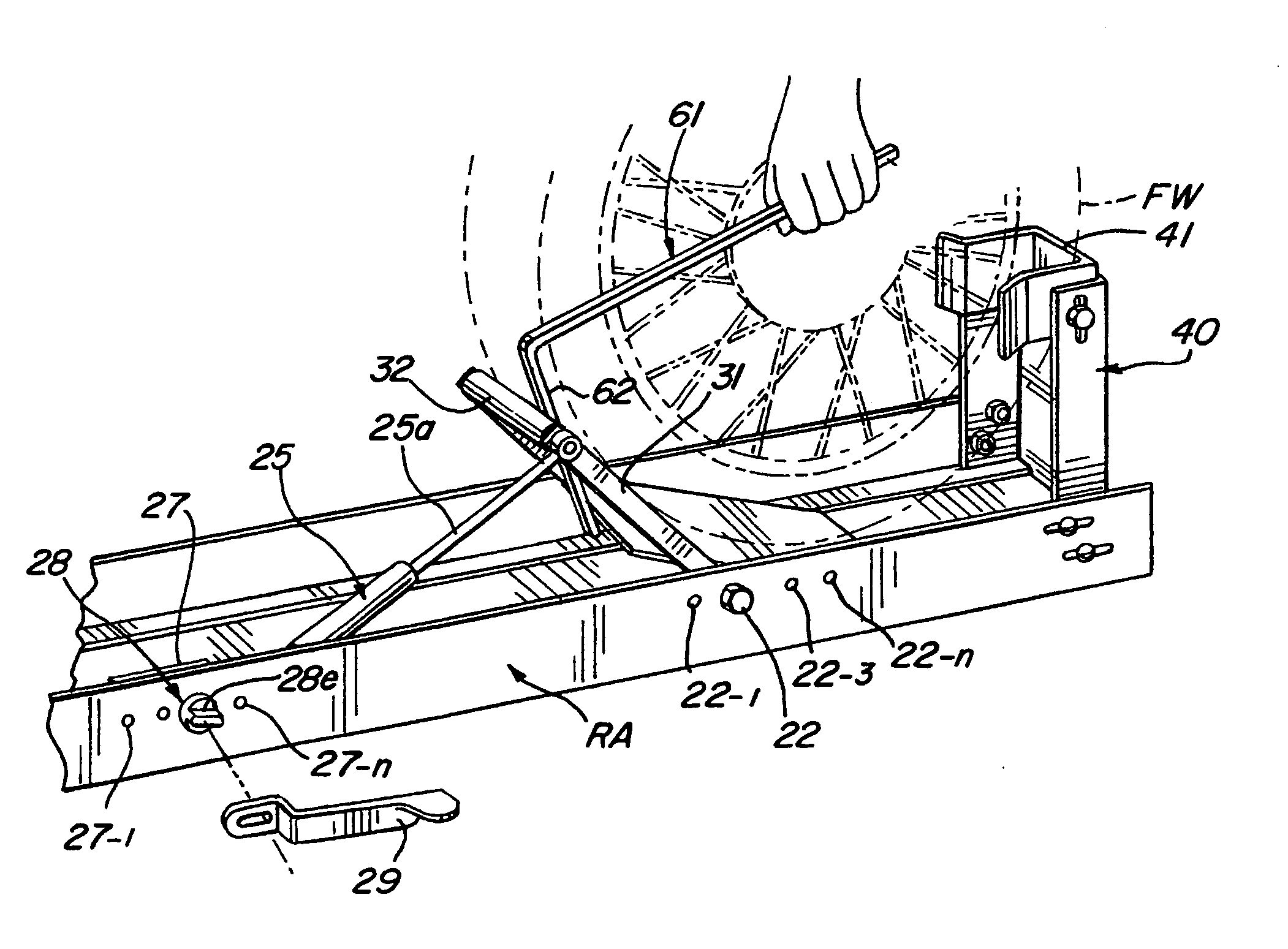

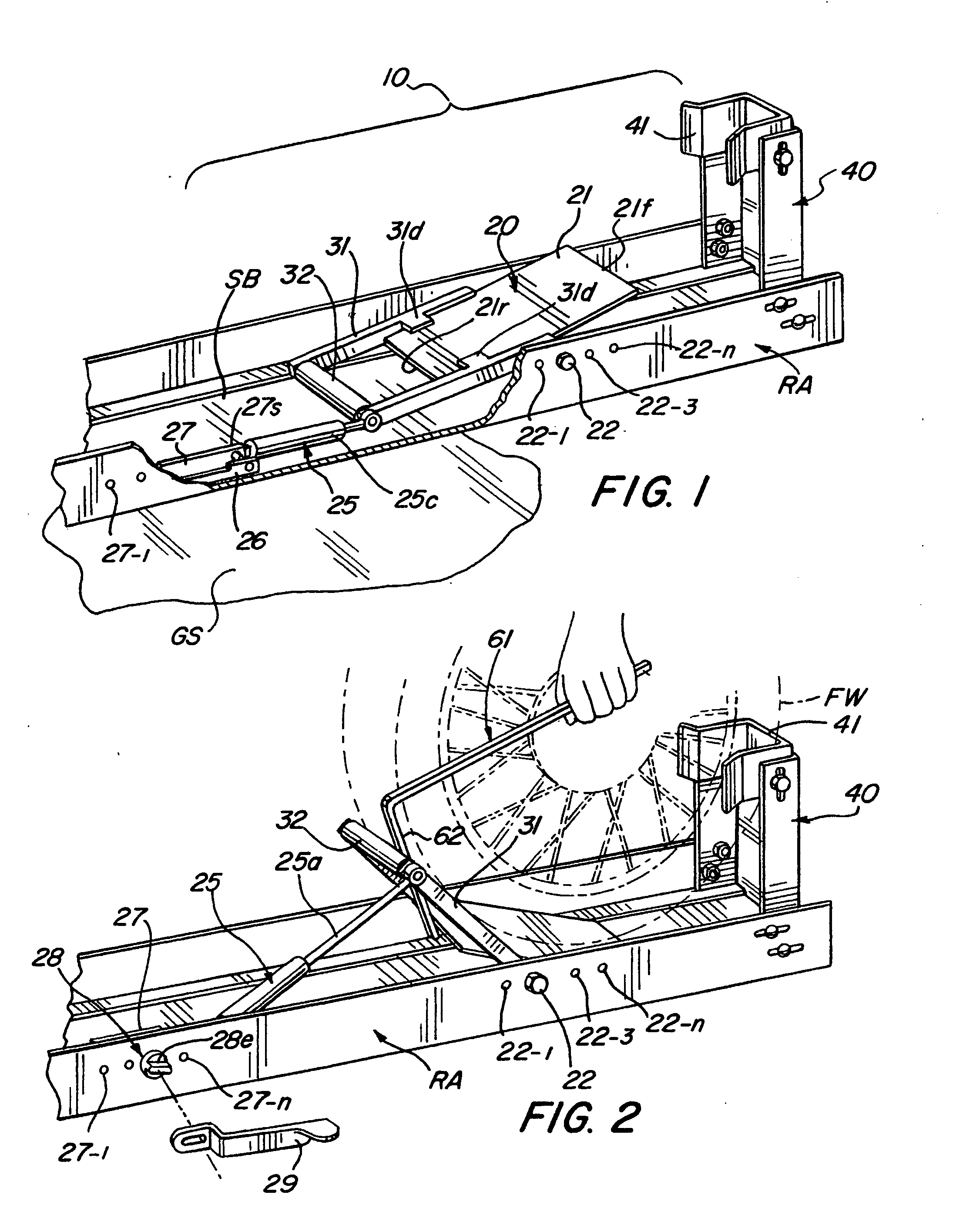

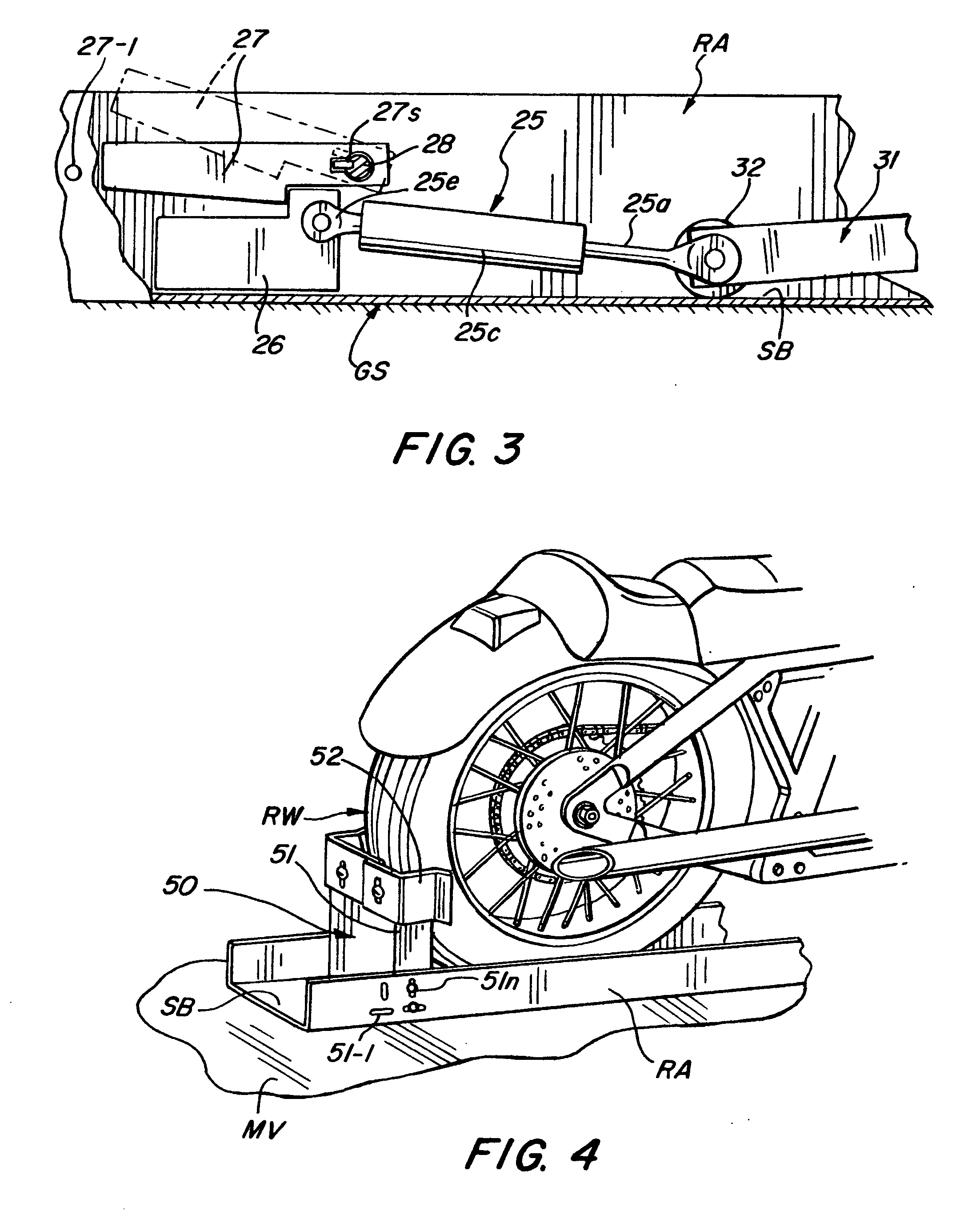

Apparatus for mounting a motorcycle on a carrier

InactiveUS20090232628A1Control loadUnloading safetyItem transportation vehiclesOther load carrying vehiclesEngineeringSelf triggering

Owner:MILLER ROBERT

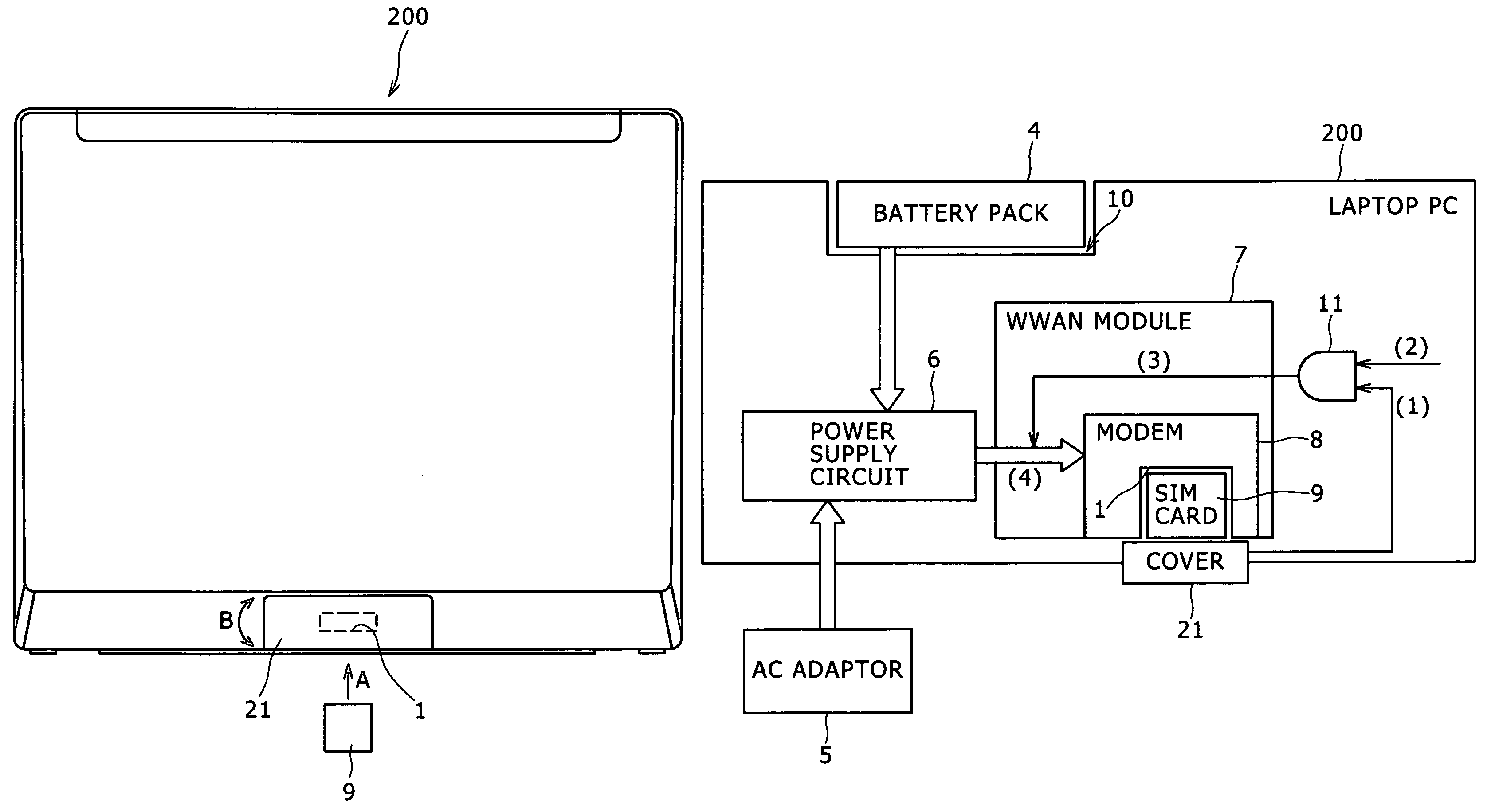

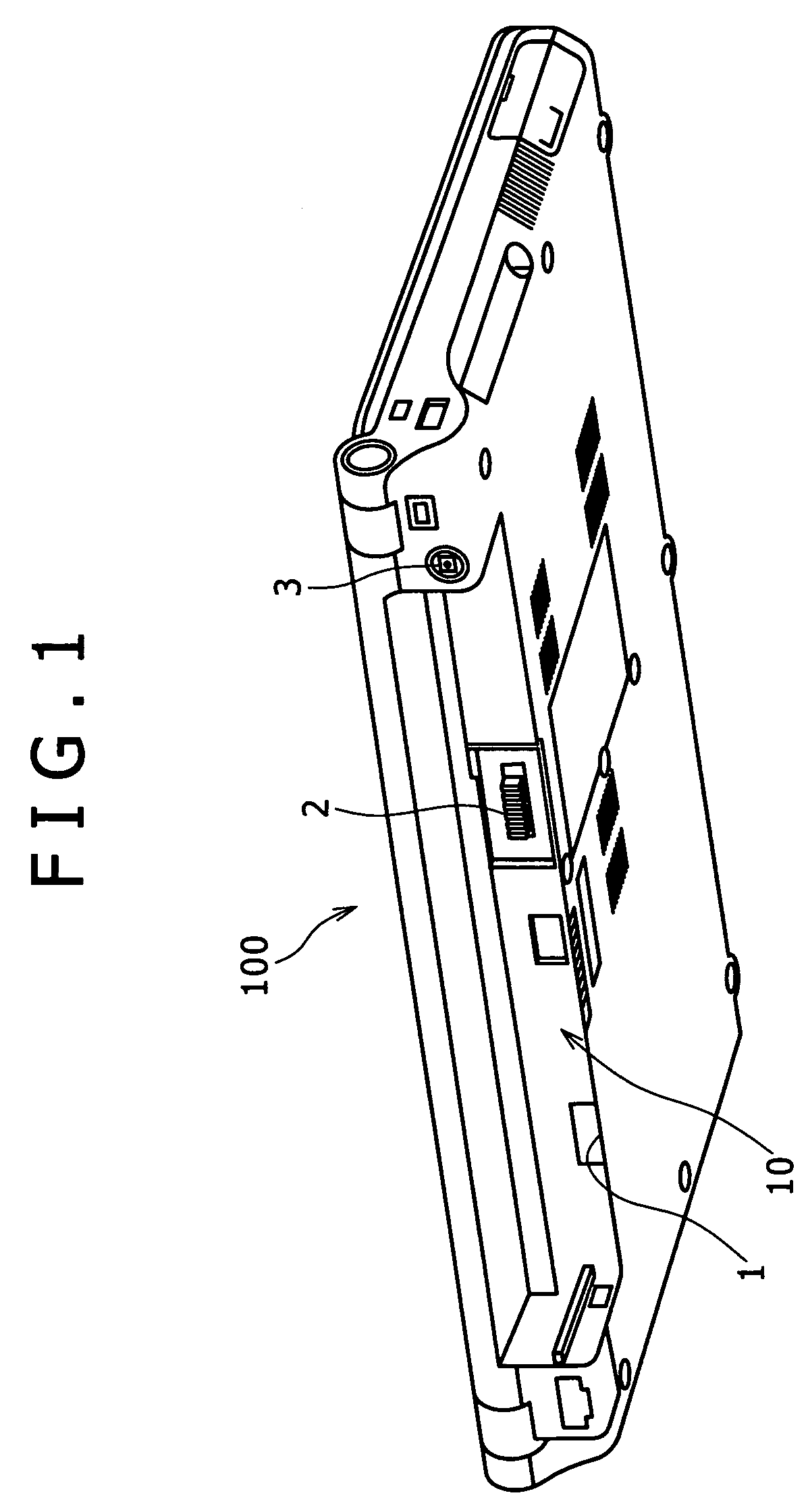

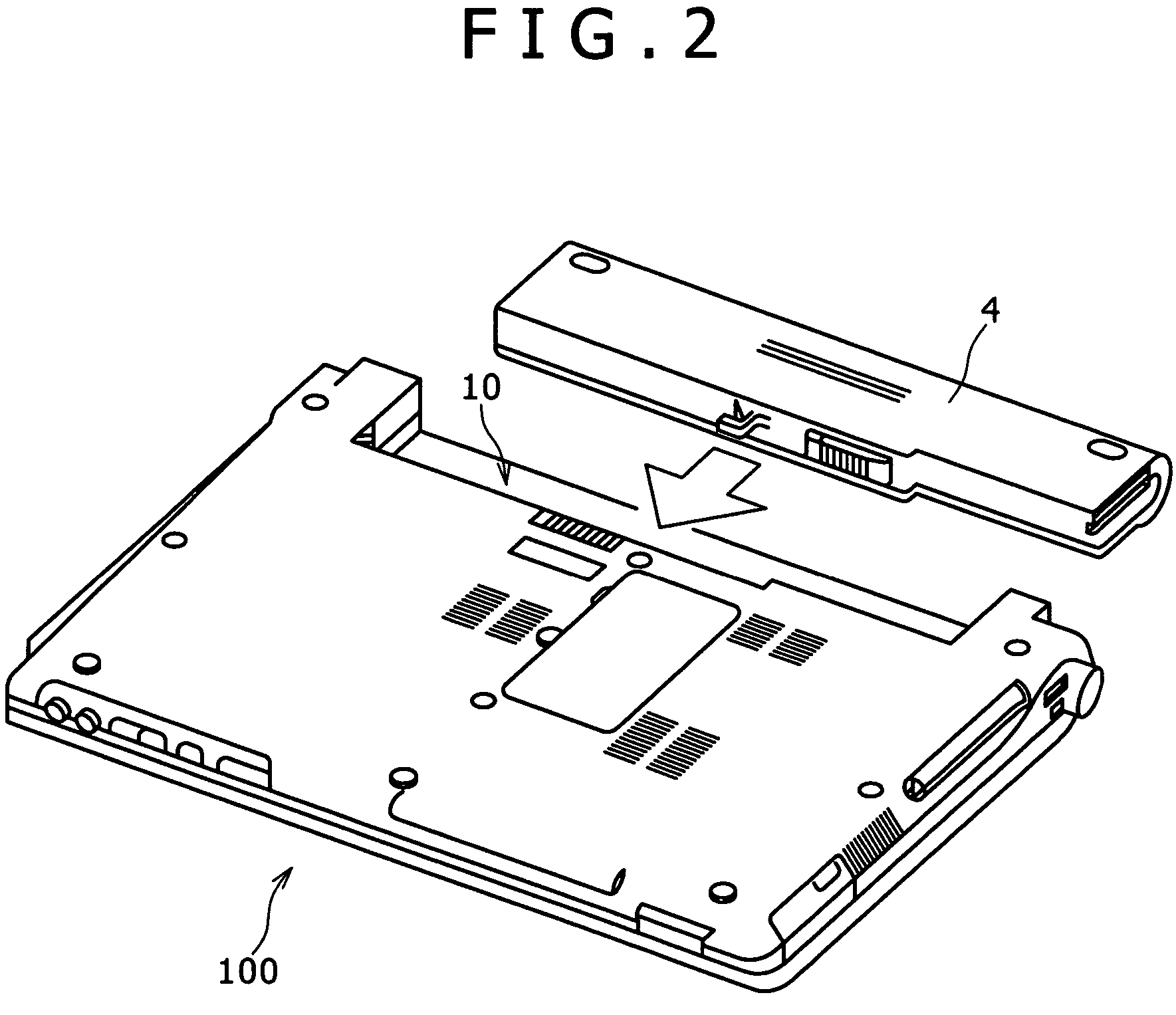

Laptop-type personal computer

ActiveUS7715189B2Unloading safetyStopping powerInterconnection arrangementsSubstation equipmentAC adapterEmbedded system

A laptop-type personal computer operable on power supplied from at least one of an AC adaptor and a battery pack includes a memory card loader configured to detachably load a memory card powered by at least one of the AC adaptor and the battery pack; a cover mechanism configured to cover and uncover the memory card loader; a detector configured to detect whether the memory card loader is covered by the cover mechanism; and a controller configured to control the power supply to a memory card loaded on the memory card loader when the cover mechanism uncovers the memory card loader.

Owner:SONY CORP

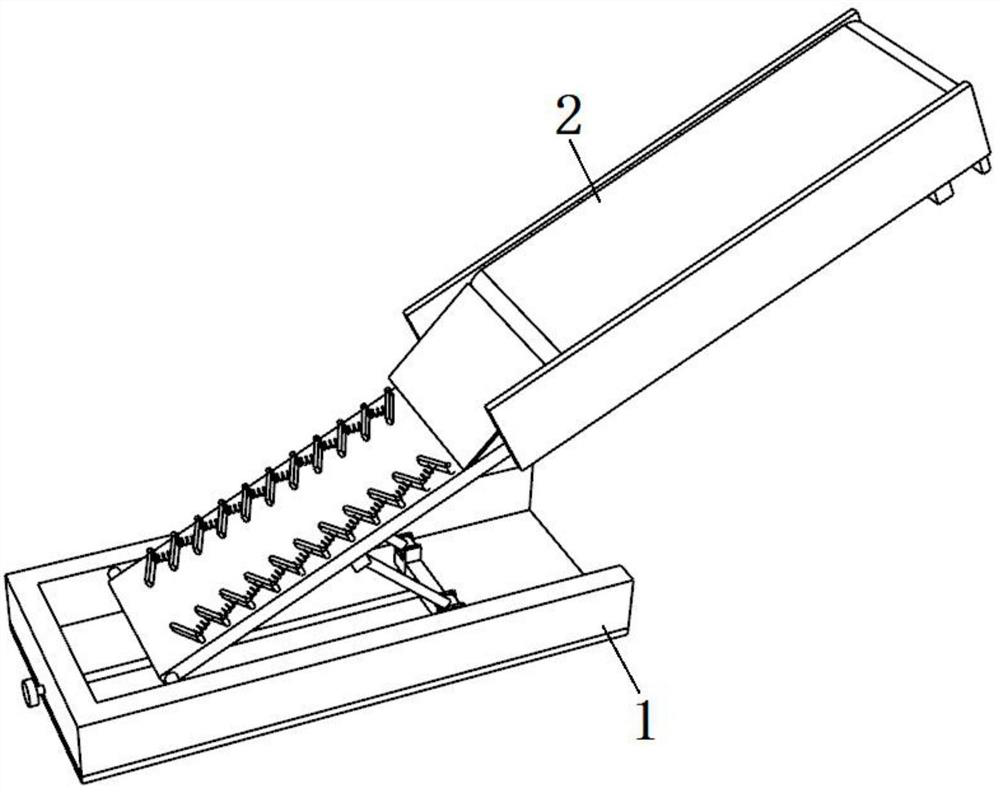

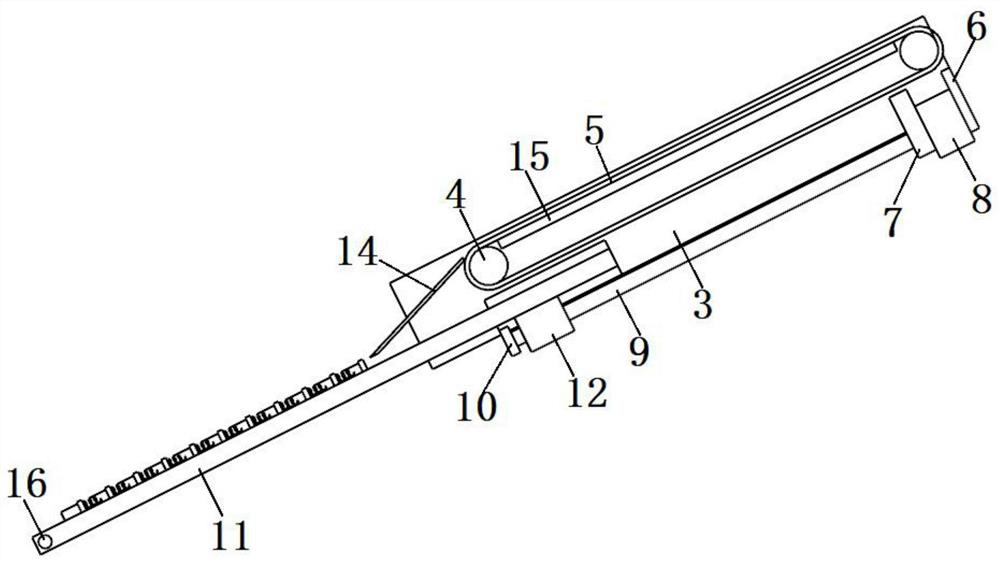

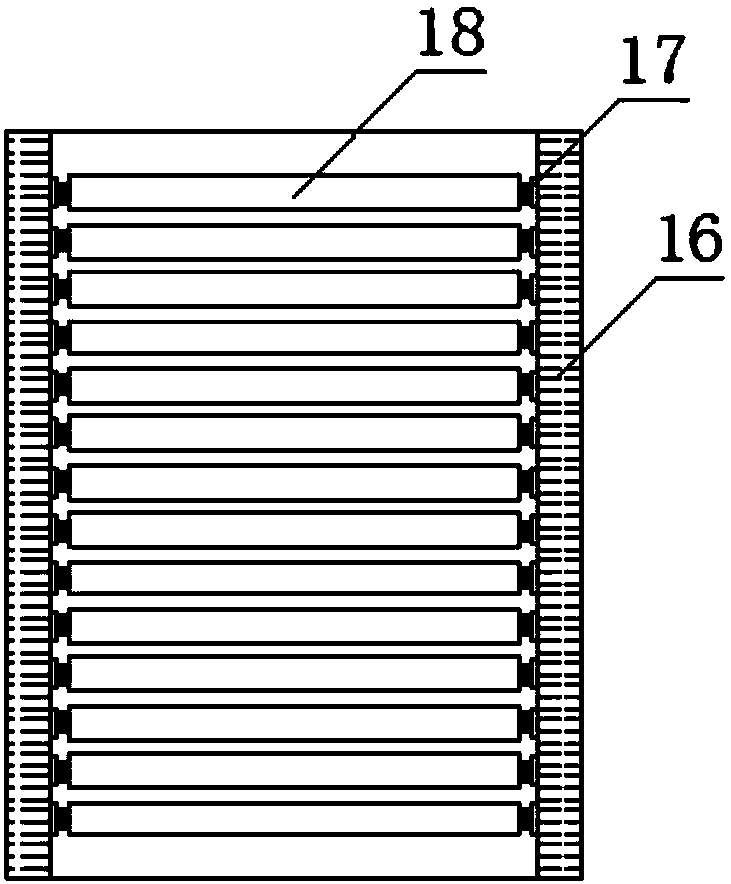

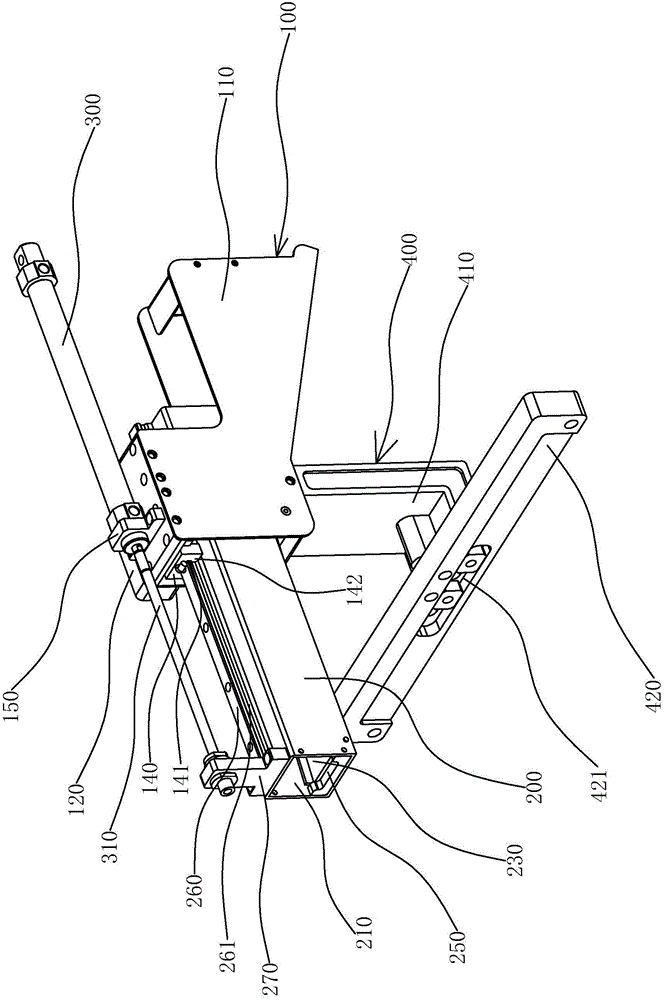

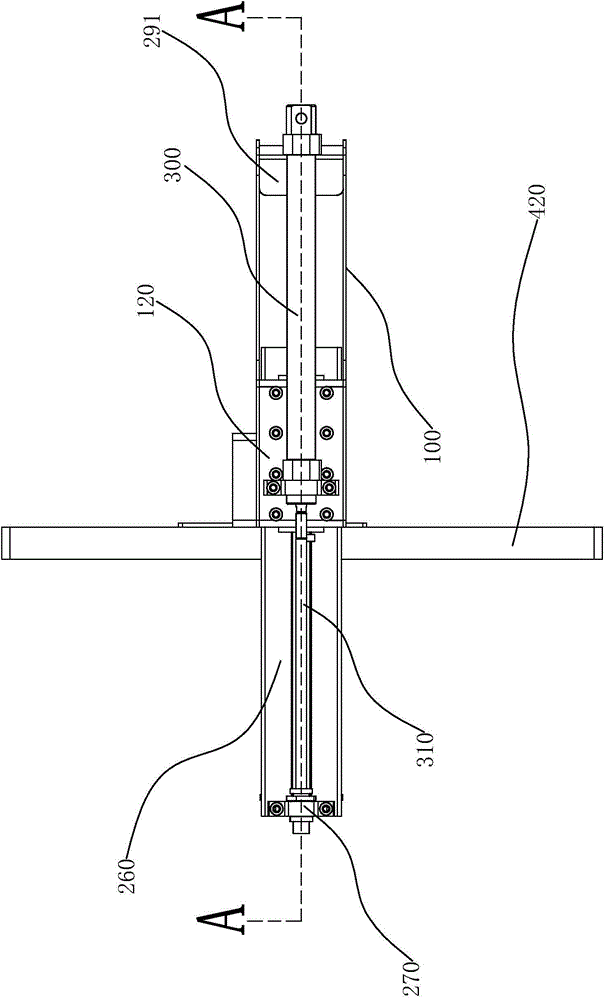

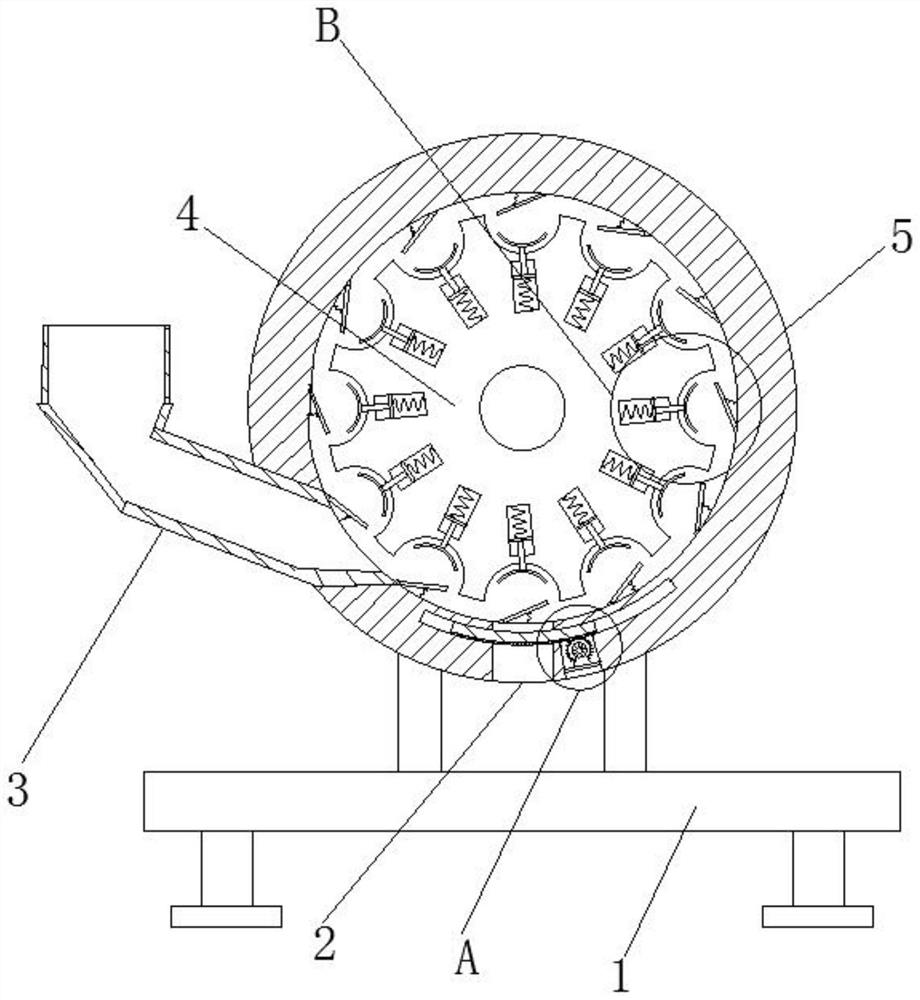

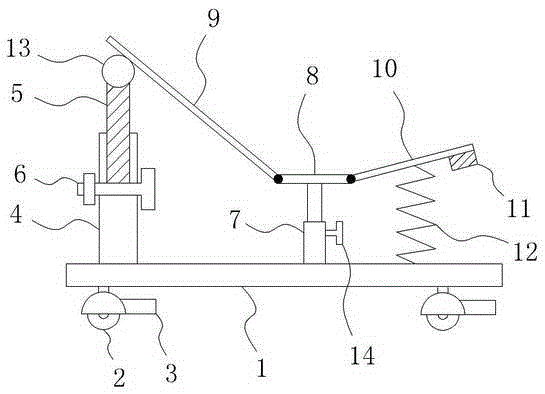

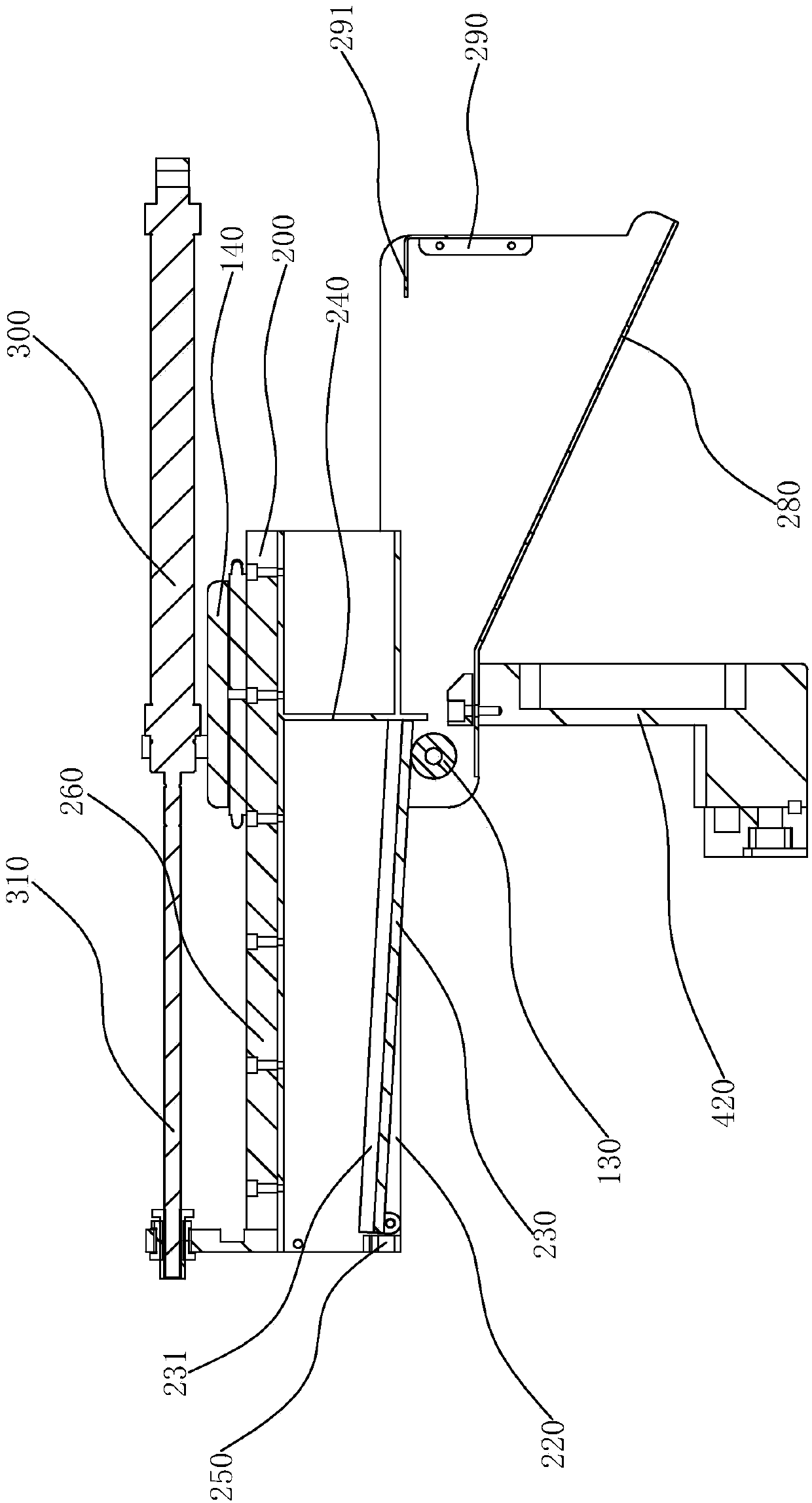

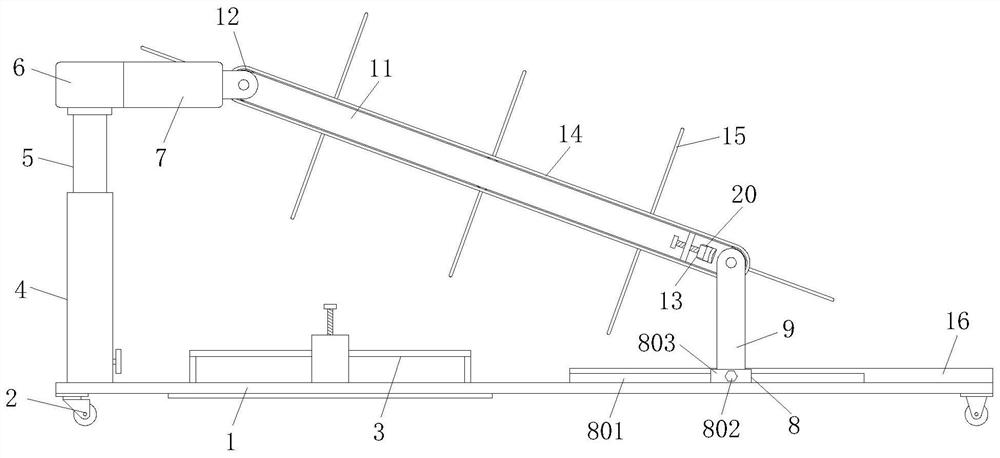

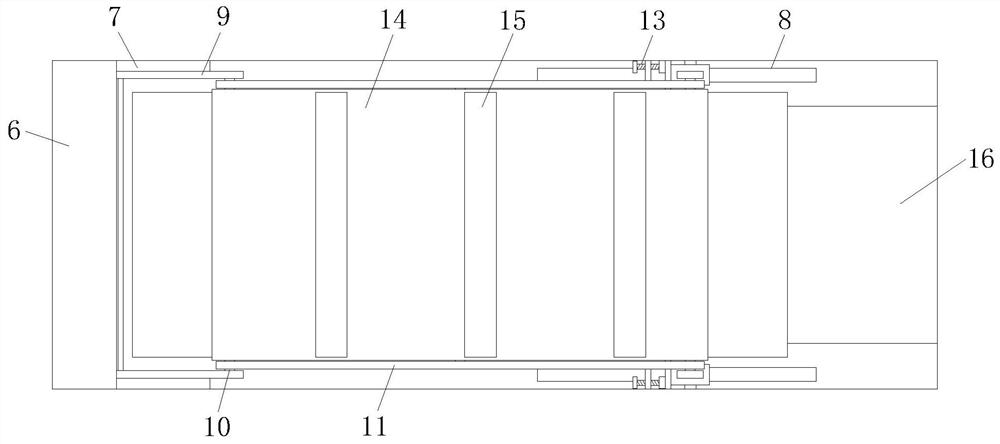

Unloading device for storage and transportation

InactiveCN111620025AReduce volumeEasy to transportConveyorsStorage devicesTransmission beltElectric machinery

The invention discloses an unloading device for storage and transportation, and relates to the technical field of storage and transportation. The unloading device for storage and transportation comprises a support adjustment mechanism, wherein an unloading mechanism is fixed on the support adjustment mechanism, the unloading mechanism comprises a group of support plates and unloading plates, a group of belt rollers are rotationally connected between the two support plates through bearings, and two belt rollers are in transmission fit with conveyor belts. According to the invention, a motor drives a thread screw to rotate, so that the unloading plates and the conveyor belts can be folded together in a screw drive mode, and then the device has smaller volume through the mutual folding of thesupport adjustment mechanism and the unloading mechanism; and the overall length after the unloading plate is combined with the conveyor belt can be adjusted freely in the screw drive mode, the support adjustment mechanism can adjust the inclination of the unloading mechanism, with the mutual cooperation of the support adjustment mechanism and the unloading mechanism, the device can meet the actual unloading demand during storage well.

Owner:安徽华中机械配套工程有限公司

Rotatable hitch mountable load carrier

Owner:THULE SWEDEN AB

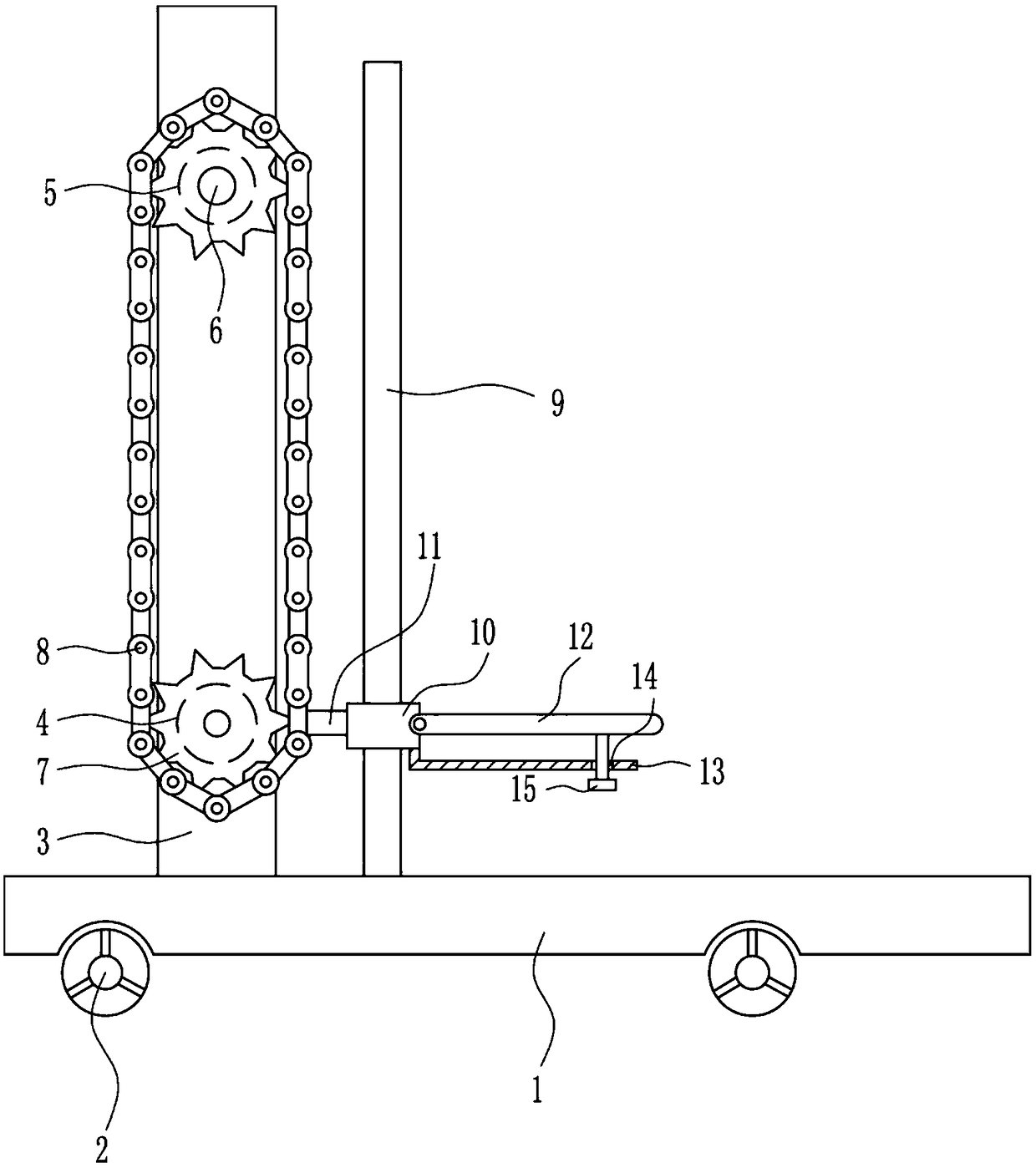

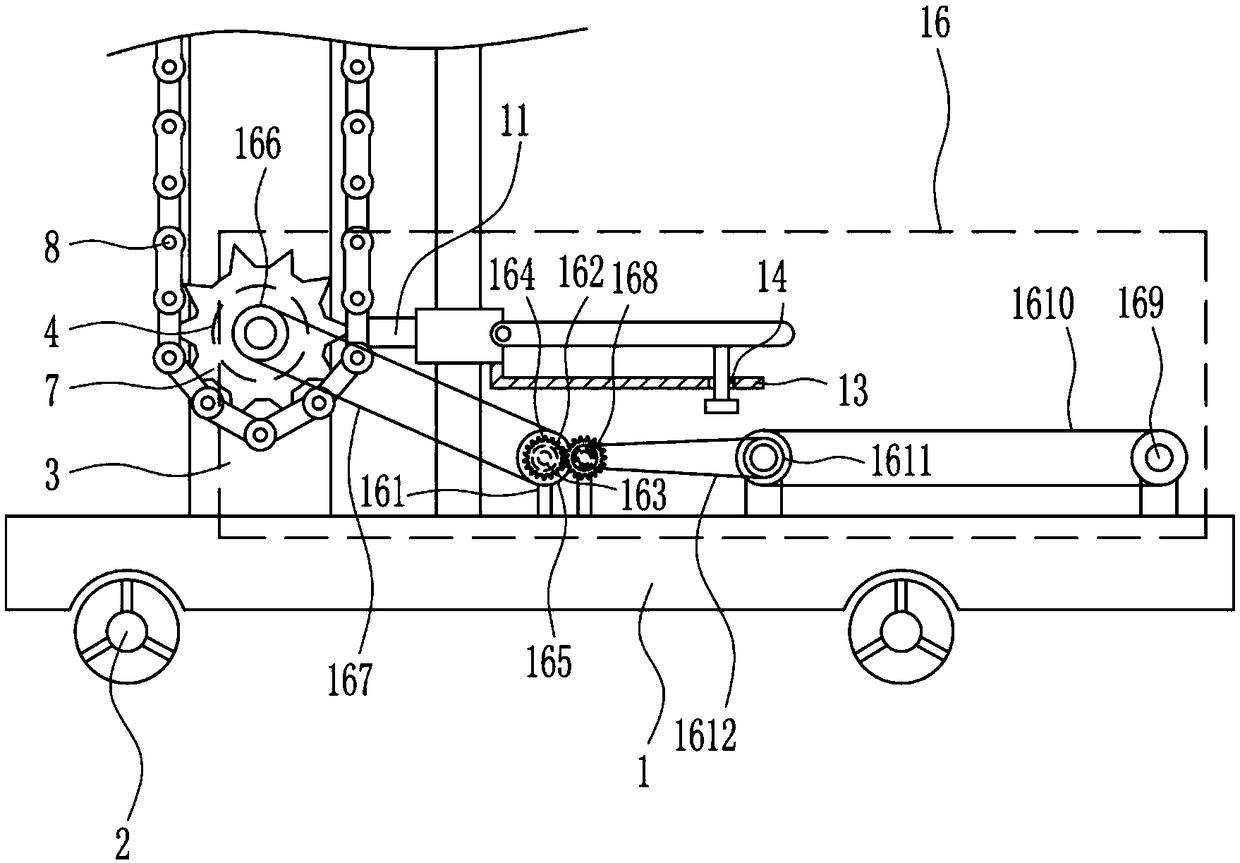

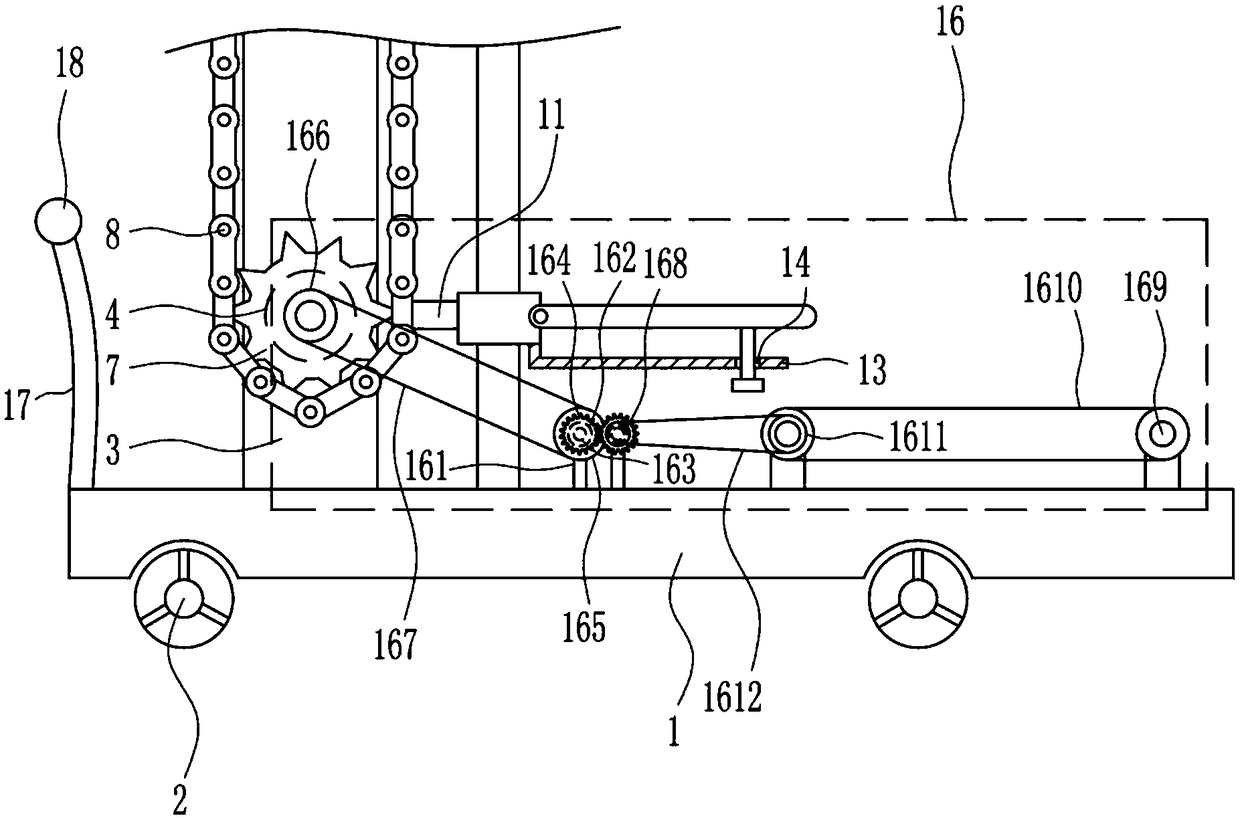

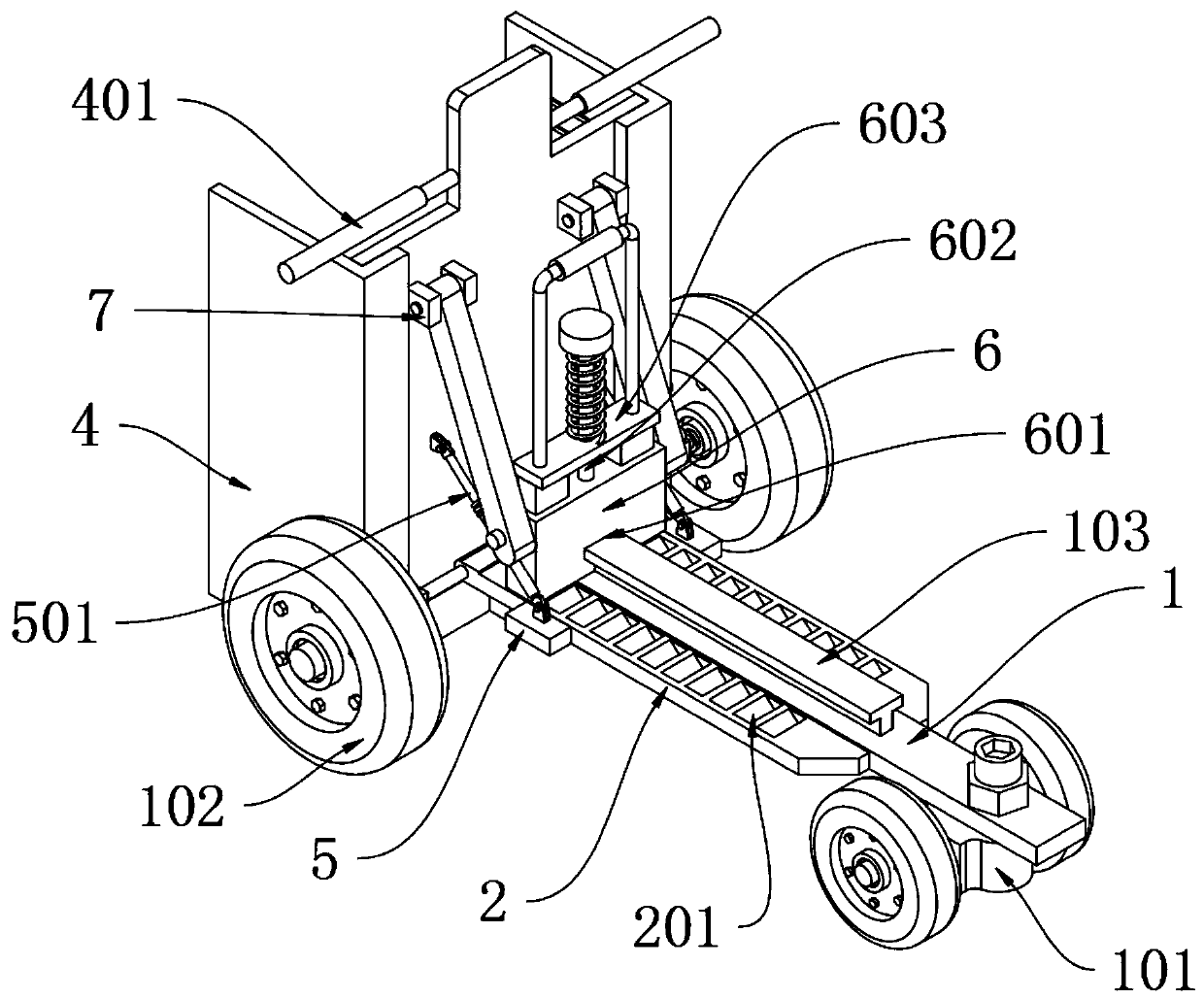

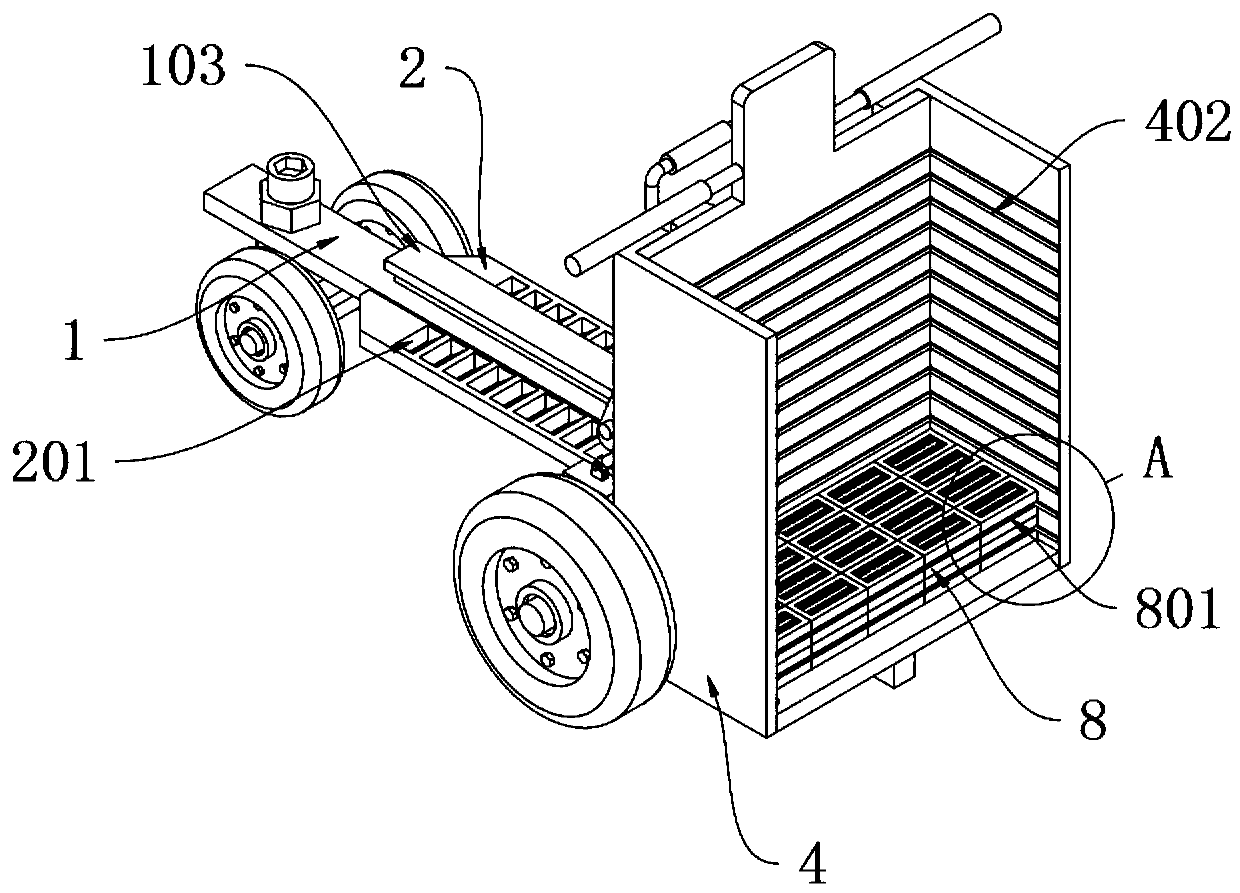

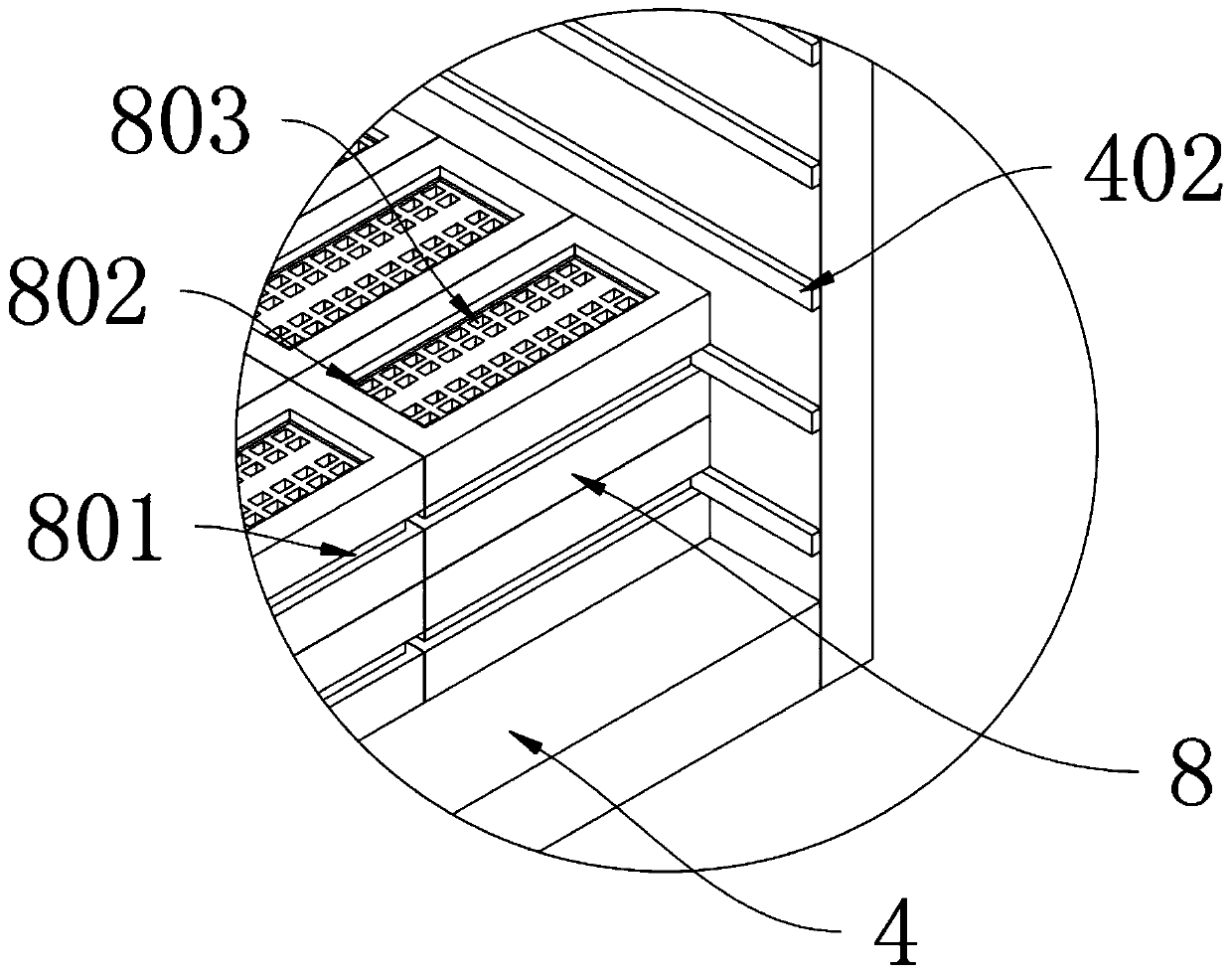

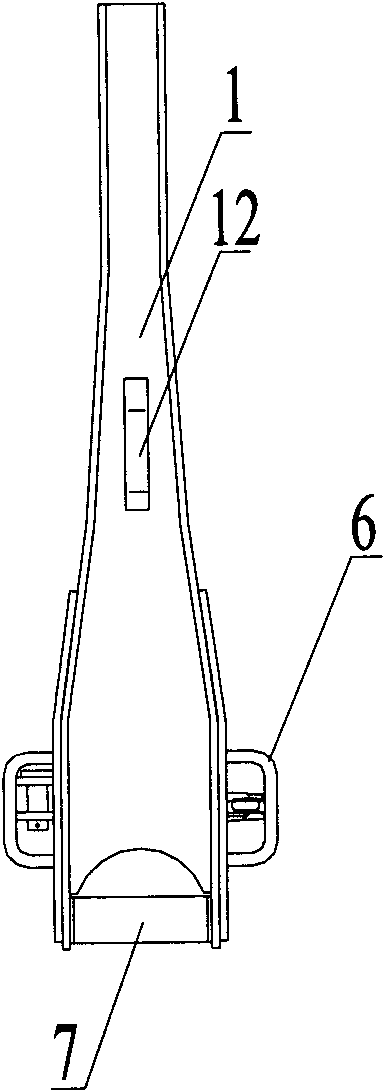

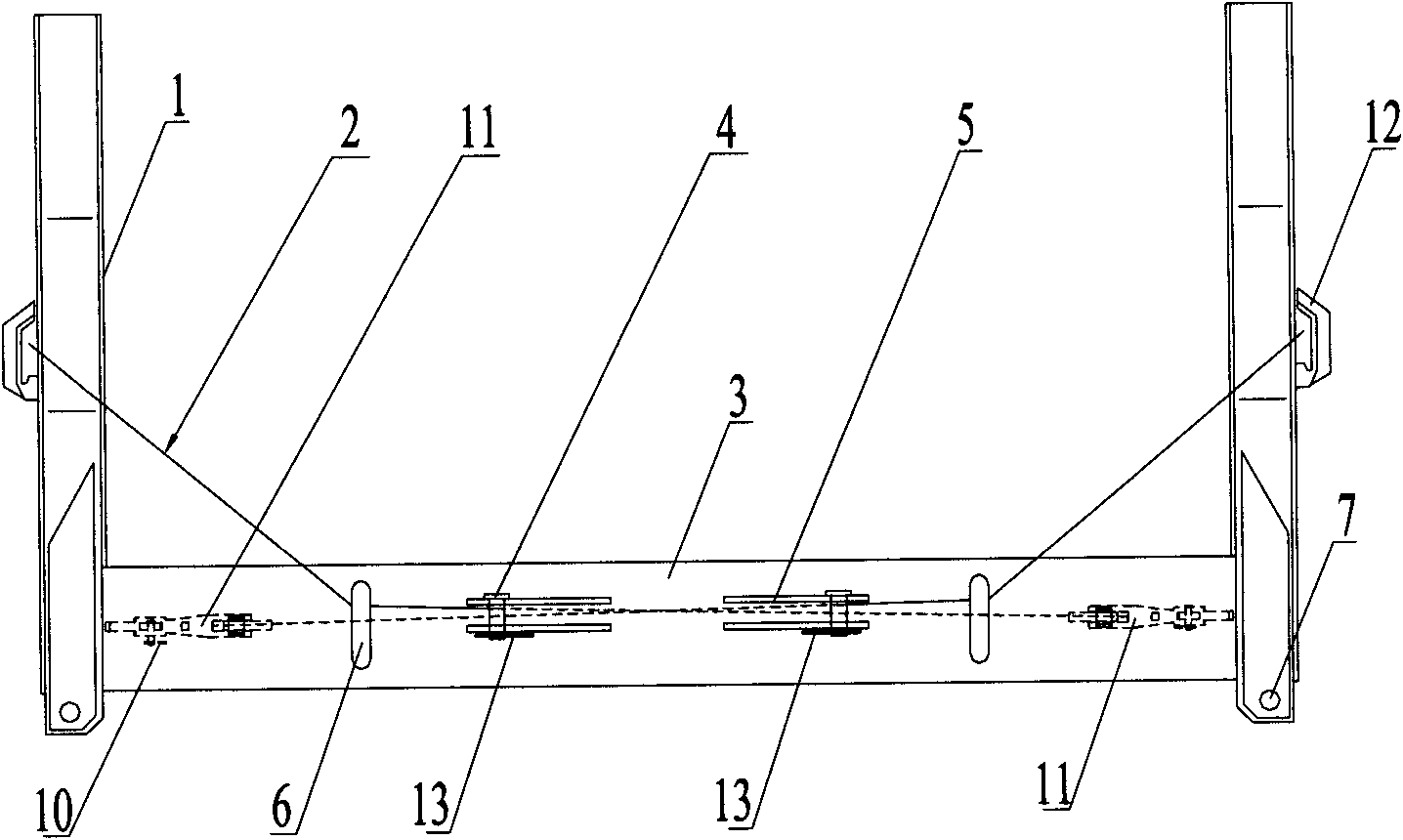

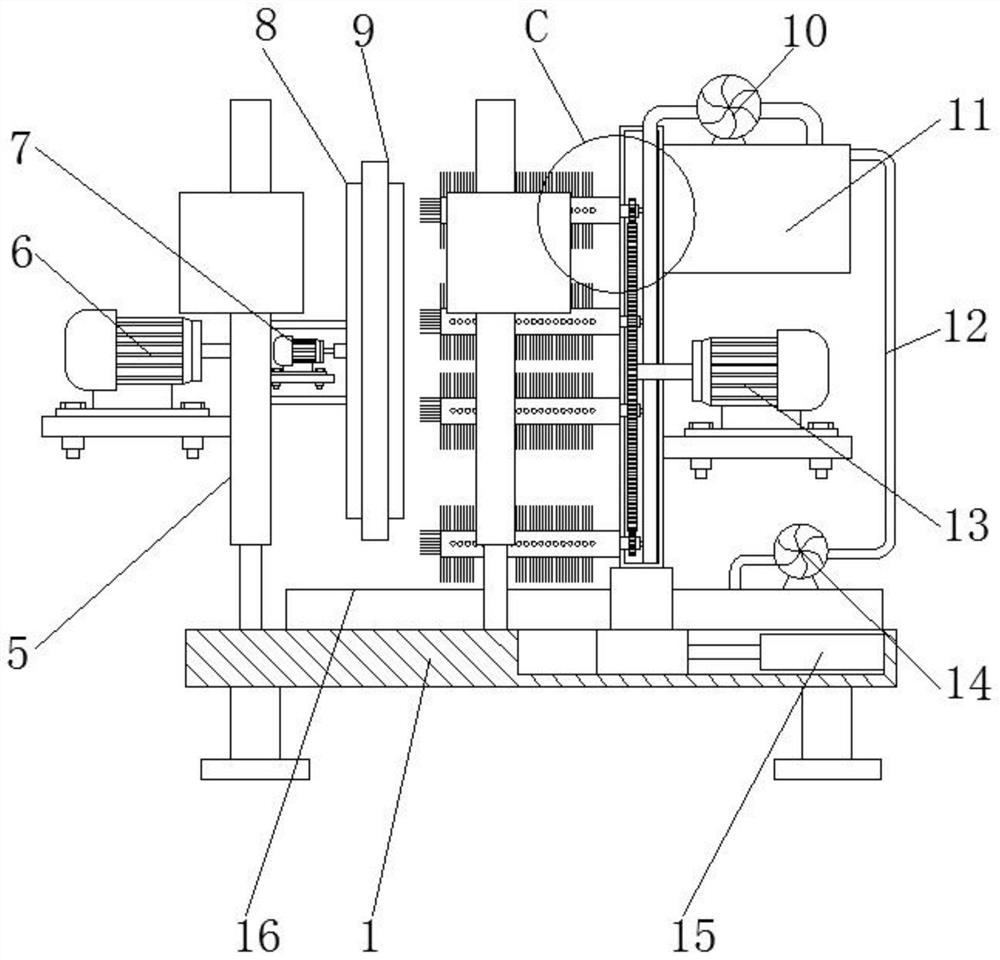

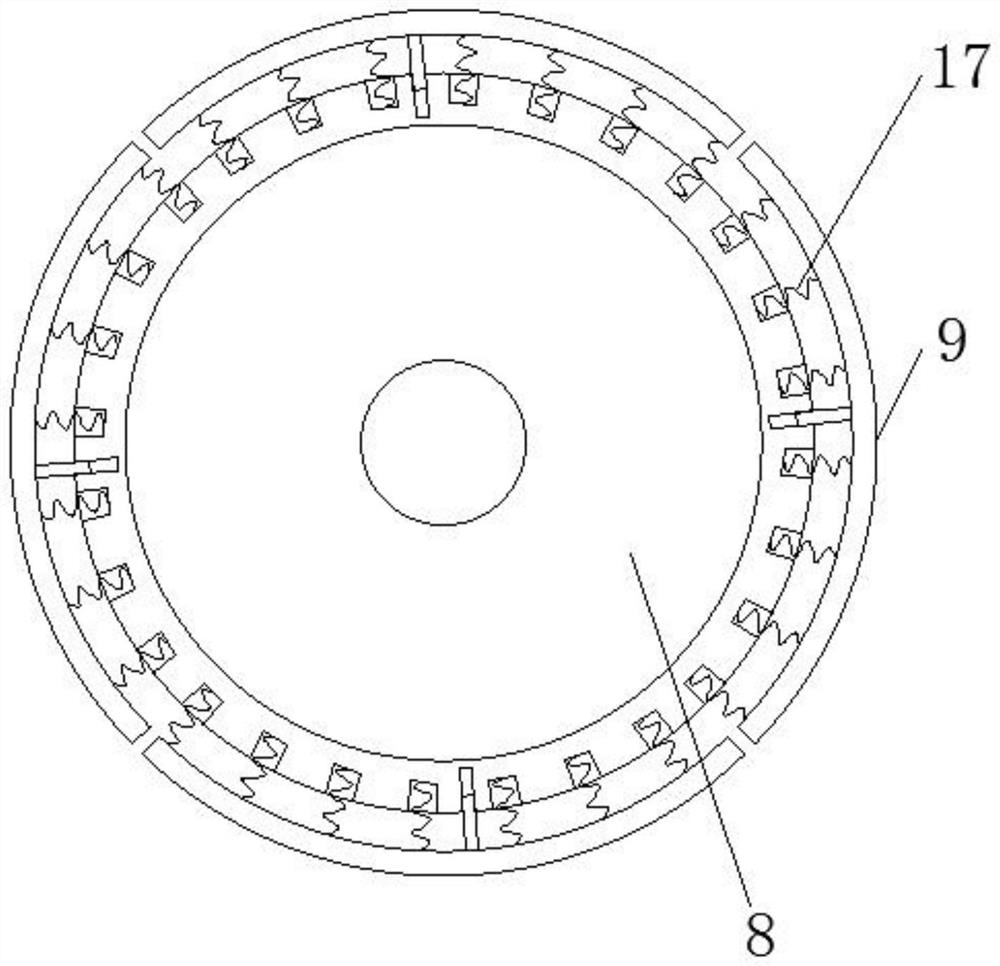

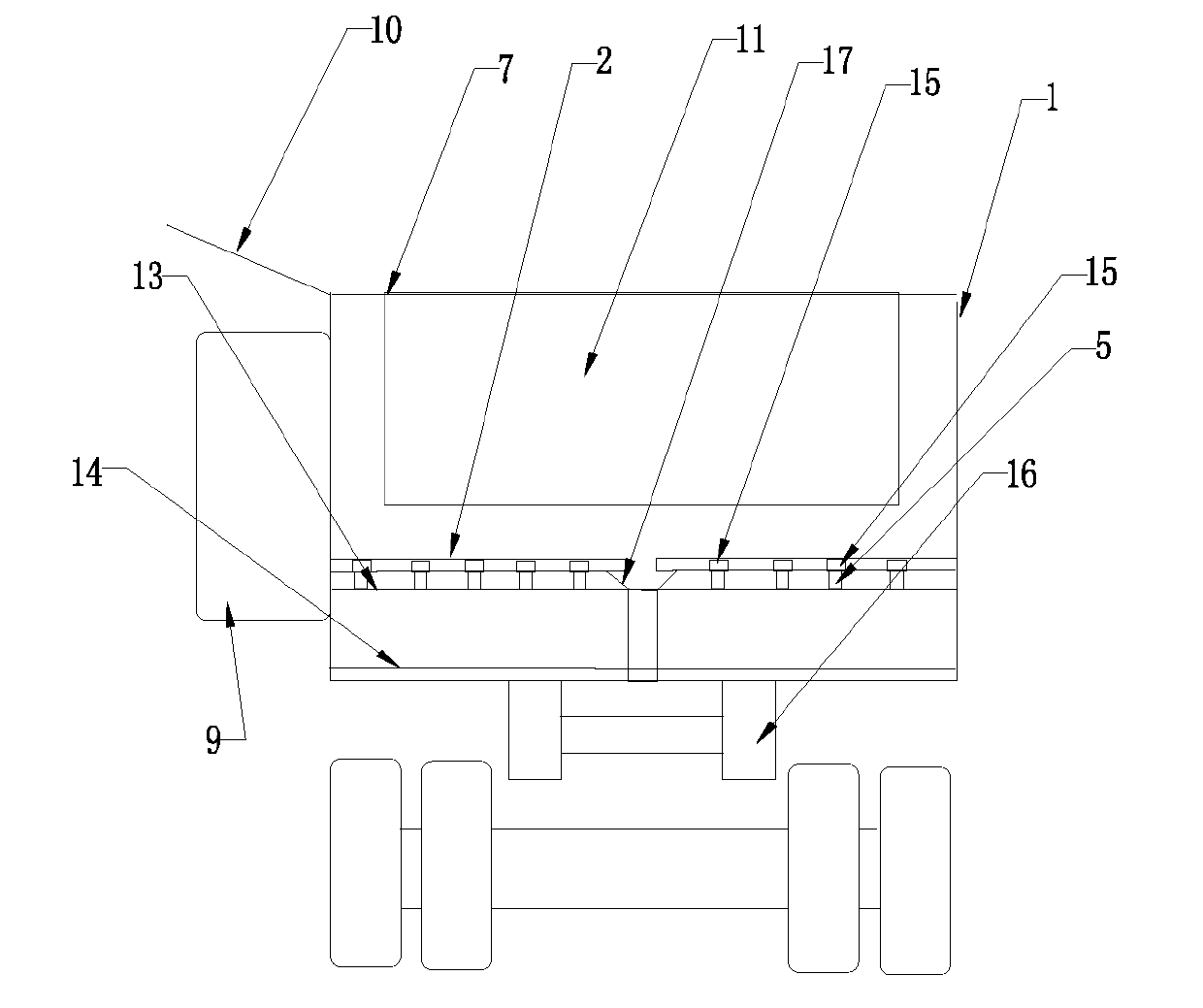

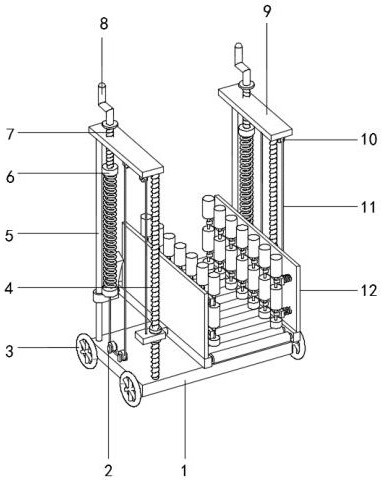

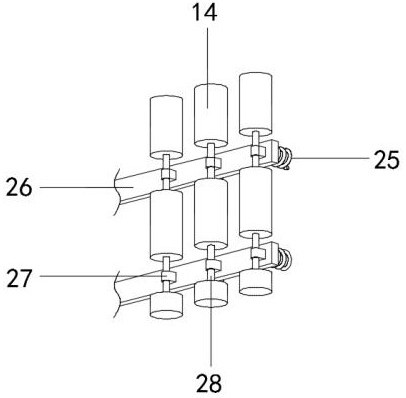

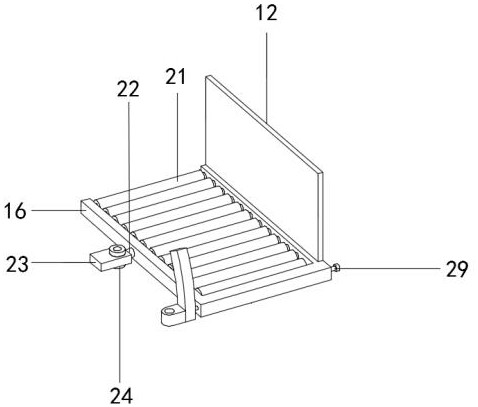

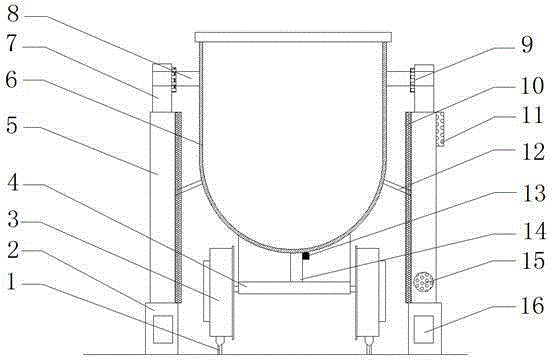

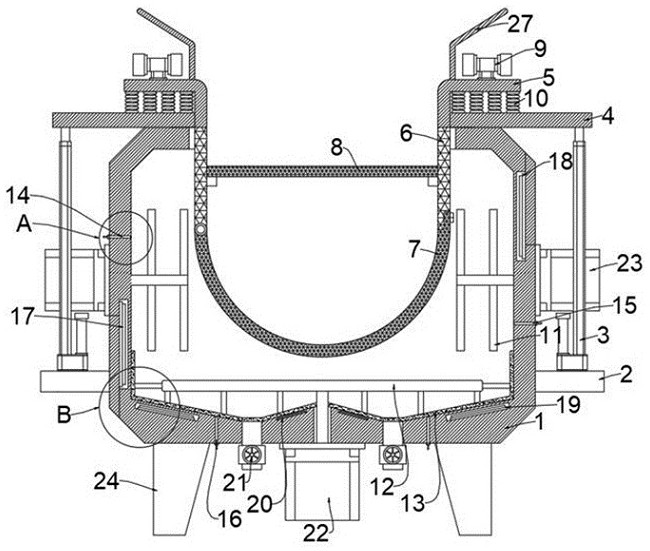

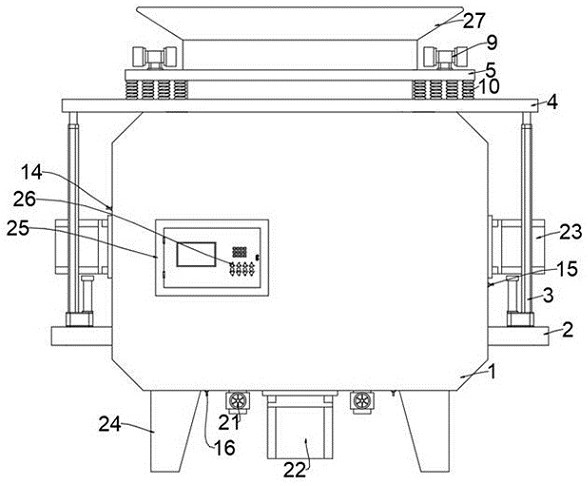

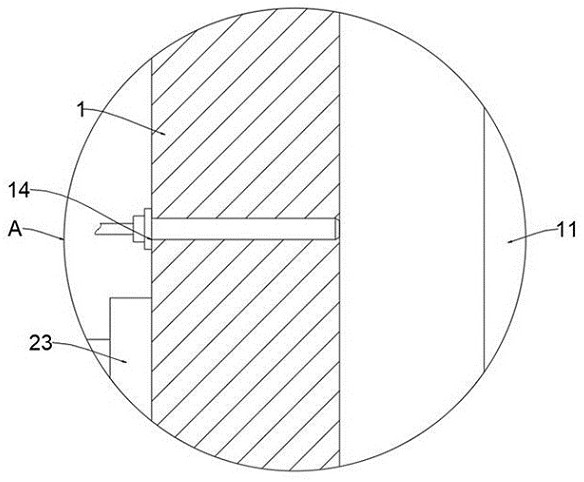

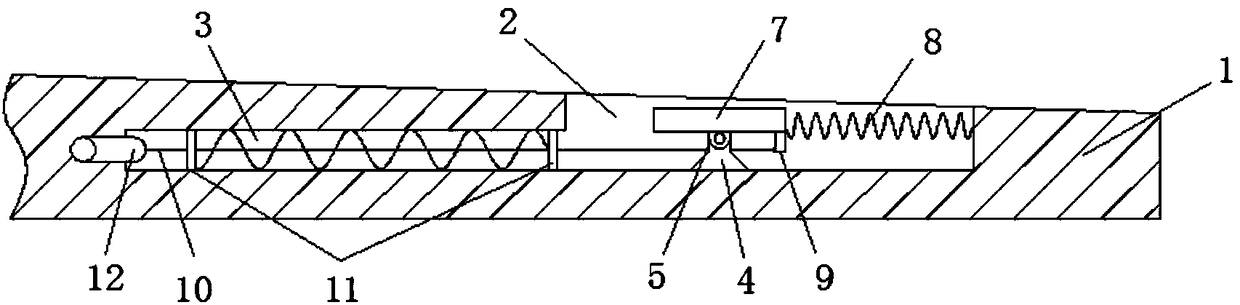

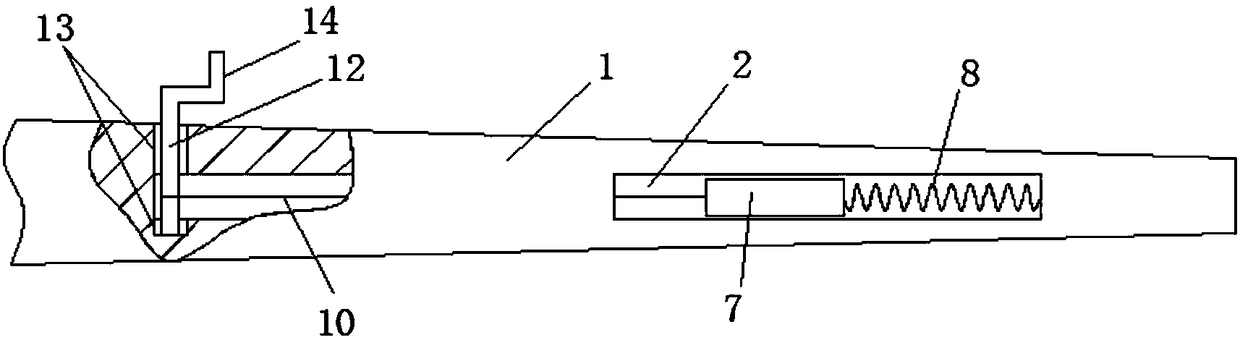

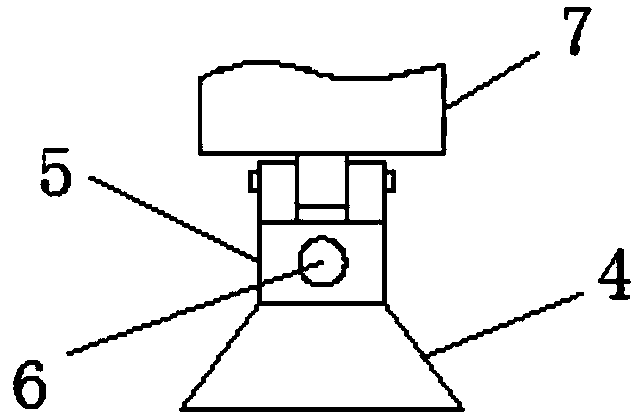

Mechanical truck-unloading device

The invention relates to a truck unloading device, in particular to a mechanical truck-unloading device. The object of the invention is to provide a mechanical truck-unloading device which can improvethe truck unloading speed and ensure the unloading safety. The invention adopts the following technical scheme: a mechanical truck-unloading device comprises a base plate, wheels, a mounting plate, amotor, a first bearing seat, a first rotating shaft, first gears, a chain, a guide rod, a guide sleeve, a connecting rod, etc., wherein the wheels are mounted at the bottom of the base plate; the mounting plate is arranged on the left side of the top of the base plate; the motor is arranged at the lower part of the front side of the mounting plate; the first bearing seat is arranged at the upperpart of the front side of the mounting plate; the first rotating shaft is arranged in the first bearing seat; and the front end of the first rotating shaft and an output shaft on the front side of themotor are both connected with the first gears. The mechanical truck-unloading device provided by the invention achieves the effects of improving the truck unloading speed and ensuring the unloading safety. Through ascending and descending of a placement plate, the mechanical truck-unloading device can conveniently and quickly unload goods from a truck; and a conveying device can convey goods on aconveying belt to the right side of the base plate, so that a user can unload the goods more conveniently.

Owner:JINYIMENG GRP CO LTD

Motorcycle Ramp with Resting Platform

InactiveUS20100223740A1Easy loadingSimple and safe processBridge applicationsLoading/unloadingEngineeringTruck

Motorcycle ramps that permit a single individual to safely and easily load a motorcycle to / from an elevated surface, such as a truck bed, without assistance of a second individual are described. The motorcycle ramp includes a fixed or moveable resting platform that receives and secures a rear wheel of the motorcycle, thereby preventing gravity from causing the motorcycle to roll uncontrolled down the ramp. When the rear wheel is resting on the platform, the person pushing the motorcycle up or down the ramp is more easily able to climb to and from the elevated surface, as the individual only needs to steady the motorcycle against sideways motion and needs not worry about backward motion down the ramp. The person is commonly able to prevent unwanted sideways motion using a single hand, freeing the person's other hand to assist in climbing up to or down from the elevated surface.

Owner:OGIO INT INC

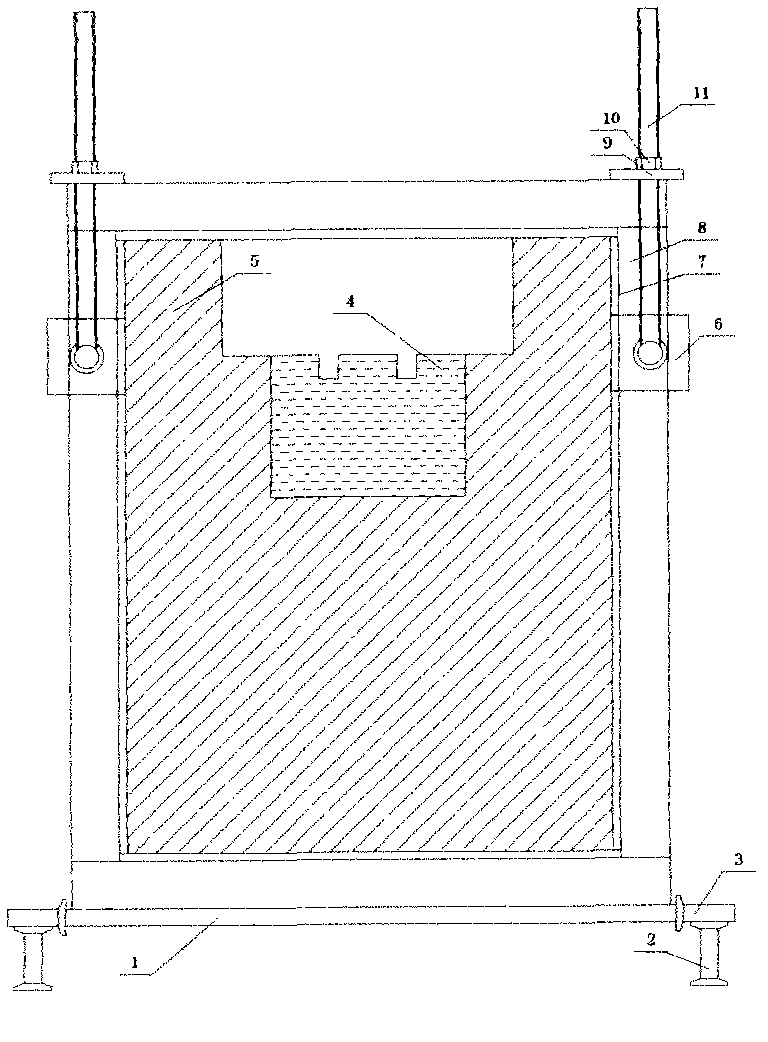

Novel discharging equipment of microcrystalline glass melting furnace

The invention discloses novel discharging equipment of microcrystalline glass melting furnace, made of heat resisting steel plate and refractory heat insulation material. The discharging equipment is composed of an outer-layer heat resisting steel plate, an inner-layer heat resisting steel plate and refractory heat insulation material in the inner-layer heat resisting steel plate, wherein at bottom of the outer-layer heat resisting steel plate, moving wheels are installed on laid light rails; refractory chute zirconia corundum bricks are placed inside frame of the inner-layer heat resisting steel plate; the frame of the inner-layer heat resisting steel plate has two sides welded with a lug, respectively, and is fixed with a screw rod on the outer-layer heat resisting steel plate; and upper part of the discharging equipment is welded with two lugs, and can be directly fixed with an I-shaped steel close to the melting furnace. The invention can reciprocate, freely adjust discharge port height in up-and-down manner, and control microcrystalline glass liquid level height and discharge amount; and has simple and compact structure, little investment, small occupied space, easy control, flexible adjustment, safe feeding and discharging, and less raw material waste.

Owner:淄博钰晶新型材料科技有限公司 +1

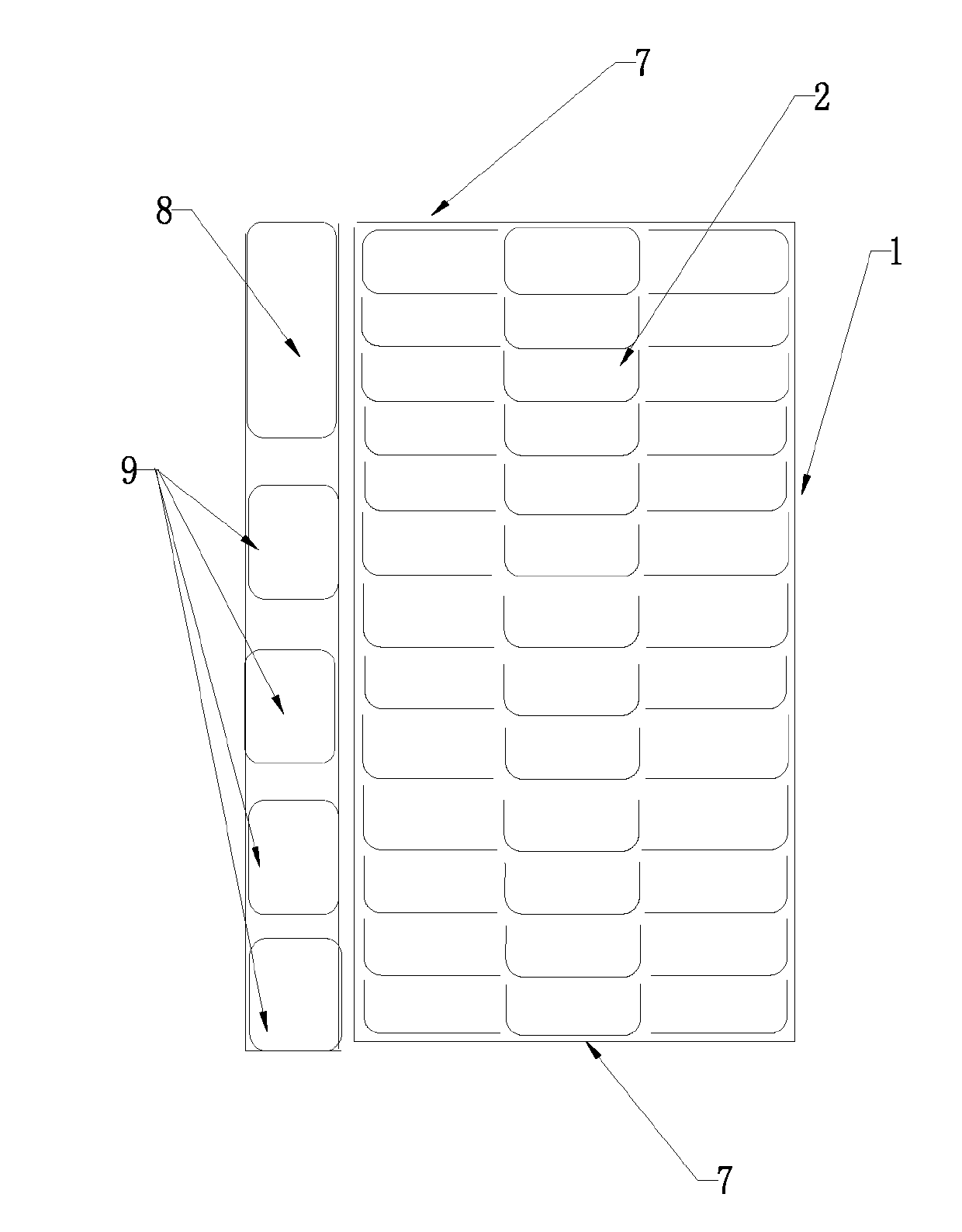

Sintered coal gangue brick composite heat preservation brick and transfer device thereof

InactiveCN111497911AIncrease ultimate loadImprove bearing capacityConstruction materialWallsVehicle frameEngineering

The invention provides a sintered coal gangue brick composite heat preservation brick and a transfer device thereof, and relates to the technical field of composite insulating bricks. The problem thatthe fireproof heat preservation structure of the composite heat preservation brickwork is damaged due to collision easily in the transferring process is solved. Moreover, due to smoothness of brick bodies, the brick bodies are prone to sliding in the transportation process and accordingly are likely to fall off, a common transfer device is mostly a flatcar or a cart, and in the loading and unloading process, the brick bodies and common brick bodies cannot be filled at will generally, the brick body transfer device comprises a frame body; and limiting plates are symmetrically mounted at the left end edge and the right end edge of the frame body correspondingly. The clamping grooves matched with the clamping strips on the box body are annularly formed in the vertical walls of the four sidesof the brick; the whole device can be pulled to move and the box body can be pulled to rotate through the push rod, bricks placed in the box body can be placed in a limited mode, the bricks are prevented from falling off or being damaged due to mutual collision in the transferring process, and the transferring integrity is guaranteed.

Owner:张祖超

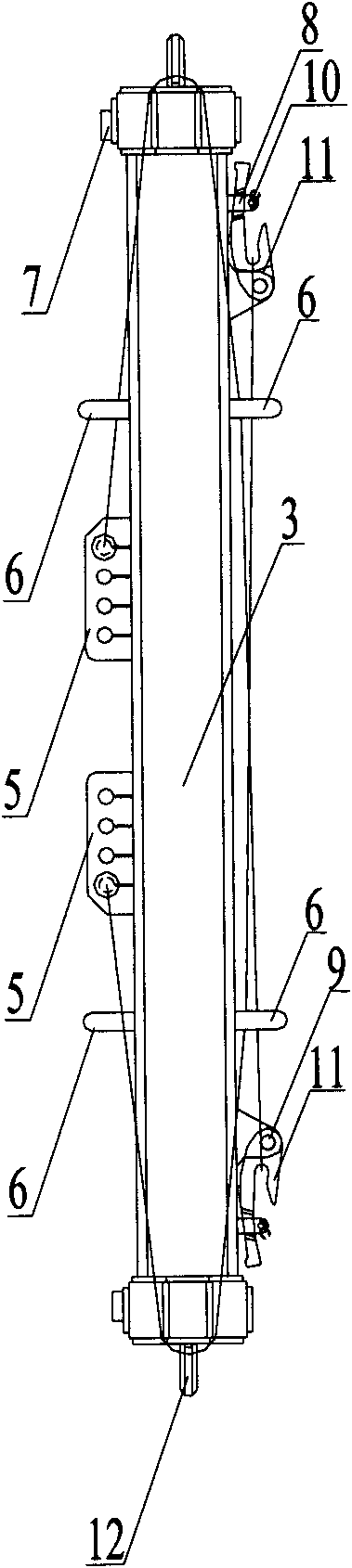

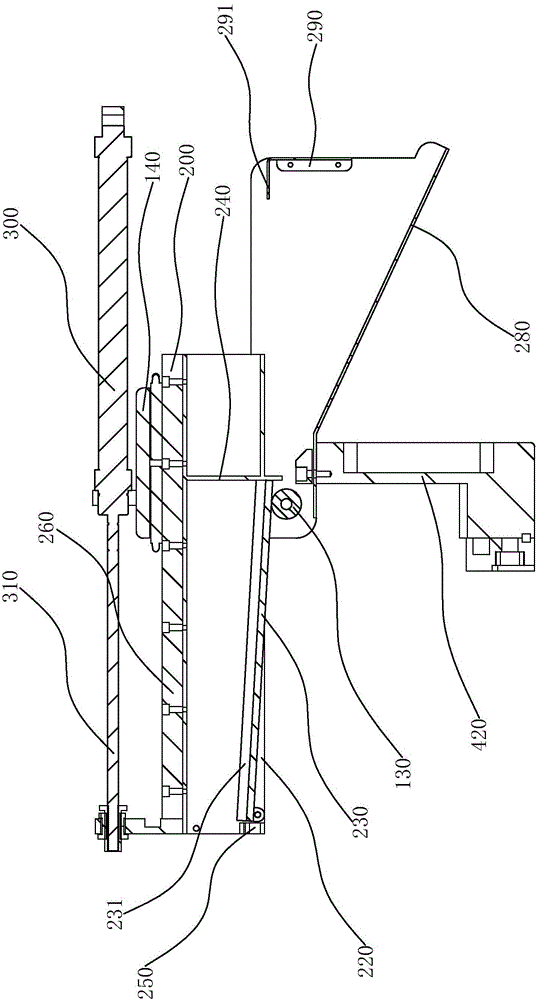

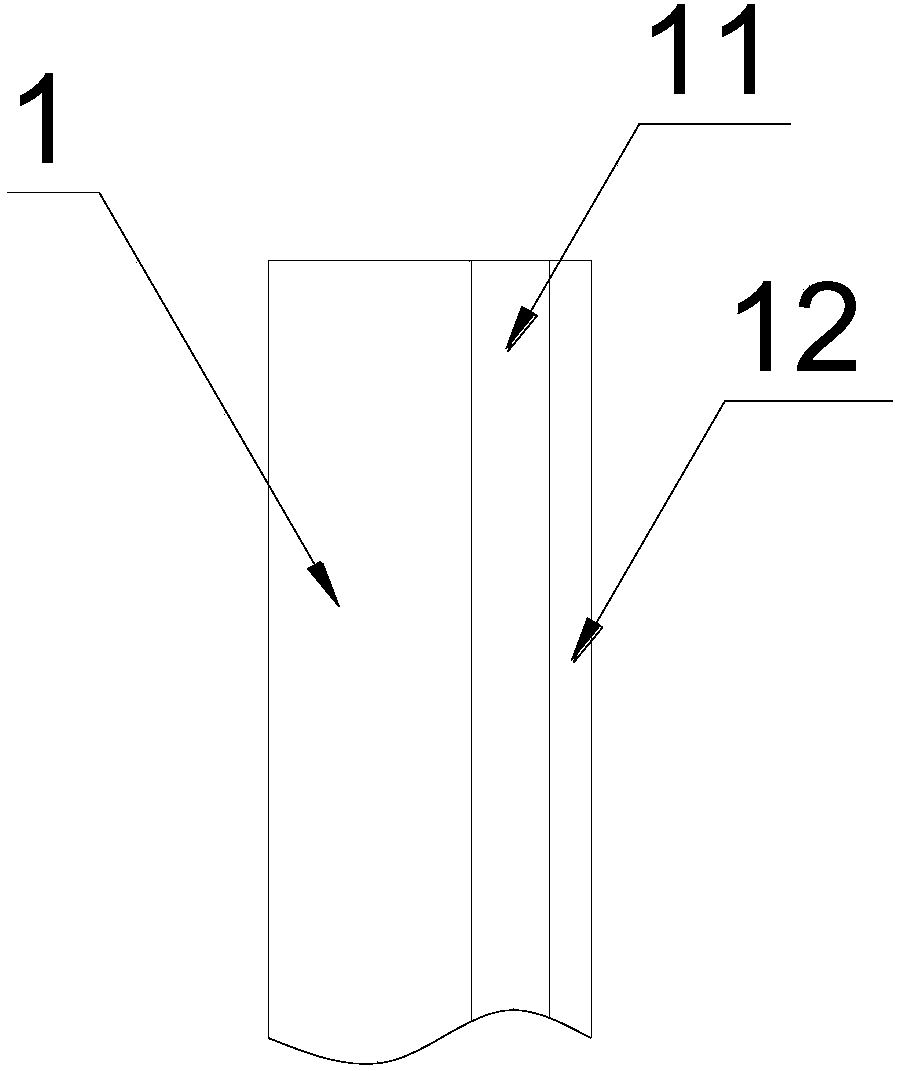

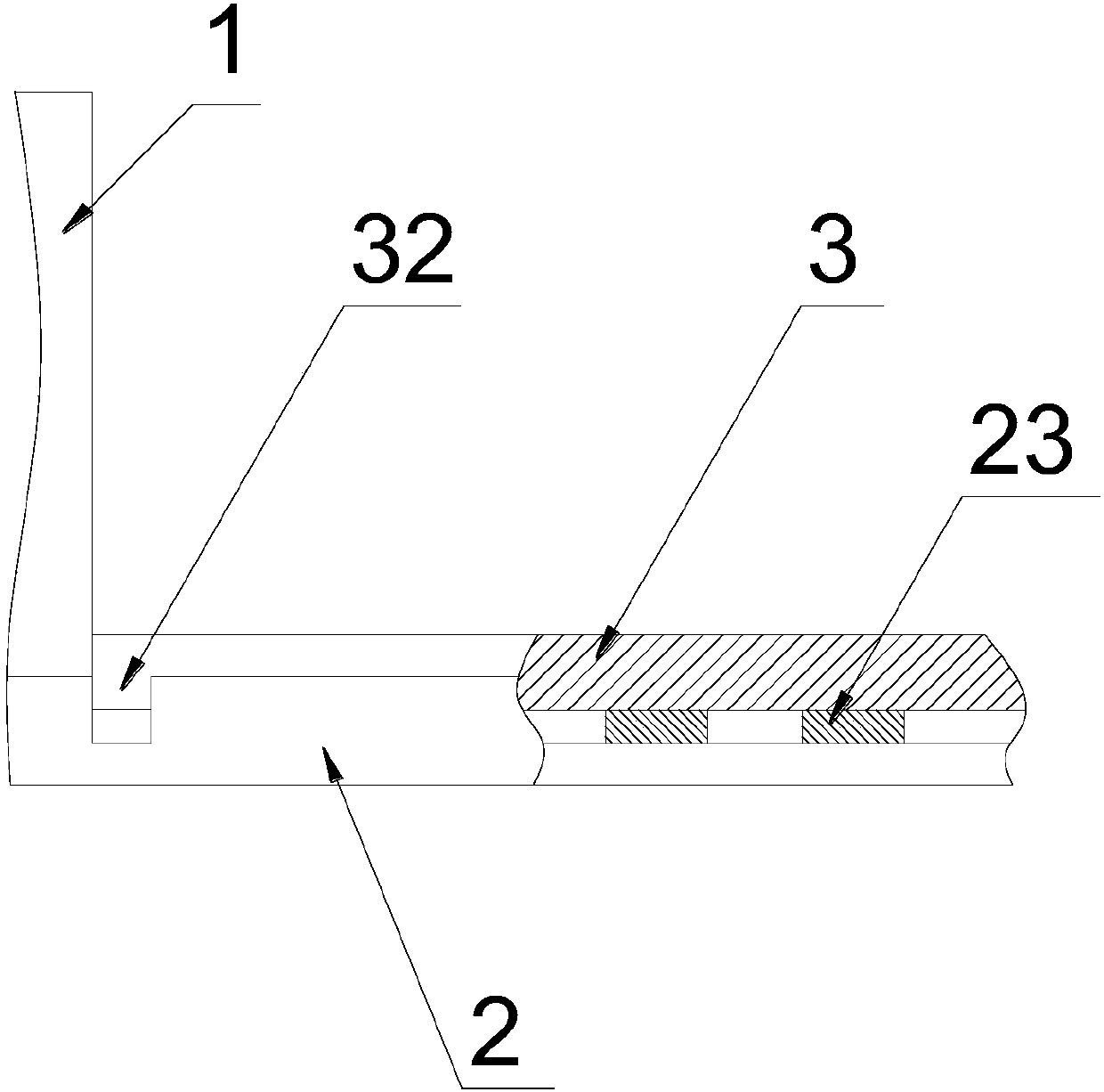

Turnover type upright column assembly, trailer and transportation method of long columnar goods

InactiveCN102145664AEasy to unloadSo as not to damageVehicle to carry long loadsLoad securingEngineering

The invention discloses a turnover type upright column assembly, a trailer and a transportation method of long columnar goods, wherein the turnover type upright column assembly is used for transporting the long columnar goods and comprises a sleeper beam, a rigid upright column and a flexible connecting piece, wherein a first connecting piece and a second connecting piece are respectively arranged on a first position and a second position on the sleeper beam; the rigid upright column is connected to one end of the sleeper beam in a rotating manner; a third connecting piece is arranged at a certain height of the upright column; the flexible connecting piece is provided with a first end and a second end which are respectively connected with the first connecting piece and the second connecting piece; and the flexible connecting piece extending between the first end and the second end penetrates through and tightens the upright column from the third connecting piece. In the invention, the damage on the structure of the trailer and the upright column due to the tension of the goods is avoided while the reliability of the transportation is ensured.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

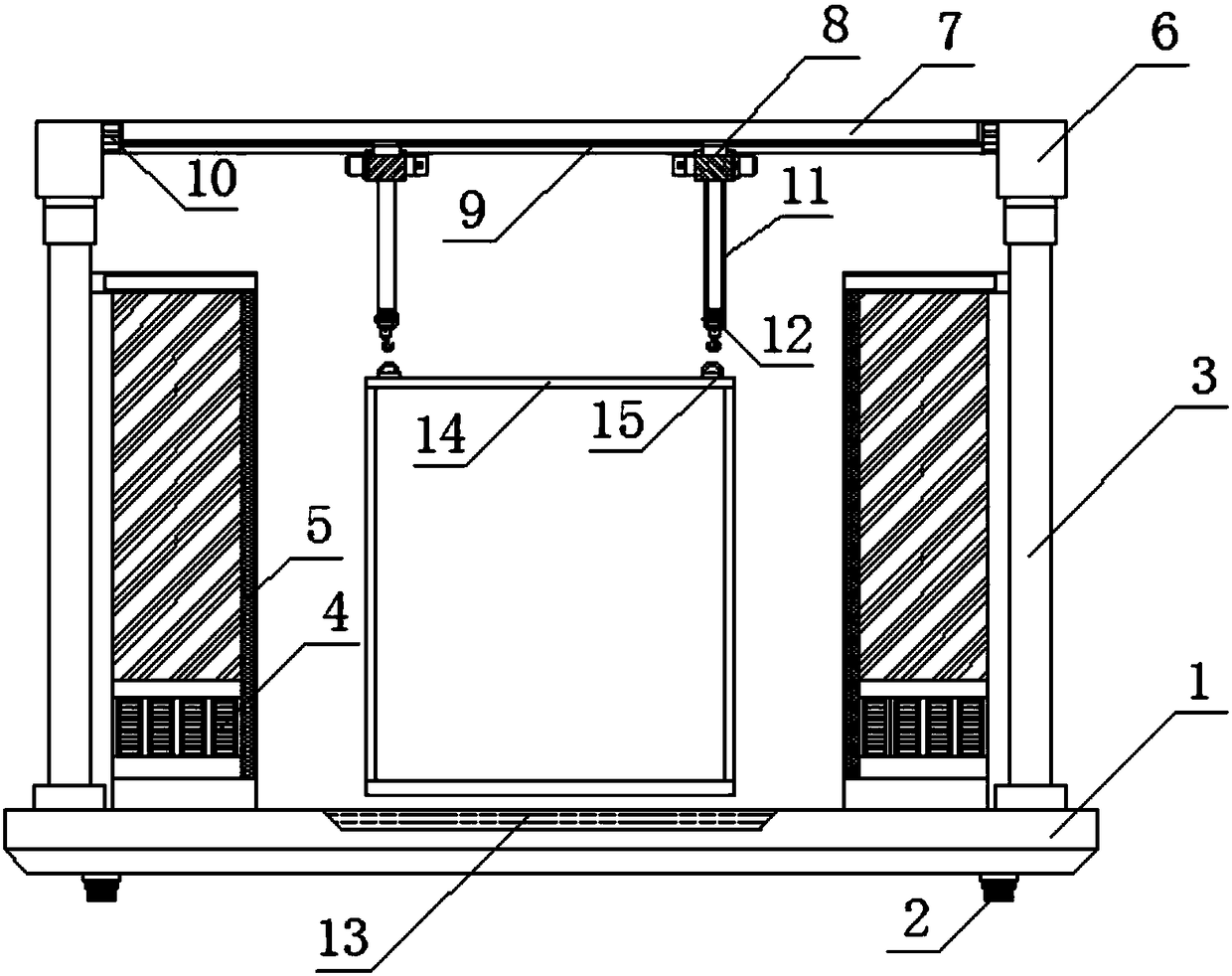

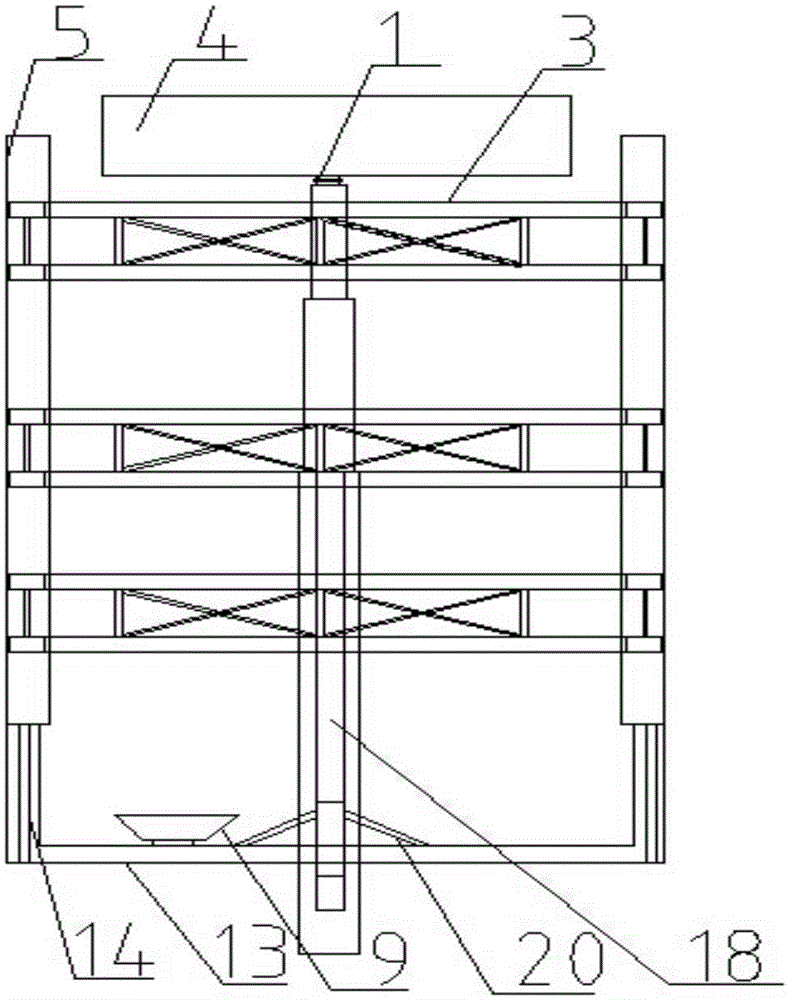

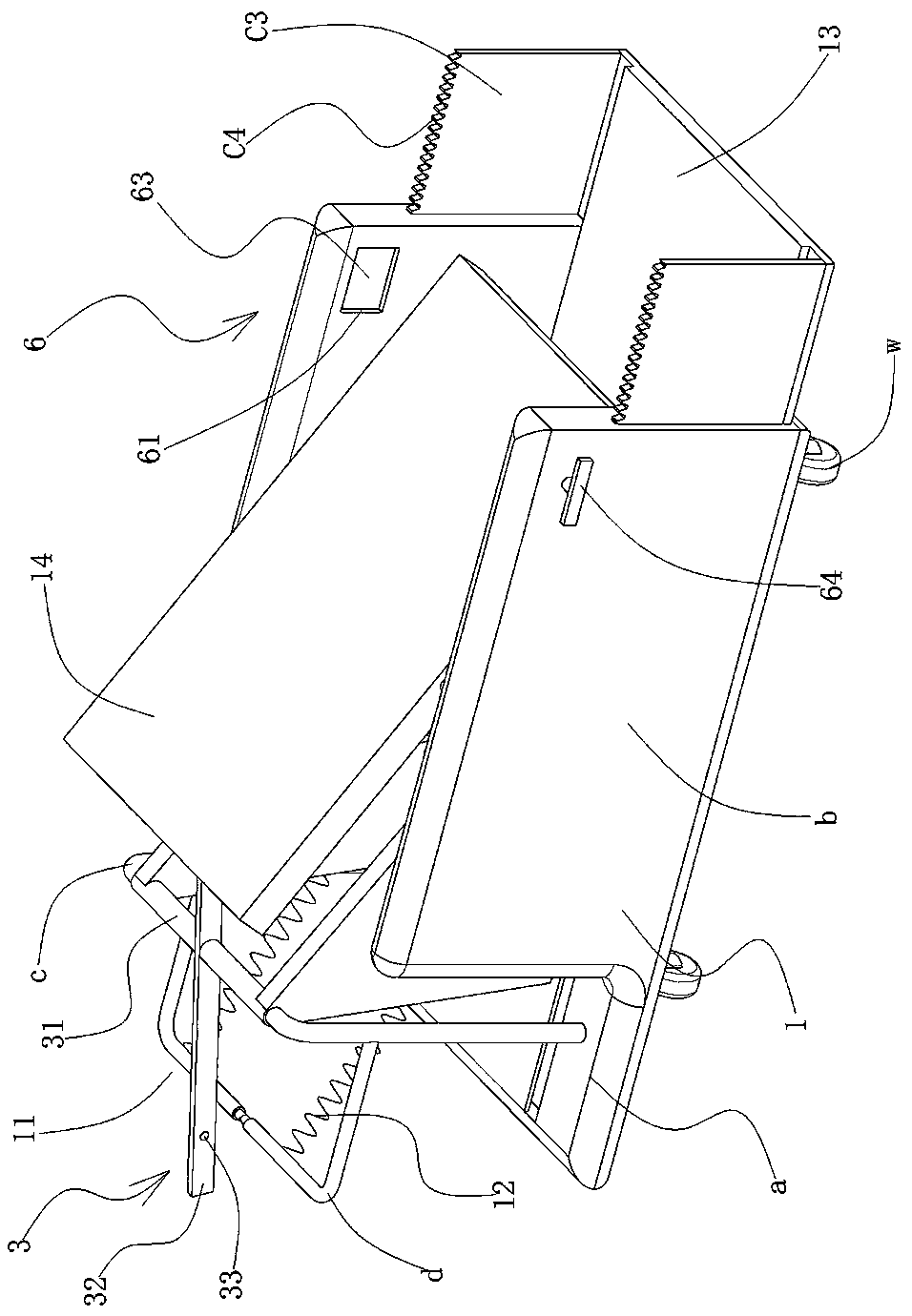

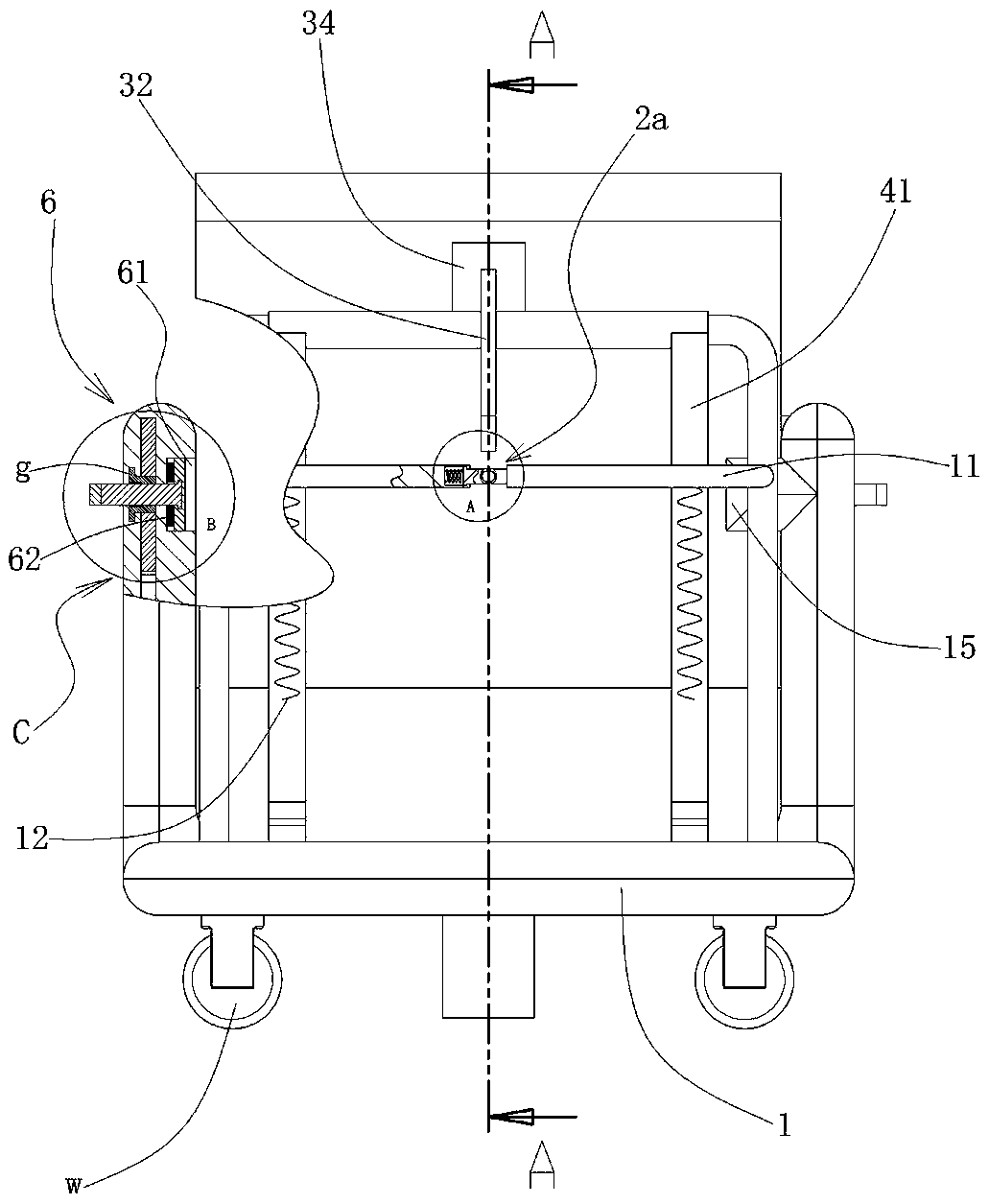

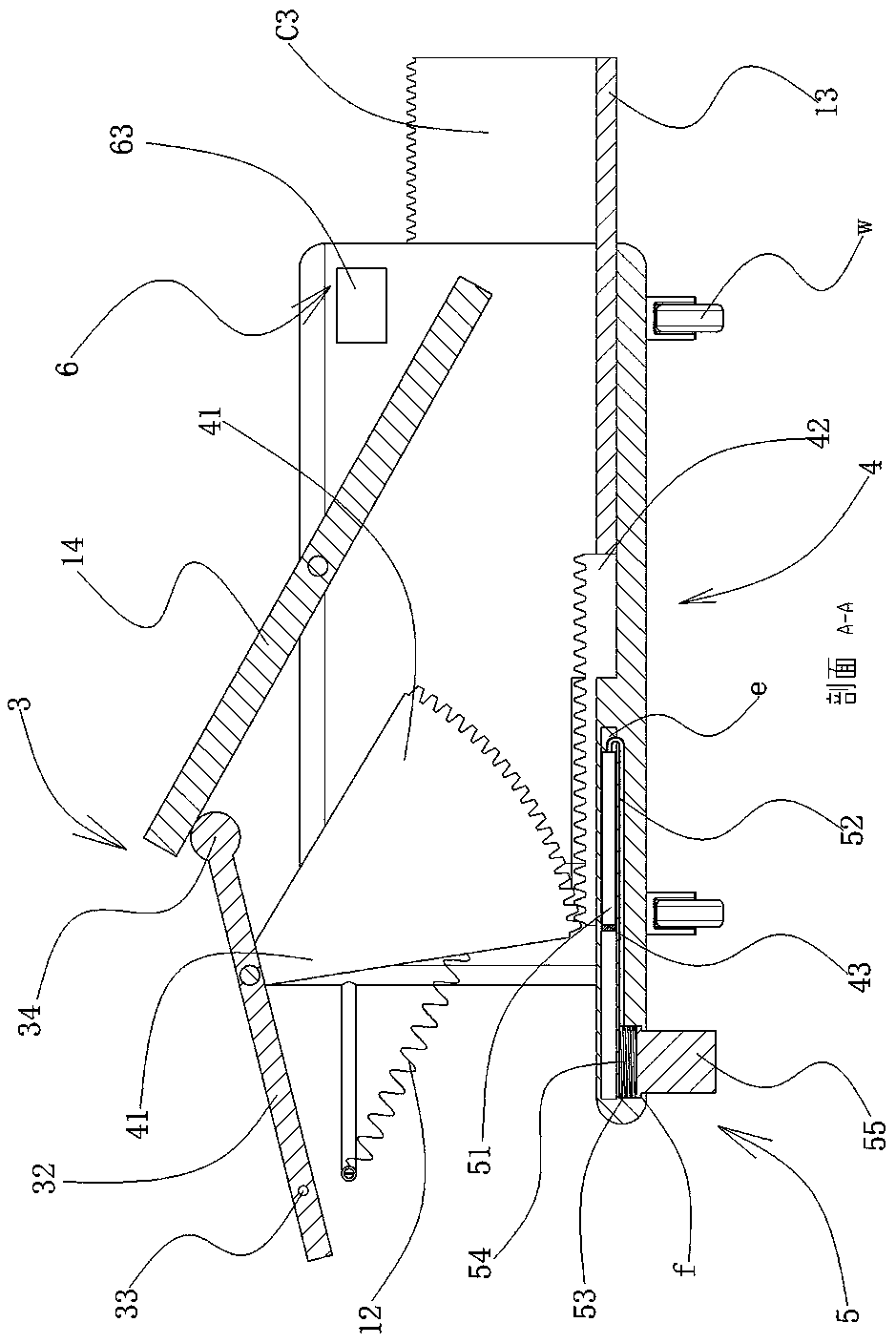

Movable hanging bracket for installation of power distribution cabinet

InactiveCN108545620AAdjust left and right positionEasy transferTrolley cranesSwitchgearEngineeringPower storage

The invention discloses a movable hanging bracket for the installation of a power distribution cabinet. The movable hanging bracket comprises a base and an electric hoist. Moving wheels are installedon four corners of the lower end face of the base. Two pillars are installed on the base. The top ends of two pillars are both provided with a fixed table. The inner side of each fixed table is provided with a beam spanning rack. The lower end of each beam spanning rack is provided with a slide rail. Two ends of each slide rail are both provided with a limit block. The slide rails are slidingly connected to the electric hoist. A hook is installed under the electric hoist. The hook is connected to the electric hoist through a steel wire. A cabinet is installed under the hook. The top end of thecabinet is provided with a suspension loop. Two sides of the cabinet are provided with protection plates. One side of each protection plate is provided with a power storage device. A groove is arranged right under the cabinet. A rotation roller is installed in the groove. Two ends of the rotation roller are provided with a plate. The provided movable hanging bracket can conveniently deliver a power distribution cabinet, can conveniently adjust the position, is convenient to use, and is convenient and safe for unloading.

Owner:盐城同舟电气有限公司

Unloading assisting device of liquefied natural gas

The invention relates to the technical field of an unloading assisting device and particularly relates to an unloading assisting device of liquefied natural gas. The unloading assisting device comprises two freight forklifts which are symmetrically fixed on a forklift portal frame; a second resetting spring is arranged between two baffles; two bearings are symmetrically arranged on the side wall, far away from one end of a limiting groove, of a horizontal blind hole; a rotary shaft is connected between inner rings of the two bearings; the middle axis of the rotary shaft is parallel to the middle axis of a through hole; the other end of a steel rope penetrates through the through hole and is connected with the two baffles and the rotary shaft; the baffle close to one end of a limiting groove is fixedly connected with the steel rope; and the baffle, far away from one side of the limiting groove, is movably connected with the steel rope. According to the unloading assisting device of the liquefied natural gas, manual unloading is not needed so that more labor is saved; a fuel gas tank does not swing greatly, so that unloading is safer; and when the forklift is used for unloading, a limiting plate is arranged on the forklift, so that unloading of the liquefied natural gas can be assisted better.

Owner:蚌埠启邦科技信息咨询有限公司

Pneumatic manipulator material receiving device

The invention provides a pneumatic manipulator material receiving device and belongs to the technical field of automatic lathes; the technical problems that workpieces are easy to damage during the material receiving process of a traditional material receiving device, and the material receiving performance of the traditional material receiving device is poorer are solved by the pneumatic manipulator material receiving device provided by the invention. The pneumatic manipulator material receiving device is arranged on a rack, and comprises a feed cover frame and a feed pipe, wherein the front part and the rear part of the feed cover frame are through; the feed pipe is arranged in the feed cover frame and can move in the feed cover frame; the top part of the feed pipe is connected with the feed cover frame; a notch is formed in the bottom part of the feed pipe, and a material receiving plate of which one end is hinged to the feed pipe is arranged in the notch, wherein the material receiving plate and the feed pipe can be opened and closed; a rolling shaft is arranged in the feed cover frame, and the material receiving plate is put on the rolling shaft; when the feed pipe moves on the feed cover frame, the material receiving plate moves on the rolling shaft, and the material receiving plate and the feed pipe are opened or closed. The pneumatic manipulator material receiving device provided by the invention has the beneficial effects during the falling process of the workpieces, the inertia of the workpieces is smaller, so that the impact between the workpieces is reduced; the friction between the workpieces and the material receiving plate is smaller, so that abrasion to the material receiving plate and the workpieces is smaller, and the service life of the material receiving plate is prolonged.

Owner:宁波宫铁智能科技有限公司

Fork of forklift for textile goods

The invention discloses a fork of a forklift for textile goods. The fork comprises a vertical plate, a transverse plate, a bearing plate and hooks. The vertical plate is vertically welded to the transverse plate. The side, facing the transverse plate, of the vertical plate is provided with a rubber pad. A cotton pad is arranged at the outer side of the rubber pad in a wrapping manner. The side, far away from the transverse plate, of the vertical plate is provided with the hooks, wherein the upper hook is arranged on the upper portion of the vertical plate, and the lower hook is arranged on thelower portion of the vertical plate. An opening of the upper hook and an opening of the lower hook are arranged oppositely, so that a limiting structure is formed. The transverse plate is provided with a containing groove. The bearing plate is placed in the containing groove. Elastic parts are fixedly arranged at the bottom of the containing groove and tightly pressed by the bearing plate. The end of the side, close to the vertical plate, of the bearing plate is provided with a clamping head. The end of the transverse plate is provided with a clamping groove in a matched manner. The clampinghead is fixedly placed in the clamping groove to form a limiting structure. The working end of the bearing plate is in a tip shape and extends out of the outer side of the transverse plate. The fork is safe to use, and the squeezing deformation, breakage and fuzziness phenomena of the textile goods are avoided.

Owner:合肥仨力机械制造有限公司

Production process and production device of sour soup sauce

ActiveCN113649378AEasy to cleanImprove cleaning efficiencyClimate change adaptationHollow article cleaningProcess engineeringWash bottle

The invention discloses a production process and a production device of sour soup sauce, relates to the technical field of sour soup sauce production. Aiming at the problem that the existing bottle cleaning effect is poor, the following scheme is put forward, and the production process comprises the following steps that S1, firstly chilies are washed, and then the washed chilies are smashed through a chili chopping machine; S2, then tomatoes are washed cleanly, and poured into a sauce making machine, and sticky liquid is made; S3, the chilies and the tomato liquid treated in the step S1 and the step S2 are poured into a stirrer to be mixed and stirred, finally sauce mixed uniformly is put in an environment of 30-35 DEG C for fermentation, and the fermentation time is controlled to be 3-5 days; and S4, bottles are washed cleanly through a bottle washing machine, and then the washed bottles are dried. The structure is simple, the bottles can be brushed through bristles while being washed with water, the washing effect is improved, garbage cleaning is more thorough, operation is easy, and use is convenient.

Owner:贵州侗寨记忆食品有限公司

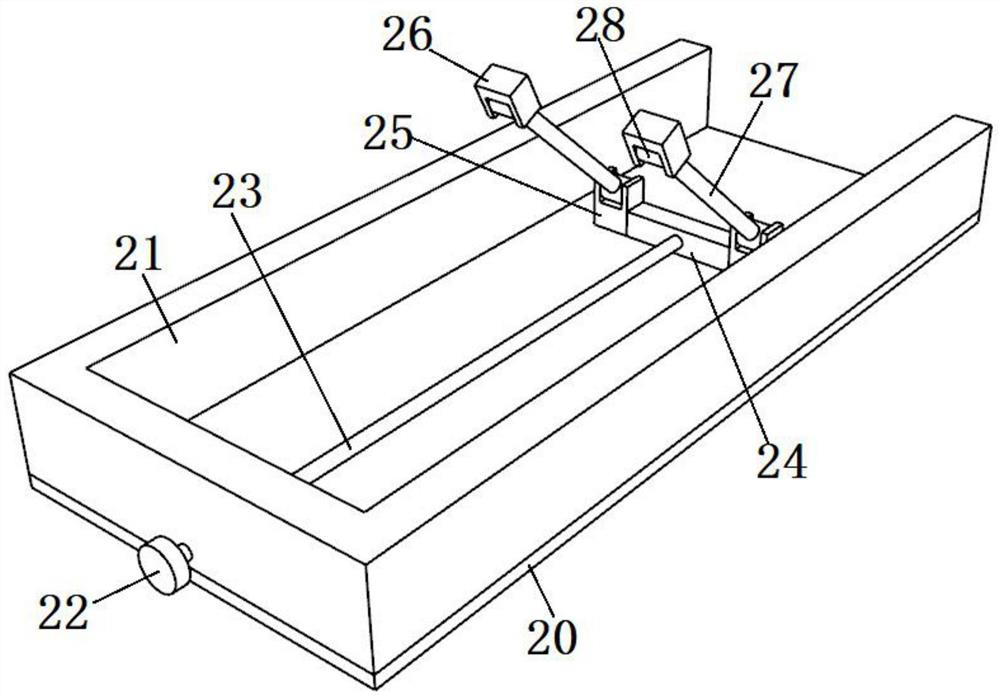

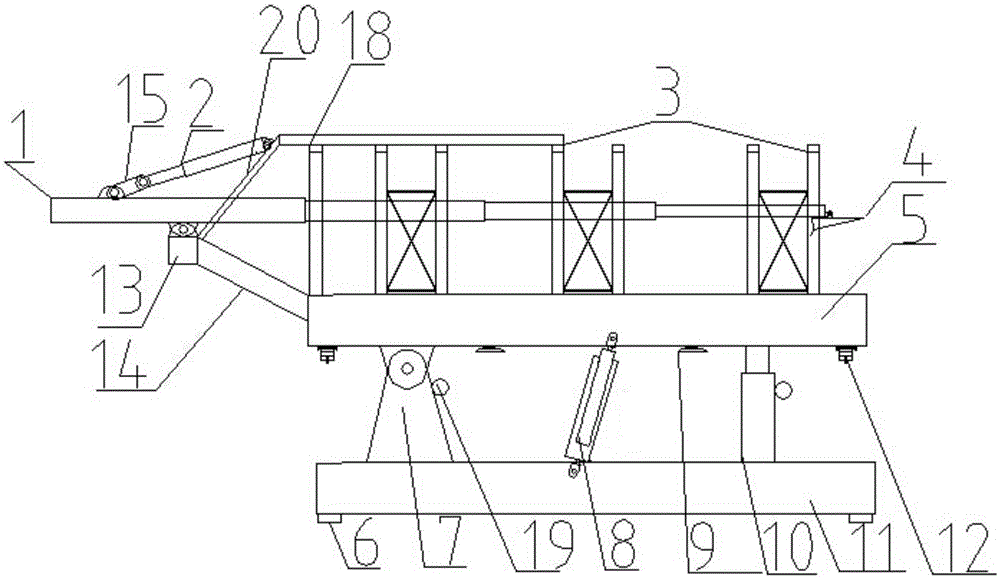

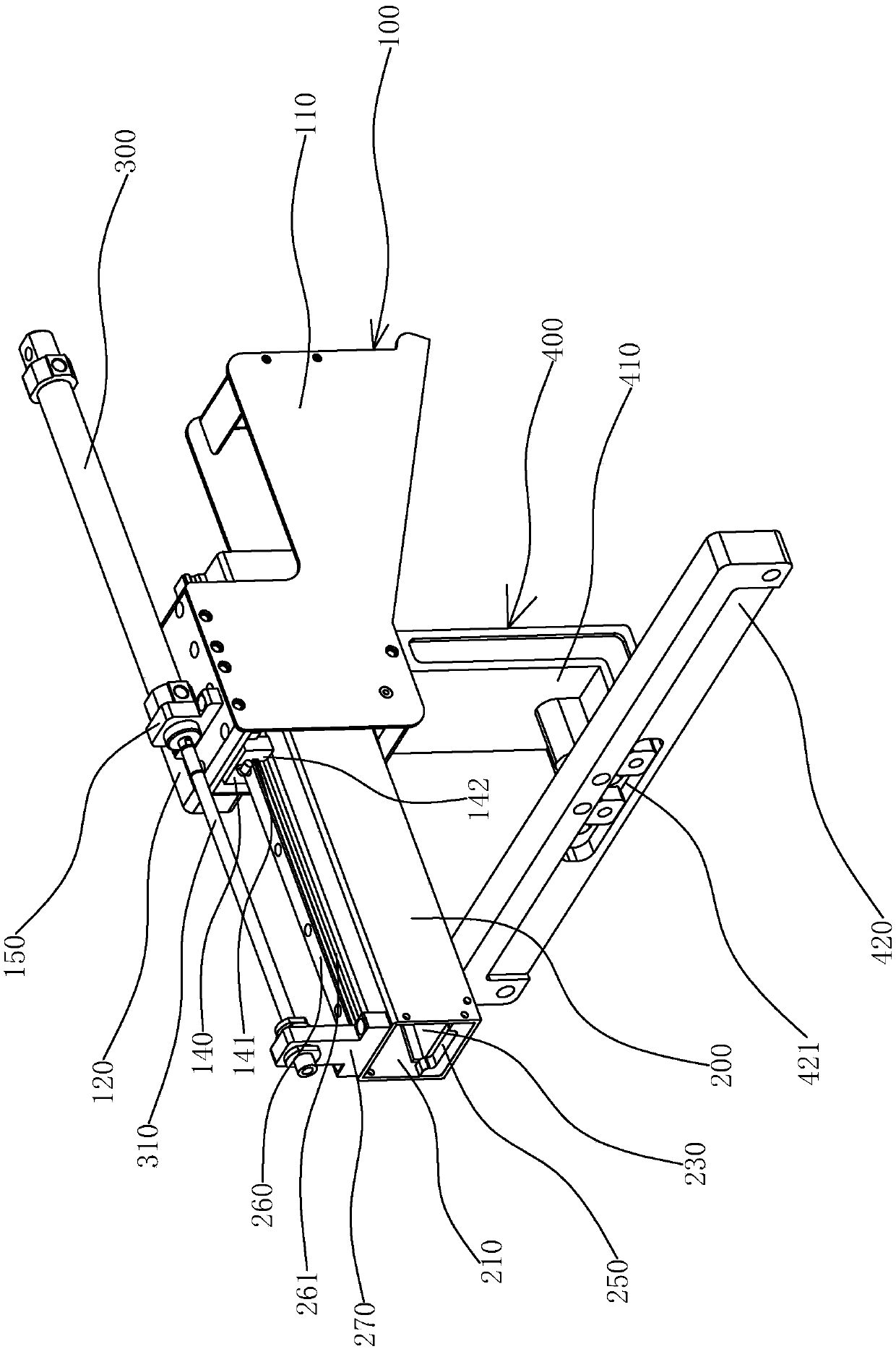

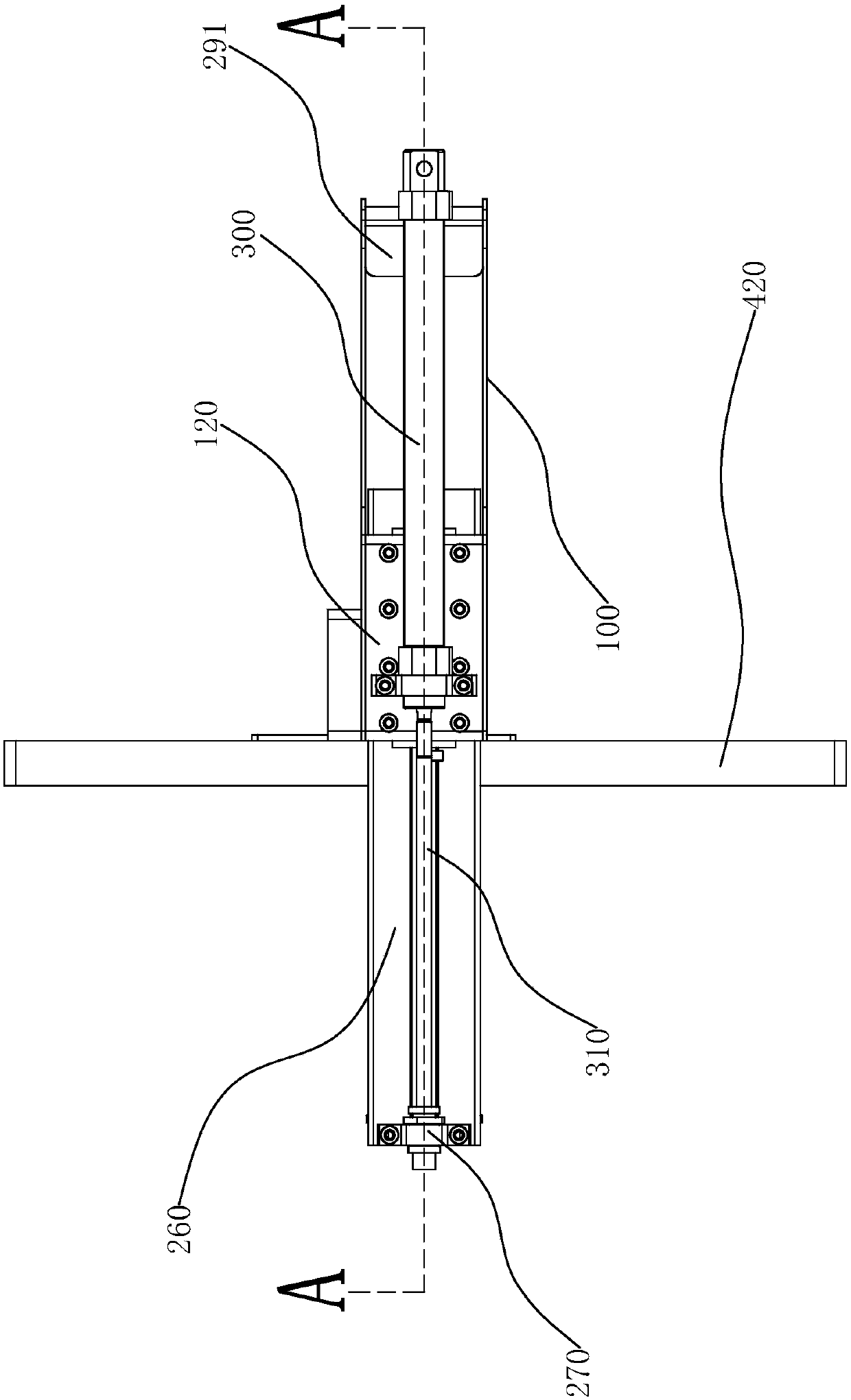

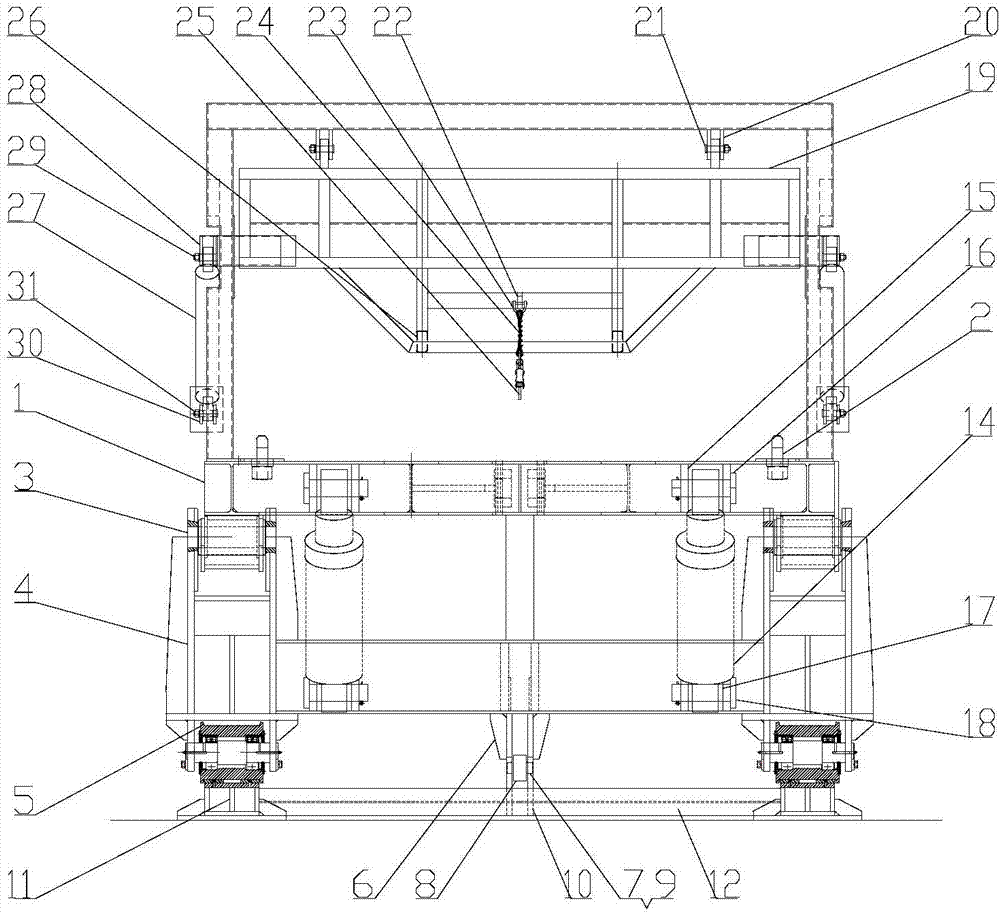

Container bulk cargo unloader

InactiveCN105110027AProvide work efficiencyReduce labor intensityBottle emptyingHydraulic ramPower equipment

The invention discloses a container bulk cargo unloader which relates to the technical field of container unloading. The container bulk cargo unloader provided by the invention is constituted of a base, an overturning structure, a telescoping structure, a left-right fine turning structure and a kind of dynamic equipment, wherein the base comprises two beams which are placed in parallel, a supporting beam is fixed on the front end of each ground beam, and a rotary support is fixed on the rear end; the overturning structure comprises two overturning beams, the rear end of the overturning beam is hinged on the rotary support, and the front end is clamped on the corresponding supporting beam of the same; a hydraulic oil cylinder I is connected between each ground beam and the overturning beam; one lock catch is installed on the lower surface of two ends of each overturning beam, the telescoping structure comprises a telescoping arm, and a shovel head is movably installed on the front end of the telescoping arm; and the left-right fine turning structure comprises fine turning idler wheels which are disposed on the bottoms of four ends of every two ground beams as well as a hydraulic oil cylinder II fixed horizontally on each rotary support and the supporting rod. The container bulk cargo unloader realizes unloading quickly, has high working efficiency, is safe and reliable and reduces labor strength.

Owner:胡居宝 +1

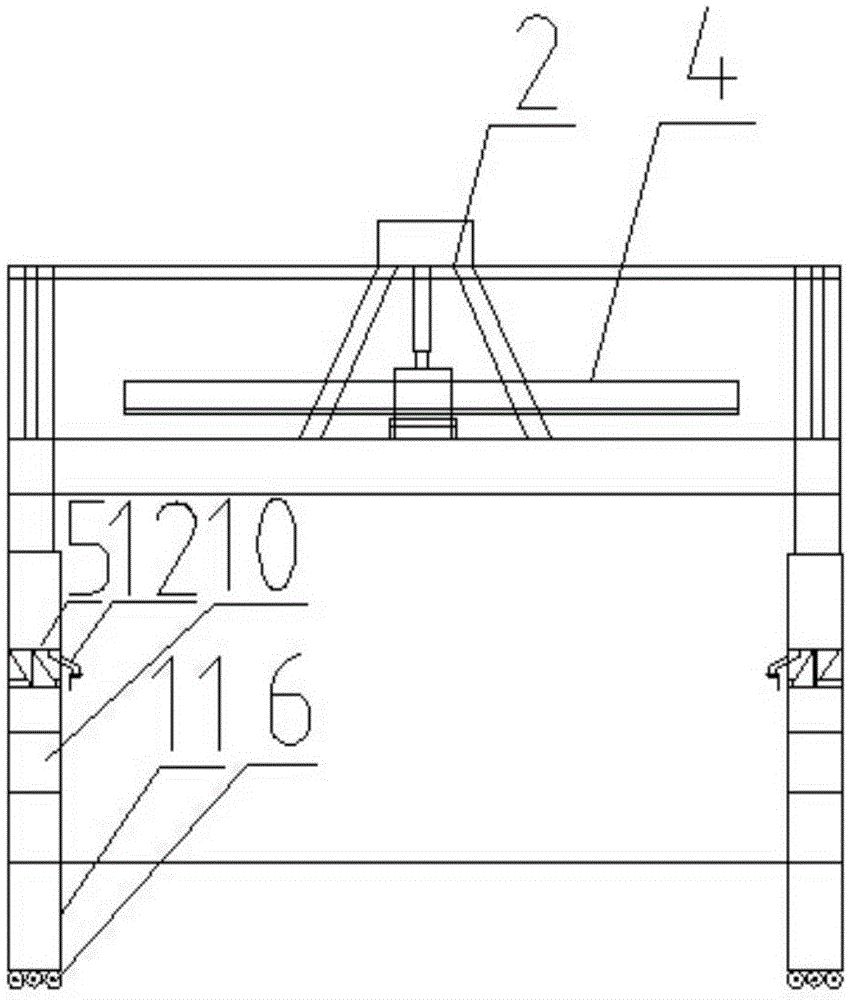

Novel logistics unloading device

The invention relates to a novel logistics unloading device. The novel logistics unloading device comprises a bottom plate and wheels. A sleeve is disposed at the left end of the bottom plate; multiple pairs of through holes are uniformly formed in the left side and the right side of the sleeve from top to bottom; a first fulcrum bar is embedded into the sleeve; a second fulcrum bar is vertically disposed on the bottom plate located on the right side of the sleeve; a buffer plate is further disposed on the second fulcrum bar. The unloading device further comprises a first sliding plate and a second sliding plate. The right end of the first sliding plate is hinged to the left end of the buffer plate; the left end of the first sliding plate makes contact with and abuts against the top end of the first fulcrum bar; the left end of the second sliding plate is hinged to the right end of the buffer plate; a rubber cushion block is further disposed at the right end of the bottom of the second sliding plate; a buffer spring is further connected between the bottom of the second sliding plate and the top of the bottom plate. By means of the structure, the novel logistics unloading device can conveniently, rapidly and safely unload goods, so that goods safety and personal safety of unloading staff are greatly guaranteed.

Owner:CHENGDU JIAMEIJIA SCI & TECH

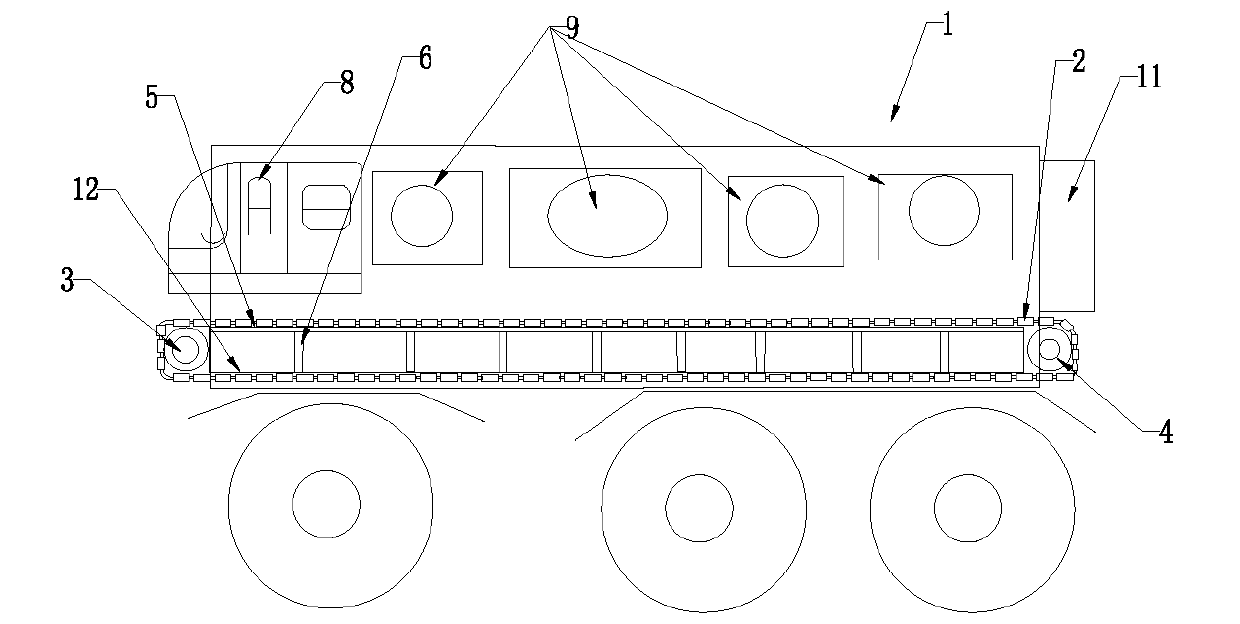

Full-box crawler-type large-scale mine truck

InactiveCN103273867AIncrease load capacityPrevent rolloverLoading/unloading vehicle arrangmentTransportation itemsControl theoryTruck

The invention relates to the field of mine trucks, in particular to a full-box crawler-type large-scale mine truck. The full-box crawler-type large-scale mine truck comprises a truck bed assembly, a front axle steering assembly and a rear axle power assembly, wherein the truck bed assembly is arranged above the front axle steering assembly and the rear axle power assembly, a crawler device is arranged on the lower portion of the inner portion of a truck bed of the truck bed assembly, and a cab and a power system device are arranged at the side of the truck bed assembly. The full-box crawler-type large-scale mine truck has the advantages of facilitating unloading, and being capable of improving the load capacity, free of backup and capable of avoiding turnover.

Owner:卢龙腾

Material receiving device

InactiveCN109940443AExtended service lifeAvoid damageMetal working apparatusEngineeringMechanical engineering

The invention provides a material receiving device and belongs to the technical field of automatic lathes. The material receiving device solves the technical problems that when an existing material receiving device is used in the material receiving process, a workpiece is easy to damage, and the material receiving performance of the existing material receiving device is poor. The material receiving device is installed on a machine frame and comprises a material cover frame and a material pipe, wherein the material cover frame is arranged in a front-and-back communicating mode, and the materialpipe is arranged in the material cover frame and can move in the material cover frame. The top of the material pipe is connected with the material cover frame. A notch is formed in the bottom of thematerial pipe. A material receiving plate is arranged in the notch, wherein one end of the material receiving plate is hinged to the material pipe and can be opened or closed together with the material pipe. A roller shaft is arranged in the material cover frame, and the material receiving plate is arranged on the roller shaft. When the material pipe moves on the material cover frame, the materialreceiving plate moves on the roller shaft, and the material receiving plate and the material pipe are enabled to be opened or closed. The material receiving device has the beneficial effects that inthe falling process of workpieces, the inertia of the workpieces is small, the impact between the workpieces is reduced, the friction between the workpieces and the material receiving plate is small,the abrasion of the material receiving plate and workpieces is small, and the service life of the material receiving plate is prolonged.

Owner:王芳

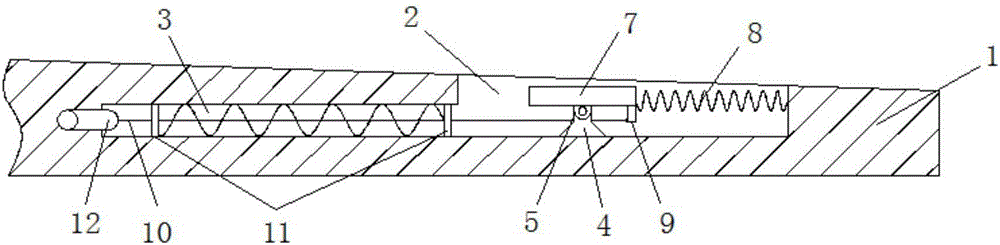

Gas tank unloading device

The invention discloses a gas tank unloading device. The following scheme is provided currently in order to solve the problems that when unloaded, gas tanks are manually carried, the carrying workloadis high, the gas tanks speed up to fall to the ground in the falling process under the gravity effect, the gas tanks easily collide with the ground, the gas tanks are not easily controlled, and the danger coefficient is high in the unloading process. The gas tank unloading device comprises a bottom plate and a top plate. The outer wall of the top of the bottom plate and the outer wall of the bottom of the top plate are fixedly connected with a sliding rod and a first threaded rod through bolts, the outer wall of the first threaded rod is connected with a sleeve block through a thread, the outer wall of the sleeve block is connected with a base block through a bearing, a connecting shaft is welded to the outer wall of one side of the base block, one end of the connecting shaft is connectedwith an unloading plate through a bearing, and a groove is formed in the inner wall of the unloading plate. The gravitational potential energy of the gas tanks is converted into the elastic potentialenergy of shrinking springs, unloading of the gas tanks slows down, the gas tank unloading device is safe and reliable and easy to control, the manpower is saved, and potential safety hazards of collisions during manual carrying to the gas tanks are eliminated.

Owner:徐州多元机械科技有限公司

Self-unloading mine car supporting mechanism

InactiveCN105292148ACan be raised and loweredSimple structureTipping wagonsEngineeringRolling chassis

The invention discloses a self-unloading mine car supporting mechanism. A lifting mechanism is arranged between a chassis and a stock bin, a height sensor is mounted at the upper end of the right side of the lifting mechanism, second supporting posts are mounted at the upper parts of first supporting posts, silencers are arranged on the inner sides of the second supporting posts, telescopic poles are arranged between the stock bins and the second supporting posts, one ends of cross beams are fixedly connected with the stock bin, the other ends of the cross beams are hinged to third supporting posts, locking devices are mounted at the hinge parts of the cross beams and the third supporting posts, jack-up alarming devices are mounted on the right sides of the second supporting posts, intelligent detecting devices are mounted inside the first supporting posts, and the height sensor and the intelligent detecting devices are all electronically connected with a voice broadcast device. The self-unloading mine car supporting mechanism provided by the invention has the characteristics of simple structure, strong structural stiffness, good stability, safety in use, long service life and the like, can effectively improve the production efficiency, and has a market promotion value.

Owner:CHONGQING YONGCHUAN DISTRICT FUQIANG MACHINERY MFG

Plaster decocting equipment with automatic temperature control adjusting function

InactiveCN112402257AEvenly heatedIncrease heatPharmaceutical product form changeDomestic articlesMedicinal herbsTemperature control

The invention discloses plaster decocting equipment with an automatic temperature control adjusting function, and relates to the technical field of plaster decocting equipment. The problems that currently, when people decoct plaster, upper, middle and lower layers of the plaster are affected by the outside, consequently, the temperatures are different, effective components in medicinal materials cannot be well excited, the temperature is not easy to control in the plaster decocting process, the medicinal materials are prone to burn, and consequently, the product quality is greatly influenced are solved. An upper heating plate is installed at the upper end of one side in a decocting box, a middle heating plate is installed at the lower end of the other side in the decocting box, bottom heating plates are installed on the two sides of the lower end in the decocting box correspondingly, and a temperature compensation heating plate is installed at the lower end in the decocting box; the temperature compensation heating plate, the bottom heating plates, the middle heating plate and the upper heating plate are all fixedly connected with the decocting box; and an upper temperature sensoris installed at the upper end of the other side in the decocting box.

Owner:江西回医堂中医药科技有限公司

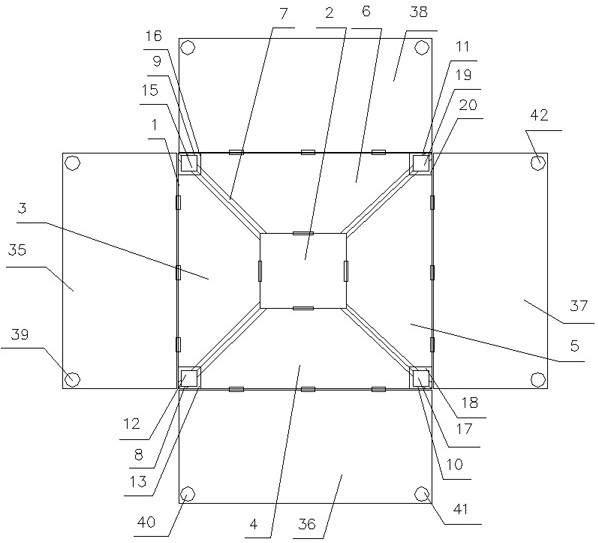

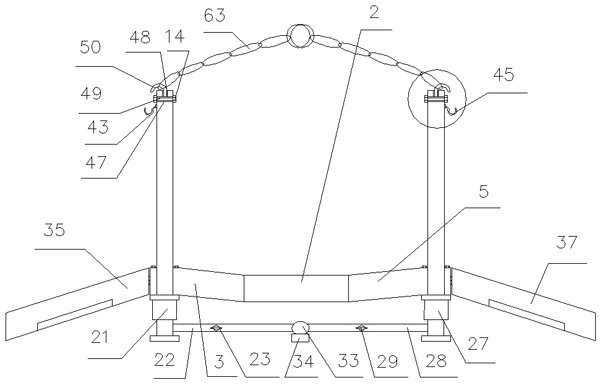

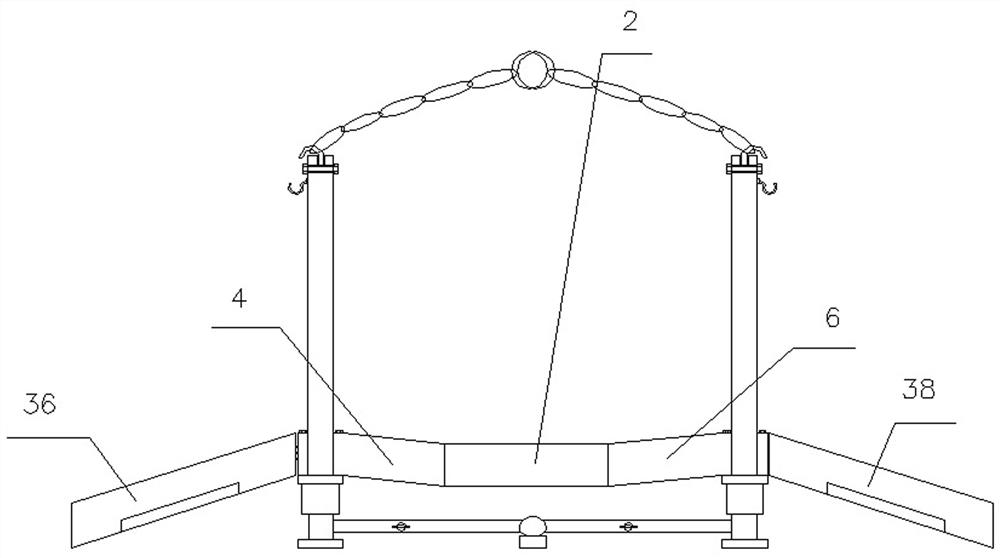

A kind of road and bridge construction loading and unloading device and using method

ActiveCN113401513BHas a connecting roleFirmly connectedClimate change adaptationLarge containersArchitectural engineeringStructural engineering

A road and bridge construction loading and unloading device and use method. The composition of this product includes: a bottom support plate, the bottom support plate includes a central square plate, and the central square plate is connected to the left bottom plate, the front bottom plate, the right bottom plate, and the rear bottom plate in sequence through hinges, and the left bottom plate , The front bottom plate, the right bottom plate, and the rear bottom plate are all low inside and high outside. The left bottom plate, the front bottom plate, the right bottom plate, and the rear bottom plate are all Both sides are hypotenuse, the hypotenuse is bonded to the magnetic plate, between the left bottom plate and the front bottom plate, between the front bottom plate and the right bottom plate, and the right bottom plate It is connected with the rear bottom plate and between the left bottom plate and the rear bottom plate through the magnetic plate. The invention is used for loading and unloading of road and bridge construction.

Owner:黑龙江农垦建工路桥有限公司

Garment transfer trolley facilitating unloading

InactiveCN110949476AEasy to fixEasy to removeHand carts with multiple axesHand cart accessoriesStructural engineeringMechanical engineering

The invention provides a garment transfer trolley facilitating unloading. The trolley comprises a trolley body provided with a plurality of universal wheels, two push rods which are provided with locking devices and are symmetrically distributed are arranged at the tail end of the trolley body; a lever device is hinged to each push rod, driving devices connected with the lower bearing plate are arranged at the two ends of each lever device, one end of each driving device is connected with the corresponding push rod through a spring, and an anti-reversing device is arranged on one side of eachdriving device; an upper bearing plate is hinged to the upper end of the vehicle body. A first fixing block is arranged below the tail end of the upper bearing plate; a retractable fixing device is arranged below the front end of the upper bearing plate. According to the garment transfer trolley convenient to unload, by means of cooperation of the lever device, the driving device, the upper bearing plate and the lower bearing plate, more labor is saved during unloading, and transfer of a whole box of garments is facilitated.

Owner:宿迁市正益纺织有限公司

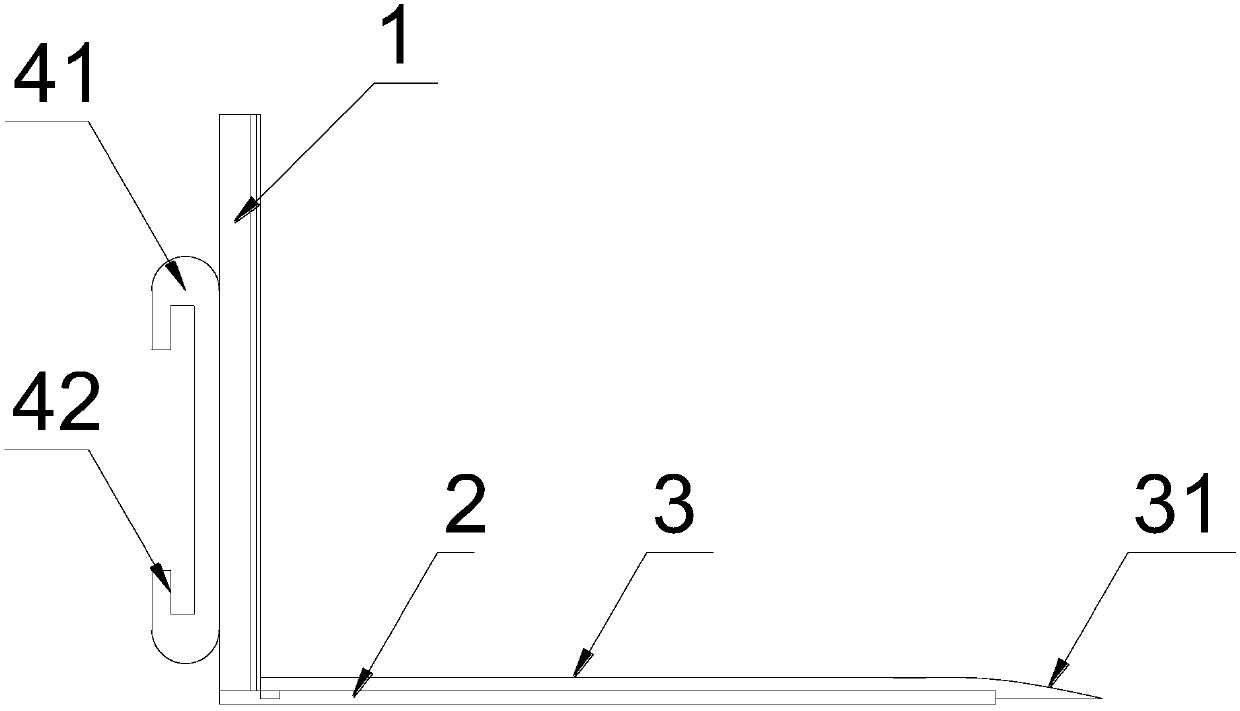

Large-diameter pipe falling-preventing device

InactiveCN112278770AAvoid collision damageMeet the needs of useConveyorsSupporting framesEngineeringFront edge

The invention discloses a large-diameter pipe falling-preventing device, and relates to the technical field of pipe carrying devices. The large-diameter pipe falling-preventing device comprises a bottom plate, wherein rolling wheels are fixedly installed at the four corners of the lower surface of the bottom plate in a rectangular shape; fixing mechanisms are arranged at the positions, close to the front edge and the rear edge, of the upper surface of the bottom plate; a rectangular sleeve is fixedly installed at the position, close to the left side, of the upper surface of the bottom plate; atransverse plate is fixedly installed in the rectangular sleeve through a lifting mechanism; connecting plates are fixedly installed at the positions, close to the front edge and the rear edge, of the right side face of the transverse plate; sliding mechanisms are fixedly installed at the positions, close to the right side, of the front edge and the rear edge of the upper surface of the bottom plate; and installing frames are fixedly installed between the upper surfaces of the sliding mechanisms and the connecting plates. According to the large-diameter pipe falling-preventing device, a conveying belt is matched with a baffle, the pipe can be effectively prevented from colliding with the ground and being damaged in the discharging process, meanwhile, the use requirements of vehicles withdifferent heights can be met, the falling device is stable in fixation and cannot move in the discharging process, and the pipe discharging process is safe.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

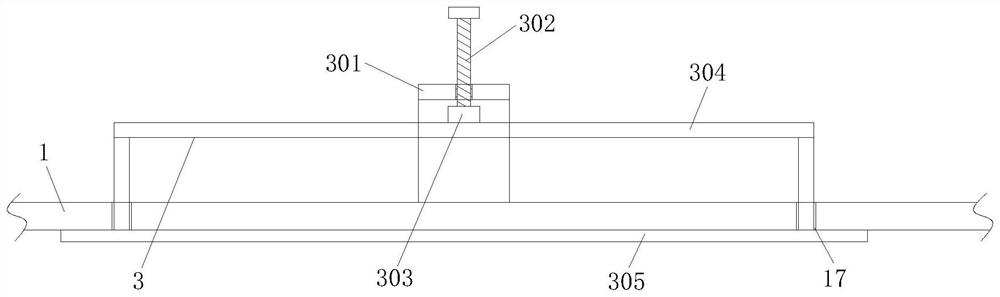

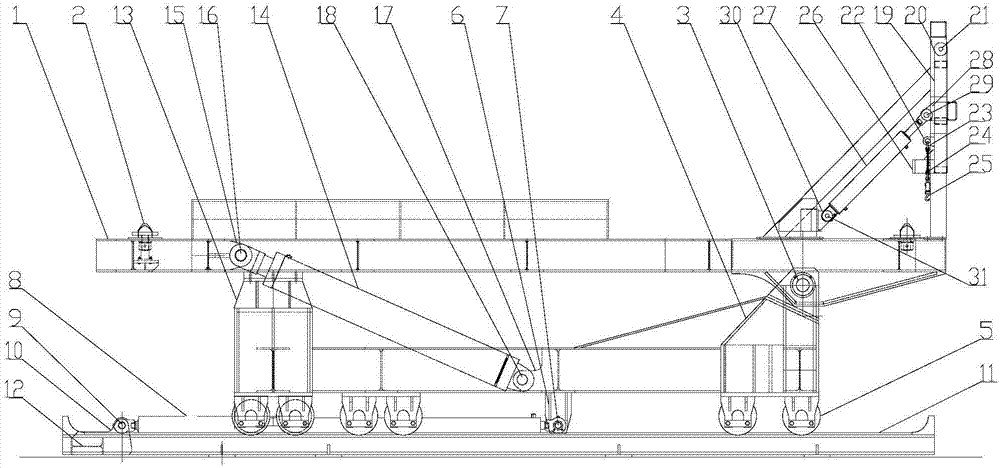

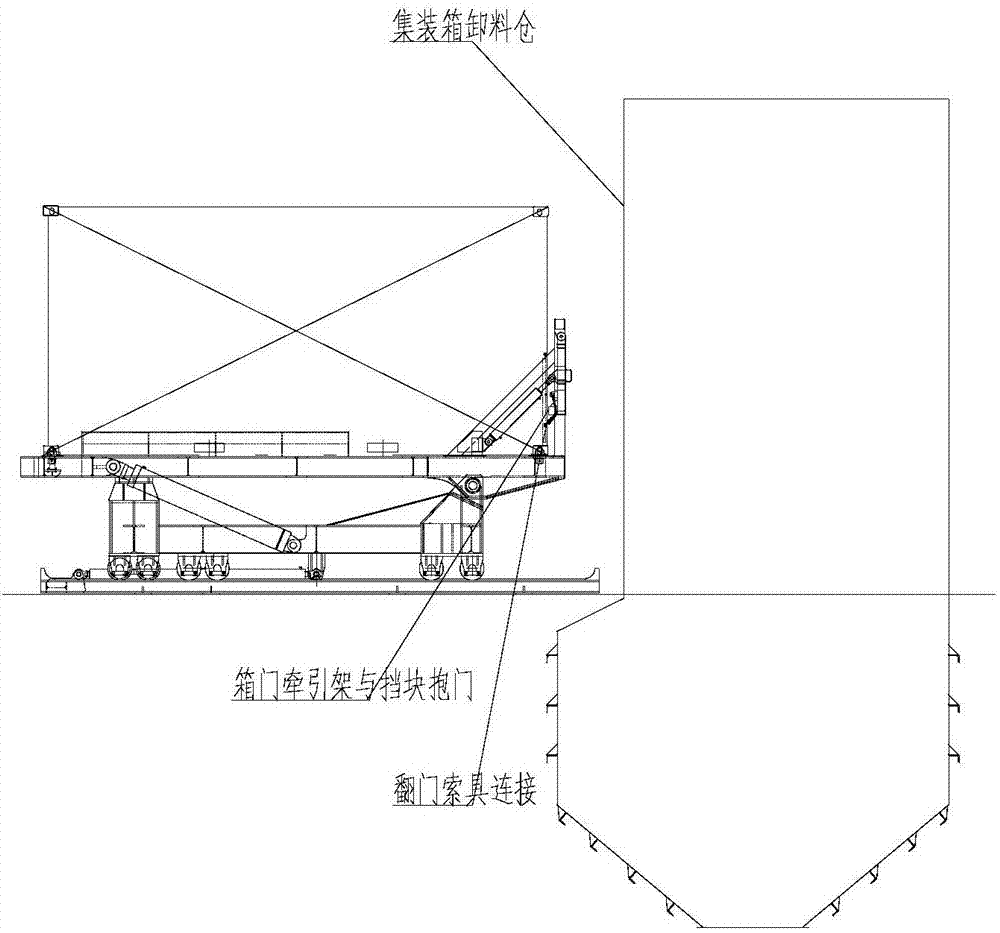

Container turnover platform capable of achieving door holding and door opening

PendingCN107055117AAvoid damageSafe and controllable door openingConveyorsBottle emptyingVehicle frameTraction frame

The invention discloses a container turnover platform capable of achieving door holding and door opening. The container turnover platform capable of achieving door holding and door opening can guarantee the safety of operation personnel to mainly aim at the situation that certain danger exists when a container door of an existing container is opened. The container turnover platform comprises a frame. The front side of the frame is hinged to the front portion of a bracket. A supporting part for supporting the rear portion of the bracket is arranged on the rear side of the frame. The bracket and the frame are hinged to the two ends of a telescopic device correspondingly. A vertical blocking frame is fixedly connected to the front side of the bracket and at least comprises two stand columns arranged to be perpendicular to the bracket. A container door traction frame is hinged to the upper side of the vertical blocking frame. The container door traction frame and the bracket are hinged to the two ends of the telescopic device correspondingly. Rigging used for connecting the container door traction frame with a container door handle of a container and a door holding check block used for tightly holding the container door of the container are arranged on the container door traction frame. The container turnover platform can guarantee the safety of the operation personnel in the container unloading process.

Owner:HUATIAN ENG & TECH CORP MCC

A liquefied natural gas unloading auxiliary device

The invention relates to the technical field of an unloading assisting device and particularly relates to an unloading assisting device of liquefied natural gas. The unloading assisting device comprises two freight forklifts which are symmetrically fixed on a forklift portal frame; a second resetting spring is arranged between two baffles; two bearings are symmetrically arranged on the side wall, far away from one end of a limiting groove, of a horizontal blind hole; a rotary shaft is connected between inner rings of the two bearings; the middle axis of the rotary shaft is parallel to the middle axis of a through hole; the other end of a steel rope penetrates through the through hole and is connected with the two baffles and the rotary shaft; the baffle close to one end of a limiting groove is fixedly connected with the steel rope; and the baffle, far away from one side of the limiting groove, is movably connected with the steel rope. According to the unloading assisting device of the liquefied natural gas, manual unloading is not needed so that more labor is saved; a fuel gas tank does not swing greatly, so that unloading is safer; and when the forklift is used for unloading, a limiting plate is arranged on the forklift, so that unloading of the liquefied natural gas can be assisted better.

Owner:蚌埠启邦科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com